Your Guide to Food Truck Equipment

Share

Outfitting your food truck is the moment your dream starts taking shape. Choosing the right food truck equipment transforms an empty vehicle into a high-powered, profit-generating kitchen on wheels. The gear you pick has a massive impact on your workflow, what you can put on your menu, and how efficiently you can operate, so these initial decisions are absolutely critical.

Your Blueprint for Essential Food Truck Equipment

Putting together a food truck kitchen is like a high-stakes game of Tetris. Every single piece has to fit and function perfectly. You’re not just filling space; you're building a complete system that needs to pump out orders during a chaotic lunch rush while meeting every health and safety code. Your success really depends on picking equipment that makes the most of every inch and every watt of power you have.

It helps to think about your equipment in four main categories:

- Cooking Equipment: This is the heart of your operation—it defines your menu. We're talking about everything from griddles and fryers to ranges and specialty ovens.

- Refrigeration and Storage: These are the workhorses keeping your food safe and your inventory organized. Think undercounter refrigerators, freezers, and ingredient coolers.

- Preparation Surfaces: This is where the magic happens. Efficient prep stations, almost always stainless steel, are where your ingredients get chopped, mixed, and assembled.

- Sanitation and Safety: This part is completely non-negotiable. It covers your sinks, water heaters, ventilation hoods, and fire suppression systems that keep you legal, safe, and open for business.

Getting how these categories work together is the first step. Before you even think about specific models, you need to be aware of the bigger picture, like NSF ratings (which health departments require) and how much power each appliance will pull. For a deeper dive into everything a professional kitchen needs, our commercial kitchen equipment checklist is a fantastic place to start.

To help you get a quick overview, here's a simple breakdown of the essential gear.

Essential Equipment at a Glance

| Equipment Category | Key Items | Primary Consideration |

|---|---|---|

| Cooking | Griddle, Fryer, Range, Oven | Match it to your menu. A burger truck needs a great griddle; a pizza truck needs a specialized oven. |

| Refrigeration | Undercounter Fridge, Freezer, Prep Table with Refrigeration | Maximize cold storage in a small footprint. Under-counter units are key. |

| Preparation | Stainless Steel Prep Tables, Cutting Boards | Durability and workflow. Choose a steel gauge that can handle daily abuse. |

| Sanitation & Safety | 3-Compartment Sink, Hand-Wash Sink, Vent Hood, Fire Suppression | Must meet local health and fire codes—no exceptions. |

This table gives you a starting point, but remember that every choice you make will affect the next one in your tight mobile space.

The Foundation: Your Prep Tables

Stainless steel prep tables are the true unsung heroes of any food truck. This is your main workspace for everything—chopping, mixing, assembling, and plating. When you're picking a table, pay close attention to the steel gauge. A lower number, like 16-gauge, means the steel is thicker and much more durable than a lighter 18-gauge option. It's worth the investment. Also, look for helpful features like an undershelf for extra storage or a backsplash to keep splashes off your truck’s walls.

A well-chosen prep table isn’t just a flat surface; it’s the central hub that connects your cooking and refrigeration zones, making a smooth, fast workflow possible.

Specialized Prep Tables for Ultimate Efficiency

Want to take your speed and consistency to the next level? Look beyond standard work tables to specialized prep tables that have refrigeration built right in. In a cramped food truck, these are an absolute game-changer.

By combining cold storage with your primary workspace, you minimize movement, reduce ticket times, and ensure ingredients remain at safe temperatures during a busy service—a critical advantage in a mobile kitchen.

Two of the most valuable types for food trucks are:

-

Sandwich Prep Tables: These units have a refrigerated base below and a top section with chilled wells for holding all your go-to ingredients like lettuce, tomatoes, cheese, and meats. There's usually a cutting board running along the front, creating a perfect all-in-one assembly line for sandwiches or salads. No more walking back and forth to the main fridge.

-

Pizza Prep Tables: These are similar, with a refrigerated base, but they feature a raised, refrigerated rail along the back to hold pizza toppings. The front work area is typically a deep cutting board, perfect for stretching dough. This setup keeps all your toppings organized and within arm's reach, streamlining the entire pizza-making process.

Whether you need a standard table or a specialized refrigerated unit comes down to your menu. If you're running a deli, pizzeria, salad bar, or taco truck, these integrated units are essential pieces of food truck equipment that will pay for themselves in pure speed and efficiency. They perfectly show how smart equipment choices can overcome the limits of a mobile kitchen.

Choosing Your Cooking and Refrigeration Gear

The real engine of your food truck isn't under the hood—it's the cooking and refrigeration equipment you install inside. This gear is the heart and lungs of your mobile kitchen, directly controlling your menu, how fast you can serve customers, and ultimately, your profits. The right combination creates a powerful, efficient system. The wrong choices? They lead to constant headaches and service bottlenecks.

Your goal is to find appliances that are not just powerful, but perfectly sized and suited for the tight, demanding environment of a kitchen on wheels.

It’s all a balancing act between power, size, and what you’re cooking. A burger truck, for instance, lives or dies by the quality of its commercial griddle. A donut concept is entirely dependent on the performance of its deep fryer. You have to match the machine to the mission.

Selecting Your Core Cooking Appliances

Your main cooking line is where the magic happens. Picking out the right pieces of food truck equipment is a strategic move that should be based completely on your menu. Let's look at the most common workhorses you'll find in a truck.

-

Commercial Griddles: These are the undisputed champions of versatility. A griddle's flat top is perfect for everything from burgers and cheesesteaks to pancakes and grilled sandwiches. They give you even heat and let you cook multiple items at once, which is a massive space-saving win.

-

Deep Fryers: Absolutely essential for crowd-pleasers like french fries, chicken wings, or donuts. For most trucks, countertop models are the way to go. You’ll want to look for fryers with a fast temperature recovery speed so you can keep cranking out orders during a rush without a dip in quality.

-

Ranges and Burners: If you’ve got soups, sauces, or anything pan-sautéed on the menu, a compact range is a must. Gas burners provide instant heat and pinpoint control. On the other hand, induction cooktops are safer, more energy-efficient, and—a huge plus in a tiny truck—they produce less ambient heat.

As you choose, you'll run into the classic gas versus electric debate. Gas equipment usually heats faster and gives you finer temperature control, but it means dealing with a propane system and serious ventilation. Electric models are often easier to install and clean, but they put a heavy load on your generator. Our complete guide on cooking equipment for food trucks can help you sort through these critical pros and cons.

Mastering Cold Storage in a Small Space

Refrigeration in a food truck is a high-stakes game. There's zero room for error when it comes to maintaining food-safe temperatures, and you’re always fighting for every last inch of space. The secret is to use compact, efficient units that make the most of your limited real estate.

In a mobile kitchen, your refrigeration isn't just for storage; it's an active part of your workflow. The goal is to keep ingredients cold, safe, and within arm's reach to shave precious seconds off every order.

The most effective food truck layouts almost always rely on undercounter units. These refrigerators and freezers slide right under your prep surfaces, keeping your workspace clear while providing the cold storage you need.

- Undercounter Refrigerators: These are the backbone of your cold line. They’re perfect for storing prepped ingredients, sauces, and drinks right where you need them.

- Undercounter Freezers: Absolutely critical for holding everything from frozen fries and burger patties to ice cream.

- Reach-In Coolers: If you have the vertical space to spare, a slim, upright refrigerator can offer a surprising amount of bulk storage.

The demand for smarter mobile kitchen gear is exploding. The global food truck equipment market is growing right alongside the food truck industry itself, which is projected to hit $4.36 billion in the U.S. by 2025. This boom is pushing manufacturers to develop smarter appliances, like IoT-enabled refrigerators that let you monitor temperatures in real-time to guarantee food safety. This trend just proves how important it is to invest in reliable, modern cooling equipment from day one.

Designing a High-Efficiency Prep Station

Think of your prep station as the command center of your food truck. It’s far more than just a surface for chopping vegetables; it’s the central hub where raw ingredients become the delicious meals you serve. The design and quality of this area have a direct line to your speed, organization, and even your food safety. Get it right, and you've got a seamless workflow. Get it wrong, and you're inviting bottlenecks and chaos during a rush.

The foundation of any solid prep station is a high-quality stainless steel work table. There's a reason this material is the industry standard: it’s incredibly durable, non-porous (which fights off bacteria), and a breeze to sanitize. This is one piece of food truck equipment you'll be leaning on all day, every day, so picking the right one is a big deal.

Understanding Stainless Steel Prep Tables

Not all prep tables are the same, and choosing the right type is crucial for an efficient food truck kitchen. The primary distinction is between standard work tables and specialized refrigerated units, each serving a unique purpose.

1. Standard Stainless Steel Work Tables: These are the basic, non-refrigerated surfaces that form the backbone of your prep area. As you shop, you’ll see terms like "gauge," which refers to the thickness of the steel. It's a bit counterintuitive, but the lower the number, the thicker and stronger the steel. A 16-gauge table is a beast compared to an 18-gauge table, making it much better for heavy-duty chopping or holding bulky equipment. For the wear and tear of a busy food truck, investing in a lower gauge is a smart play.

Beyond gauge, look for design features that maximize utility:

- Tables with Undershelves: For a food truck, this is practically non-negotiable. An undershelf gives you crucial storage for small appliances, ingredient bins, or extra cookware, keeping your main workspace from getting cluttered.

- Tables with Backsplashes: A backsplash is a raised edge along the back that stops ingredients and liquids from splattering onto your truck's walls. This simple feature makes cleanup much easier and keeps your operation more hygienic.

2. Specialized Refrigerated Prep Tables: These units combine your workspace and cold storage into one self-contained station, drastically cutting down on the time your crew spends walking back and forth. They are some of the most impactful pieces of food truck equipment you can invest in.

By integrating refrigeration directly into the prep line, you keep critical ingredients at safe temperatures and within arm's reach. This simple change can shave minutes off ticket times, a crucial advantage when a long line is forming outside your window.

Two of the most common and valuable types for food trucks are:

- Sandwich Prep Tables: Perfect for menus heavy on sandwiches, salads, burritos, or bowls. These units have a refrigerated cabinet on the bottom for bulk storage, while the top features a series of chilled wells or pans for holding toppings. A cutting board usually runs along the front, creating a perfect, all-in-one assembly line.

- Pizza Prep Tables: Engineered specifically for pizzerias on wheels. Like its sandwich counterpart, it has a refrigerated base, but the top features a raised, refrigerated rail to hold pizza toppings. The main workspace is a deep, durable cutting board, giving you plenty of room to stretch dough and build pies. For any truck focused on pizza, this isn't a luxury—it's essential for surviving the dinner rush.

Choosing between these options depends entirely on your menu. While every truck needs at least one standard work table, integrating a specialized unit like a sandwich or pizza prep table can give you a powerful competitive edge in speed and efficiency.

Powering and Ventilating Your Mobile Kitchen

Let’s talk about two of the most intimidating—but absolutely critical—systems that bring your food truck to life: power and ventilation. These are the technical guts of your operation, the foundation that makes everything else work.

Get these right, and you've got a safe, legal, and functional mobile kitchen. Get them wrong? You're staring down the barrel of costly repairs, failed inspections, and even genuinely dangerous working conditions.

Think of your power system as the truck's heart, pumping energy to every single piece of food truck equipment. Your ventilation system is the lungs, pulling out all the heat, smoke, and grease to keep your space safe and breathable. Both need serious planning to keep up with the chaos of a busy service.

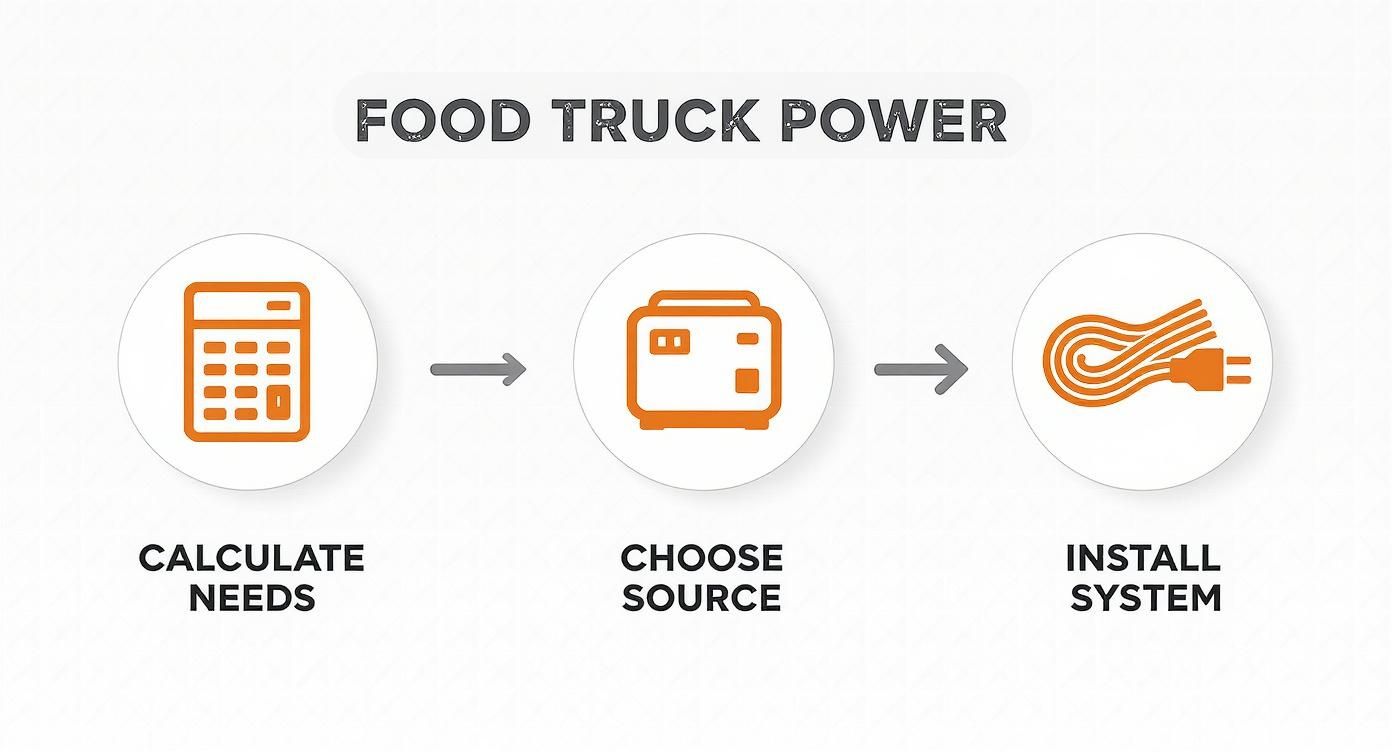

Calculating and Supplying Your Power

Before you even think about buying a generator, you need to know exactly how much juice your kitchen is going to pull. The first step is a power audit. Make a list of every single electrical appliance—from the big stuff like your griddle and fryers down to the refrigerator and lights—and add up their total wattage. That final number is your magic number; it tells you the absolute minimum power your source needs to supply.

It’s really important to get a handle on the individual wattage of each piece of gear. For a deeper dive into understanding appliance wattage, there are some great resources that break down what typical appliances use.

Once you have your total wattage, you can pick your power source:

- Gasoline Generators: These are everywhere and usually cheaper to buy upfront. The downside? They can be loud, and you have to store flammable gasoline, which is always a safety thought.

- Propane Generators: This is a super popular choice for food trucks. Propane burns cleaner and often runs quieter than gas models. Plus, since you’re probably already using propane for your cooktop, it just simplifies your fuel situation.

- Shore Power: This is when you plug your truck directly into an external outlet, like at a commissary or an event space. It's totally silent and reliable, but you can't count on it being available everywhere. A generator is still a must-have for true mobility.

The Critical Role of Kitchen Ventilation

Ventilation isn't just about staying cool. It's a non-negotiable safety and legal requirement, period. A real ventilation system, built around a commercial-grade exhaust hood, is designed to rip smoke, greasy steam, and intense heat right out of your tiny kitchen.

Without it, you’re creating a massive fire hazard and an unhealthy place for your crew to breathe. In fact, grease buildup in a poorly ventilated space is one of the top causes of food truck fires. Your exhaust hood has to work hand-in-hand with a fire suppression system, which is mandatory pretty much everywhere. This system is designed to automatically detect and snuff out a fire, especially those nasty grease fires.

Proper ventilation and fire suppression aren't just items on a to-do list; they are the single most important safety features in your entire mobile kitchen. If you fail an inspection on these systems, you will not be allowed to open.

The codes for these systems are incredibly strict. You'll notice that customized food trucks, which make up about 35% of the market, often have smartly designed layouts and specialized ventilation systems built for high-heat cooking. This custom approach can actually extend the life of your expensive equipment by up to 15% and improve your workflow, leading to service speeds that are up to 20% faster.

Health and fire codes will tell you exactly how big your hood needs to be, how powerful the exhaust fan must be, and what type of fire suppression agent to use. To make sure you get it right the first time, check out our detailed guide on commercial kitchen ventilation requirements to stay safe and on the right side of the law.

Integrating Tech for Smarter Food Truck Operations

A modern food truck doesn’t just run on fuel and propane—it runs on data. The technology you choose can be the dividing line between a struggling venture and a thriving one, turning raw information into smarter decisions on the fly. And the heart of this whole tech setup? Your Point of Sale (POS) system.

Think of a mobile-friendly POS as your command center, not just a fancy cash register. A good system gives you a real-time look at your sales, showing you exactly which menu items are flying out the window and which ones are just taking up space. That kind of data is gold, letting you fine-tune your menu, slash waste, and double down on what your customers really want.

Of course, none of that tech matters if you don't have reliable power. Getting your power system right is the foundation for everything else.

This process makes it clear: a solid power supply isn't a suggestion, it's the non-negotiable first step before you can even think about integrating all the cool tech.

Beyond Payments: The Power of a Modern POS

A great POS system does so much more than just take money. Features like integrated inventory management can automatically track your ingredient levels as you make sales. This is what helps you avoid that dreaded moment of telling a customer you're sold out of your most popular dish right in the middle of a lunch rush.

Seamless online ordering is another huge advantage. It lets customers order and pay ahead of time, which keeps your line short and service moving fast. Suddenly, your POS isn’t just processing transactions; it’s actively managing the flow of your customers.

The right technology doesn't just process payments; it provides the insights needed to refine your menu, manage inventory with precision, and understand customer behavior—turning daily sales into a roadmap for growth.

Choosing the right tech for your food truck equipment setup has a direct impact on your bottom line. The U.S. food truck industry is massive, with over 48,000 trucks pulling in an average annual revenue of $346,000. The stakes are high. Operators who bring in smart systems, like AI-driven inventory management, can cut their labor costs by around 20%—a serious boost to any truck's profitability. You can dive deeper into how tech influences food truck earnings on cloudwaitress.com.

Staying Ahead with Emerging Tech

The tech available to food trucks is always evolving. Take a Kitchen Display System (KDS), for example. It replaces all those paper tickets with a simple digital screen, sending orders straight from the POS to your cook line. It’s a small change that cuts down on errors, makes communication crystal clear, and shaves precious seconds off every single order.

There are other tools out there that can give you a real competitive edge:

- Customer Loyalty Programs: Build these right into your POS to keep your best customers coming back for more.

- Advanced Analytics: Get dashboards that show you sales trends by the hour, by location, or even by the weather.

- Mobile Payment Flexibility: Make it easy for customers to pay however they want, whether it's with a tap-to-pay card or a digital wallet on their phone.

When you thoughtfully bring these technologies into your truck, you’re doing more than just moving with the times. You’re turning a simple mobile kitchen into a smart, data-driven business that’s built for success.

Answers to Your Top Food Truck Equipment Questions

Stepping into the food truck business kicks up a ton of questions, especially when it's time to pull out your wallet for kitchen gear. Getting these choices right from day one can save you from massive headaches and the dreaded failed inspection notice. Let's tackle the most common questions we hear from new owners to help you build your truck with confidence.

What Is the Most Important Piece of Food Truck Equipment?

You might think it’s the griddle or the fryer that makes your menu possible, but the real MVPs of your truck are the systems that make everything else work: your power source (generator) and your ventilation/fire suppression system.

Think about it this way: without a solid generator, none of that shiny cooking equipment will even power on. And without a certified, up-to-code ventilation and fire suppression system, you can't legally or safely cook anything. These two are the foundation. Once you have them locked down, then the focus shifts to the heart of your menu—be it a high-capacity fryer for a fry truck or a top-notch griddle for a smash burger concept.

Should I Buy New or Used Food Truck Equipment?

This is the age-old debate between saving money upfront and avoiding risk down the line. There’s no single right answer, and honestly, a smart mix of both is usually the best strategy for getting started.

- New Equipment: You get peace of mind with a manufacturer's warranty, peak energy efficiency, and total reliability right out of the box. The only downside is the significant cash you’ll have to put down.

- Used Equipment: The biggest draw here is the savings—you can often snag gear for 30-70% less than the new price. But that comes with risks: no warranty, a mysterious history, and the potential for a sudden breakdown right in the middle of a lunch rush.

Here’s a practical way to approach it: buy new for your mission-critical equipment. Your main refrigerator, freezer, and primary cooking appliance are the lifeline of your business. For things like stainless steel prep tables, sinks, or storage shelving, quality used pieces are a fantastic way to make your budget go further. Just be sure to have any used appliance checked out by a pro before you buy.

What Does an NSF Certification Mean for My Equipment?

That little NSF certification sticker is a huge deal. It’s your guarantee that a piece of equipment meets strict standards for public health and safety. NSF stands for the National Sanitation Foundation, a third-party group that tests and certifies products to make sure they’re safe for commercial kitchens.

An NSF-certified piece of food truck equipment is designed to be easily and thoroughly cleaned, constructed from durable materials, and resistant to bacteria growth. It's a non-negotiable requirement from virtually every health department for any surface that comes into contact with food.

Trying to skate by with non-certified gear is one of the quickest ways to fail your health inspection. It could get you shut down before you sell a single taco, which makes NSF compliance an absolute must from the very beginning.

How Much Does It Cost to Fully Equip a Food Truck?

The total cost to outfit your mobile kitchen can swing wildly depending on your menu, whether you buy new or used, and the quality of the gear you choose. As a ballpark, you can expect to spend anywhere from $20,000 to over $100,000.

Let's break that down a bit:

- Simple Concepts: A truck selling coffee, smoothies, or pre-made items might get fully equipped in the $20,000 to $40,000 range.

- Complex Kitchens: If you're running a full-on mobile kitchen with multiple fryers, a charbroiler, lots of refrigeration, and other specialty gear, your equipment bill can easily climb past $75,000.

This budget needs to cover everything: every cooking appliance, all refrigeration, prep stations, your three-compartment and hand-washing sinks, the complete water system, your generator, and of course, the vital ventilation and fire suppression systems. Making a detailed list and budgeting carefully is one of the most critical steps you'll take.

At PrepTables.com, we know that the right equipment is the backbone of a successful mobile kitchen. From NSF-certified stainless steel work tables to compact, high-efficiency refrigeration and cooking gear, we have everything you need to build a food truck that’s ready for the rush. Explore our full catalog of professional-grade food truck equipment at https://preptables.com and start building your dream kitchen today.