Your Guide to Commercial Countertop Fryers

Share

Picking the right commercial countertop fryer isn't just about buying a piece of equipment; it's about finding the perfect partner for your kitchen's workflow. These specialized fryers are engineered to give you that perfect golden-crisp finish, just like a full-sized unit, but without eating up all your precious floor space. For a food truck, cafe, or concession stand, these compact powerhouses are often the heart of the operation.

Your Guide to Choosing the Right Fryer

Let's be clear: there's no single "best" fryer for everyone. The right choice for you hinges entirely on your menu, how busy you get, and the layout of your kitchen. These aren't just scaled-down fryers; they're mighty, efficient tools that can act as your main cooking station or step in as a crucial backup during those chaotic rush hours.

This guide is here to walk you through it all, breaking down the key factors you need to consider. We'll cover everything from power sources to figuring out the right capacity for your output, cutting through the jargon so you can make a smart, confident investment. By the time we're done, you'll know exactly what to look for.

Matching Equipment to Your Workflow

A great fryer deserves a great workspace. The cornerstone of any smooth-running kitchen is a tough, cleanable surface, which is exactly why stainless steel prep tables are so indispensable. They come in various types, each designed for a specific job:

- Standard Work Tables: These are the versatile workhorses of the kitchen. A simple flat-top table gives you a durable, all-purpose surface for chopping, mixing, and general prep.

- Tables with Backsplashes: These models feature a raised edge along the back, which is a lifesaver for preventing splashes and ingredients from falling behind the table, keeping your walls clean and your workspace tidy.

- Tables with Undershelves: For extra storage, many tables come with a lower shelf, perfect for keeping frequently used pots, pans, and containers organized and within easy reach.

- Sandwich Prep Tables: A dream for delis and cafes, these specialized units combine a cutting board work surface with refrigerated wells on top. This keeps all your meats, cheeses, and toppings chilled and right at your fingertips for fast assembly.

- Pizza Prep Tables: Built for pizzerias, these tables often feature a wider, refrigerated rail to hold a variety of toppings and a durable marble or stainless steel surface that stays cool, which is ideal for working with dough.

Choosing the right table ensures your new countertop fryer fits into an efficient, logical workflow. While a countertop unit is a fantastic space-saver, a bigger kitchen might really need the raw output of a full-size model. If you're weighing your options, our guide on the best commercial deep fryer can give you some more perspective.

The constant demand for quick-service food is what's really pushing kitchen equipment to get better and smarter. The market for commercial countertop fryers is currently sitting at around USD 1.2 billion, and it's expected to grow as more businesses jump on this trend.

This boom is really being driven by the global love affair with fried foods like chicken wings and french fries. In fact, industry experts predict the market will hit USD 1.8 billion by 2033, which shows a steady growth of about 5.2% each year. This trend just highlights how important it is to pick equipment that can keep up with what your customers want.

Gas vs. Electric: Which Fryer Is for You?

One of the first big decisions you’ll make when picking out a commercial countertop fryer is the power source: gas or electric? It’s a bit like choosing the engine for a race car. One gives you raw, responsive power, while the other offers pure precision and efficiency. This choice will have a huge impact on how your kitchen runs every single day.

Each type has its own strengths and is a better fit for certain kitchen environments. The right call hinges on your kitchen's current setup, the demands of your menu, and how much food you're pushing out. Let's dig into what each one brings to the table.

The Case for Electric Countertop Fryers

Electric fryers are all about simplicity and precision. If your kitchen doesn't have a gas line, they are the no-brainer choice, giving you a "plug-and-play" solution that gets you frying in no time. Their portability is also a massive win for catering gigs or kitchens that need to be reconfigured on the fly.

But the real standout feature is their incredible temperature accuracy. The heating elements are submerged right in the oil, which keeps the temperature incredibly stable. This means more consistent results, which is absolutely critical for delicate foods that demand precise heat.

- Energy Efficiency: Electric fryers are typically more energy-efficient. Since the heating elements are in direct contact with the oil, very little heat escapes into the kitchen. Over time, that can translate to lower utility bills.

- Simple Installation: Most smaller electric fryers can plug right into a standard wall outlet. Larger, more powerful models might need a higher voltage hookup, but the setup is still straightforward, making them perfect for food trucks and small cafes.

- Safety and Maintenance: With no open flame, electric fryers are often considered a safer bet, cutting down on fire risks. They also tend to be easier to clean since you don't have to work around gas lines or burners.

The Power of Gas Countertop Fryers

When it comes to high-volume kitchens, gas fryers are the undisputed workhorses. Running on either natural gas or propane, these units are known for one thing above all else: pure power and speed. If your kitchen is constantly banging out orders of fries, wings, or other fried favorites, the performance of a gas fryer is tough to beat.

Their biggest advantage is heat recovery time. When you drop a basket of frozen food into hot oil, the temperature nosedives. A gas fryer’s powerful burners can get that oil back up to the perfect cooking temperature much, much faster than most electric models. This rapid recovery is the key to maintaining food quality and keeping up with orders during a crazy dinner rush.

A faster recovery time isn't just about speed; it's about quality. When oil temperature recovers quickly, food absorbs less grease, resulting in a crispier, more appealing final product that keeps customers coming back.

Understanding the Key Differences

To make the best call, it helps to see how they stack up side-by-side. While both will fry your food, their performance characteristics are built for very different needs.

| Feature | Electric Fryer | Gas Fryer |

|---|---|---|

| Heat-Up Time | Slower initial heat-up | Faster initial heat-up |

| Recovery Time | Generally slower | Extremely fast |

| Temperature Control | Highly precise and stable | Good, but can have wider fluctuations |

| Installation | Simple plug-in for most models | Requires professional gas line connection |

| Portability | High; easy to move | Low; fixed to gas line |

| Best For | Lower-volume kitchens, delicate foods, mobile setups | High-volume kitchens, frozen foods, fast-paced service |

Ultimately, the right choice comes down to your unique situation. An electric commercial countertop fryer gives you precision and convenience, making it ideal for controlled cooking and flexible layouts. On the other hand, a gas model delivers the raw power and rapid recovery you need to keep up with relentless demand, ensuring you never get buried during a rush.

Evaluating the Features That Matter Most

Once you've decided between gas and electric, it's time to dig into the details. The specific features of a commercial countertop fryer are what really separate a good one from a great one. Think of this as your buyer's checklist—the stuff that makes a real difference in your daily kitchen grind.

These aren't just bells and whistles. The right features directly impact your food quality, keep your staff safe, and protect your bottom line. Let's break down the most important things to look for, from oil capacity and controls to build quality and how easy it is to clean.

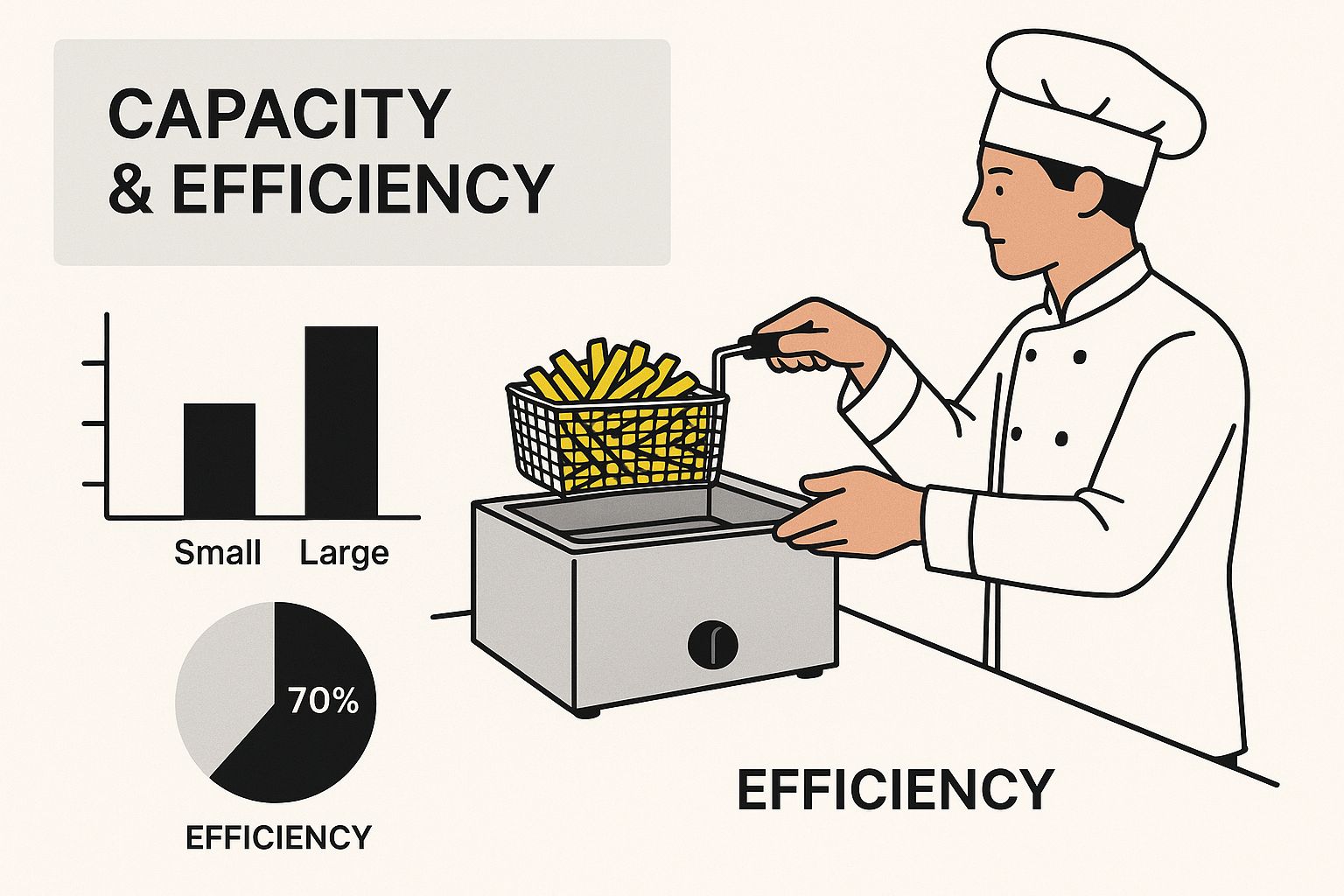

As you can see, matching your fryer's oil capacity to your menu's demands is crucial. It's how you get that consistent, high-quality output without wasting a drop of oil or a watt of energy.

Oil Capacity and Fry Pot Design

The first thing to check is the oil capacity, which is almost always measured in pounds. This isn't just about how much oil the fryer holds; it’s about how much food you can cook at once without the temperature plummeting. A 15-pound fryer might be perfect for a small café that only does a side of fries, but a busy wing spot will probably need a 30-pound model just to keep up with orders.

Next, you'll need to look at the fry pot itself. Your main choice is between a single-pot and a dual-pot setup.

- Single-Pot Fryers: This is the standard design with one large basin for frying. They're great for kitchens that are dedicated to one type of fried food, like a place that specializes in chicken tenders.

- Dual-Pot Fryers: These units give you two smaller, independent fry pots side-by-side in one machine. The huge advantage here is preventing flavor transfer—you can fry fish in one pot and fries in the other without your fries tasting fishy.

This choice really comes down to your menu. A dual-pot model gives you a ton of versatility, which can be a game-changer if you have a diverse fried food lineup.

Construction and Safety Features

The build quality of a fryer tells you a lot about how long it will last. You want to see units built from heavy-duty stainless steel. It’s not just tough enough to handle the chaos of a commercial kitchen; it's also non-porous and easy to sanitize, which is non-negotiable for food safety.

Speaking of safety, these features are an absolute must. They're what protect your staff and your business from disaster.

An automatic high-limit shutoff is one of the most vital safety mechanisms on any commercial fryer. This feature automatically cuts power to the heating elements if the oil temperature exceeds safe limits, preventing dangerous and costly grease fires.

Other key safety features include cool-touch exteriors and front-mounted controls. Cool-touch handles and surfaces cut down on the risk of accidental burns during a hectic service. Having the controls right on the front means your staff can make quick adjustments without having to reach over a vat of hot oil.

This push for better, safer equipment is driving the whole industry forward. The commercial fryer market, which includes these advanced countertop units, was valued at around USD 561.63 million and is expected to hit USD 780.07 million by 2030. This growth is all about the demand for safer, more efficient machines that meet modern food safety rules. You can dive deeper into these trends in this detailed industry analysis.

Controls and Cleaning Efficiency

Finally, think about the day-to-day use and maintenance. Precise thermostatic controls are essential for consistency. They let you dial in the exact temperature your food needs, batch after batch. Digital controls usually give you a bit more accuracy than the old-school manual dials.

Cleaning is nobody's favorite job, but it’s arguably the most important part of owning a fryer. Any feature that makes this chore easier is worth its weight in gold. Look for models with removable fry pots or a built-in drain valve. Both make emptying out old oil much safer and less of a mess.

Some higher-end fryers even come with built-in filtration systems. These are incredible because they extend the life of your cooking oil, which can save you a surprising amount of money over time.

Installation and Power Supply Essentials

So you've picked out your new commercial countertop fryer. Great! But that’s only half the battle. Now comes the part that really matters: making sure your kitchen can actually handle it. Think of it like this—you wouldn't build a house on a shaky foundation, right? Getting the installation prep right saves you from headaches, costly fixes, and dangerous situations later on.

First, you need to speak the language of electricity. Every fryer’s spec sheet will throw terms like voltage, wattage, and amperage at you. This isn't just tech-speak; it's the DNA of your machine. Ignoring these details is like putting regular gas in a race car. It’s not going to end well.

Decoding Electrical Requirements

Let's start with voltage. Most of the smaller gear in a U.S. kitchen plugs into a standard 120V outlet, just like you have at home. But the more powerful electric fryers need a bigger kick—usually a 208V or 240V connection. This is non-negotiable. You absolutely have to match the fryer’s voltage to the outlet you have available.

Next up is wattage, which is basically a measure of how much power the fryer sucks up. More watts usually mean quicker heat-up times and better performance when you're busy. This is directly linked to amperage (amps), the flow of the electrical current. You have to be certain the circuit you’re using can handle the amps your fryer will draw. If it can't, you'll be tripping breakers all day. For a heavy-duty piece of equipment like a fryer, a dedicated circuit is almost always the right move.

Imagine your kitchen’s circuit is a water pipe. Amperage is the water pressure. If you try to force too much pressure (a high-amp fryer) through a small pipe (a low-amp circuit), something is going to burst. In your kitchen, that’s a tripped breaker or, far worse, a fire.

Gas Connections and Ventilation Rules

Going with a gas model? Your focus shifts from wires to pipes. Gas fryers run on either natural gas (NG) from a utility line or liquid propane (LP) from a tank. Your fryer has to be set up for the right fuel type, and this is definitely not a DIY job. You need a licensed plumber or gas fitter to make sure the connections are tight and leak-free.

Even more critical than the gas hookup is your ventilation. Any appliance burning gas is spitting out heat, greasy smoke, and dangerous fumes like carbon monoxide. To operate legally and safely, your commercial countertop fryer must live under a proper commercial ventilation hood. This system is designed to pull all that nasty stuff out of your kitchen, keeping your staff safe and preventing fires. Skimping on this can get you shut down or hit with massive fines. If you need to brush up, take a look at these commercial kitchen ventilation requirements to make sure your setup is up to code.

Your Pre-Installation Checklist

Before that fryer even shows up on a delivery truck, do yourself a huge favor and run through this quick checklist. It will make the conversation with your electrician or plumber go much smoother and ensure installation day is a breeze.

- Confirm Power Source: Does the spot you picked have the right outlet with the correct voltage and enough amps?

- Measure Your Space: Will the fryer actually fit on the counter? Make sure there's enough room around it for air to circulate and keep it from overheating.

- Check Gas Lines: For a gas fryer, is there a gas shutoff valve nearby that’s easy to get to in an emergency?

- Verify Ventilation: Is the spot directly under your commercial hood? Is that hood working and up to code?

Ticking these boxes ahead of time means your new fryer will start making you money from day one, instead of becoming your next big problem.

A Practical Guide to Cleaning and Maintenance

A well-maintained commercial countertop fryer isn't just another piece of equipment; it's the heart of your fried food program and a real profit engine. To protect that investment, you have to think beyond the day you unbox it. Consistent cleaning and proactive maintenance are what keep your food safe, make your cooking oil last longer, and ensure every single order comes out perfectly crispy and delicious.

Ignoring these crucial steps is like never changing the oil in your car—sooner or later, you're looking at a serious breakdown. A dirty fryer is a fire hazard, plain and simple. It also wrecks the quality of your oil, which means your food will taste off, leading to unhappy customers and a damaged reputation, one greasy bite at a time.

The Daily Cleaning Ritual

Consistency is everything. A quick, thorough cleaning at the end of every shift is the secret to preventing grease and food bits from turning into a carbonized nightmare. This daily habit is the single best thing you can do to keep your fryer running like new.

Think of it as hitting the reset button on your workstation for the next day's service. It's a non-negotiable process that lets you start fresh with clean oil and a sanitized unit, ready for whatever the lunch rush has in store.

Here’s a straightforward daily plan:

- Power Down and Cool Down: First things first, turn the fryer off completely. Let the oil cool to a safe temperature for handling, usually around 150°F (65°C). Never, ever try to drain scorching hot oil.

- Drain and Filter the Oil: Carefully drain the oil into a food-safe container. It's best to run it through a filter cone or use a built-in filtration system to catch the crumbs and sediment that make oil break down faster.

- Scrape and Wipe the Fry Pot: Grab a non-abrasive scraper and get any stuck-on gunk off the fry pot walls and heating elements. Then, wipe out the leftover residue with paper towels.

- Wash and Sanitize: Clean the fry pot using warm water and a good fryer cleaning solution. Rinse it out thoroughly to get rid of all the soap, then sanitize any surface that touches food.

- Clean the Exterior: Give the fryer’s stainless steel exterior a good wipe-down with a clean, damp cloth and a mild detergent to get rid of any grease splatter from the day.

Periodic Deep Cleaning and Boil-Outs

Even if you're a rockstar with daily cleaning, stubborn, baked-on grease will eventually build up. This is where a periodic deep clean, known in the industry as a boil-out, comes in. A boil-out is like a spa day for your fryer; it uses a powerful cleaning compound and boiling water to dissolve the carbonized gunk that regular scrubbing just can't handle.

Doing a boil-out once or twice a month, depending on how heavily you use your fryer, really revitalizes it. This dramatically improves the life of your oil and stops old, burnt flavors from tainting your fresh food.

A regular boil-out is one of the best ways to protect your oil investment. Clean oil heats more efficiently and lasts significantly longer, directly cutting down on your operational costs and improving food quality.

The growth of the foodservice industry is pushing manufacturers to build equipment that's more durable and efficient. The global market for commercial countertop ranges, which includes fryers, is valued at USD 12.2 billion and is projected to hit USD 16.8 billion by 2035. This trend shows just how much demand there is for machines that are not only powerful but also easier to maintain. You can learn more about these market dynamics and equipment innovations in this commercial ranges market report.

Essential Maintenance Checks

Beyond cleaning, a few simple mechanical checks will help you catch small problems before they turn into expensive repairs. Think of this as a quick health checkup for your machine—a proactive step that ensures it's reliable and safe.

Regular inspections are a core part of any smart kitchen strategy. For a more complete overview, check out our guide on commercial kitchen equipment maintenance for tips that apply to all your valuable gear.

Keep an eye on these key components:

- Power Cords and Plugs: For electric models, give the cord a regular look-over for any signs of fraying, cracking, or damage. Make sure the plug fits snugly in the outlet.

- Gas Lines and Connectors: On gas fryers, visually check the gas hose for any cracks or kinks. If you ever smell gas, shut off the supply immediately and call a professional.

- Thermostat Calibration: If you notice your food is consistently overcooked or undercooked, your thermostat might be off. Every so often, check its calibration with a reliable thermometer and adjust it if needed.

Common Questions About Countertop Fryers

Jumping into a new piece of equipment always comes with a few questions. When it comes to something as vital as a commercial fryer, you want to be sure you're getting it right from day one. This section tackles the most common things we hear from kitchen pros about choosing, using, and caring for their countertop fryers.

Think of this as your go-to guide for all those little details. We'll get into the nitty-gritty of safety, oil life, and performance to help you sidestep common problems before they even start. Getting these answers now will save you a ton of time and headaches later.

How Much Space Do I Need Around My Fryer?

This is one of the first and most important questions to answer. A fryer can't just be squeezed onto a counter; it needs some breathing room to work safely and effectively. For most models, you'll need to leave a minimum of 6 inches of clear space on the sides and back of the unit.

That gap isn't just for looks—it’s a critical safety feature. Proper airflow keeps the fryer from getting too hot, which protects its internal parts and dramatically reduces the risk of a fire. It also creates a safer work area for your staff around the hot surfaces.

Always double-check the manufacturer's manual for their specific clearance rules before you set anything up. Ignoring these guidelines could void your warranty and, more importantly, create a serious hazard in your kitchen.

How Often Should I Change the Cooking Oil?

There isn't a one-size-fits-all answer here. How often you need to change your fryer oil really hinges on what you’re cooking and how busy you are. A kitchen pumping out tons of breaded chicken will probably need fresh oil daily, while a smaller spot just doing fries might get 3-4 days out of a batch.

Instead of just guessing, learn to read the signs of tired oil. If your food starts tasting greasy, looking too dark, or just tastes "off," it’s time for a change. Other red flags include oil that smokes before it hits the right temperature or gets extra foamy when you drop food in.

To get the most out of every drop of oil, stick to these habits:

- Filter It Daily: This is the single best thing you can do. Filtering the oil after every shift gets rid of all the little burnt food bits that cause it to break down.

- Skim Often: Keep a skimmer handy during service to pull out any debris floating on top.

- Keep It Covered: When the fryer's not in use, put a cover on it. This keeps oxygen and light from degrading the oil.

Making these steps part of your routine won't just save you money on oil; it ensures every plate of fried food you serve is top-notch.

What Safety Precautions Are Most Important?

Safety around a commercial countertop fryer is absolutely non-negotiable. You're dealing with extremely hot oil and a major potential fire risk, so training your team is essential for keeping everyone safe.

The number one rule is to never let water or ice get into hot oil. Even a tiny bit of water will cause a violent explosion of scorching grease. Make sure food and baskets are as dry as possible before they hit the oil.

Here are a few other critical safety points:

- Have a Class K fire extinguisher nearby and make sure everyone knows how to use it. These are made specifically for grease fires.

- The fryer must be on a solid, level surface where it can’t get bumped or knocked over.

- Train your crew to never fill the fry pot past the max line. Oil can easily bubble over and ignite.

Can I Fry Different Foods in the Same Oil?

You can, but you probably shouldn't. The biggest problem you'll run into is flavor transfer. Powerful flavors from things like fish or spicy coatings will seep into the oil and make everything else you cook taste like them. Nobody wants their donuts to have a hint of last night's fish and chips.

If your menu has a lot of different flavors, investing in a dual-pot fryer is a smart move. You can keep one pot for neutral items like fries and the other for stronger-flavored foods like seafood.

Don't have a dual-pot fryer? You can work around it by frying things in a specific order. Start your day with bland items (like fries) and save the heavily seasoned or strong-flavored foods for the end of the shift. This helps, but you'll still want to filter that oil thoroughly or change it before the next service.

At PrepTables.com, we know that great kitchens are built on the right equipment. Take a look at our complete selection of commercial countertop fryers and other professional cooking gear to find exactly what your business needs. Head over to https://preptables.com to start building a more productive and profitable kitchen.