Heavy Duty Stainless Steel Table with Wheels Ultimate Guide

Share

A heavy duty stainless steel table with wheels isn't just another piece of furniture. Think of it as a critical tool for kicking efficiency into high gear, especially in tough environments. It's a mobile workstation that marries industrial-strength durability with the freedom to move, making it a dynamic player in commercial kitchens, labs, and workshops where you can't afford to stand still.

The Essential Role of Mobile Stainless Steel Tables

In any fast-paced professional setting, workflow is everything. Fixed equipment can quickly create bottlenecks, forcing your team to waste time and energy walking back and forth. A heavy duty stainless steel table with wheels changes the game, turning a static workspace into an adaptable command center that follows the action.

It’s the ultimate utility player for your operation. In a bustling kitchen, it might be a prep station one minute and a plating area the next, wheeled right up to the service line. In a medical lab, it’s a secure way to transport sensitive equipment. For a workshop, it becomes a portable project surface you can easily push aside when you need more floor space.

Strength Meets Mobility

The real magic of these tables is their dual personality. You get the brute strength of industrial-grade steel—often built to handle over 500 pounds—paired with the smooth glide of robust casters. This blend means you never have to choose between a sturdy surface and a flexible floor plan. This unique combination solves three critical operational needs at once.

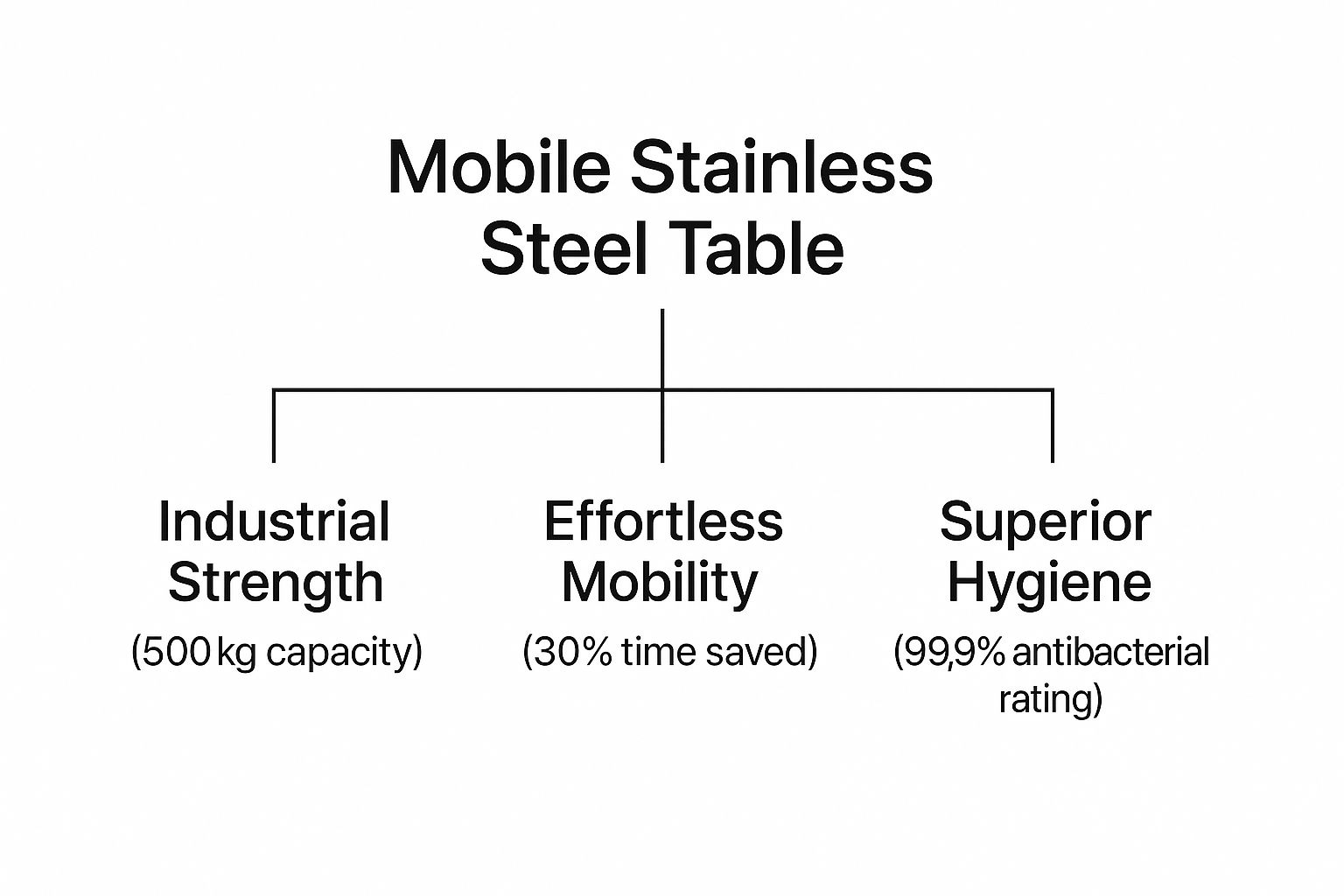

The infographic below really nails down the main benefits.

As you can see, these tables deliver a powerful trio: industrial strength, major time savings from being mobile, and top-tier hygiene.

A Foundation for Efficiency and Hygiene

It’s not just about the wheels, though. The material itself is a huge part of the story. Stainless steel has a non-porous surface that naturally resists bacteria, corrosion, and stains, which makes it incredibly easy to sanitize. This is a non-negotiable feature anywhere with strict health codes, like food service or healthcare.

The ability to easily reconfigure a workspace is a game-changer for efficiency. A mobile table can reduce physical strain on staff and cut down on wasted motion, directly improving productivity and safety.

Ultimately, choosing a heavy duty stainless steel table with wheels is an investment in how well your operation runs. It smooths out processes, holds up under heavy workloads, and helps you maintain the highest standards of cleanliness. In this guide, we'll get into the nitty-gritty of what to look for—from steel grades to caster types—so you can pick the perfect mobile solution for your space.

Exploring Different Types of Prep Tables

Not all stainless steel tables are created equal. Sure, a simple flat-top table offers incredible versatility, but many operations really start to hum when they bring in specialized designs for specific jobs. When you move beyond the standard model, you find a world of efficiency-focused workstations, each one engineered to solve a particular challenge in a busy commercial or industrial space.

For instance, a heavy duty stainless steel table with wheels can be kitted out with unique features that make complex workflows feel effortless. These aren't just minor tweaks; they fundamentally change how the table works in its environment. They turn a general-purpose surface into a specialized tool built for precision and speed.

Food Service Powerhouses: Pizza and Sandwich Prep Tables

In the food world, speed and organization are everything. This is where specialized prep tables truly prove their worth, especially the ones designed for cranking out pizzas and sandwiches. These units are so much more than just tables—they’re fully self-contained, refrigerated workstations.

- Pizza Prep Tables: These are the command centers of any pizzeria. You’ll usually see a wide, refrigerated rail running along the top, packed with cooled pans holding every topping you can think of, from pepperoni to peppers. This setup keeps ingredients perfectly fresh and right at your fingertips. Many of these tables also feature a heavy-duty marble or stone work surface, which stays naturally cool and is perfect for stretching out pizza dough.

- Sandwich Prep Tables: Built on a similar idea, these tables are engineered for the fast-paced assembly line of sandwiches and salads. They come with refrigerated compartments for all your meats, cheeses, and veggies, often topped with a cutting board that runs the full length of the unit. This lets your staff slice, assemble, and finish orders in one smooth motion without ever taking a step.

These specialized food prep tables are absolute game-changers in commercial kitchens. By merging cold storage with a dedicated workspace, they cut down on wasted movement, lower the risk of cross-contamination, and seriously boost output. They're the poster child for a streamlined culinary workflow.

Functional Designs for Every Need

Beyond the highly specialized pizza and sandwich units, there are plenty of other designs that add new layers of function to a standard stainless steel work table. These designs solve common problems related to storage, sanitation, and organization, making them a fit for a huge range of industries.

The right design elements can transform a simple table into a multi-functional workstation. Features like an integrated sink or a backsplash aren't just add-ons; they are strategic enhancements that directly improve safety and efficiency.

Let’s look at some of the most common and practical variations you’ll find:

- Tables with Integrated Sinks: These are a lifesaver for any job that requires frequent rinsing or cleaning. By building a sink right into the tabletop, you create a self-contained station for washing produce, cleaning tools, or just washing hands, saving trips across the room. They're incredibly useful in labs, food processing plants, and even art studios. There are many stainless steel applications for this kind of setup.

- Tables with Undershelves: This is probably the most common modification you'll see, and for good reason—an undershelf basically doubles the table's utility by adding a critical layer of storage. This space is perfect for keeping bulk ingredients, equipment, or containers off the floor but still within easy reach. Most undershelves are adjustable, too, so you can set the height to fit whatever you need to store.

- Tables with Backsplashes: It's a simple feature, but a highly effective one. A backsplash is just a raised lip along the back of the table. Its main job is to protect the wall from splashes and spills, which is a must for keeping things hygienic and preventing damage in kitchens or wet labs. As a bonus, it also stops small tools or ingredients from rolling off the back of the table.

Choosing the Right Wheels for Maximum Mobility

The stainless steel top might get all the glory for its durability and clean look, but the wheels—or casters, as they’re called—are the real MVPs when it comes to mobility. The right set of casters can turn a hulking, stationary table into a nimble workstation that glides across your kitchen. Get it wrong, though, and you’re looking at scratched floors, a table that’s a nightmare to move, and even potential safety issues.

Picking casters for your heavy-duty stainless steel table is a lot like choosing tires for a truck. You wouldn’t put flimsy street tires on a vehicle meant for rugged terrain, and you definitely shouldn't put weak plastic wheels on a table built to hold hundreds of pounds. The secret is matching the caster type, material, and features to your specific space and how you plan to use it.

Caster Types: Swivel, Rigid, and Locking

Your first decision is all about how you want the table to move. This really boils down to three main caster setups that control how the table handles. Getting this right is the first step to creating a workspace that works with you, not against you.

- Swivel Casters: Think of these as the acrobats of the wheel world. They can spin a full 360 degrees, giving you incredible maneuverability. Putting swivel casters on all four legs means you can pivot in tight corners and move the table in any direction with ease.

- Rigid Casters: Sometimes called fixed casters, these are locked into a straight line. They don't turn at all, which is perfect for stable, straight-line movement. A popular combination is putting two swivel casters on one end and two rigid ones on the other—just like a shopping cart—to get a good mix of agility and control.

- Locking Casters: This feature is absolutely non-negotiable for safety. A locking mechanism, which is usually a simple foot lever, stops the wheel from spinning and often locks the swivel action, too. This ensures your table stays put right where you want it when you're working, preventing any dangerous rolling.

The Impact of Caster Materials

Once you know how you want your table to move, the next thing to consider is the wheel material itself. This choice directly impacts your floors. Every material offers a different mix of toughness, floor protection, and smooth rolling. Making the right call here will save your floors from damage and keep your workspace quiet.

Here are the most common options:

- Polyurethane: This is a fantastic all-around choice. Polyurethane is tough, rolls quietly, and is non-marring, which means it won’t leave ugly scuff marks on sensitive floors like tile or vinyl. It’s a go-to for hospitals, labs, and modern kitchens.

- Rubber: A bit softer than polyurethane, rubber wheels have great grip and provide a cushioned ride. This makes them ideal for rolling over uneven spots or small bits of debris on the floor. The only downside is they might leave marks on some flooring types.

- Steel or Cast Iron: For the toughest environments like industrial workshops or garages with concrete floors, you can’t beat metal wheels. They can handle massive amounts of weight and stand up to chemicals, but be warned—they're loud and will chew up softer floors.

The demand for good mobility solutions is on the rise. The industrial caster wheels market was valued at around USD 8.5 billion and is expected to grow at a 5.2% rate through 2030, largely thanks to the needs of logistics and e-commerce. This just goes to show how vital high-quality casters are, especially those that support loads over 1500 lbs while also being designed for noise reduction.

Key Factors for Safety and Functionality

Beyond the type and material, a couple of technical specs are crucial for making sure your table is safe and performs as it should. If you overlook these details, you could end up with a failed caster or an unstable table, turning your mobile workstation into a real problem.

A caster's load capacity isn't just a suggestion; it's a critical safety threshold. Always ensure the combined capacity of your casters significantly exceeds the maximum weight you plan to put on the table.

Finally, run through these last few checkpoints before making a decision:

- Load Capacity: Every caster has a weight rating. To figure out the minimum you need, just divide the total weight of your table (plus everything you’ll put on it) by the number of casters. It’s always a good idea to choose a rating that gives you plenty of headroom.

- Wheel Diameter: Bigger wheels are better. They roll over cracks, cords, and other small stuff on the floor much more easily. A 5-inch diameter wheel is a popular and solid choice for most heavy-duty setups.

- Brake Reliability: Actually test the locking mechanism. It should click securely into place and be easy to use with your foot. A good brake ensures the table is completely stationary when you park it.

For a deeper look into how a commercial kitchen work table can be optimized for your space, our detailed guide offers even more helpful tips.

Exploring Different Types of Prep Tables

Let's be honest, not all stainless steel tables are cut from the same cloth. A basic flat-top table is a workhorse, no doubt, but the real magic happens when you find a specialized design built for the exact job you need to do. When you move past the standard models, you'll find a world of workstations engineered to solve very specific problems in a busy kitchen or workshop.

A heavy duty stainless steel table with wheels becomes incredibly powerful when it's outfitted with the right features. These aren't just little add-ons; they completely change how the table works, turning a simple surface into a precision tool built for speed and efficiency.

Food Service Powerhouses

In the culinary world, organization and speed are everything. This is where you really see specialized prep tables shine, especially the ones designed for cranking out pizzas and sandwiches. These units are more than just tables—they’re self-contained, refrigerated workstations designed for a high-volume flow.

-

Pizza Prep Tables: Think of these as the command center for any pizzeria. They usually have a wide, refrigerated rail along the top, filled with cooled pans holding every topping imaginable, from pepperoni to peppers. This setup keeps ingredients perfectly chilled and right at your fingertips. Many also come with a heavy-duty marble or stone work surface that stays cool, which is ideal for stretching out pizza dough.

-

Sandwich Prep Tables: Built on a similar concept, these tables are made for the fast assembly of sandwiches, salads, and wraps. They include refrigerated compartments for meats, cheeses, and veggies, often with a cutting board running the full length of the unit. This allows your team to slice, build, and finish orders in one smooth motion without taking a single extra step.

These specialized food prep tables are absolute game-changers in a commercial kitchen. By combining cold storage with a dedicated workspace, they cut down on wasted movement, reduce the risk of cross-contamination, and seriously boost how much you can produce.

Functional Designs for Every Need

Beyond the highly specialized pizza and sandwich stations, you’ll find plenty of other designs that add new functionality to a standard stainless steel work table. These setups solve common issues with storage, sanitation, and organization, making them a great fit for all kinds of industries, from healthcare to manufacturing.

The right design elements can transform a simple table into a multi-functional workstation. Features like an integrated sink or a backsplash aren't just add-ons; they are strategic enhancements that directly improve safety and efficiency.

Let's look at some of the most practical variations you'll come across:

-

Tables with Integrated Sinks: These are a lifesaver for any job that requires frequent rinsing or washing. By building a sink right into the tabletop, you create a self-contained station for cleaning tools, washing produce, or sanitizing hands, which saves a ton of time. They’re incredibly useful in labs, food processing plants, and even art studios where quick cleanups are a must.

-

Tables with Undershelves: This is probably the most common modification, and for good reason. An undershelf basically doubles your table's storage space. It’s the perfect spot to keep bulk ingredients, equipment, or containers off the floor but still easy to grab. Most undershelves are adjustable, so you can set the height to fit whatever you need to store.

-

Tables with Backsplashes: It’s a simple feature, but a very effective one. A backsplash is just a raised lip, usually a few inches high, that runs along the back of the table. Its main job is to keep splashes and spills from hitting the wall, which is essential for hygiene and preventing damage in kitchens or wet labs. It also has the added benefit of stopping small tools or ingredients from rolling off the back.

Each of these designs takes the core benefits of a heavy duty stainless steel table with wheels—its strength, mobility, and cleanability—and customizes them for a specific purpose. Picking the right one means you're not just getting a surface to work on; you're getting a tool that actively makes your whole process better.

Where These Tables Shine: Real-World Applications

It's one thing to talk about steel gauges and caster types, but it’s another to see how a heavy-duty stainless steel table with wheels actually performs in the real world. This isn't just a piece of metal on wheels; it's a workhorse that solves real problems in demanding environments.

From the organized chaos of a professional kitchen to the sterile, quiet focus of a medical lab, this table's core strengths—mobility, durability, and hygiene—are what make it so valuable. Let's look at a few places where these tables make a huge difference in workflow, safety, and overall efficiency.

The Fast-Paced Restaurant Kitchen

In any commercial kitchen, space is gold and every second counts. A heavy-duty stainless steel table on wheels quickly becomes a chef's best friend. Picture a line cook prepping vegetables. Once they're done, they can roll the entire station right up to the stove, creating a perfectly contained and efficient workspace exactly where they need it.

This mobility is also a lifesaver when it comes to cleanup. At the end of a chaotic shift, the crew can simply wheel the tables out of the way. This gives them full access to the floors and walls for a deep clean, which is absolutely critical for passing health inspections and keeping pests out.

The Sterile Medical Lab

In medical and scientific labs, there's zero room for error. Cleanliness and precision are everything. Here, a stainless steel table with casters acts as a mobile, sterile platform for delicate equipment or preparing samples. Its surface is non-porous, a must-have for preventing any kind of cross-contamination, and it can be sanitized aggressively between uses without breaking down.

Imagine a lab tech needing to move a sensitive diagnostic machine across the room. Instead of lifting and risking a costly accident, they can place it on a stable table, lock the wheels, and roll it securely to its new spot. The locking casters are key—they ensure the table is rock-solid and completely stationary during critical procedures.

The real magic of a mobile stainless steel table is its adaptability. It lets one room serve multiple purposes, transforming on the fly to meet the needs of the moment.

Their versatility is why demand has shot up globally. The market for stainless steel tables has seen serious growth, especially in sectors like healthcare and food service. Adding wheels makes them essential for modern workflows, a trend that really took off during recent health crises when flexible, easy-to-sanitize surfaces became a top priority. You can explore more data on this market expansion and see how these tables are reshaping different industries.

The Precision Manufacturing Cleanroom

In environments like electronics or pharmaceutical manufacturing, keeping contaminants out is the name of the game. A heavy-duty stainless steel table with wheels built from 304-grade steel is perfect for this. It's designed to minimize particle shedding and stands up to the harsh cleaning agents used in these facilities.

Workers can transport components from one stage of the assembly line to the next without them ever touching a less sterile surface. Plus, the ability to reconfigure a cleanroom layout by just rolling tables around allows for quick pivots to new production runs, boosting agility without ever compromising on cleanliness.

The Creative Home Workshop

And it’s not just for commercial use. For the serious DIYer or hobbyist, a mobile stainless steel table brings a professional-grade tool into the garage or home workshop. It can be a rugged workbench for messy projects, a clean assembly station for electronics, or even a sturdy potting bench for a gardener.

When you need more floor space for a big project, the table rolls out of the way in seconds. It’s also resistant to oil, grease, and most chemicals, so it can handle whatever you throw at it and still clean up easily, ready for your next big idea.

Maintaining Your Table for Lasting Performance

You've made the investment, now let's protect it. Keeping your heavy-duty stainless steel table in top shape is easier than you think, but it does require a little know-how. Many people assume stainless steel is indestructible, but that's not quite the full story. With just a few consistent habits, you can keep it looking and working like new for years to come.

First things first, let's talk about what not to do. Stay away from harsh, abrasive cleaners. That means no steel wool or wire brushes, which will leave behind scratches that can trap gunk and ruin the steel's protective finish. Most importantly, never use cleaning agents containing chlorine bleach. It can cause permanent pitting and ugly discoloration on the surface.

Your Daily Cleaning Routine

When it comes to daily cleaning, simple is best. A soft cloth or sponge with a bit of warm water and mild dish soap is all you need to handle everyday spills and grime. If you're dealing with stubborn fingerprints or tougher spots, a simple paste of baking soda and water works wonders without being abrasive.

Here's a pro tip: always wipe in the direction of the steel's grain. Look closely at the surface, and you'll notice very fine lines running one way. Wiping along with those lines helps prevent tiny scratches and keeps that clean, uniform shine everyone loves.

A well-maintained stainless steel surface is not just about aesthetics; it's a critical component of hygiene. Proper cleaning ensures the non-porous surface remains free of bacteria, which is essential in any food service or sterile environment.

For a deeper dive into cleaning techniques, check out our complete guide on how to clean stainless steel for more tips and tricks.

Don't Forget the Casters

The whole point of a mobile table is that it moves, and that's all thanks to the casters. Make it a habit to check the wheels for debris—hair, string, and dirt can get tangled up and jam them. A quick wipe-down and clearing of any blockages will keep your table rolling effortlessly.

It's also a good idea to test the locking brakes on each caster from time to time. Make sure they click firmly into place and hold the table steady. A brake that doesn't lock properly is a major safety risk, so fixing any issues right away is key to a safe workspace. Keeping your whole kitchen spotless is important, and learning how to clean baking sheets effectively is another great step toward total kitchen hygiene.

Have Questions? We've Got Answers

Picking out a piece of equipment as vital as a heavy duty stainless steel table with wheels naturally brings up a few questions. Getting straight answers is key to making sure you choose a table that fits your needs perfectly for years to come. Here are some of the most common things people ask us.

We want to give you the practical insights you need to decide with confidence, from weight limits and self-assembly to crucial design choices.

What Is the Typical Weight Capacity?

These heavy-duty tables are built to handle a serious amount of weight, usually between 500 and 1,500 pounds (about 227 to 680 kg). But that number can change a lot depending on the manufacturer and the specific design.

What really makes the difference? It comes down to the steel's thickness (its gauge), how the legs and frame are built, and, most importantly, what each individual caster is rated to hold. Always double-check the specs for both the tabletop and the wheels to make sure they can handle what you have in mind. To be safe, it's always best to spread the weight out evenly across the top.

Can I Assemble a Heavy Duty Stainless Steel Table Myself?

Yes, most of the time you absolutely can. These tables are usually designed for a pretty simple setup. You’ll only need basic tools like an Allen wrench, which often comes right in the box. The process is pretty standard: attach the legs, secure the undershelf where you want it, and then screw in the casters.

Just a heads-up, though—the parts can be heavy. It’s a lot easier and safer to have a second person give you a hand, especially when it's time to carefully flip the fully assembled table over.

Is a Table with an Undershelf Always Better?

Not always. It really depends on how you work. An undershelf is a game-changer for storage, giving you a handy spot for equipment, bins, and supplies. In a busy kitchen or workshop where every inch of space counts, it's practically a must-have.

But, if you plan on sitting at the table for detailed work, or if you need to roll large carts underneath it, a table without an undershelf (often called an H-frame style) is the way to go. It gives you all the legroom and clearance you could want. Think about how you’ll use the space under the table before you buy.

Ready to find the perfect mobile workstation for your space? At PrepTables.com, we offer a wide selection of top-quality, heavy-duty stainless steel tables designed for durability and efficiency. Explore our collection today and upgrade your workflow.