Essential Commercial Kitchen Equipment Checklist for Success

Share

Whether you're building a restaurant from the ground up or giving a tired kitchen a much-needed overhaul, your success hinges on smart planning. Nothing is more crucial to that process than a solid commercial kitchen equipment checklist. This guide is designed to be that tool, breaking down everything you need, category by category, so you can outfit your kitchen for peak efficiency, safety, and compliance right from the start.

Your Quick-Reference Equipment Checklist

A commercial kitchen isn't just a room with appliances; it's a dynamic system of interconnected zones, each with a job to do. When you think about your equipment in terms of these zones—prep, cooking, storage—instead of just a long, random shopping list, the whole process becomes more organized and your workflow makes a lot more sense.

Get this right, and you'll see the payoff in everything from food quality and faster ticket times to a safer, happier crew. But if you miss a key piece of gear, it can create frustrating bottlenecks that throw your entire operation out of whack.

Before you even think about specific brands or models, you need to get a handle on the foundational categories of equipment. Looking at the big picture first gives you a roadmap for budgeting and mapping out your kitchen's layout. It’s all about making sure every function, from chopping vegetables to washing dishes, is covered.

Core Commercial Kitchen Equipment Categories

To make planning easier, we've broken down all the essential gear into the five main functional areas of any professional kitchen. Think of this table as your high-level cheat sheet. It helps you confirm you've got all your bases covered before you dive into the nitty-gritty details of each section.

| Category | Core Function | Key Equipment Examples |

|---|---|---|

| Cooking & Baking | This is the heart of the kitchen, where raw ingredients become the dishes on your menu. | Ranges, Ovens, Fryers, Griddles, Charbroilers |

| Refrigeration & Storage | Absolutely critical for keeping food safe, managing inventory, and preserving ingredient freshness. | Walk-In Coolers, Reach-In Refrigerators, Freezers |

| Food Preparation | The zone where all the initial work happens—washing, chopping, mixing, and portioning ingredients. | Prep Tables, Mixers, Food Processors, Slicers |

| Warewashing & Sanitation | Essential for staying clean, meeting health codes, and keeping dishes and tools ready for service. | 3-Compartment Sinks, Dishwashers, Hand Sinks |

| Safety & Compliance | The non-negotiable gear required by law to protect your staff, your customers, and your business. | Hood/Ventilation Systems, Fire Extinguishers, First-Aid Kits |

Using this structure gives you a clear framework to build out your complete checklist. When you approach it systematically, category by category, you can be confident that you won't miss a single essential item.

Selecting Your Cooking and Baking Equipment

The cooking line is the very heart of your kitchen. It’s the engine room that dictates how well you can execute your menu and how quickly you can serve your customers. Choosing the right appliances isn't just about cool features; it’s a critical business decision that affects your workflow, food quality, and ultimately, your profits. From the power source to the size of the unit, every choice has to line up with how you actually operate.

This is a major investment, no doubt about it. The global market for commercial cooking equipment is expected to hit USD 26.5 billion by 2035, which tells you the industry is constantly pushing for more efficient and specialized gear. That growth just underscores how important it is to pick equipment that’s not only powerful but also smart about energy use.

Ranges and Ovens: The Kitchen's Foundation

A commercial range is probably the single most essential piece on your cooking line. The big decision right out of the gate is gas versus electric. Most chefs swear by gas ranges because they provide instant heat and incredibly precise temperature control, which is perfect for sautéing and searing. On the other hand, electric ranges, especially the newer induction cooktops, offer very even heating and are a breeze to clean, making them a solid pick for kitchens without a gas hookup.

Ovens also come in a few different flavors, each built for a specific job:

- Convection Ovens: These use fans to blow hot air around, which means food cooks faster and more evenly. They're the workhorses for baking, roasting, and any high-volume task.

- Combi Ovens: Think of these as the ultimate multi-tasker. They can act as a convection oven, a steamer, or a combination of both. You can roast, steam, bake, and even reheat food, making them an incredibly versatile and space-saving powerhouse.

- Deck Ovens: With heated stone or ceramic decks, these ovens blast intense, direct heat from below. If you run a pizzeria or an artisan bakery, this is how you get that perfect, crispy crust.

Specialized Cooking Units for High-Volume Output

Once you have your range and oven sorted, specialized equipment is what really lets your kitchen handle a diverse menu without breaking a sweat. A busy diner, for instance, would be dead in the water without a big, tough flat-top griddle for the morning rush. A high-end steakhouse, however, might put its money into a charbroiler to get those perfect sear marks on steaks and veggies.

Here are a few other specialized units to consider for your commercial kitchen equipment checklist:

- Commercial Fryers: These are non-negotiable for everything from appetizers and sides to main courses. You’ll want to look at oil capacity, how fast the oil heats back up (recovery time), and whether a built-in filtration system makes sense to make your oil last longer.

- Griddles (Flat-Tops): A large, even cooking surface is a godsend for cooking pancakes, eggs, burgers, and cheesesteaks all at once.

- Charbroilers: Using radiant heat, these units give food that distinct smoky flavor and those classic grill marks. They're a must-have for steakhouses, BBQ joints, and gastropubs.

At the end of the day, the right equipment for your kitchen comes down to your menu and how many people you expect to serve. Every piece you buy should have a clear purpose, helping you run a smoother and more profitable operation.

Mastering Refrigeration and Cold Storage

Let's be honest: your refrigeration is the heart of your kitchen's food safety and inventory management. Getting cold storage right isn't just about keeping things chilly. It’s about holding ingredients at precise, consistent temperatures to maintain their quality, stop spoilage in its tracks, and stay on the right side of the health inspector. A solid refrigeration plan is an absolute non-negotiable on your commercial kitchen equipment checklist.

The choices you make here will have a direct ripple effect on your kitchen's daily workflow and, maybe just as importantly, your utility bills. From massive walk-ins to tuck-away undercounter units, every piece has a specific job. Making the right call from the start means you'll handle inventory like a pro, slash food waste, and keep your whole operation humming.

Essential Refrigeration Unit Types

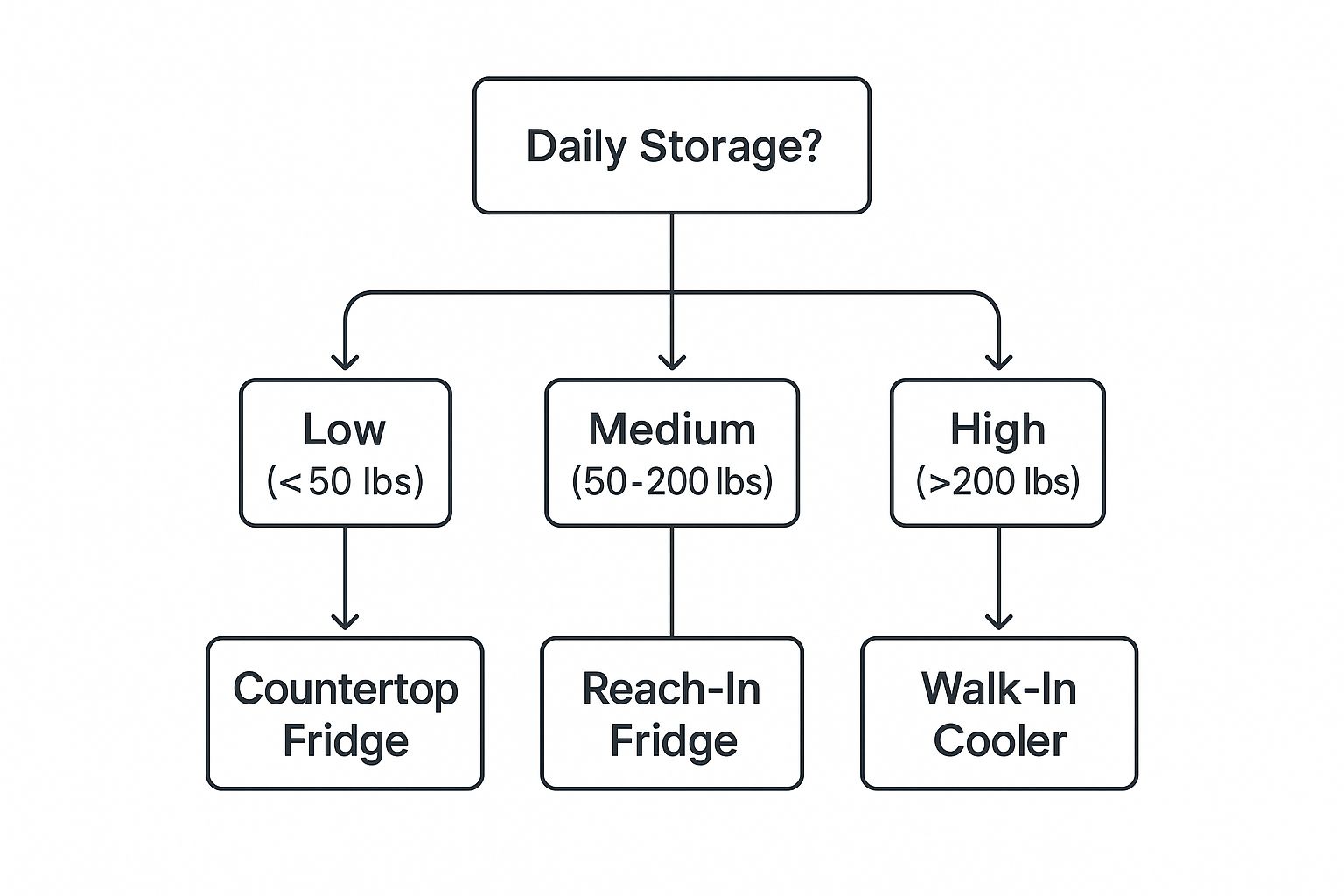

The right mix of refrigeration really comes down to your kitchen's size, your menu, and how many covers you do on a busy night. You’ve got to match the equipment to the task. It's the only way to get the most out of your space and keep things running efficiently.

- Reach-In Refrigerators and Freezers: Think of these as the everyday workhorses. They're the upright units you see in every kitchen, perfect for storing ingredients your line cooks need to grab constantly during service. They come in one, two, or three-door models, so you can find one that fits your footprint.

- Walk-In Coolers and Freezers: If you're moving a lot of product, a walk-in is essential. There's just no substitute for that kind of bulk storage space for cases of produce, proteins, and dairy. This unit is the central command for your entire cold storage system.

- Undercounter Refrigeration: These little guys are workflow heroes. They slide right under your prep tables or service stations, giving you instant access to ingredients exactly where you need them. They are absolutely key to keeping a busy line organized and efficient.

Here's a pro tip that often gets missed: think about where the compressor is located. A top-mount compressor is a smart move for hot kitchens because it breathes in the cooler air up top instead of dusty floor-level air. But, a bottom-mount unit is way easier for your tech to service and makes the bottom shelf more ergonomic to access.

Specialized and Combination Units

Once you have the basics covered, it's time to look at specialized units that can really support specific parts of your menu. These combination units are brilliant because they merge cold storage with a functional workspace, which seriously boosts speed and consistency when the ticket machine is screaming.

If you're running a sandwich shop, salad bar, or pizzeria, these are must-haves. For a complete rundown on picking the right one, you can learn more about commercial refrigerator options in our detailed guide.

One of the best investments a deli or pizza place can make is a prep table refrigerator. These units have refrigerated wells right on top to hold all your pans of ingredients at safe temperatures, plus a refrigerated cabinet below for all your backups. This setup keeps everything—from sliced deli meats and cheeses to fresh-chopped veggies—right at your fingertips, making assembly a breeze. That blend of workspace and cold storage is a total game-changer for high-volume service.

Designing Your Food Preparation Stations

A smooth kitchen workflow starts right at the prep station. This is where your ingredients begin their journey, and the right setup is the difference between chaos and efficiency. Getting the right prep tables on your commercial kitchen equipment checklist is one of the most fundamental steps to building a workspace that actually works.

The absolute backbone of any prep area is the stainless steel work table. It's the industry standard for a reason—it’s tough, non-porous, and built to last, making it a champion for hygiene. When you're looking at tables, the most important spec to check is the steel gauge. It's a bit counterintuitive, but a lower number means thicker, stronger steel. For example, 16-gauge steel is a beast compared to the more common 18-gauge, making it perfect for heavy-duty work like butchering or holding heavy equipment.

Standard and Specialized Stainless Steel Tables

Beyond a simple flat top, stainless steel tables are configured in all sorts of ways to streamline specific kitchen jobs. Figuring out these differences is key to picking a table that fits your workflow like a glove.

- Standard Work Tables: These are your all-purpose workhorses for chopping, mixing, and general assembly. A lot of them come with an undershelf, which is a lifesaver for stashing containers or small appliances and making the most of your space.

- Tables with Integrated Sinks: Combining a work surface with a prep sink is a huge time-saver. It keeps all your produce washing and chopping contained in one efficient spot, cutting down on back-and-forth trips across the kitchen.

- Tables with Backsplashes: A backsplash is just a raised edge along the back of the table, but it’s a crucial feature. It stops liquids and food scraps from falling behind the unit, which makes cleanup easier and protects your walls from splashes and stains.

One thing you absolutely can't skip is looking for NSF (National Sanitation Foundation) certification. An NSF-certified table is guaranteed to meet strict public health standards for easy cleaning. It's a non-negotiable if you want to pass your health inspections without a headache.

Pizza and Sandwich Prep Tables

If you're cranking out pizzas, sandwiches, or salads, a specialized refrigerated prep table isn't a luxury—it's essential. These units are a game-changer, merging a solid workspace with built-in cold storage to create a self-contained station that makes assembly faster and keeps food safe.

Pizza Prep Tables are built from the ground up for making pies. They usually have a wide, flat work surface, often made of marble or another stone that naturally stays cool for stretching dough. Right above the workspace, you’ll find a refrigerated rail with pans to hold all your toppings at the perfect temperature. The base of the unit is a refrigerated cabinet, giving you plenty of room for dough boxes and backup ingredients.

In the same vein, Sandwich Prep Tables (often called sandwich/salad units) are designed for the fast-paced world of building sandwiches, salads, and wraps. These always have a cutting board running the length of the table, sitting right in front of a refrigerated rail full of pans for meats, cheeses, and veggies. Just like the pizza tables, they have a refrigerated cabinet underneath for extra storage. Keeping every ingredient chilled and right at your fingertips is how you crush a busy lunch rush with speed and consistency.

Equipping Your Kitchen with Smallwares and Utensils

While big-ticket items like ovens and coolers are the foundation of your kitchen, it’s the smallwares that bring your menu to life. These are the tools your team has in their hands all day, every day—the pots, pans, knives, and storage containers that are the real workhorses of food production. Having a well-stocked supply of quality smallwares is an absolute must for any serious commercial kitchen equipment checklist.

Don't underestimate their importance. The food service equipment market in North America hit around USD 10.74 billion in 2024, and the segment covering items like pots, pans, and blenders claimed the largest piece of that pie. This just goes to show that successful operators know that investing in good smallwares is just as critical as picking out the right range. You can dig deeper into these market trends and equipment insights through industry research.

Essential Cookware and Cutting Tools

Your menu is always your best guide when it comes to choosing specific cookware. That said, every single kitchen needs a solid base of pots and pans that can stand up to the rigors of a commercial setting. You’ll want to look for heavy-duty materials like stainless steel or aluminum that won't warp or fail under constant, high-heat use.

Your starting checklist for cookware and cutting tools should include these essentials:

- Stock Pots and Sauce Pans: You'll need an assortment of sizes for everything from simmering stocks and soups to finishing delicate sauces.

- Sauté Pans and Fry Pans: These are your go-to pans on the line, essential for searing proteins, frying, and sautéing vegetables.

- Chef’s Knives: A good knife is a chef's best friend. Make sure you invest in several high-quality chef's knives, along with paring knives and serrated knives for specific tasks.

- Color-Coded Cutting Boards: To keep things safe and prevent cross-contamination, a color-coded system is non-negotiable. The standard is green for produce, red for raw meat, blue for fish, and yellow for raw poultry.

Mixing, Measuring, and Storage Solutions

Consistency is king in the restaurant business, and that starts with accurate measurements and proper mixing. Setting up your prep stations with reliable measuring tools and a good variety of mixing bowls is fundamental. It’s the only way to guarantee every dish that leaves your kitchen is exactly as you designed it.

Once the prep is done, proper food storage becomes the top priority for both safety and inventory control. This is where NSF-certified food pans and storage containers are an absolute necessity, not just a suggestion.

Here's a pro tip that often gets missed: think about quantity. A solid rule of thumb is to have at least two to three of each core utensil—spatulas, tongs, ladles—for every cook working the line on a busy night. This simple step prevents a bottleneck when one tool inevitably needs to be washed.

Key items you'll want to stock up on in this category are:

- Mixing Bowls: Get a full range of stainless steel bowls. You'll use them for everything from tossing salads to mixing massive batches of dough.

- Measuring Tools: Load up on measuring cups and spoons, but don't forget digital kitchen scales for precision and portion control.

- Whisks, Spatulas, and Tongs: These are the most-used utensils in the kitchen, involved in nearly every step of the cooking process.

- NSF-Certified Food Pans: Whether they're polycarbonate or stainless steel, having food pans in various sizes (full, half, third-pan, etc.) is crucial for safely storing ingredients in your prep tables and walk-ins.

Setting Up Your Warewashing and Sanitation Area

A spotless kitchen that sails through health inspections is built around a solid warewashing station. This isn't just about cleaning dishes; it's your frontline defense against cross-contamination. Every piece of equipment you choose for this zone has to support top-notch hygiene and an efficient workflow.

A great sanitation area is more than just the gear you buy—it's about how you arrange it. You need a logical flow. Dirty dishes come in at a drop-off point, then move systematically to scraping, washing, rinsing, sanitizing, and finally, to a clean drying and storage area. This prevents clean and dirty items from ever crossing paths, which is a core principle of kitchen safety.

Core Warewashing Equipment

The absolute foundation of any warewashing station is the three-compartment sink. Health departments consider this a non-negotiable requirement for manual washing, making sure every dish goes through the proper steps.

- Wash: The first sink is for hot water and a commercial-grade detergent to scrub everything down.

- Rinse: The middle sink holds clean, hot water to get all that soap residue off.

- Sanitize: The third sink contains a chemical sanitizing solution, mixed to the right concentration and temperature.

If you’re running a higher-volume operation, a commercial dishwasher is a must for both speed and consistency. They come in a few different flavors, each built for different needs:

- Undercounter Dishwashers: These are compact units perfect for small cafes or bars. They fit right under a counter and handle one rack at a time.

- Door-Type Dishwashers: A good step up in capacity. A rack slides in and out, making it ideal for restaurants with a steady stream of dirty dishes.

- Conveyor Dishwashers: These are the real workhorses for high-volume places like hospitals or huge restaurants. They continuously pull racks of dishes through the wash and rinse chambers.

Sanitation and Compliance Essentials

Beyond the big washing units, you’ll need a few other critical pieces to keep things sanitary and legal. Dedicated handwashing sinks are mandatory. They need to be installed in both prep and warewashing areas and must be fully stocked with soap, paper towels, and proper signage.

A crucial piece of gear that often gets overlooked is the grease trap. This device catches grease and solids before they can get into the wastewater system. It's a lifesaver that prevents massive plumbing clogs and keeps you in compliance with local environmental rules.

Finally, think about where your clean wares will live. You'll need proper storage, like NSF-approved shelving or racks that allow for good air drying. Never stack wet dishes—it traps moisture and becomes a breeding ground for bacteria. Proper air circulation is a must.

Meeting Safety and Compliance Standards

A safe kitchen isn't just a goal; it's non-negotiable. Your first job, even before serving great food, is to protect your staff and customers. That means meeting a long list of strict safety and compliance standards from day one.

This section of your commercial kitchen checklist covers the mandatory gear you absolutely need to pass inspections and create a secure workplace. Overlooking these items isn't an option—they're legal requirements designed to stop accidents before they can even start.

Fire Suppression and Personal Safety

The risk of fire is always present in a commercial kitchen, which is why your fire suppression system is the single most critical safety investment you'll make. Your entire cooking line must sit under a commercial ventilation hood that has a professionally installed, integrated fire suppression system—often an Ansul system. This is your first line of defense against dangerous grease fires.

Just as important are the fire extinguishers themselves. While you'll need standard extinguishers throughout the building, every kitchen is legally required to have Class K fire extinguishers. These are specifically made to fight grease, fat, and oil fires.

One of the most common mistakes new owners make is assuming any old fire extinguisher will do. Health and fire inspectors will look specifically for that Class K rating near your cook line. Not having one is a serious violation that can get you shut down on the spot.

Beyond fire safety, you have to protect your staff with the right gear. Providing Personal Protective Equipment (PPE) is essential for minimizing injuries in a fast-paced environment.

- Non-Slip Footwear: An absolute must for reducing the risk of slips and falls on floors that are often wet or greasy.

- Cut-Resistant Gloves: A lifesaver for any station involving heavy knife work. These gloves protect hands from serious, costly cuts.

- Heat-Resistant Gloves or Mitts: You can't run a kitchen without them. They're essential for safely grabbing hot pots, pans, and sheet trays straight from a blazing oven.

First Aid and Required Signage

Even in the safest kitchens, accidents can still happen. Being ready to respond immediately is what matters. A fully stocked, easily accessible commercial first-aid kit isn't just a good idea—it's required by law.

Right alongside it, an eyewash station is also mandatory. It provides immediate relief if chemicals or hot liquids splash into an employee's eyes.

Finally, don't forget the simple stuff. Clear, visible safety signage guides your team and keeps inspectors happy. This includes signs for handwashing stations, fire exits, and wet floors. Proper equipment care is also a huge part of long-term safety; you can learn more in our guide to commercial kitchen equipment maintenance.

Your Top Kitchen Equipment Questions Answered

Picking out equipment for a commercial kitchen is a huge undertaking, with big financial decisions at every turn. Before you invest, it's critical to get clear, straightforward answers to the most common questions. This ensures every single item on your commercial kitchen equipment checklist is a smart buy that sets you up for success down the road.

What Is the Difference Between Commercial and Residential Equipment?

It really boils down to three things: durability, capacity, and safety certifications. Commercial equipment is built tough, usually from high-grade stainless steel, to handle the constant, intense use of a professional kitchen. It's also designed for much higher output and absolutely must meet NSF and UL safety standards to be legally operated.

Trying to get by with residential appliances in a commercial space isn't just a bad idea from an efficiency standpoint—it can actually void your business insurance. That makes commercial-grade gear a complete non-negotiable.

Should I Buy New or Used Commercial Equipment?

This one is a classic tug-of-war between your budget and how much risk you're willing to take on. New equipment gives you peace of mind; it comes with warranties, the latest tech, and guaranteed reliability right out of the box. Used equipment can save you a significant chunk of change upfront, but you're rolling the dice with risks like no warranty, a higher chance of breakdowns, and often, lower energy efficiency.

A savvy approach I've seen many operators take is to buy new for the "heartbeat" of the kitchen—things like your main cooking range and refrigeration. For simpler, less mechanical items like stainless steel tables or shelving, going used can be a great way to save. This strategy gives you a nice balance of cost savings and operational security.

How Do I Choose the Right Equipment Size and Capacity?

You need to focus on three core factors here: your menu, your projected sales volume, and the actual physical layout of your kitchen. Start by breaking down your menu to see which pieces of equipment will get the heaviest workout. That tells you where you need to invest in higher capacity.

Next, dig into your business plan's sales projections to get a handle on your busiest hours. You have to be sure your gear can keep up when you're slammed. Finally, draw up a detailed floor plan and map out where everything will go. This is the only way to confirm your chosen units will physically fit while still leaving a safe and efficient path for your team to move between stations.

Why Is NSF Certification Important for Kitchen Equipment?

Think of the NSF (National Sanitation Foundation) certification as your guarantee that a piece of equipment meets strict public health and safety rules. It's an independent verification that the item is designed to be cleaned easily and completely, is built from non-toxic materials, and is constructed in a way that discourages bacterial growth, promoting food safety.

Health departments across the country require most of the equipment in a commercial kitchen to be NSF-certified before you can pass inspection and legally open your doors. Simply looking for that NSF mark is one of the easiest ways to know you're buying compliant, high-quality equipment.

At PrepTables.com, we stock the durable, NSF-certified equipment you need to build a kitchen that’s efficient, safe, and ready for the long haul. From heavy-duty stainless steel work tables to specialized refrigeration, find everything on your checklist by visiting https://preptables.com.