A Guide to Buying Food Prep Tables

Share

Think of your food prep tables. They’re more than just stainless steel surfaces; they are the heart of your kitchen. Everything flows from them. The right table makes your kitchen hum with efficiency, while the wrong one can cause bottlenecks, safety issues, and chaos. This guide will walk you through what really matters when choosing one.

A Guide to Buying Food Prep Tables

Whether you're running a packed restaurant, a cozy café, or a focused ghost kitchen, your prep tables dictate your team's rhythm. A good table isn't just a place to chop vegetables; it's a command center. It's where all the action happens—chopping, mixing, portioning, and plating. This is where your culinary vision starts to take shape.

The market for these tables is booming for a reason. Valued at USD 1.18 billion in 2023, it's expected to climb to USD 1.62 billion by 2029. This isn't just a random number; it shows how much the food service industry relies on smart, durable kitchen setups to succeed. You can dig deeper into these trends over at Arizton.com.

Exploring Different Types of Prep Tables

Walking into the world of prep tables can feel overwhelming, but the choices boil down to your menu and workflow. Stainless steel is the industry standard, but within that category, you'll find a variety of designs tailored for specific tasks. Understanding these types is the first step to building a more efficient kitchen.

The most common workhorse is the standard stainless steel work table. It’s the jack-of-all-trades, perfect for general prep work like chopping, mixing, and plating. Its surface is non-porous, durable, and easy to sanitize, making it a fixture in almost every commercial kitchen.

For kitchens with high-volume, specific menu items, specialized tables are essential. These units integrate key features to create a mini-assembly line for specific dishes. The most popular specialized options include:

- Sandwich/Salad Prep Tables: These units feature refrigerated wells or pans (often called rails) that keep cold ingredients like meats, cheeses, and vegetables chilled and within arm's reach. They often include a built-in cutting board, allowing staff to build orders in one seamless motion.

- Pizza Prep Tables: Built for speed and efficiency in pizzerias, these tables combine a large, often marble or steel, work surface for dough with deep refrigerated rails for sauce, cheese, and toppings. This setup streamlines the entire pizza-making process from start to finish.

Matching the table's design to your workflow can drastically reduce prep times, minimize staff movement, and maintain stricter temperature control over sensitive ingredients.

Specialized Tables for Peak Efficiency

If your menu is built around specific items, a specialized table is a total game-changer. They bring everything you need into one compact, organized space.

Two of the most popular types are:

- Pizza Prep Tables: These are brilliant. You get a wide marble or steel surface for working dough, right next to refrigerated rails holding all your toppings. Cheese, sauce, pepperoni—it's all chilled and right at your fingertips. No more running back and forth to the walk-in.

- Sandwich and Salad Prep Tables: These work on the same principle. They feature cooled wells to hold everything from sliced turkey and provolone to crisp lettuce and dressings. Most even come with a built-in cutting board, so your team can build a sandwich or toss a salad in one seamless motion. It's all about smooth, efficient flow.

Understanding Stainless Steel for Kitchens

When you're outfitting a commercial kitchen, the material you choose for your prep tables is a foundational decision. It impacts everything from safety to how long your investment will last. While you might see wood or plastic tables out there, stainless steel is the undisputed king in professional settings, and for good reason. It’s tough as nails and incredibly hygienic—its non-porous surface means bacteria, funky smells, and stains have nowhere to hide.

But here’s the thing: not all stainless steel is the same. You’ll hear two words thrown around a lot: gauge and grade. Getting a handle on these two specs is what separates a smart purchase from a future headache. It’s the key to making sure your table can take the heat of a busy kitchen without denting, rusting, or giving up on you mid-service.

Gauge: The Armor of Your Table

Think of gauge as the thickness of the steel, its armor plating. It’s a bit counterintuitive, but with steel gauge, the numbers work in reverse—a lower gauge number means thicker, stronger steel. This is probably the most important factor when you're thinking about what you’ll be doing on the table and how much weight it needs to hold.

- 14-Gauge: This is the heavyweight champ. If you’re doing serious butchering, setting up a massive stand mixer, or parking heavy countertop equipment, you want 14-gauge. It's exceptionally thick and built to handle the absolute toughest jobs.

- 16-Gauge: For most kitchens, 16-gauge is the sweet spot. It strikes a perfect balance between serious strength and good value. It’s more than sturdy enough for all your general prep, chopping, and holding moderately heavy gear without any worrisome flexing.

- 18-Gauge: This is the lightest-duty option you'll typically find in a pro kitchen. It's perfectly fine for lighter tasks like tossing salads, plating up finished dishes, or just as an extra surface for storing items that aren't too hefty.

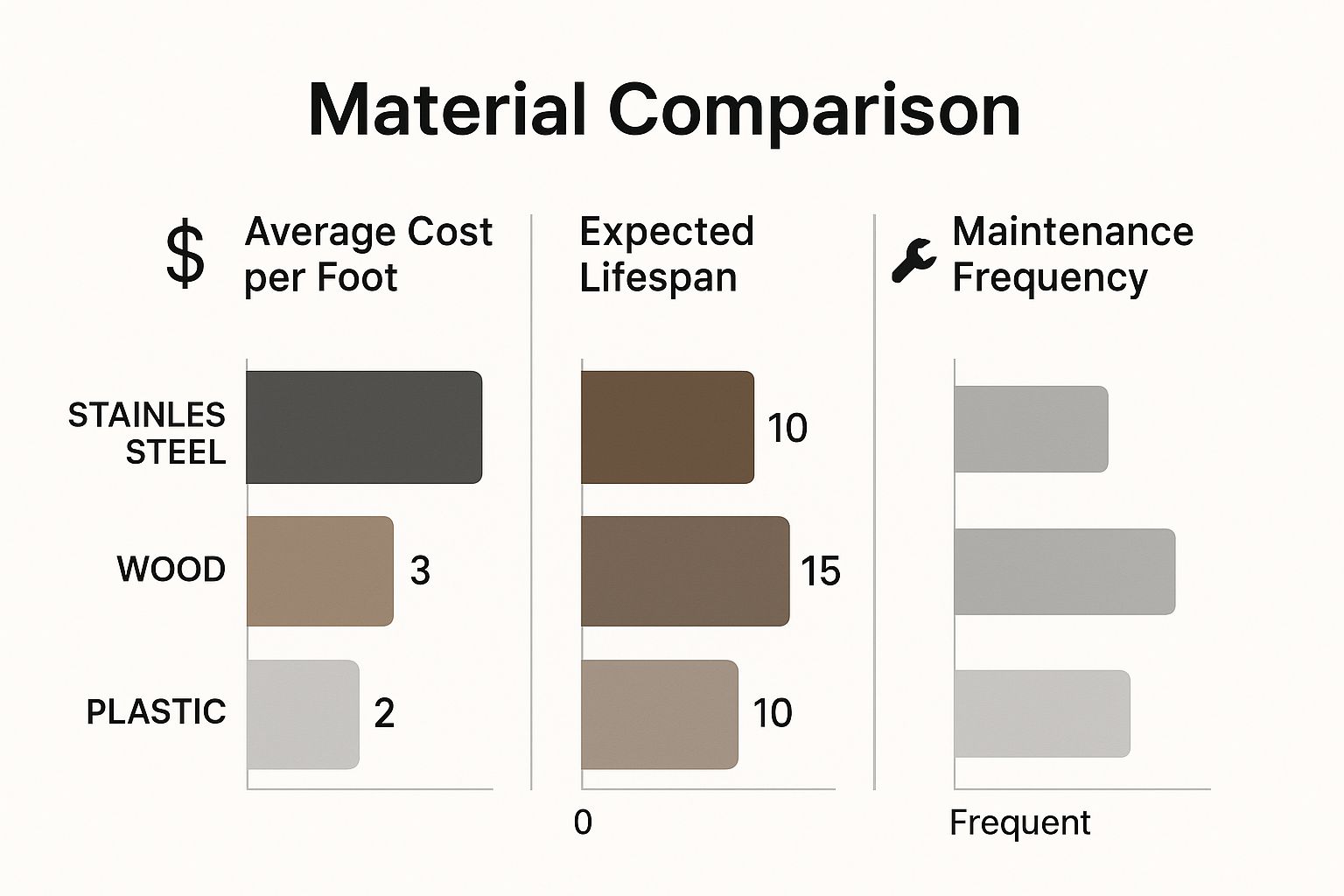

This image gives a quick visual rundown of how stainless steel stacks up against other materials over time.

As you can see, while the upfront cost of stainless steel might be higher, its incredible lifespan and minimal maintenance make it the clear winner for any serious kitchen in the long run.

Grade: The Shield Against Corrosion

If gauge is the steel's armor, then grade is its invisible shield. It's all about fighting off rust and corrosion. A steel's grade is decided by its chemical makeup, specifically how much chromium and nickel are in the mix.

Key Takeaway: The grade of your stainless steel is what determines how well it stands up to moisture, acidic foods like citrus and tomatoes, and all the cleaning chemicals you'll be using. It's a non-negotiable factor for food safety.

You'll mainly come across two grades when shopping for prep tables: 304 and 430.

- 304-Grade Stainless Steel: This is the gold standard for most food-related work. It’s packed with more chromium and nickel, giving it top-tier resistance to rust. If your table is going to be in a "wet" area—near a sink, used for marinating, or just washed down constantly—304-grade is the only way to go.

- 430-Grade Stainless Steel: This is a more wallet-friendly choice. It has less nickel, which means it’s a bit more likely to corrode over time, especially if it's always wet. That said, it's a solid, cost-effective pick for "dry" tasks like rolling out dough, general storage, or as a stand for equipment away from the splash zone.

To help you visualize these differences, here's a quick comparison table.

Stainless Steel Gauge and Grade Comparison

| Feature | Lower Gauge (e.g., 14-16) | Higher Gauge (e.g., 18) | 304 Grade | 430 Grade |

|---|---|---|---|---|

| Durability | Thicker, more dent-resistant | Thinner, more prone to dents | Superior rust/corrosion resistance | Good corrosion resistance |

| Best For | Heavy equipment, butchering | Light prep, storage | Wet environments, direct food contact | Dry environments, equipment stands |

| Cost | Higher | Lower | Higher | Lower |

Knowing the difference is what leads to a smart buy. By matching the right gauge and grade to what your kitchen actually needs, you’re not just buying a table; you’re investing in a workstation that will be a reliable part of your team for years to come. For an even deeper dive, you can check out our complete guide to choosing a stainless steel work table.

Finding the Perfect Type of Prep Table

Picking a food prep table isn't a one-size-fits-all situation. The right table can be a force multiplier for your kitchen crew, making every movement efficient and boosting your output. The wrong one? It just creates frustrating bottlenecks and slows down service. Think of it like using a hammer to drive a screw—it’s just not the right tool for the job.

The world of food prep tables is surprisingly diverse. You've got everything from simple, do-it-all surfaces to highly specialized, refrigerated workstations. Each one is built to solve a specific problem in a busy commercial kitchen.

Getting a handle on this spectrum is your first step toward building a more organized and efficient back-of-house. Let's break down the most common types you'll run into.

The All-Purpose Workhorse: Standard Stainless Steel Tables

The standard stainless steel work table is the absolute foundation of almost every commercial kitchen. It’s like a blank canvas for a chef—a simple, tough, and endlessly adaptable surface ready for pretty much anything you throw at it.

These tables are all about simplicity and resilience. They don't have fancy features like refrigeration; their main job is to give you a clean, non-porous, and roomy area for all sorts of general prep work.

You’ll see these tables used for everything:

- Chopping mountains of vegetables and breaking down proteins.

- Mixing ingredients, kneading dough, or portioning out meals.

- Plating finished dishes right before they head out to the dining room.

- Holding countertop equipment like blenders, food processors, or slicers.

Because they’re so straightforward, these tables are incredibly affordable and come in a huge range of sizes and setups. They are the unsung heroes of the kitchen, providing that essential space where all the culinary magic begins.

Specialized Stations: Sandwich and Salad Prep Tables

When your menu is packed with fresh, made-to-order items like salads and sandwiches, a standard table can turn into an organizational mess in a hurry. This is exactly where specialized sandwich and salad prep tables shine, transforming a chaotic process into a smooth, efficient assembly line.

These units are smartly designed with built-in refrigeration. The top of the table has a series of chilled wells or pans—often called a "rail"—that hold all your key cold ingredients. Everything from sliced deli meats and cheeses to crisp lettuce, tomatoes, and dressings is kept at a safe, cool temperature and is always within arm's reach.

A well-designed prep station isn't just equipment; it's a workflow philosophy. By keeping ingredients and tools in one central spot, it cuts down on staff movement, speeds up ticket times, and keeps your product quality consistent.

Most of these tables also have a full-length cutting board right in front of the refrigerated rail. This setup lets a team member stand in one place, build an order from start to finish, and pass it down the line without taking a single extra step. For delis, cafes, and quick-service spots, this kind of efficiency is a total game-changer. For a closer look at how these units work, check out our guide on commercial refrigerated prep tables.

The Pizzeria Powerhouse: Pizza Prep Tables

Just like their sandwich-making cousins, pizza prep tables are built for one specific, high-volume job: making perfect pizzas, fast. They combine a big, durable work surface with powerful, built-in refrigeration to create the ultimate pizza station.

The work surface is often made of marble or a thick gauge of stainless steel, giving you a cool, smooth area that’s ideal for stretching and working with dough. The refrigerated rail at the back is usually deeper and wider than what you’d find on a sandwich table, designed to hold large pans of sauce, cheese, and all sorts of toppings.

This kind of specialization is driving huge growth in the market. The global pizza prep tables market was valued at USD 1.75 billion in 2024 and is expected to reach USD 4.92 billion by 2033, growing at an impressive 11.9% CAGR. This boom shows the rising demand for efficient tools in the booming pizza delivery and restaurant industry. You can dig into more insights on this trend by reading the full market analysis from Verified Market Reports.

By combining dough prep, saucing, and topping into one consolidated station, these food prep tables let a pizzeria crush the dinner rush with incredible speed and consistency.

Decoding Essential Features and Certifications

Once you’ve settled on the right material and type of table, it’s time to look at the finer details. Certain features and official certifications are what separate a decent table from a professional-grade workhorse. For any commercial kitchen, these aren't just nice-to-haves—they're non-negotiable.

Think of these elements as your final checklist. They’re what guarantee your table will hold up to the daily grind while keeping your staff safe and the health inspector happy.

The Unmistakable Importance of NSF Certification

If there’s one seal of approval you absolutely need to see on your equipment, it’s the NSF (National Sanitation Foundation) certification. This isn't just a sticker; it's a promise that the table meets strict public health and safety standards. Trust me, it’s the first thing health inspectors look for on any surface that touches food.

An NSF-certified table is engineered from the ground up to be:

- Easy to Clean: Built with smooth, non-porous materials that leave no cracks or crevices for bacteria to hide.

- Safe for Food Contact: The materials are guaranteed not to leach any harmful chemicals into your ingredients.

- Corrosion-Resistant: It’s tough enough to handle acidic foods and strong cleaning chemicals without breaking down.

Simply put, an NSF-certified table is your first line of defense against cross-contamination and foodborne illness. It's a must-have for passing health inspections. To really dig into this critical standard, you can learn more about what NSF certification truly means for your kitchen in our detailed guide.

Matching Load Capacity to Your Kitchen's Demands

Not all tables are created equal when it comes to strength. The load capacity tells you exactly how much weight a table can safely hold before it starts to wobble or buckle. You have to match this to the job you have in mind for it.

For light prep work like chopping vegetables, a table with a 300-400 pound capacity will do just fine. But if you’re planning to park a heavy piece of equipment on it—like a 150-pound stand mixer or a commercial meat slicer—you’ll need a heavy-duty model rated for 600 pounds or more. Overloading a table is a huge safety risk, leading to broken equipment and even injuries.

Ergonomics and Mobility Features

A smart kitchen is one that takes care of its people. Ergonomic features are designed to reduce the physical strain of long shifts, which ultimately boosts productivity and helps prevent injuries.

- Adjustable Legs: These are a game-changer. They let you set the table height perfectly for the person using it, preventing the constant back and shoulder strain from hunching over or reaching too high. A comfortable working height is usually somewhere between 34 and 36 inches.

- Adjustable Undershelves: Just like the legs, these shelves can be moved to fit different-sized bins and equipment, making storage more efficient and keeping everything within easy reach.

Mobility is another thing to think about, especially if your kitchen layout needs to be flexible.

- Casters (Wheels): Pop a set of casters on, and your stationary table becomes a mobile prep station. This makes it incredibly easy to clean underneath and reconfigure your space on the fly.

- Locking Casters: Always—and I mean always—get locking casters. They keep the table firmly in place when you’re working, so it won’t dangerously slide around while you’re chopping or using heavy machinery.

Customizing Your Workstation with Accessories

A bare food prep table is really just a starting point. Its true potential is only unlocked when you move beyond a simple surface and build it into a complete, high-efficiency workstation. Smart accessories are how you get there, turning an empty table into a command center designed for your specific kitchen workflow.

This is all about maximizing space and minimizing movement. Every single step a team member saves is precious time gained during a busy service. By adding the right components, you create a station where every tool and ingredient has its own home, making the whole prep process smoother.

Expanding Storage Vertically and Horizontally

The most direct way to make a prep table more useful is by adding storage. In a crowded kitchen, any wasted space—whether it's below or above the worksurface—is a missed opportunity.

- Undershelves: This is easily the most common and vital accessory you can add. An undershelf literally doubles your storage, giving you a solid, easy-to-reach spot for bulk ingredients, containers, or smaller appliances. It keeps the floor clear and your essentials close.

- Drawers: When it comes to organizing smaller tools like knives, thermometers, and whisks, nothing beats a set of drawers. They keep your main worksurface clear of clutter and protect delicate tools from getting banged up, so your staff isn't fumbling to find what they need.

- Overshelves: These tiered shelves go above the main surface, putting that vertical space to good use. They're perfect for holding spices, plating garnishes, or even serving as a pass-through for finished dishes. A bakery, for instance, could use an overshelf for cooling racks, freeing up the main prep area for mixing and kneading.

The real goal of adding accessories is to create a "station" mentality. A well-equipped table becomes a self-contained zone for a specific job—whether it's butchering, baking, or assembling salads—which drastically cuts down on wasted motion.

Integrating Task-Specific Components

Beyond just general storage, you can add components that turn your prep table into a specialized hub. These integrated accessories build efficiency right into the workstation, merging different kitchen jobs into one seamless unit.

One of the most powerful additions is a built-in sink. Putting a small prep sink directly into the table creates a self-sufficient cleaning station. This is a huge help for tasks that need frequent rinsing, like washing vegetables or cleaning utensils between jobs, since it means no more walking across the kitchen to a main sink.

Another game-changer is an integrated poly-top cutting board. Instead of loose cutting boards that can slide around, a poly-top gives you a large, stable, and food-safe surface that covers part or all of the table. This is a dream for high-volume chopping or butchering, offering a dedicated and durable cutting area that’s also easy to clean and sanitize. By thoughtfully combining these elements, you don’t just add features—you build a smarter, faster kitchen from the ground up.

Keeping Your Prep Tables Safe and Lasting a Lifetime

Think of your food prep table as a long-term investment in your kitchen's future. Keeping it in top shape is about more than just looks; it's the bedrock of a safe, efficient operation. A quick wipe-down at the end of a shift just doesn't cut it. Proper maintenance is your front-line defense for food safety and a surefire way to make sure your equipment serves you well for years to come.

Sticking to a daily and weekly cleaning routine is non-negotiable. These simple habits are what stop food residue and bacteria from building up, which is exactly how cross-contamination and health code violations happen.

Daily and Weekly Cleaning Routines

Staying on top of cleaning keeps small messes from snowballing into massive headaches. A disciplined daily routine is your first line of defense, but you also need a more thorough weekly deep clean to hit those spots that get missed during the dinner rush.

Your Daily Must-Dos:

- Wipe and Sanitize: After every single task, and especially at the end of the day, wash all surfaces with warm, soapy water. Follow that up with a food-safe sanitizer, letting it sit for the recommended time before wiping it dry.

- Clear Debris Immediately: Don't let spills, crumbs, or food scraps hang around. Wiping them up right away stops bacteria in its tracks and makes your final cleanup a whole lot faster.

- Clean with the Grain: Here's a pro tip for stainless steel: always wipe in the direction of the grain. This simple trick helps you avoid creating tiny scratches where germs love to hide.

Proper maintenance isn't just about being clean—it's a core part of managing food safety. A well-kept prep area is a huge step toward acing health inspections and keeping your customers safe.

Of course, a clean table doesn't mean much if the rest of the kitchen isn't up to par. Keeping the entire environment free from pests is just as critical. For a complete strategy, it’s worth checking out a definitive guide to pest control for restaurants.

How to Handle Common Issues Before They Start

Even the toughest stainless steel can show some wear and tear over time. The key is to jump on minor issues like a small scratch or a tiny rust spot before they get any worse. This is how you protect your table's integrity and keep it hygienic. For little rust spots, a simple paste of baking soda and water applied with a soft cloth can often work wonders without damaging the steel.

The demand for food prep tables is always shifting based on local health codes and food trends. In North America, for instance, the mature foodservice market is always looking for versatile tables that meet incredibly strict safety standards. You can dive deeper into these market trends on markwideresearch.com.

Whatever you do, stay away from harsh abrasives like steel wool or any cleaners with chlorine. They can strip the protective layer right off your stainless steel, leading to corrosion. By making these simple habits part of your kitchen's DNA, you'll ensure your prep tables remain the safe, reliable workhorses you need them to be.

Your Top Questions About Food Prep Tables Answered

Choosing the right food prep table can feel like a big decision, and it’s natural to have a few questions. Let's clear up some of the most common things people ask, so you can feel confident you're making the right choice for your kitchen.

What’s the Best Stainless Steel Grade for a Prep Table?

For most commercial kitchens, 304-grade stainless steel is your best bet. It's built to resist corrosion, which makes it perfect for busy, wet environments and dealing with acidic ingredients like tomatoes or citrus.

But, if your table is just for dry storage or some light prep work in a low-humidity spot, the more budget-friendly 430-grade will do the job just fine.

Do I Really Need an NSF Certified Prep Table?

Yes, absolutely. For almost any commercial food business, an NSF-certified prep table isn't just a nice-to-have; it's a must. Health inspectors look for that NSF mark because it guarantees the surface is non-porous, smooth, and easy to clean, which is critical for stopping bacteria in its tracks.

Think of it this way: buying an NSF-certified table is a key part of passing your health inspections and showing you're serious about food safety. It's simply non-negotiable in a professional kitchen.

How Do I Choose Between Refrigerated and Standard Tables?

This choice really boils down to how your kitchen works. If you're constantly putting together cold items like salads, sandwiches, or pizzas, a refrigerated prep table is a game-changer. It keeps all your ingredients perfectly chilled and right where you need them, which makes your whole process faster and more efficient.

A standard work table, on the other hand, is the all-around player. It's perfect for general tasks like chopping vegetables, butchering meat, or plating dishes that don’t need to stay cold. It gives you a simple, open surface for all kinds of kitchen jobs.

Ready to find the perfect workstation for your kitchen? Explore a wide selection of durable, NSF-certified food prep tables at PrepTables.com and build the efficient, safe, and organized kitchen you need. Visit us today at https://preptables.com to get started