A Practical Guide to Grease Trap Sizing

Share

Getting your grease trap sizing right isn't just some minor technical detail. It's one of the most important foundational decisions you'll make for your commercial kitchen, and it has a direct impact on your daily operations and your budget. A properly sized trap is your best defense against expensive plumbing emergencies and keeps you on the right side of the law.

Get it wrong, and you're basically signing up for future headaches, from nasty sewer backups to eye-watering fines.

The High Stakes of Getting Sizing Right

You can think of your grease trap as the quiet, unsung hero of your kitchen's entire plumbing system. Its one job is to catch all the fats, oils, and grease (FOG) before they have a chance to escape into the main sewer lines. Once FOG gets out there, it cools, hardens, and creates blockages that can be absolutely catastrophic.

When you mess up the grease trap sizing, that whole system just breaks down. It's not a question of if you'll have problems, but when.

This is about more than just dodging a messy cleanup. We're seeing local municipalities enforce FOG regulations more aggressively than ever. They see non-compliance as a serious threat to public health and the environment, and they act accordingly.

The Ripple Effect of Miscalculation

An undersized unit is, by far, the most common mistake I see people make, and it causes problems almost immediately. The trap gets overwhelmed in no time, letting FOG slip right past it and into your pipes. This leads directly to a cascade of issues:

- Frequent and Costly Backups: That solidified grease is the number one cause of sewer line clogs. You'll start with foul odors and slow drains, but it will eventually lead to wastewater backing up right into your kitchen.

- Emergency Plumbing Bills: A major blockage isn't a DIY fix. You're looking at calling in professionals for expensive hydro-jetting services, not to mention the cost of being shut down while they work.

- Health Code Violations and Fines: Health inspectors don't play around with grease-related plumbing problems. You'll get cited and fined, and repeat offenses can get your business temporarily shut down, which can kill your reputation and your cash flow.

Choosing the right size isn't an expense; it's an investment in keeping your doors open. The upfront cost of a correctly sized interceptor is a drop in the bucket compared to the endless cycle of emergency maintenance and regulatory fines that come with a bad choice.

The Global Push for Better FOG Management

This intense focus on managing FOG isn't just a local thing; it's a worldwide trend. The global market for grease traps hit about USD 1.20 billion in 2024 and is on the rise, pushed by these stricter regulations.

This just underscores how critical grease trap sizing is. If it's too small, it's useless at capturing grease. If it's too big, you've wasted valuable space and money. You can find out more about the growing grease trap market and see how it's influencing regulations across the board.

Calculating Your Kitchen's Grease Load

Getting your grease trap sizing right is a game of numbers, not guesswork. If you want to nail it, you need to get familiar with the two main methods that plumbers and local inspectors use: calculating the flow rate in Gallons Per Minute (GPM) and using Drainage Fixture Units (DFU).

Each approach has its place, but both are designed to do one thing: make sure your interceptor can handle what your kitchen is actually dishing out.

The GPM method is the most direct way to size your trap. It hones in on the maximum amount of wastewater your sinks and equipment could possibly produce at one time. This is a huge deal for preventing overflows when things get chaotic during a dinner rush and every piece of equipment is running full tilt.

On the other hand, the DFU method is more of a standardized approach pulled straight from plumbing codes. It assigns a set value (a DFU) to every fixture, from a three-compartment sink to a floor drain. You just add up the DFUs for everything connected to the trap. It’s a bit less customized than a GPM calculation, but for many jurisdictions, it's the required standard.

GPM vs DFU Sizing Methods at a Glance

So, how do you know which method to focus on? It really depends on your local codes and the complexity of your kitchen. Here’s a quick breakdown to help you see where each one shines.

| Sizing Method | Best For | Calculation Basis | Common Application |

|---|---|---|---|

| Gallons Per Minute (GPM) | Custom, precise sizing | Maximum potential water flow from fixtures | Restaurants with high-volume, specific equipment |

| Drainage Fixture Units (DFU) | Standardized code compliance | Pre-assigned values per fixture type | New construction or when local code mandates it |

Ultimately, many projects will require you to be familiar with both, but knowing the difference helps you speak the same language as your plumber and health inspector.

Mastering the GPM Formula for Sinks

Let’s get into the weeds with the GPM calculation for a sink, which is where most of your grease is coming from. It's actually pretty straightforward.

First, you’ll need to measure the dimensions of your sink basin—length x width x depth in inches—to figure out its total volume in cubic inches.

Next, you need to turn that into gallons. The magic number here is 231, which is how many cubic inches are in one U.S. gallon. But since you're never filling a sink completely to the brim, the industry standard is to multiply that total gallon number by 0.75 to account for a more realistic 75% fill capacity.

The last piece of the puzzle is how fast it drains. A sink that empties in one minute has a much higher flow rate than one that takes two. It’s a simple adjustment:

- For a 1-minute drain time: Your GPM is whatever that 75% capacity number was.

- For a 2-minute drain time: You’ll divide that 75% capacity number by two.

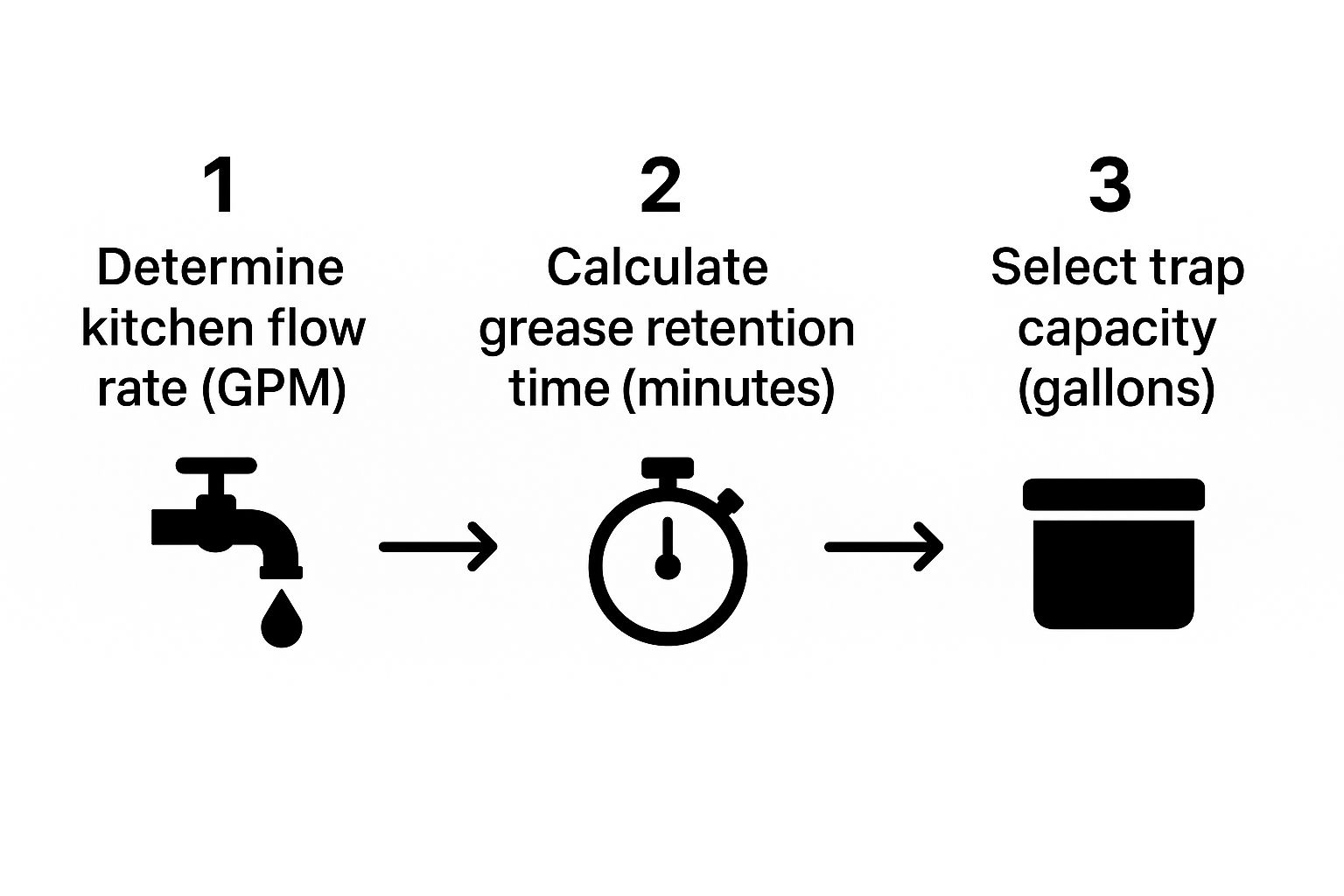

This visual really helps put the pieces together, showing how that flow rate connects to the final trap size you'll need.

As you can see, the GPM and the required retention time work hand-in-hand to point you toward the right interceptor for your specific setup.

Applying the Formulas in the Real World

Let's look at how this plays out in a couple of different kitchens.

Picture a small coffee shop. They have one three-compartment sink for washing mugs and equipment. Using the GPM method, their flow rate might only come out to 10-15 GPM. For a setup like this, a smaller, point-of-use interceptor installed right under the sink would be perfect.

Now, think about a busy, high-volume restaurant. They're running a massive three-compartment sink, a powerful commercial dishwasher, a couple of prep sinks, and several floor drains all at once. The combined flow rate here could easily shoot past 75-100 GPM, and the DFU calculation would be off the charts. This kitchen absolutely requires a big, high-capacity grease interceptor to keep up.

The sheer amount of commercial kitchen equipment you operate directly impacts that final number, which is why having an accurate inventory of your fixtures is the essential first step.

The biggest takeaway here is that no two kitchens are the same. A pizzeria churning out greasy pans is going to have a wildly different output than a small salad-and-sandwich spot. You have to size your grease trap based on your specific fixtures, your menu, and how busy you actually are.

Choosing the Right Grease Trap and Prep Tables for Your Space

Okay, so you’ve crunched the numbers and have a solid handle on your kitchen's flow rate. Now comes the real-world part: matching those calculations to the right equipment. This is a huge step in the grease trap sizing process, but it goes hand-in-hand with selecting other core components like your prep tables. The right interceptor for a tiny coffee shop would be completely swamped in a busy hotel kitchen, and similarly, the right prep surface is critical for workflow efficiency.

Types of Stainless Steel Prep Tables

While your grease trap handles the waste, your prep tables are where the work happens. Stainless steel is the industry standard for its durability and ease of sanitation. There are several types to consider:

- Standard Work Tables: These are the versatile workhorses of the kitchen, providing a simple, flat surface for chopping, mixing, and general prep. They often come with an undershelf for storage.

- Tables with Backsplashes: A small raised edge at the back of the table prevents ingredients and liquids from splashing onto the wall, making cleanup easier.

- Sandwich and Pizza Prep Tables: These specialized units are designed for high-speed assembly lines. They feature refrigerated compartments below the work surface to keep ingredients cold and accessible, often with a refrigerated rail on top for holding pans of toppings. This design is essential for pizzerias and sandwich shops where speed and food safety are paramount.

Types of Grease Traps

You’ll generally run into three main options for grease traps: hydromechanical grease interceptors (HGIs), gravity grease interceptors (GGIs), and the more high-tech automatic grease removal units (AGRUs). They all do the same core job, but each is built for a different scale and budget.

- Hydromechanical Grease Interceptors (HGIs): These compact units fit under sinks and are best for small cafes, delis, or food trucks with low-to-moderate grease production.

- Gravity Grease Interceptors (GGIs): Large, high-capacity tanks (500+ gallons) installed underground, ideal for busy restaurants and large commercial kitchens.

- Automatic Grease Removal Units (AGRUs): High-tech, automated units that actively skim and remove grease, reducing manual cleaning needs but at a higher initial cost.

Choosing the right combination of grease trap and prep tables ensures your kitchen operates smoothly, from food preparation to waste management. For a deeper dive into the mechanics of grease traps, you can check out our guide on how a kitchen grease trap works.

How to Navigate Local Plumbing Codes

Your GPM and DFU numbers are a great starting point, but that's all they are—a start. When it comes to grease trap sizing, the final say doesn't come from a formula. It comes from your local plumbing inspector. Getting their specific requirements right is the most important step to keep your installation legal and prevent a shutdown.

Think of national standards like the Uniform Plumbing Code (UPC) as the general rulebook. They offer a solid foundation, but your city or state nearly always adds its own, stricter rules called "amendments." These local codes can completely override standard calculations and enforce very specific requirements for businesses in your area.

Finding Your Jurisdiction's Rules

First, you have to figure out who's in charge. This isn't always as simple as it sounds, since different departments can have jurisdiction depending on where your business is located. You'll need to reach out to your local government to get the exact rules.

A good place to start is your city or county's official website. Look for departments like these:

- Wastewater Management or Pretreatment Program: This is usually the main office concerned with keeping fats, oils, and grease (FOG) out of the public sewer.

- Building and Safety Department: They're the ones who handle permits and make sure any installation is up to code.

- Public Works Department: In smaller municipalities, this department often oversees all utility installations, including grease traps.

Honestly, a quick phone call is the fastest way to get clear answers. Ask them for their "grease interceptor sizing requirements" or their "FOG control program guidelines." Most departments have a handy PDF or a webpage that lays out everything you need to know.

Don't make an expensive assumption. I’ve seen restaurant owners buy a perfectly good interceptor based on a standard formula, only for the inspector to show up and tell them the city requires a minimum 500-gallon capacity for all new food businesses, no matter what the math says.

Understanding Local Code Specifics

Local codes can be surprisingly detailed. One city might just follow the UPC, while the one next door has a long list of its own special rules. Be ready for requirements that specify things like a minimum retention time, which is how long wastewater has to sit in the trap to separate properly—often 30 minutes or more.

Some other common local rules you might run into include:

- Minimum Interceptor Size: Many areas set a hard minimum, like 750 gallons for any new gravity interceptor.

- Specific Sizing Formulas: Your city might have its own proprietary formula that you must use instead of the standard DFU or GPM methods.

- Material and Certification Requirements: Codes frequently require that interceptors be NSF-certified or built from specific materials before they can be approved.

The absolute best thing you can do is get written approval from your local authority before you buy anything. Submit your kitchen plans, a list of your fixtures, and the specific grease trap model you want to install. Getting that official sign-off on paper is your insurance policy against any last-minute surprises during the final inspection. It's a simple step that can save you thousands of dollars and a world of frustration.

The True Cost of Sizing and Maintenance Mistakes

Choosing a grease trap isn't just about the initial purchase; it’s a long-term financial commitment. The decisions you make during the grease trap sizing phase will dictate your operational costs for years. Getting it wrong creates a domino effect of expensive, disruptive problems that eat away at your bottom line.

An undersized interceptor is easily the most common and costly mistake I see. It doesn't just perform poorly—it actively creates a cycle of emergencies. The trap gets overwhelmed fast, letting fats, oils, and grease (FOG) escape and solidify down the line, which always leads to blockages.

And this isn't some minor inconvenience. We're talking foul odors that drive customers away, slow drains that frustrate your staff, and eventually, raw sewage backing up into your kitchen. The result is always the same: an emergency call to a plumber for expensive hydro-jetting and lost revenue from being forced to close for repairs.

The Problem with Oversizing

It might seem like buying a much larger unit is a safe bet, but oversizing introduces its own set of issues. A massively oversized interceptor is a significant waste of capital that could have been invested elsewhere in your business. The large volume of water can also move too slowly, which allows it to cool.

This slow, cool flow can cause grease to solidify inside the trap before it's properly separated. This creates a difficult-to-remove hardened grease buildup that makes pump-outs less effective and can even shorten the unit's lifespan.

Proper grease trap sizing is all about finding that sweet spot. You want a unit large enough to handle your peak flow but not so big that it wastes money or creates new maintenance headaches.

Finding this balance is critical. Historical data shows that grease accumulation accounts for over 70% of wastewater system blockages in urban areas. Poor sizing is a direct contributor, leading to more frequent and costly service calls. You can discover more insights on the growing grease trap service market to see how proper sizing impacts the entire industry.

Connecting Sizing to Predictable Costs

When you invest the time to size your grease trap accurately, you're not just buying equipment. You're creating a predictable and affordable maintenance schedule. A correctly sized unit captures FOG efficiently, letting you establish a regular cleaning routine you can budget for, rather than reacting to constant plumbing emergencies.

Think about the fixtures producing the most grease, like your primary wash station. The flow from a 3-bay commercial sink is a major factor in your GPM calculation. Getting this right from the start ensures your maintenance costs are stable and your kitchen stays operational, protecting both your revenue and your reputation.

Grease Trap Sizing Common Questions Answered

Even after you've waded through all the formulas and codebooks, a few practical questions always seem to pop up during the grease trap sizing process. Getting these sticking points sorted out can save you from some seriously costly mistakes and make sure your kitchen runs smoothly right from the start. Let's tackle some of the most common questions we hear from restaurant owners.

Can I Just Use an Online Calculator?

Sure, online calculators are a decent place to start. They can give you a rough estimate of what you might need by using generic GPM or DFU formulas, offering a ballpark figure to get the conversation going. But they should never be the final word on your sizing.

The problem is, these tools can't possibly know the unique details of your restaurant. They have no idea about the specific grease output of your menu, and more importantly, they are completely unaware of your local plumbing code's specific rules or minimum requirements.

Think of an online calculator as a helpful guide, not the final authority. Use it to get an initial idea, but always have a licensed plumber and your local wastewater official verify the final size before you pull the trigger on a purchase.

What if My Menu Changes After Installation?

This happens all the time. A big menu change, especially if you start adding more fried foods or dairy-heavy dishes, is going to directly ramp up your FOG output. That means your grease trap will fill up a lot faster than you originally planned for.

If you do make a major shift in your menu, you absolutely need to monitor your interceptor's performance. For the first few weeks, check the grease level more often than usual. If you find it's filling up way quicker than before, you have to adjust your pumping schedule to be more frequent. In some extreme cases, you might even need to start thinking about upgrading the unit itself.

Does My Commercial Dishwasher Need a Connection?

Yes, absolutely. This isn't even a question—it's non-negotiable. Commercial dishwashers are a massive source of FOG. They blast dishes with incredibly hot water and powerful detergents that emulsify grease, basically turning it into a liquid that seems to flow right down the drain.

But once that super-hot, greasy water bypasses the interceptor and hits the cooler pipes downstream, it's going to solidify and create some of the worst blockages you can imagine. Pretty much every plumbing code in existence mandates that commercial dishwashers, pot-washing sinks, and kitchen floor drains must be connected to the grease trap.

How Is Sizing Different for a Food Truck?

The basic ideas of calculating flow rate are the same, but the reality on the ground—or on wheels—is totally different. For a food truck, you'll still figure out the GPM from your sinks, but your severe space limitations mean you’re almost certainly going to be using a compact, under-sink hydromechanical unit.

The single most important factor for a food truck is regulatory compliance. Every city, county, and even the specific event venue you park at will have its own rules for mobile food vendors. Before you even think about operating in a new spot, you have to check their specific requirements for grease trap size, how it’s installed, and what kind of maintenance logs you need to keep. Not doing this can get you shut down right on the spot.

At PrepTables.com, we know that the right equipment is the foundation of any efficient kitchen. From durable stainless steel prep tables to the essential fixtures that keep your workflow moving, we provide the high-quality gear you need to succeed. Explore our full range of commercial kitchen equipment to find the perfect solutions for your business.