Your Guide to Commercial Ice Makers Machine Models

Share

Picking the right commercial ice makers machine is less about the machine itself and more about understanding what your business actually needs. Think of it as the unsung hero of your beverage service—get it right, and everything runs like clockwork. The perfect model means you'll always have a steady stream of clean, clear ice, keeping your operations humming and your customers smiling.

How to Choose Your Commercial Ice Makers Machine

Choosing the right commercial ice maker really boils down to three key things: how much ice you'll go through, what kind of cooling system (condenser) fits your kitchen, and the specific type of ice your customers love. Nailing these details from the get-go saves you a ton of headaches down the road and makes sure your investment pays off.

Think of the condenser as the machine's lungs. You have two main options, and each one is built for a different environment.

An air-cooled condenser is the most common choice. It works a lot like a car's radiator, using fans to blow air over coils to cool everything down. It’s a great, efficient pick for most kitchens, as long as you have decent ventilation and the room doesn't get scorching hot.

On the other hand, a water-cooled condenser is like the liquid cooling system in a high-end gaming PC. It uses a steady flow of water to pull heat away, which is perfect for tight, hot, or stuffy spaces where an air-cooled unit would just choke and overheat.

Calculating Your Daily Ice Needs

First things first: you need to figure out how much ice you use on your busiest day. This isn't the time to guess—you need a solid number to make sure you never, ever run out. It's always a good idea to aim a little high to cover those unexpected rushes or a last-minute catering order.

For instance, a bustling café might only need about 1.5 lbs of ice per customer. But a high-volume cocktail bar? You could be looking at closer to 3 lbs per seat. Don't forget to account for all the little things, like filling up a salad bar or packing ice for to-go orders.

A classic rookie mistake is buying a machine based on your average day's use. That's a recipe for disaster when the Friday night dinner rush hits. Always, always plan for your absolute peak demand.

Matching Ice Type to Your Business

Not all ice is created equal. Seriously. The shape and size of the cube can dramatically change how fast it melts, how much space it takes up in a glass, and even how customers feel about their drink.

This table breaks down the most common ice types to help you find the perfect match for your establishment.

Matching Ice Types to Your Business Needs

| Ice Type | Description | Best For | Melt Rate |

|---|---|---|---|

| Full Cube | Large, classic square or rectangular cube. | Spirits, cocktails, bagged ice, general beverage service. | Slow |

| Half Cube | Smaller, easy-to-handle rectangular cubes. | High-volume beverage dispensing, fast food, cafes. | Medium |

| Nugget | Soft, small, chewable pellets of ice. | Fountain drinks, smoothies, iced coffee, healthcare. | Fast |

As you can see, the choice between full cubes for a slow-sipping bourbon and nugget ice for a refreshing soda can make a big difference.

The demand for these machines is soaring, which tells you just how critical they are. The global ice maker market was valued at USD 5.3 billion in 2024 and is expected to hit around USD 7.4 billion by 2033. This boom is almost entirely driven by the foodservice industry, where a reliable ice machine isn't a luxury—it's a necessity. You can explore more about these market dynamics to see where the industry is headed.

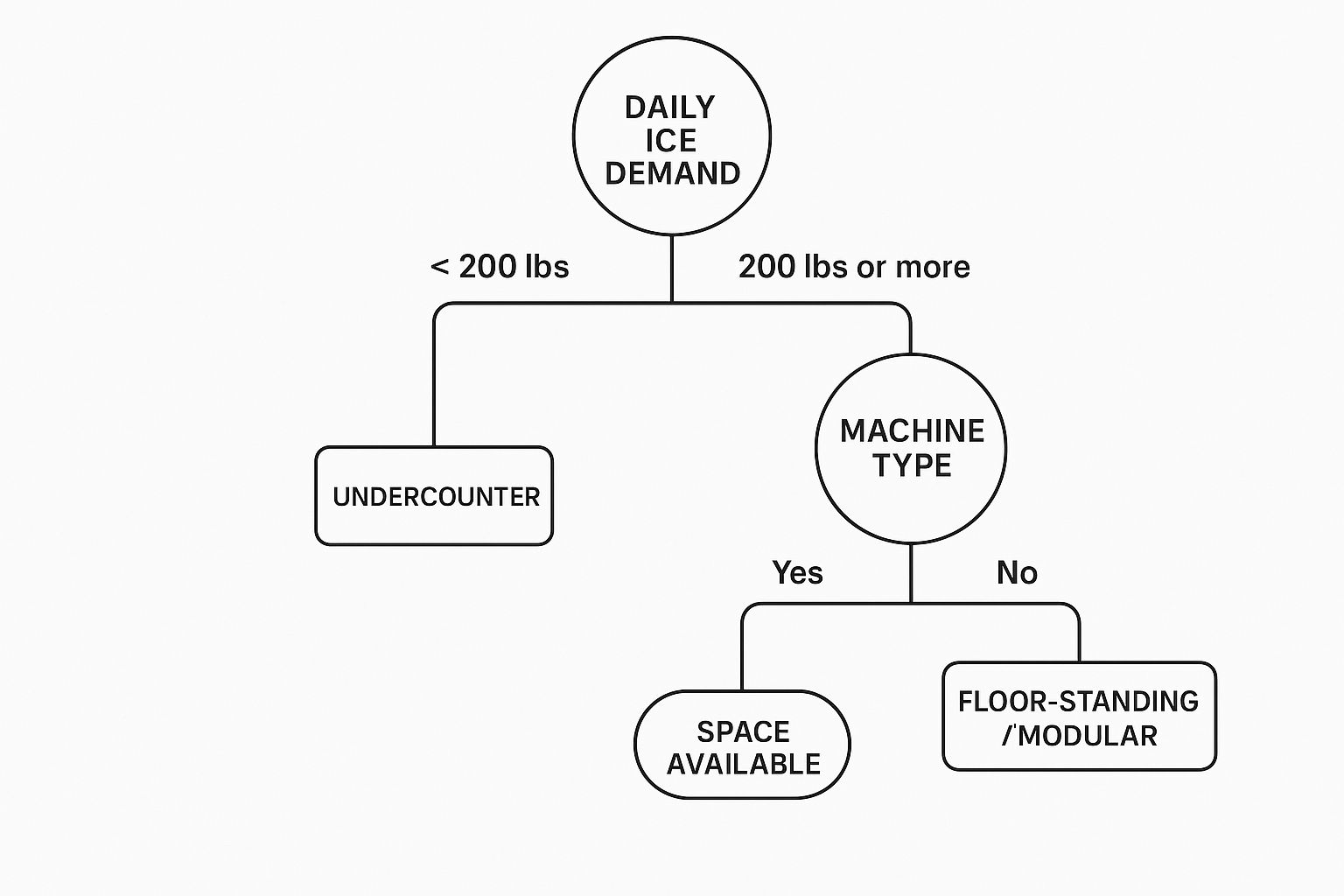

This decision tree gives you a quick visual on how to pick a machine based on your ice needs and kitchen space.

The takeaway here is pretty clear. If your business plows through more than 200 lbs of ice a day, you’re almost certainly in the market for a modular unit. For lighter needs, a more compact undercounter model will probably do the trick.

Finding the Right Commercial Ice Machine Type

Alright, you've figured out how much ice you'll go through and the perfect ice shape for your drinks. Now comes the practical part: picking a machine that actually fits into your kitchen's unique flow. A commercial ice makers machine isn't a one-size-fits-all purchase; the right one should feel like it was built just for your space and how your team works.

You'll generally run into four main designs: modular units, undercounter models, countertop dispensers, and even specialty prep tables. Each is engineered for a different job, from cranking out massive volumes of ice to providing convenient, on-the-spot access. Getting to know the difference is what separates a good investment from a daily headache.

Modular Ice Machines

Think of a modular ice machine as the undisputed heavy-lifter of the ice world. These are high-capacity "ice heads" that sit on top of a separate storage bin or a beverage dispenser. Their whole purpose is production, and they excel at it, capable of churning out hundreds—or even thousands—of pounds of ice every day.

The beauty of this design is its flexibility. You can pair an ice-making head with a storage bin of almost any size. If your business takes off and your ice needs double, you can just swap out the bin for a bigger one without having to buy a whole new machine.

- Best For: Busy restaurants, hotels, hospitals, and any large-scale cafeteria that can't afford to run out of ice.

- Pros: The highest ice production available, fully customizable storage, and it can grow with your business.

- Cons: These units demand a good amount of floor space and come with a higher upfront cost.

Undercounter Ice Machines

When space is tight, an undercounter ice machine becomes your best friend. These are all-in-one units, combining the ice maker and storage bin into a single, compact appliance. They're specifically designed to slide neatly under a standard 40-inch bar or countertop.

They are the go-to solution for bars, cozy cafes, and smaller restaurant kitchens where you have to make every square foot count. While they produce less ice than their modular cousins—usually between 50 to 300 pounds a day—they put fresh ice right where your staff needs it most.

Countertop Ice Dispensers

Countertop ice dispensers are all about letting customers help themselves. You've probably seen these in hotel breakfast bars, office break rooms, or healthcare settings. They make, store, and drop ice directly into a cup with a simple push of a lever or button.

Their biggest advantage is hygiene. By getting rid of the shared ice scoop, you dramatically cut down the risk of germs and cross-contamination. They typically produce soft, chewable nugget or flake ice, which is a big hit for sodas and other beverages.

Stainless Steel Prep Tables for Ultimate Efficiency

For the ultimate in kitchen efficiency, many operations integrate their food prep into specialized stainless steel workstations. While not strictly ice makers, these tables are a vital part of a streamlined workflow.

- Work Tables: These are the essential workhorses, providing a durable, sanitary surface for chopping, mixing, and assembling. Models with an undershelf offer valuable extra storage.

- Sandwich Prep Tables: A game-changer for delis and cafes, these refrigerated units combine a cutting board with chilled wells on top for holding pans of lettuce, tomatoes, and meats, with a refrigerated cabinet below for backups.

- Pizza Prep Tables: Built on the same concept, these tables are adapted for pizza making. They feature a wider, deeper refrigerated rail to hold all the necessary toppings, and the oversized work surface is perfect for stretching dough and assembling pies.

By putting everything a cook needs in one consolidated station, these integrated tables slash preparation time, improve consistency, and are crucial for maintaining food safety by keeping ingredients perfectly chilled.

The foodservice industry's consistent growth continues to fuel demand for every type of commercial ice makers machine. In fact, market projections show a steady expansion for these machines, with an expected compound annual growth rate of about 3.5% between 2023 and 2030. This just goes to show how much businesses rely on having efficient, trustworthy cooling equipment. If you want to see how different machine types can fit into your own business, take a look at our in-depth guide on selecting the right commercial ice machine.

Understanding Key Features and Modern Technology

The commercial ice maker machine of today has come a long way from the simple freezers of the past. Think of them less as appliances and more as smart, efficient workhorses loaded with tech that improves hygiene, slashes costs, and keeps your operation running smoothly. When you understand what these features really do, you see them not as bells and whistles, but as smart investments for your business.

A great example is built-in antimicrobial coatings. Manufacturers now integrate these special surfaces into the parts that touch water and ice, actively slowing the growth of bacteria, mold, and that dreaded slime. This one feature alone makes a huge difference in ice safety and means you'll spend less time and labor on deep cleanings.

Another game-changer is integrated water filtration. Since ice is essentially 99% water, the quality of your H₂O is everything. It directly affects how your ice tastes and looks. Built-in filters are designed to pull out chlorine, sediment, and other gunk that creates cloudy, foul-tasting ice and causes damaging scale to build up inside your machine.

Smart Technology for Smarter Operations

The best modern features are all about making your life easier and your machine more efficient. This technology gives you more control and can even head off expensive repairs before they happen.

- Smart Diagnostics: This is like having an early warning system built right in. Onboard sensors keep an eye on how the machine is running and will alert you to potential problems, like a filter that needs changing or a part that's wearing out. It's a proactive approach that helps you avoid a breakdown in the middle of a dinner rush.

- Programmable Ice Production: Why run the machine full-blast when your doors are locked? Many newer models let you set a production schedule that lines up with your busiest hours. It's a simple tweak that stops wasteful overflow and puts a real dent in your energy and water bills.

- Energy and Water Efficiency: Keep an eye out for models with an ENERGY STAR certification. These machines use advanced compressors and components to make the same amount of ice with a lot less electricity and water, which translates to serious savings on your utilities month after month.

These aren't just minor upgrades; they're driving the entire industry forward. The global market for commercial ice machines, sitting at around $1.4 billion in 2024, is projected to climb to $1.86 billion by 2033. This growth is all about innovations like digital touchscreens and self-contained purification systems that deliver real, long-term operational savings.

The Right Equipment for an Efficient Kitchen

An ice machine is a cornerstone, but it works best as part of a whole kitchen ecosystem designed for speed and safety. This is especially true when you look at your prep stations.

For any kitchen cranking out high volumes of food, specialized prep tables are non-negotiable. They aren't just stainless steel surfaces; they're complete workstations that make the entire prep process flow better.

- Sandwich Prep Tables: A must-have for delis, cafes, and sandwich shops. These combine a countertop with refrigerated rails that hold all your fresh ingredients in pans, keeping everything chilled, organized, and right where you need it.

- Pizza Prep Tables: Built on the same idea but designed for pizzerias. They feature wider, raised refrigerated rails to hold a ton of different toppings, plus a large workspace perfect for stretching dough.

By merging the workspace with refrigeration, these tables make a massive difference in your workflow and are absolutely vital for meeting food safety standards. To get a better sense of the big picture, you can read more about the commercial ice machine ice maker and see how it all fits together.

Proper Installation and Setup for Peak Performance

Think of your commercial ice maker's installation like the foundation of a house. If you cut corners or make a mistake here, you're setting yourself up for years of problems. A bad setup can lead to poor ice production, unexpected breakdowns, and might even void your warranty.

Getting this right is about more than just plugging it in. A commercial ice maker is a serious piece of equipment with very specific needs for water, power, drainage, and even airflow. If you don't meet these requirements, you simply won't get the machine's rated output of clean, clear ice. This guide will give you the confidence to either handle the setup yourself or properly manage a professional technician to protect your investment.

Your Pre-Installation Site Checklist

Before your new ice machine even shows up on a pallet, you need to be sure your facility is actually ready for it. A few minutes spent walking through this checklist now can save you hours of headaches and costly delays on installation day.

Here’s a practical rundown of what to check at your location before the new unit arrives.

Your Pre-Installation Site Checklist

| Checklist Item | Requirement/Specification | Why It's Important |

|---|---|---|

| Clearance & Ventilation | A minimum of 6-12 inches of open space on all sides and the top. | Air-cooled units have to breathe. Without enough airflow, the condenser can't get rid of heat, forcing the machine to work harder, make less ice, and eventually burn out. |

| Water Line Access | A dedicated cold water line with a nearby shut-off valve. | This ensures a consistent water supply. That shut-off valve is absolutely essential for maintenance, filter changes, and emergencies. |

| Water Pressure | Usually 20-80 PSI (always double-check the manufacturer's specs). | Too little pressure and the machine won't fill correctly. Too much pressure can damage sensitive internal parts like the water inlet valve. |

| Electrical Supply | A dedicated circuit matching the machine's voltage and amperage. | This prevents tripped breakers and protects the machine’s electronics from power dips and surges. Never, ever use an extension cord. |

| Drainage System | A floor drain located close to the machine. | Ice makers constantly purge water during and after cycles. The drain line needs a steady, gravity-fed downward slope to stop water from backing up into the machine—a major health code violation. |

| Ambient Temperature | Ideally, the surrounding air should be between 70°F and 90°F. | Extreme heat or cold pushes the machine outside its sweet spot, seriously cutting down on ice production and jacking up your energy bill. |

Making sure these key items are in place is the most important prep work you can do. It ensures a smooth, problem-free installation when the time comes.

The Step-by-Step Installation Process

Once your site is prepped and ready, the actual installation can start. Whether you're hiring a pro or doing it yourself, understanding these steps ensures nothing gets overlooked.

-

Level the Machine: Your first move is to get out a level and make sure the machine is perfectly flat. If the unit is tilted, it can mess with water flow and cause internal sensors to give bad readings, throwing off the entire ice-making cycle.

-

Connect the Water Line: Securely attach the water supply line. This is also the perfect time to install an in-line water filter if your machine doesn’t have one built-in. A good filter will protect your machine from scale and mineral buildup, and it will make your ice taste a whole lot better.

-

Set Up the Drain Line: Connect the drain tube, making sure it runs in a continuous downward slope all the way to the floor drain. Critically, you must leave a one-inch air gap between the end of the tube and the drain itself. This prevents dirty drain water from ever being siphoned back into the machine.

Crucial Tip: Never tie an ice machine's drain line directly into other plumbing. A dedicated, gravity-fed drain is a non-negotiable for proper sanitation and is required by most local health codes.

-

Plug It In and Power Up: With all the connections made, plug the machine into its dedicated outlet. Flip the switch and let it begin its initial startup sequence.

-

Run a Test Cycle: Now, just let the machine run. Allow it to complete at least one full harvest cycle from start to finish. You're looking for any leaks at the water connections, making sure it drains correctly, and inspecting that first batch of ice. This final check confirms everything is good to go before you rely on it for service.

Essential Maintenance to Keep Your Ice Machine Running

Think of your commercial ice makers machine as the workhorse of your kitchen. Just like any high-performance piece of equipment, it needs regular care to keep running smoothly, efficiently, and safely. If you neglect maintenance, you're practically asking for expensive repair bills, cloudy or poor-tasting ice, and potential health code headaches.

A good maintenance plan doesn't have to be overwhelming. It's really just a set of simple, routine tasks. Breaking it down this way protects your investment and, more importantly, ensures every drink you serve contains clean, safe ice.

Your Daily and Weekly Maintenance Checklist

Consistency is the secret to a long-lasting ice machine. A few minutes spent on small tasks each day and week can prevent minor issues from turning into catastrophic failures. These checks should become a standard part of your kitchen's opening and closing procedures.

Your daily routine is quick and easy:

- Wipe Down the Exterior: Grab a soft cloth and a food-safe cleaner to give all the outside surfaces a quick wipe. This keeps the machine looking sharp and free of dust and kitchen grime.

- Check the Ice Scoop: Always make sure the ice scoop is clean and stored in its proper holder. It should never be left inside the ice bin—that's a classic cross-contamination mistake.

The weekly tasks dig a little deeper:

- Clean the Air Filter: For any air-cooled model, this is non-negotiable. Just slide the filter out, give it a good rinse with warm water, let it air dry completely, and put it back. A clogged filter is like trying to breathe with a pillow over your face; it chokes the machine, kills ice production, and puts a huge strain on the compressor.

- Inspect Water Filters: If your machine has an external water filter, take a look at its status. Most have an indicator that signals when it's time for a change.

Neglected maintenance is the single biggest reason for emergency service calls. In fact, some studies show that up to 70% of ice machine failures can be directly traced back to a simple lack of routine cleaning.

The Importance of Deep Cleaning and Sanitizing

While daily wipe-downs are great, your machine needs a proper deep clean every few months. This is where you tackle the invisible gunk—mold, slime, and bacteria—that can build up inside. This process always involves two distinct steps: cleaning to remove mineral buildup, and then sanitizing to kill germs. Most brands recommend specific cleaners and sanitizers made for their units.

- Cleaning Cycle: This step uses a nickel-safe scale remover to dissolve hard water mineral deposits (scale) from all the internal parts. Scale buildup is the silent killer of ice machines, acting like an insulator that forces the machine to work much, much harder.

- Sanitizing Cycle: After you've cleaned out the scale, you run a sanitizing solution through the system. This eliminates any bacteria, mold, or slime that might be lingering. This is absolutely critical for food safety.

You should plan on this deep clean at least every six months. If you're in an area with hard water or your kitchen has a lot of yeast in the air (like a brewery or bakery), you'll need to do it more often. To get a feel for how different models handle these demands, looking through some commercial ice maker reviews can offer great insight into their real-world durability and how easy they are to maintain.

How to Properly Descale Your Ice Machine

Descaling is the most critical part of your deep-cleaning routine. Think of mineral scale—mostly calcium and magnesium from the water supply—as cholesterol for your machine's arteries. It clogs up water lines, coats important sensors, and blankets the evaporator plate, which is what actually freezes the water. When that happens, your ice production will plummet.

Here’s a simple rundown of how descaling usually works:

- Empty the Machine: Start by turning the machine off and getting all the ice out of the storage bin.

- Initiate the Clean Cycle: Most modern machines have a "Clean" or "Descale" button. Push it to get the cycle started.

- Add the Descaling Solution: The machine will let you know when it's ready for the scale remover. Pour the solution into the water trough, following the manufacturer's directions.

- Let the Cycle Run: The machine will take over from here, circulating the solution to dissolve all that mineral gunk. This usually takes between 20 and 45 minutes.

- Rinse Thoroughly: Once the cleaning is done, the machine will flush itself out several times to make sure no cleaning solution is left behind.

Sticking to this schedule will ensure your commercial ice makers machine keeps churning out clean, clear ice for years to come.

Troubleshooting Common Ice Machine Issues

Even the most dependable commercial ice makers machine is going to have an off day. When that happens, your first instinct might be to make a frantic call to a repair technician, but that doesn't have to be your first move.

Many common problems have surprisingly simple fixes you can handle yourself. This saves you precious time, a hefty service fee, and gets your ice production back on track fast. Think of this as your first-response diagnostic tool. By spotting the usual suspects behind common symptoms, you can often solve the problem and keep your operation running smoothly.

My Machine Stopped Making Ice

This is easily the most common—and panic-inducing—problem, but the solution is often incredibly simple. Before you assume the worst, just run through a few basic checks. It’s like troubleshooting a lamp that won’t turn on; you always check if it’s plugged in first.

- Check the Water Supply: Is the water shut-off valve open all the way? Sometimes it gets bumped and partially closed, starving the machine of the water it needs.

- Inspect the Power: Make sure the machine is plugged into a working outlet. It's also worth a quick look at your circuit breaker to see if it's been tripped.

- Clean the Air Filter: On an air-cooled model, a clogged filter is a classic culprit. The machine will overheat and shut itself down to protect the compressor. A quick clean can get it going again.

- Examine the Bin Control: Nearly all machines have a little arm or a sensor that stops making ice when the bin is full. Check that it hasn't gotten stuck in the "up" or "off" position.

If you’ve gone through these steps and there's still no ice, the issue might be something more complex. It could be a faulty water inlet valve or a bad sensor, which is when you'll likely need to call in a professional.

The Ice Is Cloudy or Looks Bad

You're aiming for crystal-clear, solid ice cubes. If your machine starts churning out cloudy, soft, or partially formed ice, the problem almost always comes down to two things: water quality or internal cleanliness.

Poor water quality is the number one reason for cloudy ice and component failure. Minerals and other impurities in the water don't freeze correctly, which leads to ugly, off-tasting cubes and creates damaging scale buildup inside your machine.

First things first, check your water filter. If it's old or clogged, it simply can't do its job. Swapping out the filter cartridge is often the quickest and easiest fix. If a new filter doesn't solve it, that's a huge sign your machine is overdue for a deep cleaning and descaling cycle to remove the mineral deposits that are messing with the freezing process.

My Machine Is Making Strange Noises

Any new or weird noise coming from your commercial ice makers machine is your cue to pay close attention. Rattling, grinding, or loud squealing often signals a mechanical problem.

A simple rattling sound could just be a loose panel that needs to be tightened. Easy fix. But grinding or squealing noises usually point to something more serious, like a failing water pump or a worn-out bearing in the gear motor.

If you hear those more aggressive sounds, your best bet is to turn the machine off immediately to prevent more damage. Don't risk it. This is the time to call a qualified technician, because continuing to run it could turn a small repair into a very expensive replacement.

Frequently Asked Questions

Jumping into the world of commercial ice machines can feel like there's a lot to learn. Whether you're buying your first machine or you've been running one for years, getting straight answers to your questions is the key to making good decisions. Here are a few of the most common things we get asked about owning and running a commercial ice makers machine.

How Often Do I Really Need to Clean My Ice Machine?

This is easily the most important question, and the answer is probably more often than you think. As a rule of thumb, every machine needs a full, deep cleaning and sanitizing cycle at least once every six months to keep it safe and running efficiently.

But that’s just the starting point. If your business is in an area with hard water, or if your kitchen environment has lots of airborne particles like grease or yeast (think bakeries and breweries), you'll want to bump that up to every three months. Sticking to a schedule like this is the best way to prevent scale buildup and stop slime or mold from ever getting a foothold, ensuring your ice is always pure and safe for customers.

Can I Use Any Cleaner or Sanitizer?

Definitely not. This is a common mistake that can cause some serious headaches. Using the wrong chemicals can easily damage the sensitive parts inside your ice machine and might even void the warranty.

Always, always use a nickel-safe scale remover for the cleaning part of the cycle. Most evaporator plates have nickel plating, and harsh, non-approved chemicals can strip it right off. For sanitizing, you need a food-grade sanitizer that’s specifically made for ice machines. Your best bet is to just use the products recommended by the manufacturer—it takes all the guesswork out of it.

A quick word of caution: Reaching for household bleach or other unapproved chemicals is a fast track to expensive repair bills. They corrode metal parts and can leave behind nasty residues that you definitely don't want ending up in your customers' drinks.

What Is an ENERGY STAR Certified Ice Maker?

An ENERGY STAR certified machine is one that’s been officially recognized by the Environmental Protection Agency (EPA) for being much more efficient than standard models. It's a stamp of approval that means you're getting a high-performance, low-cost unit.

On average, these machines are about 15% more energy-efficient and 10% more water-efficient than their conventional counterparts.

Opting for an ENERGY STAR model translates directly to lower monthly utility bills, which really adds up over the life of the machine. While the upfront cost might be a little higher, the long-term savings almost always make it a worthwhile investment for both your wallet and the environment.

At PrepTables.com, we know that a steady supply of clean ice is the lifeblood of your operation. From finding the perfect machine to helping you keep it running like new, we’ve got the equipment and the know-how you need. Explore our full range of commercial kitchen equipment and let’s build a more efficient kitchen together.