Finding the Best Deep Fryer Brands for Your Kitchen

Share

When you're in the market for the best deep fryer brands, a few names always come to the front of the line: Frymaster, Pitco, Henny Penny, and Vulcan. Each one has carved out a niche in the commercial kitchen world. Some are built for the blistering pace of a fast-food chain, while others are designed for kitchens that need precise, specialized frying. The trick is matching the brand's strengths to what your kitchen actually needs to do, day in and day out.

Choosing Your Commercial Deep Fryer Brand

Think of a high-performance deep fryer as the engine of your kitchen. Picking the right one isn't just a purchase; it's a strategic investment that shows up in your food quality, your kitchen's efficiency, and your bottom line. This guide is here to get past the flashy brochures and compare the industry's most trusted names on the things that actually matter.

The commercial deep fryer market is a massive piece of the global foodservice industry. In 2024, it was expected to hit a value of roughly $583 million, with over 52,000 units sold across the globe. That alone tells you how vital these machines are in professional kitchens everywhere. If you want to dive deeper into those numbers, you can review the growth analysis on MordorIntelligence.com.

Navigating Your Options

Getting a handle on each brand's core strengths is the first step. Some are engineered for non-stop, high-volume punishment. Others focus on energy savings or high-tech features like automatic oil filtration. Our goal here is to give kitchen managers and owners the real-world information they need to pick the perfect fit. For a solid primer, take a look at our guide covering the key components of a commercial deep fryer.

To get started, here’s a quick-glance comparison to help you see which brands might line up with your kitchen's demands.

A deep fryer isn’t just another piece of equipment; it's central to your menu's success. The right brand won't just cook food well—it will fit into your kitchen's workflow like it was always meant to be there, saving you time, money, and headaches.

Top Commercial Deep Fryer Brands at a Glance

This table gives you a bird's-eye view of the top players. It highlights what each brand is known for and where they shine, making it easier to narrow down your options from the get-go.

| Brand | Known For | Ideal Use Case |

|---|---|---|

| Frymaster | Advanced technology, oil filtration systems, and precise temperature controls. | High-volume restaurants, fast-food chains, and operations prioritizing consistency and long-term oil savings. |

| Pitco | Unmatched durability, simple design, and reliable performance under pressure. | Demanding kitchens, food trucks, and businesses that need a workhorse fryer with minimal downtime. |

| Henny Penny | Specialized pressure frying technology and open frying systems built for quality. | Businesses specializing in fried chicken and other poultry, where moist results and crispy skin are essential. |

| Vulcan | Innovative heat transfer systems, energy efficiency, and reliable construction. | Institutional kitchens, restaurants, and any operation focused on reducing utility costs without sacrificing performance. |

Each of these brands brings something valuable to the table. The key is knowing which of those strengths will make the biggest difference in your specific kitchen environment.

Key Criteria for Evaluating Commercial Fryers

Before we start comparing brands, let's talk about what actually separates a kitchen workhorse from a constant headache. Picking the right fryer isn't about the longest feature list; it's about matching the machine's real-world performance to what your kitchen actually needs.

When you know what to look for, you can accurately judge any fryer, no matter the brand, on how it’ll hold up during a chaotic dinner rush. This framework helps you look past the price tag and focus on what truly matters for your food quality, workflow, and bottom line.

Power and Heat Recovery

If there's one make-or-break metric for a commercial fryer, it’s heat recovery time. This is how fast the oil gets back to temperature after you drop in a basket of frozen food. A slow recovery time is a recipe for greasy food, inconsistent quality, and bogged-down ticket times. It’s a classic kitchen bottleneck.

Two numbers tell you almost everything you need to know about recovery speed:

- BTU (British Thermal Unit) for gas fryers. This is a raw measure of heat output. More BTUs almost always mean faster recovery, which is critical if you’re frying high volumes of frozen fries or wings.

- Wattage for electric fryers. Just like BTUs, higher wattage means more power to heat the oil. Electric models are often champs at holding a precise temperature once they get there.

During peak hours, every second counts. A fryer that struggles to get back to temp will ruin your rhythm and your product.

A fryer's ability to rapidly bounce back to 350°F after dropping in five pounds of frozen product is a direct indicator of its value. This capability prevents oil from soaking into the food, ensuring a crispy, golden-brown finish every time.

Build Quality and Durability

A fryer’s lifespan is written in its steel. The commercial kitchen is a brutal environment, and the most important factor here is the stainless steel gauge. Remember, a lower number means thicker, tougher steel. A fry tank made from 14-gauge stainless steel will fight off warping and corrosion much better than a flimsy 18-gauge one.

Look for a fully welded tank, ideally from type 304 stainless steel. This construction minimizes leak risks and just makes the unit easier to clean and maintain for years to come. This same logic of balancing cost and long-term performance applies to other kitchen investments, too. For instance, you can compare costs and durability for kitchen cabinet materials using a similar mindset.

Certifications and Safety Features

In a professional kitchen, safety and compliance aren't optional. The first thing you should look for is the NSF certification. This seal from the National Sanitation Foundation tells you the fryer is designed for easy and effective cleaning, which is a must-have to pass health inspections.

Beyond that, look for practical safety features that protect your crew and your business. These aren't just nice-to-haves; they're essential.

- High-Limit Temperature Shutoff: This is your fire prevention. It's a non-negotiable feature that automatically kills the power if the oil gets dangerously hot.

- Cool-Touch Handles: Simple but crucial. Insulated handles on baskets and doors prevent nasty burns when the kitchen is moving fast.

- Automatic Shutoff: Many newer fryers will power down if they sit idle for too long, adding another smart layer of safety.

By keeping these core criteria in mind, you can cut through the marketing noise and choose a fryer that truly works for your business.

A Deep Dive on Leading Commercial Fryer Brands

When you're in the market for a new commercial fryer, you're not just buying a piece of equipment. You're buying into a specific philosophy on how to get food crispy and delicious. The big names in the game aren't just selling steel boxes; they're offering a solution tailored to a certain kind of kitchen. The real trick is figuring out which brand's approach lines up with how you run your operation.

The commercial fryer market is a big one, valued at around USD 549.8 million in 2023 and still growing. Powerhouse companies like Henny Penny and Welbilt (who own Frymaster) are leading the charge, constantly innovating and shaping what these machines can do. If you want to get into the weeds on market trends, the Grand View Research industry analysis is a great place to start.

For now, let's break down four of the most respected brands you'll see on any kitchen line: Frymaster, Pitco, Henny Penny, and Vulcan. We’ll look at what they do best, where they fit, and how they can impact your bottom line.

Frymaster: The Technology and Efficiency Leader

If you run a high-volume kitchen where every second and every drop of oil counts, Frymaster is probably already on your radar. This is the brand for operators who obsess over precision, consistency, and long-term costs. Think large chains and quick-service restaurants where the burger in Boston has to taste exactly like the one in Boise.

Frymaster's claim to fame is its advanced tech, especially when it comes to oil management. Their units feature sophisticated computer controls and built-in filtration systems that work together to make your cooking oil last longer. And since oil is a massive operational expense, this is a huge deal. A well-managed Frymaster can cut your oil consumption by as much as 40%.

That tech, however, comes at a price. The upfront cost is higher, and maintenance can be more involved. For a massive chain, the ROI is a no-brainer. For a smaller, independent spot, it might be overkill.

The Frymaster pitch is simple: spend more now to save a ton on oil and labor later. They build machines for kitchens that measure profit in fractions of a cent per serving.

Pitco: The Indestructible Workhorse

On the other end of the spectrum is Pitco. While Frymaster leans into tech, Pitco doubles down on pure, brute-force durability. These fryers are absolute tanks, built to take a beating in the busiest kitchens and just keep going.

Pitco's philosophy is all about simplicity and reliability. Their designs, like the famous Solstice burner technology, deliver incredible heat transfer and recovery without a bunch of complicated electronics. The result? A fryer that heats up fast, keeps its temperature during a rush, and almost never breaks down. It's the kind of machine your staff can operate easily and your local tech can fix without a specialized degree.

You won't find the fancy automated filtration or detailed programming of a Frymaster. But if you’re running a food truck, a 24-hour diner, or any kitchen where downtime is the ultimate enemy, Pitco’s reliability is the most valuable feature you can ask for.

- Primary Strength: Unmatched durability and straightforward, reliable operation.

- Ideal User: Kitchens that prioritize uptime and simplicity over advanced features.

- Key Differentiator: Built to last with minimal maintenance complexity.

Henny Penny: The Pressure Frying Specialist

Henny Penny owns a very specific—and very important—corner of the market: fried chicken. They are the undisputed kings of pressure frying. This method cooks food faster and at lower temperatures, locking in moisture and creating that incredibly juicy product that open fryers just can't touch.

If your menu is built around poultry, a Henny Penny is practically a requirement. Their equipment is engineered specifically to handle the pressures (literally) of this cooking style safely and consistently. Even their open fryers are top-tier, often packed with smart features like built-in filtration that are designed for high-volume, high-quality production.

This level of specialization doesn't come cheap. A Henny Penny is a serious investment. But if your restaurant's reputation lives and dies by the quality of your fried chicken, it’s an investment that pays for itself over and over again.

Choosing Henny Penny is a decision driven by your menu. If bone-in fried chicken is your star player, their pressure fryers give you a competitive edge that customers can taste.

Vulcan: The Energy-Efficient Innovator

Vulcan has smartly positioned itself by focusing on energy efficiency. In a world of rising utility costs, they build powerful fryers that are engineered to use less gas or electricity. This makes them a go-to for places like hospitals, schools, and other institutional kitchens where budgets are tight and operational costs are scrutinized.

Vulcan's engineers have developed unique heat transfer systems that get more energy into the oil and less up the exhaust hood. This efficiency doesn't mean you sacrifice performance; Vulcan fryers are known for their quick recovery times and reliable cooking power.

They sit in a very competitive middle ground. They might not have the cutting-edge tech of a Frymaster or the specialized niche of a Henny Penny, but they offer an incredible balance of performance, reliability, and cost-consciousness. For the operator who needs a dependable workhorse that also helps manage the monthly utility bill, Vulcan is one of the best deep fryer brands out there.

Matching the Right Fryer to Your Menu

The best deep fryer is the one that fits seamlessly into your kitchen’s daily grind. It’s not about finding the brand with the longest feature list, but about picking the machine that directly supports your menu, volume, and workflow. To make a smart investment, you have to translate brand strengths into practical, real-world situations.

We need to move beyond spec sheets and look at how these fryers perform on the line. The right choice for a slammed quick-service restaurant is completely different from the ideal unit for a compact food truck. Understanding these distinct operational needs is what clarifies which brand is the right partner for your business.

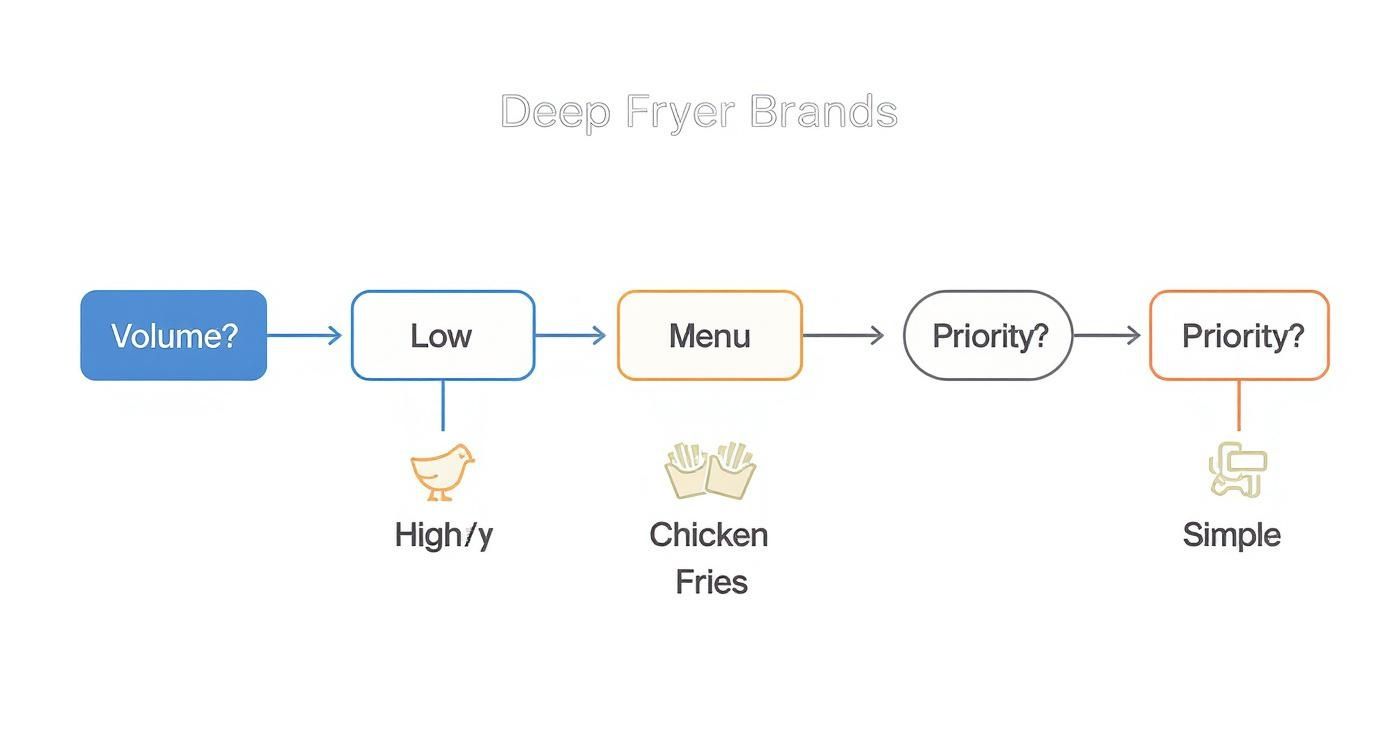

This decision flowchart walks you through the key questions—volume, menu focus, and operational priorities—to help you narrow down the options.

As the chart shows, your menu's demands and daily output are the biggest factors pointing toward a specific brand's strengths.

High-Volume Quick-Service Restaurants

For a high-volume QSR where speed and consistency are everything, a battery of Frymaster fryers is the industry standard for a reason. Picture a lunch rush where hundreds of orders of fries have to be perfectly crispy. Frymaster's rapid heat recovery and advanced computer controls ensure every single batch hits the same quality standard, getting rid of greasy, undercooked product that slows down your line.

Their built-in filtration systems are also a huge deal for managing operational costs. By automating the oil cleaning process, they can extend the life of your cooking oil by 40-50%. That translates into thousands of dollars in annual savings. For an operation this large, the higher initial investment is quickly paid back by the massive savings in oil and labor.

The Compact Food truck or Concession Stand

Now, let's think about a food truck. You've got limited space and an even more limited electrical supply. Durability and a small footprint are your top priorities. This is where a tough, no-nonsense Pitco gas fryer really shines. These units are built like tanks and designed to handle the bumps and demands of a mobile kitchen.

Their simple, reliable mechanics mean fewer things can go wrong—a critical point when you don’t have a maintenance team on standby. A Pitco fryer delivers consistent heat without complex electronics, making it a dependable workhorse that gets the most out of a tiny space. For operations where every square inch matters, you might also find that a powerful commercial countertop fryer gives you the perfect mix of performance and efficiency.

The decision for a small operator is simple: maximize reliability and output within a tight footprint. A fryer that is easy to operate and fix is way more valuable than one with bells and whistles you’ll never use.

Specialized Menus and Institutional Kitchens

Your menu itself can point you to the perfect fryer. If your signature item is bone-in fried chicken, a Henny Penny pressure fryer isn't just a choice—it's a necessity. This specialized equipment cooks faster and at lower temperatures, locking in moisture for a juicy product that open fryers just can't match.

On the other hand, an institutional kitchen in a hospital or university has to balance performance with strict budgets and energy constraints. In this case, a Vulcan energy-efficient model is the ideal solution. These fryers are engineered with innovative heat-transfer systems that cut down on gas consumption without sacrificing the power needed to keep up with cafeteria service, directly lowering your utility bills.

Decision Matrix for Selecting Your Commercial Fryer

To simplify this even further, we've created a decision matrix. This tool helps you quickly line up your kitchen's specific needs with the best brand and fryer type for the job.

| Kitchen Type | Key Priority | Recommended Brand/Type | Consideration |

|---|---|---|---|

| High-Volume QSR | Speed, Consistency, Oil Savings | Frymaster (Battery with Filtration) | Higher initial investment but lower long-term oil and labor costs. |

| Food Truck/Concession | Durability, Compact Footprint | Pitco (Gas) or Countertop Fryer | Simple mechanics for reliability on the go. Focus on BTU output in a small space. |

| Full-Service Restaurant | Versatility, Performance | Vulcan or Frymaster | A solid all-around choice that balances power with efficiency for varied menus. |

| Specialty Menu (e.g., Chicken) | Unique Cooking Method | Henny Penny (Pressure Fryer) | Essential for specific products; not a general-purpose fryer. |

| Institutional Kitchen | Energy Efficiency, Budget | Vulcan (Energy-Efficient Models) | Designed to lower utility costs without sacrificing output for large-scale service. |

Choosing the right fryer comes down to an honest assessment of your operation. By matching the equipment's strengths to your daily demands, you ensure your investment pays off in performance, reliability, and profitability.

Maximizing Your Fryer's Performance and Lifespan

Choosing one of the best deep fryer brands is a big investment, but the real work starts once it's on your line. Proactive, consistent maintenance is the single biggest factor in getting peak performance, great food, and a long, reliable service life from your machine. If you skip these steps, you're setting yourself up for equipment failure, bad-tasting food, and costs you don't need.

Protecting your investment is all about setting up clear, non-negotiable cleaning rules. These daily and weekly jobs stop the buildup of carbonized gunk and old food bits that don't just ruin your oil but can damage the fryer itself over time. A well-kept fryer is simply safer, more efficient, and more profitable.

Essential Daily and Weekly Protocols

Consistency is everything when it comes to effective fryer maintenance. Simple daily tasks keep small issues from turning into major headaches, while a weekly deep-clean resets the equipment for top-tier operation.

Daily Maintenance Checklist:

- Wipe Down Exterior: At the end of every shift, give all outside surfaces a thorough wipe-down with a food-safe cleaner. This gets rid of grease and splatter before it builds up.

- Clean Baskets: Scrub your fry baskets to get rid of any stuck-on food. Let them dry completely overnight.

- Skim Debris: Throughout the day, use a skimmer to pull floating food particles out of the oil. This one small step slows down oil degradation in a huge way.

Weekly Deep-Cleaning Routine:

- Perform a Boil-Out: A weekly "boil-out" is absolutely critical. You’ll drain the old oil, fill the tank with water and a special cleaning solution, and bring it to a boil. This process strips away stubborn, caked-on grease.

- Inspect Components: Take a close look at the heating elements or gas burners for any signs of wear or carbon buildup.

- Clean Filtration System: If your fryer has a built-in filtration system, clean the filter pan and swap out the filter paper or powder based on the manufacturer’s instructions.

A boil-out is more than just a cleaning task; it’s preventative maintenance. By getting rid of that hardened carbon in the fry pot, you ensure heat transfers efficiently. That means better recovery times and lower energy bills.

The Critical Role of Oil Management

Your cooking oil is a major operational expense. Managing its quality is key to your budget and your food's flavor. The goal is to extend your oil's life without ever compromising on quality. Regular filtration is the best way to do this, as it pulls out the tiny food particles that make oil break down faster.

For a more comprehensive look at upkeep for all your kitchen gear, check out this guide on commercial kitchen equipment maintenance. Proper care routines across the board lead to a more reliable and efficient kitchen.

Troubleshooting and OEM Parts

Even the best-built equipment runs into problems. Your staff should be trained to spot common issues, like slow heat recovery (often a dirty heating element) or temperatures that won't stay consistent. Remember, it's not just about the fryer; keeping your whole kitchen clean is vital for equipment longevity. This guide to cleaning commercial kitchens offers some great broader insights.

When you do need a repair, always insist on using Original Equipment Manufacturer (OEM) parts. Generic parts might seem cheaper at first, but they can void your warranty, fit poorly, and cause even bigger problems later. Using OEM parts ensures your fryer keeps running exactly as it was designed to, protecting your investment for years to come.

Frequently Asked Questions About Commercial Fryers

You've got the specs on the fryers, but what about the station itself? We get a lot of questions from kitchen managers and restaurant owners who are trying to make that final decision. Sometimes, the right choice becomes much clearer when you consider the whole picture.

This guide has zeroed in on the fryer, but the equipment you put around it is just as important for a smooth, fast workflow. A solid stainless steel prep table, for example, is non-negotiable. You need a durable, hygienic spot for breading, seasoning, and staging food before it hits the oil. Picking the right table is a huge part of designing a fry station that actually works.

Understanding Stainless Steel Prep Tables

In a commercial kitchen, stainless steel is king. It's tough and stands up to the heat and constant cleaning. But not all prep tables are built the same. They come in a few different setups, and the one you choose will have a real impact on how your fry station runs.

Here are the most common types you'll see:

- Standard Work Tables: These are the all-purpose workhorses of any kitchen. You can get them with a simple flat top or with an undershelf for extra storage. They give you a clean, open space for all kinds of prep work.

- Tables with Backsplashes: If your table is going against a wall, you absolutely need a backsplash. It keeps food and grease from splashing all over the wall, which makes cleanup way easier and helps maintain sanitation.

- Open Base Tables: These tables don't have an undershelf. That gives you open space underneath to store big mobile bins for things like flour or potatoes, or to tuck other equipment out of the way.

The right prep table isn't just a surface; it's an organizational tool. Choosing a table that complements your fryer setup can dramatically reduce wasted movement and keep your workflow organized during the busiest shifts.

Exploring Specialized Prep Tables

Beyond the basic models, you can get specialized prep tables designed for specific menu items. These often combine prep space with refrigerated storage, and putting one next to your fryer battery can create a super-efficient, self-contained workstation.

For instance, a sandwich prep table has refrigerated wells on top to hold cold ingredients like lettuce, tomatoes, and sauces, right next to a built-in cutting board. Underneath, you've got a refrigerated cabinet for more storage. This setup is perfect if you're serving things like fried chicken sandwiches or fish tacos. Your crew can fry the protein and assemble the final product in one seamless motion.

Likewise, a pizza prep table is built with a long, refrigerated rail for holding tons of different toppings, plus a big work surface. While it's made for pizza, its design is surprisingly useful for any operation where you need a wide variety of cold, prepped ingredients right at your fingertips. It can be a great addition to more complex fry stations.

Deciding between these really comes down to your menu. If your fried foods are part of complex, assembled dishes, a refrigerated prep table can be a game-changer for your speed and food safety. But if you're focused on simpler items like fries or wings, a standard stainless steel work table gives you the durable space you need for staging and finishing. The key is to match the table to the task.

At PrepTables.com, we know a great kitchen is built on reliable, high-quality gear. From the most durable work surfaces to specialized refrigerated units, we have the tools you need to build an efficient and hygienic workspace. Check out our complete selection of commercial-grade equipment to put together the perfect fry station for your operation. Visit us at https://preptables.com to see more.