Choosing Your Commercial Deep Fryer

Share

Choosing the right commercial deep fryer can feel like a huge task, but it really just boils down to three key decisions. If you want to make a purchase you feel good about, you need to focus on your power source (gas vs. electric), the fryer's design (how it heats the oil), and its size (matching output to your busiest hours). Get these core choices right, and you're setting your kitchen up for success.

Your Guide to Choosing the Right Fryer

Picking the perfect commercial deep fryer isn't just about buying another piece of equipment. It's a real investment in your kitchen's workflow, the quality of your food, and your bottom line. The whole decision rests on truly understanding what your kitchen needs to run smoothly.

Think of it like choosing a vehicle. A food truck needs something compact and nimble, while a high-volume restaurant needs a powerful workhorse built to take a beating day in and day out.

The demand for these machines is definitely growing. The global commercial deep fryer market was valued at around USD 583.92 million and is expected to climb, reaching an estimated USD 798.24 million by 2032. This jump really shows how critical these appliances are for any modern foodservice operation. You can discover more insights about the commercial deep fryer market from recent research.

The Three Pillars of Your Fryer Decision

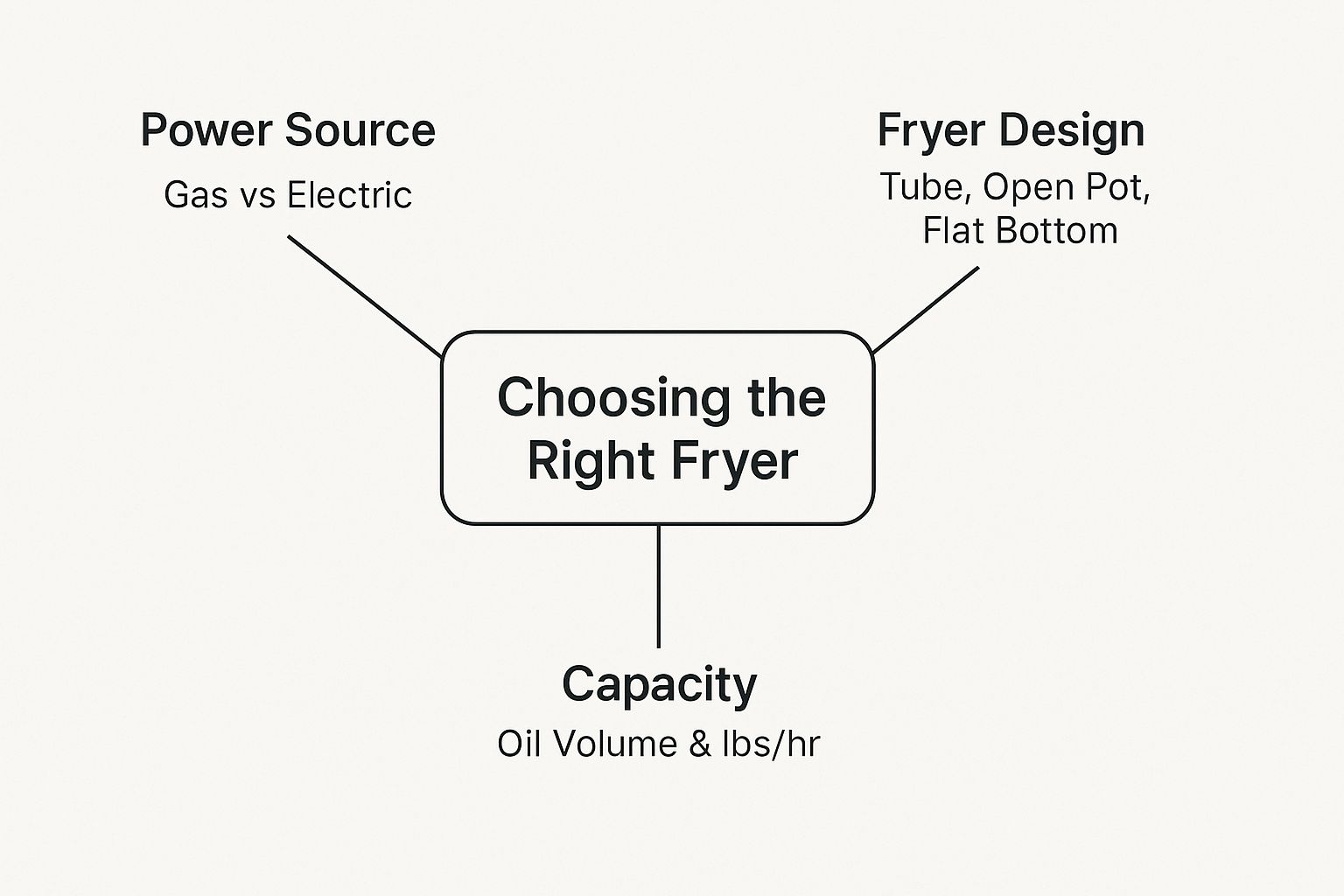

To make this whole process simpler, let's break it down into three foundational elements. Each one directly impacts your daily operations, from your utility bills to how consistently crispy your final product is.

-

Power Source: Are you going with gas or electric? Gas fryers heat up faster and usually hit higher temperatures, which is perfect for rapid recovery during those crazy dinner rushes. Electric models, on the other hand, give you more precise temperature control and are often easier to install, especially if you don't have existing gas lines.

-

Fryer Design: How the fryer heats the oil is a big deal. The main types—tube, open-pot, and flat-bottom—are all engineered for different kinds of food. A tube fryer is a champion with heavily breaded items, while a flat-bottom design is what you want for delicate, free-floating foods like doughnuts.

-

Capacity and Size: This is all about matching the fryer's output (in pounds per hour) to your peak demand. A unit that's too small will create a bottleneck and frustrate your cooks. One that's too big just wastes energy and oil.

This concept map helps visualize how these three core factors all tie together in the decision-making process.

To give you a quick cheat sheet, here's a table breaking down these essential choices.

Key Decision Factors for Commercial Deep Fryers

| Factor | Option 1 | Option 2 | Best For |

|---|---|---|---|

| Power Source | Gas | Electric | Gas: High-volume kitchens needing fast recovery. Electric: Precision cooking, kitchens without gas hookups. |

| Fryer Design | Tube Fryer | Open-Pot Fryer | Tube: Heavily battered items like fried chicken. Open-Pot: Lightly battered foods like fries or onion rings. |

| Capacity | Low Volume | High Volume | Low: Smaller cafes or food trucks. High: Busy restaurants, fast-food chains, and institutions. |

Ultimately, your choice in power, design, and capacity will determine just how efficiently your kitchen can churn out consistently delicious fried foods. Getting it right from the start saves a lot of headaches down the road.

Decoding Fryer Types and Power Sources

Let’s be clear: not all fryers are created equal. Choosing the right one isn't about finding the "best" model on the market, but about finding the perfect match for your specific menu, your kitchen's workflow, and your team.

The first big decision you'll face is the power source. This splits the world of fryers into two fundamental camps: gas and electric.

Gas vs. Electric: The Power Decision

Think of a gas fryer as a sprinter. It uses powerful burners to heat oil with incredible speed, making it a beast when it comes to quick temperature recovery. This is absolutely critical during a punishing dinner rush when you're dropping basket after basket of frozen fries.

An electric fryer, on the other hand, is more like a marathon runner. It heats the oil with immersed elements. While it might take a bit longer to get up to temperature initially, it’s a master at maintaining a precise and consistent heat. This is perfect for more delicate foods that demand accuracy.

Your choice often boils down to your kitchen's existing setup and what you're cooking. Gas models are the undisputed champions for high-volume spots needing raw power and rapid recovery. To get a better sense of how this fuel works, you can explore the different uses of natural gas in commercial settings.

Electric fryers, however, have their own advantages. Because the heating elements are right in the oil, they're often more energy-efficient. That level of precision makes them a fantastic choice for items like tempura or artisan doughnuts where the exact temperature is everything. They can also be cheaper and easier to install if you don't already have a gas line run to the right spot.

Fryer Design: The Shape of Performance

Beyond the power source, the actual design of the fry pot—the "tank"—has a huge impact on what you can cook efficiently. There are three main designs to know: Tube, Open Pot, and Flat Bottom. Each one is engineered for specific kinds of food.

-

Tube Fryers: These are the workhorses for anything with a lot of breading or sediment. Gas-fired tubes run through the oil, creating a "cold zone" at the very bottom of the pot. Crumbs and sediment fall into this cooler area instead of burning and ruining your oil. This makes them ideal for fried chicken, breaded fish, and mozzarella sticks.

-

Open Pot Fryers: Just like the name implies, these fryers have a wide-open, easy-to-access pot with heating elements on the outside. The lack of internal tubes makes them a dream to clean. They are the go-to for low-sediment foods like french fries, onion rings, or cheese curds.

-

Flat Bottom Fryers: This design is shallow and wide with no cold zone, so it's not meant for breaded items. But it absolutely excels at cooking delicate, free-floating foods that need room to spread out and cook evenly. Think funnel cakes, doughnuts, or tempura.

If you're tight on space, a good commercial countertop fryer can give you that crucial frying capacity without eating up valuable floor real estate.

The biggest takeaway here is to match the fryer's design directly to your highest-volume menu items. Using the wrong fryer won't just give you a subpar product; it will torch your cooking oil, driving up your operating costs day after day.

Choosing the right commercial deep fryer means lining up its power and design with the reality of your kitchen. When you understand these fundamental differences, you can pick a machine that will be a profitable workhorse, not a frustrating bottleneck.

Calculating the Right Fryer Size and Capacity

The right-sized commercial deep fryer is the unsung hero of a productive kitchen. Go too small, and you’ve created a frustrating bottleneck during your busiest hours, slowing down orders and tanking service quality. On the other hand, a fryer that’s way too big is a silent drain on your profits, guzzling expensive oil and burning excess energy every single day.

Think of your fryer's oil capacity like a thermal battery. A larger volume of oil stores more heat, creating a powerful buffer against the temperature drop when you dump in a basket of frozen food. That stability is the secret to consistently crispy, golden-brown results instead of soggy, oil-logged disappointments.

Decoding Pounds Per Hour

When you start browsing spec sheets, you'll see a rating like "pounds per hour" (lbs/hr). This number gives you a ballpark idea of how much frozen food the fryer can cook to completion in sixty minutes. But it's a benchmark, not a guarantee.

A common rule of thumb is to take the fryer's oil capacity in pounds and multiply it by 1.5 or 2. This gives you a rough estimate of its hourly output. For example, a 50 lb fryer can typically churn out between 75 and 100 pounds of french fries per hour.

It's crucial to remember this is just an estimate. Heavily breaded items like fried chicken soak up a lot more heat and take longer to cook than fries. This will lower your real-world pounds-per-hour output.

How to Estimate Your Kitchen's Demand

To really dial in the right size, you need to do a little homework on your kitchen’s peak demand. A quick assessment can save you from the headache of over- or under-buying.

-

Identify Your Busiest Hour: Dig into your sales data and find your single busiest hour of the week. This is the crunch time your fryer must be able to handle without breaking a sweat.

-

Calculate Peak Food Volume: Figure out how many pounds of your most popular fried item—let's say french fries—you sell during that peak hour. If you sell 50 orders of fries, and each order is half a pound, you need to cook at least 25 pounds of fries in that hour.

-

Add a Buffer for Growth: Always plan for the future. A good practice is to add a 20-30% buffer to your peak demand number. In our example, a 30% buffer on 25 pounds means you should be looking for a fryer that can handle at least 32.5 pounds per hour.

This simple framework takes you beyond guesswork. It ensures the commercial deep fryer you choose becomes a profitable asset that fits your kitchen's rhythm, not an operational nightmare. When you match capacity to your actual demand, you get a smoother workflow and, most importantly, a better final product for your customers.

Essential Features of a Modern Fryer

Today’s commercial deep fryers are much more than just a hot tank of oil. They’re packed with smart features that deliver a real return on your investment. To build an efficient and profitable kitchen, you need to look past the sticker price and see how these key upgrades will save you serious time, labor, and money down the road.

One of the most valuable innovations you'll find is a built-in oil filtration system. Anyone who's worked in a kitchen knows that manually filtering oil is a messy, time-consuming, and often dangerous job that everyone dreads. An integrated system turns that entire headache into a simple process, often just flipping a switch and opening a valve.

By making filtration ridiculously easy, these systems can literally double the life of your cooking oil. Not only does that slash your oil costs by up to 50%, but it also keeps your food quality consistently high, ensuring every single batch tastes fresh and clean.

Automation and Precision Control

We've moved way beyond the old-school analog dials. Modern fryers now sport sophisticated digital controls that give chefs an incredible amount of command over the cooking process.

-

Programmable Temperature Controls: These let you dial in precise temperatures for different foods and even create pre-set cooking cycles. It’s how you get perfect consistency every time, whether you're frying delicate tempura or crispy chicken wings.

-

Automatic Basket Lifts: This feature is like having an extra set of hands on the line. The lifts automatically drop baskets into the hot oil and pull them out the second the cook cycle is finished. This prevents overcooking and frees up your staff to tackle other tasks.

These smart features are absolutely critical for a smooth-running operation. Things like adjustable thermostats and digital timers are becoming standard for a reason, especially in busy kitchens where speed is everything. You can find more details on how these features enhance food safety and business performance.

Focusing on Long-Term Savings

It’s true that advanced features can bump up the initial cost of a commercial deep fryer, but their long-term value is undeniable. An ENERGY STAR certification is a perfect example of this.

An ENERGY STAR certified fryer is independently verified to be more energy-efficient than standard models. That means it heats up faster and holds its temperature using less gas or electricity, which directly lowers your monthly utility bills.

Choosing a fryer with these modern features isn't just buying a piece of equipment; it's a strategic business decision. When you invest in tools that promote efficiency, consistency, and cost savings, you're setting your kitchen up to perform at its absolute best.

Mastering Fryer Safety and Compliance

A commercial deep fryer is a true workhorse, but let's be honest—it’s also one of the most hazardous pieces of equipment in your kitchen. We're talking about massive vats of flammable oil held at incredibly high temperatures. This isn't something to take lightly. A safety-first culture isn't just a buzzword here; it's a non-negotiable part of running a professional kitchen to protect your staff, your customers, and your entire business.

Proper training and crystal-clear procedures are your first line of defense. Every single person who touches that fryer, whether they're cooking with it or cleaning it, must understand the violent reaction that happens when water meets hot oil. Even a tiny splash can trigger an explosive eruption, causing horrific burns and sparking a dangerous grease fire in seconds.

Understanding Essential Safety Certifications

When you're shopping for a fryer, you'll see a few logos and marks on the equipment. These aren't just for show—they're your guarantee that the machine has been built to specific safety and quality standards. Two of the big ones you need to know are NSF and UL.

-

NSF (National Sanitation Foundation): Seeing this mark means the fryer is designed with food safety in mind. The materials are non-toxic, the surfaces are smooth and easy to scrub down, and there are no hidden cracks or crevices where bacteria can multiply. Health inspectors look for this.

-

UL (Underwriters Laboratories): This certification tells you the fryer's electrical parts have passed rigorous testing to prevent fire and electrical shock. For gas fryers, a similar mark like UL Gas-Fired or ETL-Sanitation provides the same peace of mind, confirming it meets safety standards for gas-burning appliances.

These certifications are essential for passing health inspections and are often a requirement to get business insurance. Don't even consider a fryer without them.

Building a Fire-Safe Environment

Grease fires are a constant and very real threat in any kitchen with a deep fryer. Your main defense is a professionally installed fire suppression system built right into your ventilation hood—this is mandatory in most places. To keep things safe, it's also critical that you follow all local commercial kitchen ventilation requirements.

Your team needs to be drilled on exactly what to do if a fire breaks out. The absolute number one rule is to NEVER use water on a grease fire. It will only make it explode. Staff must be trained to use a Class K fire extinguisher, which is made specifically for fires involving cooking oils and fats.

Knowing how to react is one thing; knowing how to properly use the equipment is another. Make sure everyone on your team knows how to operate a fire extinguisher so they can act quickly and effectively in an emergency.

Fryer Cleaning and Maintenance for Peak Performance

Treating your fryer right isn't just about keeping the health inspector happy—it’s a core part of running a profitable kitchen. A clean, well-maintained fryer simply works better. It lasts longer, cooks more consistent food, and gets the most life out of every drop of expensive cooking oil.

If you’re not following a strict cleaning schedule, you're literally burning money. The key is breaking down the work into manageable daily, weekly, and monthly jobs. This keeps your fryer in prime shape without ever feeling like a massive chore for your team.

Your Essential Maintenance Checklist

Think of your maintenance plan like building a pyramid. The foundation is made up of quick, consistent daily habits. Those are supported by more involved weekly scrubs and a full monthly deep clean.

Daily Tasks (5-10 Minutes):

- Wipe Down Exterior: At the end of every shift, give all the outside surfaces a good wipe-down with a clean, damp cloth and a food-safe degreaser. This stops that sticky film from ever building up.

- Clean Baskets: Scrub the fryer baskets well. You want to get rid of any caked-on bits of food and batter.

- Filter the Oil: This one is non-negotiable. Filtering your oil every single day gets rid of all the loose food particles that would otherwise just sit there, burn, and ruin the flavor of everything you cook.

Weekly Tasks (30-45 Minutes):

- Deep Clean Fry Pot: Once a week, drain the filtered oil and give the inside of the fry pot a thorough scrub. Use a long-handled brush and a proper fryer cleaner, paying special attention to the heating elements or tubes where carbon loves to build up.

This weekly scrub is your best defense against that stubborn, cooked-on gunk. It makes the big monthly "boil-out" way easier and helps prevent flavor transfer—so your fries don't taste like your fish.

The Monthly "Boil-Out" Deep Clean

About once a month, it's time for a full reset. A "boil-out" is exactly what it sounds like: you boil a solution of water and a heavy-duty cleaning compound inside the fry pot. This powerful chemical reaction dissolves the really tough, carbonized grease that simple scrubbing can't touch.

This process is what brings your fryer's heating efficiency back to life and gives you a perfectly clean cooking environment. It's a bit more work, but it’s absolutely essential for making your fryer last and keeping your food quality high. For a bigger picture, our guide on commercial kitchen equipment maintenance has more tips for keeping all your gear running smoothly.

By sticking to a simple, structured routine like this, you'll turn your fryer from just another appliance into one of your most reliable, money-making tools.

Commercial Fryer FAQs

When it comes to commercial fryers, a few questions pop up time and time again. Getting clear, practical answers is the first step to choosing the right machine and keeping your kitchen running without a hitch. Here are the answers to some of the most common questions we get from restaurant owners.

How Often Should I Filter My Fryer Oil?

For most restaurants, filtering your oil at least once a day is the standard, usually after the dinner rush is over. But if you're running a high-volume spot, especially one frying up a ton of heavily breaded items like fried chicken or fish, you’ll probably need to filter it twice a day. This simple step is key to maintaining food quality and getting the most life out of your cooking oil.

What Is the Difference Between a Standard and Tube Fryer?

A standard fryer, also known as an open-pot fryer, has its heating elements on the outside of the fry pot. This design makes it incredibly easy to get in and clean, which is perfect for operations frying up lightly breaded foods like french fries.

On the other hand, a tube-type fryer has gas-fired tubes that run directly through the oil. This creates a "cold zone" at the very bottom of the pot where sediment and crumbs can settle without getting scorched. This feature makes it the go-to choice for heavily breaded foods that shed a lot of coating.

Think of it this way: the cold zone in a tube fryer acts like a safety net for crumbs, preventing them from burning and tainting the oil. This is a game-changer for keeping your oil quality high when you're cooking items that shed a lot of breading.

Can I Use a Countertop Fryer in a High-Volume Restaurant?

Countertop fryers are really built for low-volume jobs. They’re fantastic for whipping up appetizers in a small café, handling a single, low-demand item on a big menu, or for a food truck where every inch of space counts.

They just don't have the capacity or the fast recovery time needed to keep up with a busy restaurant's main frying demands. Trying to rely on one during a dinner rush would create a serious bottleneck in your service line.

At PrepTables.com, we provide the durable, high-performance cooking equipment that professional kitchens rely on. Explore our selection of commercial deep fryers and find the perfect model to boost your kitchen's efficiency and food quality today. Visit us at https://preptables.com.