Complete Guide to Commercial Kitchen Ventilation Requirements

Share

Commercial kitchen ventilation isn't just a box to check on a building code list. It's the life-support system for your entire operation—a critical safety feature designed to prevent devastating fires, protect your staff's health, and keep the workspace functional. A well-designed system is constantly working to pull dangerous, grease-laden vapors and intense heat out of the air, making it an absolute non-negotiable for any professional kitchen.

Why Proper Kitchen Ventilation Is Critical for Safety

Think about the controlled chaos of a busy commercial kitchen. Every sizzle, every fry, and every sauté generates a massive amount of heat, smoke, and airborne grease. Without a powerful ventilation system, all that gunk doesn't just vanish. It hangs in the air, sticks to surfaces, and creates a hazardous environment that puts your team, your customers, and your entire investment on the line.

The best way to think of your ventilation system is as the lungs of your kitchen. It inhales the contaminated, greasy air and exhales fresh, clean air, allowing everyone inside to work and breathe safely.

Its primary job is fire prevention. Grease is incredibly flammable, and when it turns into vapor, it travels up into your ductwork and sticks to the inside. Over time, this buildup creates a hidden and extremely dangerous fire hazard that can ignite in an instant. A properly installed and maintained exhaust hood is your first line of defense, capturing that greasy air right at the source, pulling it through a series of filters, and safely venting it outside. This simple process dramatically cuts down the risk of a catastrophic fire.

Improving Air Quality and Staff Well-Being

Beyond preventing fires, ventilation is absolutely essential for maintaining healthy indoor air quality. Cooking releases all sorts of things you don't want your staff breathing, like carbon monoxide, steam, and other particulates that can lead to respiratory problems and general discomfort.

A well-ventilated kitchen is a productive kitchen. By removing excessive heat and airborne irritants, you create a more comfortable and safer working environment, which can lead to higher staff morale and reduced turnover.

Proper airflow also helps keep odors in check. Nobody wants the smell of last night's fish special wafting into the dining room. A good ventilation system ensures those cooking smells stay in the kitchen, making for a much more pleasant experience for your guests. It’s a key piece of the operational puzzle.

The Role of Kitchen Layout and Equipment

An effective ventilation system doesn't exist in a vacuum; it’s directly tied to the design of your kitchen. The placement of your cook line—your fryers, grills, and ranges—in relation to the exhaust hood is everything. But it doesn't stop there. Even the arrangement of your prep areas can impact how well the air flows. For instance, the strategic placement of your stainless steel prep tables can either help or hinder your ventilation's ability to do its job. A smart layout ensures airflow is clear and unobstructed, guiding smoke and vapor straight toward the hood's filters.

There are several types of stainless steel prep tables designed for different kitchen needs:

- Standard Work Tables: These are the versatile workhorses of any kitchen, featuring a simple flat top, often with an undershelf for storage. They come in various sizes and grades of stainless steel.

- Tables with Backsplashes: To protect walls from splashes and spills, many tables come with an integrated backsplash, making cleanup easier and more hygienic.

- Sandwich Prep Tables: These specialized units combine a refrigerated base with a cutting board work surface and refrigerated wells on top for holding cold ingredients like meats, cheeses, and vegetables. They are essential for delis and sandwich shops.

- Pizza Prep Tables: Similar to sandwich prep tables, these units have a refrigerated rail for toppings but often feature a wider, marble or granite countertop that stays cool, which is ideal for working with pizza dough.

To get a deeper understanding of how to set up your space for success, take a look at our guide to https://preptables.com/blogs/prep-tables/commercial-kitchen-layout-planning. It dives into how smart equipment placement boosts both efficiency and safety. Taking this kind of holistic approach ensures every piece of your kitchen works in harmony to create a safer, cleaner, and more productive environment.

Decoding Essential Ventilation Codes and Standards

Trying to make sense of the rules for commercial kitchen ventilation can feel like learning a new language. But these codes aren't just red tape—they're a critical roadmap for building a safe, functional kitchen. They’re there to protect your staff, your customers, and your entire investment from the very real dangers of a commercial cooking line.

Think of it as a layered safety net. No single code covers every single detail. Instead, they work together to build a strong framework that tackles everything from fire safety and air quality to public health. For any kitchen owner or operator, getting a handle on these standards is the first step toward staying compliant and running a smoother, safer business.

NFPA 96: The Gold Standard for Fire Protection

At the heart of almost every rule you'll encounter is NFPA 96, the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations. This is the big one. It's the document your local fire marshal lives by, and its main goal is simple: prevent and control grease fires.

NFPA 96 isn't a list of friendly suggestions; it's a comprehensive rulebook that dictates nearly everything about your exhaust system.

- Materials: It demands non-combustible materials, like welded steel for ductwork, because they're built to contain a fire if one breaks out.

- Clearances: It spells out the exact distances required between hot equipment and any flammable surfaces to stop a fire before it even starts.

- Cleaning Schedules: The standard sets firm deadlines for professional hood and duct cleaning, with the frequency based on what and how you cook.

- System Design: It lays out detailed requirements for your hoods, filters, fans, and fire suppression systems, making sure every part works together as a single, cohesive safety unit.

Ignoring NFPA 96 isn't just a minor slip-up. In the event of a fire, it could give your insurance company a reason to deny your claim, leaving you to foot the entire bill.

The International Mechanical Code (IMC)

While NFPA 96 zeroes in on fire safety, the International Mechanical Code (IMC) looks at the bigger picture. It covers the entire mechanical system, including ventilation. The IMC is a model code that most states and cities adopt, setting the baseline for how all mechanical equipment should be safely installed.

For kitchens, the IMC provides the "how-to" for the system. It gets into the nitty-gritty of ductwork integrity, the right way to install exhaust fans, and the absolute necessity of makeup air to keep the whole system in balance. It ensures your ventilation doesn't just suck out smoke and grease, but does so without causing other problems for the building.

The IMC and NFPA 96 are designed to be a team. NFPA 96 tells you what fire safety measures you need for cooking, while the IMC provides the engineering and installation rules to make sure the whole system is built to last and operates safely.

Local Health and Building Codes

The last piece of the puzzle is your local regulations. City and county health departments and building authorities will take the IMC and NFPA 96 as their foundation, but they often add their own specific rules. This is where you might find regulations on things like noise from your exhaust fan or specific air quality goals for your area.

In major markets like the United States and the United Kingdom, commercial kitchen ventilation is strictly regulated to protect workers, prevent fires, and maintain indoor air quality. In the US, for instance, groups like the National Fire Protection Association (NFPA) and ASHRAE set the bar for ventilation rates and performance. These standards require systems that can effectively remove smoke, grease-filled air, and heat, protecting both the people in the kitchen and the building itself. You can discover more insights about commercial ventilation system standards for a deeper dive.

To help simplify this, here’s a quick look at the main players in the world of ventilation codes.

Key Regulatory Codes at a Glance

This table breaks down the primary codes and standards, who oversees them, and what they focus on.

| Code / Standard | Governing Body | Primary Focus Area |

|---|---|---|

| NFPA 96 | National Fire Protection Association (NFPA) | Fire prevention and control for commercial cooking operations. |

| International Mechanical Code (IMC) | International Code Council (ICC) | Safe installation and operation of all mechanical systems, including ventilation. |

| ASHRAE Standard 154 | ASHRAE | Air quality and ventilation rates for commercial kitchens. |

| Local Building & Fire Codes | Municipal/County Authorities | Adoption and enforcement of national standards with local amendments. |

| Local Health Codes | Local Health Departments | Sanitation and public health requirements related to kitchen ventilation. |

Navigating these codes is a fundamental part of planning and running a commercial kitchen. While they might seem complex, they all share the same goal: creating a safe environment for everyone.

Choosing the Right Commercial Kitchen Hood

The exhaust hood is the heart and soul of your kitchen's ventilation system. Think of it as the first line of defense, capturing all that smoke, heat, and grease-filled steam right at the source. If it doesn't do its job, that gunk ends up everywhere else.

But here's the thing: there's no single "best" hood. The right choice completely depends on what you're cooking and how your kitchen is laid out. Getting this decision right is non-negotiable for meeting ventilation codes and keeping your staff safe and comfortable.

The first step is getting to grips with the two main categories of hoods.

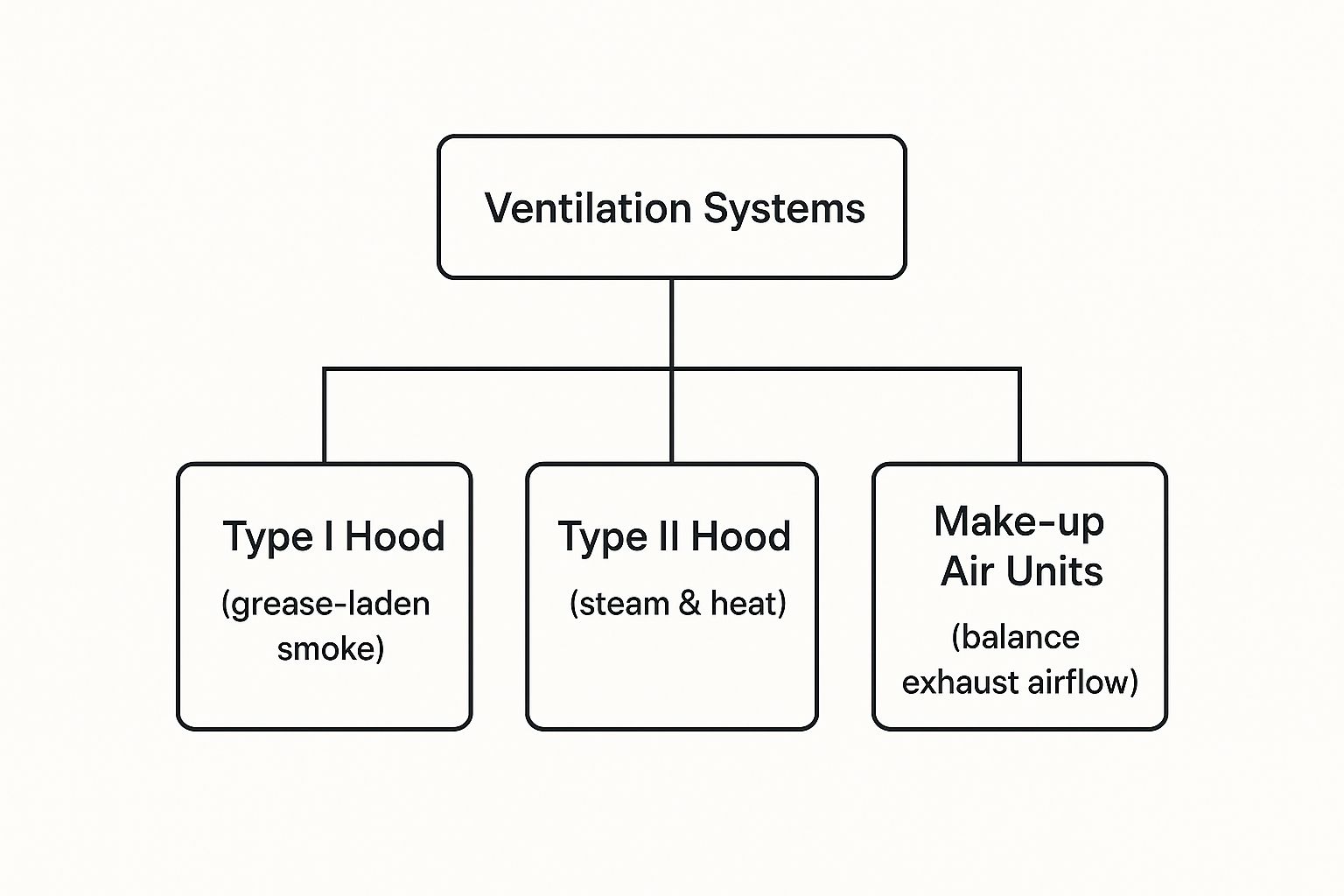

This diagram breaks down the key parts of a commercial kitchen ventilation setup. You can see how the exhaust hoods and makeup air units have to work together in a balanced system.

As you can see, it's a constant cycle. The hoods pull out the dirty air, and the makeup air units bring in fresh air to replace it.

Type I vs. Type II Hoods

The biggest dividing line in the world of commercial hoods is between Type I and Type II. It all comes down to what's coming off your cooking equipment.

A Type I hood, often just called a grease hood, is an absolute must for any appliance that produces grease or smoke. We're talking about your heavy hitters:

- Grills and charbroilers

- Fryers

- Ranges and woks

- Griddles

Because they deal with flammable grease, Type I hoods are all about fire safety. They have to be equipped with a fire suppression system and use special baffle filters to trap grease particles before they can build up in the ductwork—which is a huge fire risk. Properly managing that collected grease is a big deal, and it ties directly into how you maintain a kitchen grease trap to keep the whole system safe.

On the other hand, a Type II hood (or a condensate hood) is for appliances that only give off heat and steam, with zero grease. Think dishwashers, steamers, and some ovens. Since there's no grease, there's no fire hazard, so they don't need all the heavy-duty filters and fire suppression gear. This makes them a much simpler and more affordable option when you can use one.

Matching Hood Style to Your Kitchen Layout

Once you know if you need a Type I or Type II, you have to pick a style that actually fits your kitchen. The name of the game is total coverage over your cooking line.

- Wall-Mounted Canopy Hoods: These are what you see most often. They mount right up against a wall, hanging over a line of equipment. Super effective.

- Island Canopy Hoods: Got a big cooking island in the middle of your kitchen? You need one of these. They're larger, hang from the ceiling, and are designed to capture fumes from all sides.

- Proximity Hoods: These are low-profile hoods that sit much closer to the cooking surface. They're a great solution for kitchens with low ceilings or for specific pieces of gear like flat-top griddles.

Picking a hood that's the right size isn't just a suggestion—it's a requirement. A hood that's too small is basically useless. It will let smoke and grease spill out into the kitchen, creating a nasty and dangerous environment. Codes generally mandate that the hood must overhang the cooking equipment by at least six inches on all sides.

The Rise of Smart Ventilation Systems

Modern kitchens are always on the lookout for ways to be more efficient without cutting corners on performance. That's where smart ventilation systems are starting to change the game.

Demand-Controlled Kitchen Ventilation (DCKV) systems are the future. These systems use sensors that can actually detect how much heat and smoke are being produced.

When things are slow, the system automatically dials back the fan speed, saving a ton of electricity. The second a big rush starts and the sensors pick up more heat, the fans instantly ramp up to full power to clear the air. It's an intelligent approach that makes sure you're only paying for the energy you actually need, right when you need it.

Understanding Airflow and Makeup Air Systems

A big, powerful exhaust hood looks impressive, but it’s only doing half the job. For every cubic foot of air your system yanks out of the kitchen, another cubic foot has to come back in to replace it. This is the simple but critical principle behind a balanced air system, and it's a non-negotiable part of meeting commercial kitchen ventilation requirements.

Imagine your kitchen is a sealed box. If you only suck air out without letting any back in, you create a vacuum. This is called negative pressure, and it triggers a surprising number of problems in a busy kitchen. Suddenly, the front door is mysteriously hard to pull open. Pilot lights on your gas ranges start flickering out. Even your expensive exhaust hood will struggle to grab smoke and heat like it’s supposed to.

Worse yet, this imbalance can cause dangerous back-drafting. This is where harmful gases like carbon monoxide get pulled back into the kitchen instead of being vented safely outside. The whole system becomes inefficient and downright unsafe, all because the air going out isn't being replaced.

The Role of Makeup Air Units

The fix for negative pressure is a dedicated Makeup Air (MUA) unit. This is a totally separate fan system, usually parked on the roof, designed with one job in mind: bringing fresh, filtered outdoor air back into the kitchen. Its sole purpose is to "make up" for the air being exhausted, keeping the building’s pressure neutral and balanced.

Getting the MUA unit sized correctly is vital for both performance and passing inspection. Most codes are very clear: if your exhaust system moves a certain amount of air—measured in Cubic Feet per Minute (CFM)—a mechanical makeup air system is mandatory. This is how you ensure your ventilation actually works, keeping the air clean and your staff safe.

Think of it like trying to drink from a straw with your finger plugging the other end. No matter how hard you suck, nothing moves. The MUA unit is like taking your finger off the straw—it lets the air flow freely so the exhaust fan can do its job without a fight.

Tempered vs. Untempered Makeup Air

Okay, so you need an MUA unit. The next question is a big one: does that incoming air need to be treated? Your answer will depend almost entirely on your local climate, and it has a major impact on your budget and your team's comfort.

You have two main options:

- Untempered Systems: These are the most basic MUA units. They just pull outside air in and pump it into the kitchen as-is, without any heating or cooling. If you’re in a mild climate where the weather is pretty comfortable year-round, this can be a great, cost-effective solution.

- Tempered Systems: For everywhere else with cold winters or scorching summers, dumping untreated air into the kitchen just won't work. A tempered system conditions the air first, heating it in the winter (and often cooling it in the summer) before it ever hits your workspace.

Sure, tempered systems cost more upfront. But they are absolutely essential for keeping a kitchen productive and comfortable in most climates. Blasting your cook line with 30°F air in the middle of January isn't just unpleasant; it's a guaranteed way to crush morale and can even affect food quality.

Calculating Your Airflow Needs

So, how much air are we talking about? The amount your system needs to move is found by calculating the required CFM for your specific equipment and hood. This isn't simple guesswork; it’s a complex calculation that hinges on a few key details.

Here’s a quick look at what goes into the math:

- Appliance Type: A smoky charbroiler needs way more CFM than a small convection oven.

- Hood Size: The total square footage under the hood dictates the volume of air you have to capture.

- System Design: A wall-mounted canopy hood has different airflow dynamics than an island hood hanging in the middle of the room.

Because nailing the CFM calculation is so important for safety and code compliance, this is a job for a certified HVAC professional. They have the tools and expertise to make sure your exhaust fan and MUA unit are perfectly matched, creating a balanced, safe, and efficient system that meets all commercial kitchen ventilation requirements.

Best Practices for Ductwork and Fan Installation

While the exhaust hood gets all the glory, the ducts and fans are the unsung heroes of your kitchen's ventilation system. They create the critical pathway that pulls all that grease-laden air safely out of your building. If that pathway isn't built and installed just right, even the best hood in the world can’t do its job.

This isn’t just about connecting a few pieces of metal. It's about engineering a sealed, fire-resistant channel that meets strict commercial kitchen ventilation requirements. Getting this right is non-negotiable for safety, passing inspections, and the long-term health of your entire system.

Constructing Code-Compliant Ductwork

The ducts snaking through your kitchen ceiling are nothing like the ones in a standard HVAC system. Because they're designed to handle flammable grease vapor, the rules for building them are incredibly strict. Think of it less like an air duct and more like a sealed pipeline designed to contain a fire.

NFPA 96 lays out several non-negotiable requirements for this pipeline:

- Material: All ductwork must be made of carbon steel or stainless steel. Why? Because these materials won't burn and can withstand the intense heat of a potential grease fire.

- Welded Seams: The individual sections of ductwork must be joined with continuous liquid-tight welds. This is a critical detail that prevents highly flammable grease from leaking out and creating a hidden fire hazard in the spaces between your walls and ceilings.

- Proper Sloping: To keep grease from building up in low spots, ducts must be sloped to drain back toward the hood. This clever design ensures any collected grease makes its way back to the collection traps where it can be safely removed.

These rules ensure that if a fire ever does ignite inside a duct, it stays locked inside that fire-resistant steel tube, stopping it from spreading through the rest of the building.

Designing for Optimal Air Velocity

Beyond the materials, the design of the ductwork is a huge factor in how well it works. One of the key principles here is maintaining the right air velocity—the speed at which air travels through the ducts. If the air moves too slowly, grease vapor has a chance to cool down and stick to the duct walls, creating a dangerous, flammable buildup.

An ideal air velocity is typically between 500 and 2,500 feet per minute (FPM). This is the sweet spot: fast enough to keep grease particles airborne until they’re safely outside, but not so fast that it creates a racket or puts too much strain on the fan.

To make sure every inch of the ductwork can be cleaned, codes also require the installation of grease duct access doors. These are sealed panels that give professional cleaners the access they need to scrub the interior, which is absolutely vital for preventing catastrophic fires.

Selecting and Installing the Right Exhaust Fan

The exhaust fan is the engine that powers this whole operation. Its job is to pull air from the hood, through the ducts, and shoot it outside. For any kitchen dealing with grease, the fan has to be installed on the rooftop. This ensures all that contaminated air is discharged far away from the building and any fresh air intakes.

You’ll typically see two main types of fans for this job:

- Upblast Exhaust Fans: This is the most common workhorse. It pulls air up and blasts it straight into the sky, away from the roof. This design is great for preventing grease from coating your roof, which would create a fire hazard and ruin your roofing materials.

- Utility Set Fans: You'll find these in more complex systems, especially when the ductwork has long, winding horizontal runs. They're bigger, more powerful units that can handle higher air volumes and more resistance.

Proper installation is just as important as the fan itself. The fan must be mounted securely and, per NFPA 96, must have a hinge kit. This simple but brilliant device allows a technician to safely tilt the fan open for cleaning and maintenance without having to lift the entire heavy unit off its curb. It’s a small detail that protects both the tech and your expensive equipment.

Maintaining Your System for Safety and Compliance

Getting your ventilation system installed is a huge step, but the work doesn't stop there. Think of it like a high-performance car; you can't just drive it off the lot and forget about it. It needs regular tune-ups to keep running safely and efficiently. Ongoing maintenance isn't just a smart move—it’s a legal requirement under NFPA 96 and your best defense against a catastrophic grease fire.

A system that isn't cared for is a ticking time bomb. Day after day, grease builds up on the filters and coats the inside of your ductwork. This creates a highly flammable fuel source just waiting for a stray spark. The only way to handle this risk is through regular, professional cleaning, which keeps you compliant with all commercial kitchen ventilation requirements.

Establishing a Consistent Cleaning Schedule

Good maintenance is all about routine. It’s a mix of daily checks your own staff can handle and periodic deep cleans from certified pros. NFPA 96 lays out the bare minimum frequency for professional cleaning, and it all depends on what—and how much—you're cooking.

- Monthly: This is for solid-fuel cooking operations. If you’re using wood-fired ovens or charcoal broilers that produce heavy soot and grease, you need a monthly deep clean.

- Quarterly: High-volume spots like 24-hour diners, places that do a lot of charbroiling, or restaurants with wok cooking fall into this category. They generate a ton of grease and need cleaning every three months.

- Semi-Annually: This is the standard for most restaurants with moderate volume. If you’re doing typical grilling, frying, and sautéing, a cleaning every six months is usually required.

- Annually: For kitchens with low volume—think churches, day camps, or seasonal businesses—an annual cleaning is often sufficient.

It’s critical to remember these are just the minimums. If you can see heavy grease buildup, don’t wait. You need to get a cleaning scheduled sooner rather than later. For a better feel for the kinds of appliances that demand this level of care, you can check out our guide on essential commercial kitchen equipment.

The Role of Integrated Fire Suppression Systems

Even with the most diligent cleaning schedule, the risk of a fire never truly goes away. That's precisely why every Type I hood must have an integrated fire suppression system. This is your last line of defense, an automated system designed to spring into action the second it detects a fire.

Most of these systems use a wet chemical agent that sprays directly onto the cooking surfaces and up into the hood's plenum. The chemical works in two ways: it smothers the flames and chemically reacts with the hot grease—a process called saponification—to turn it into a non-flammable, soapy foam. At the exact same time, the system automatically kills the gas or electricity to your cooking line, cutting off the fire's fuel.

A properly functioning fire suppression system can be the difference between a minor incident and a total loss. Regular inspection and certification by a licensed professional, typically every six months, are mandatory to ensure it will work when you need it most.

The need for these integrated safety systems is a big part of why the commercial kitchen ventilation market, valued at around USD 2.5 billion in 2024, is expected to climb to USD 4.2 billion by 2033. This growth is being pushed by tougher safety rules and an explosion in the number of restaurants that need effective, compliant ventilation. You can read the full analysis on this market growth.

Putting off maintenance doesn't just create a serious fire hazard. It can also lead to steep fines from inspectors and could even void your insurance coverage if a fire does happen. Regular, documented cleaning is one of the most important investments you can make in the safety and future of your business.

Frequently Asked Questions

It's natural to have questions when you're wading through the codes and technical specs of commercial kitchen ventilation. We get it. Here are some of the most common things kitchen managers and owners ask us, with straightforward, no-nonsense answers.

How Often Do I Really Need to Clean My Hood System?

This isn't a suggestion; it's a hard-and-fast rule dictated by NFPA 96. The real answer depends entirely on what you're cooking and how much of it.

If your kitchen is running high-volume, greasy operations like charbroiling or wok cooking, you're looking at a quarterly cleaning. For most typical restaurants, a deep clean every six months is the standard. Operations with very low cooking volume, like a church or a day camp, might only need it done once a year.

But here's the most important rule: if you can see grease building up, it’s time to call the cleaners. Don't wait for the calendar.

Think of these schedules as the absolute minimum. Being proactive about cleaning is your single best defense against a devastating kitchen fire. It’s non-negotiable for a safe, compliant kitchen.

What Is the Difference Between a Type I and Type II Hood?

The dividing line is simple: grease. That’s it.

Type I hoods are the heavy-hitters, legally required for any appliance that kicks out grease-laden vapor—think grills, fryers, ranges, and salamanders. They have to be armed with a full set of grease filters and an integrated fire suppression system to tackle the serious fire risk that grease presents.

Type II hoods, sometimes called condensate hoods, are for the tamer equipment. They handle appliances that only produce heat and steam, like your high-temp dishwasher or certain ovens. Because there's no grease involved, they don’t need the same intense level of fire protection, which makes them a simpler, more affordable option when you can use them.

Why Is Makeup Air So Important for My Kitchen?

Makeup air isn't just a "nice-to-have"; it's a critical part of a safe, functional kitchen. Your exhaust fan is a beast, pulling a massive amount of air out of your kitchen every single minute. If you don't replace that air, you create a vacuum effect known as negative air pressure.

This imbalance is a recipe for trouble. You'll notice your exhaust hood isn't pulling smoke effectively, doors will be weirdly hard to open, and pilot lights might get snuffed out. Most dangerously, it can cause a back-draft, pulling deadly carbon monoxide from your gas appliances back into the kitchen instead of letting it vent out.

A correctly sized makeup air unit is the only solution. It brings fresh air back in, balances the pressure, and ensures your whole ventilation system works just the way it was designed to—safely and efficiently, meeting all commercial kitchen ventilation requirements.

For all your kitchen equipment needs, from heavy-duty cooking appliances to the essential prep surfaces that complete your workflow, trust PrepTables.com. Find durable, NSF-certified equipment at https://preptables.com.