Top Appliances for Food Truck Success | Essential Equipment Guide

Share

Choosing the right appliances for a food truck is probably the single biggest decision you’ll make for your new business. I’m not just talking about what you’ll cook on; this choice is the blueprint for your entire operation. It dictates your menu, your daily workflow, your profits, and even your reputation on the street.

This guide isn't a shopping list. It's a way of thinking—a framework for building a smart, powerful, and efficient kitchen on wheels.

Building Your Mobile Kitchen for Success

Outfitting a food truck is a unique kind of puzzle. You don't have the luxury of a sprawling restaurant kitchen with endless space and power outlets. A mobile kitchen runs on tight constraints.

Every single appliance has to fight for its spot. It needs to be compact, energy-efficient, and tough enough to handle the constant bumps and rattles of being on the road. This is exactly why commercial-grade, multi-functional gear isn’t a "nice-to-have"—it's a must.

The food truck scene is exploding. The market is projected to grow from USD 5.22 billion to an estimated USD 8.78 billion. That boom means more competition, and the trucks that succeed are the ones with specialized equipment that cranks out restaurant-quality food from a tiny space.

To give you a clearer picture, we've put together a quick summary of the essential appliance categories.

Core Food Truck Appliance Categories at a Glance

| Appliance Category | Primary Function | Top Consideration |

|---|---|---|

| Cooking Equipment | Brings your menu to life (grills, fryers, ovens). | Must directly match your specific menu items. |

| Refrigeration | Keeps ingredients fresh and safe (fridges, freezers). | Must hold temperature reliably, even on hot days and in motion. |

| Prep Stations | Creates an organized and efficient workspace. | Needs to maximize workflow in a very limited footprint. |

These categories form the backbone of your mobile kitchen. Let's dig a bit deeper into how they fit together.

The Core Appliance Categories

Your success really boils down to how well these three core appliance groups work together. Think of them as a single, interconnected system, not just a random collection of equipment.

- Cooking Equipment: This is the heart and soul of your truck, and your menu is its boss. A burger concept lives and dies by its griddle. A donut truck is useless without top-notch fryers. The equipment must serve the food, not the other way around.

- Refrigeration: Your coolers are the life support for your inventory. They have to hold safe temperatures without fail, through bumpy rides and hectic service rushes. Solid refrigeration protects your investment, ensures food safety, and cuts down on costly waste.

- Prep Stations: Speed and efficiency start right here. A well-designed prep area—whether it's a simple stainless steel table or a refrigerated sandwich unit—is the foundation for organization, hygiene, and getting orders out fast.

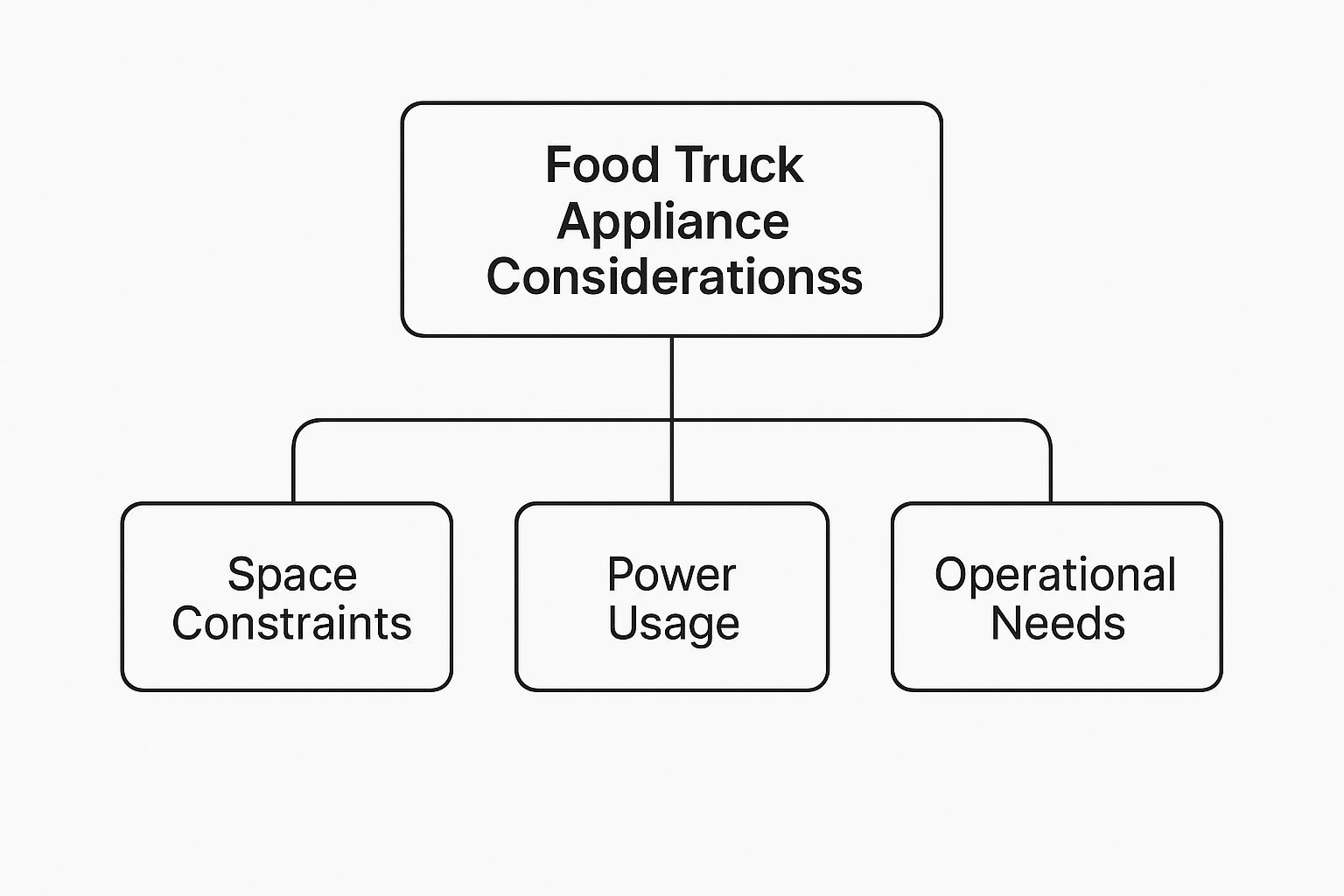

The image below shows the balancing act you'll have to perform when picking out your gear.

As you can see, every choice gets filtered through the realities of your available space, your power supply, and what your menu actually demands.

Your food truck's layout is a game of inches, not feet. The best appliances are those that perform multiple functions or are designed specifically for compact environments, allowing you to maximize output without sacrificing quality or safety.

Start thinking about your kitchen as one integrated system. Each piece should complement the others to create a smooth, logical flow from raw ingredients to a happy customer. For a closer look at outfitting your mobile kitchen, check out our comprehensive guide to essential food truck kitchen equipment. Getting this balance right is what separates the thriving food trucks from the ones that can't quite keep up.

Selecting Your Core Cooking Equipment

Your menu is your food truck's identity. And the cooking equipment you choose is what brings that identity to life. This isn't just about grabbing the biggest or fanciest gear; it’s about strategically investing in the right appliances for a food truck that will pump out your signature dishes—efficiently, consistently, and safely. Your cooking line is the heart of your mobile kitchen, and every piece of it has to directly support what you sell.

Think of it like picking the right engine for a race car. A dragster needs an explosive burst of power, but an endurance car needs something that’s efficient and reliable for the long haul. It's the same in your truck. A burger concept lives and dies by its large, flat-top griddle for smashing patties. But that same griddle would be useless for a taco truck that needs the distinct, fiery sear you can only get from a charbroiler.

Griddles and Charbroilers: The Searing Specialists

For a lot of new food truckers, the first big decision comes down to the griddle versus the charbroiler. A commercial griddle gives you a solid, flat cooking surface, which makes it incredibly versatile. It’s the undisputed champ for menus built around breakfast items like pancakes, grilled cheeses, and of course, the classic smash burger. You get even heat across the whole surface, which means consistent results every time.

A charbroiler, on the other hand, works with open grates over a direct flame. This is how you get that smoky, charred flavor and those perfect grill marks that are absolutely essential for menus with steak, carne asada, chicken skewers, or grilled veggies. It’s definitely less versatile than a griddle, but the unique flavor it creates is something you just can't fake.

Fryers and Ranges: The Kitchen Workhorses

If your menu has anything crispy and golden on it, a commercial deep fryer is a must-have. It’s a major profit-driver for everything from french fries and onion rings to donuts and fried chicken. When you’re picking one out, look closely at the oil capacity and, more importantly, the recovery time. That’s how fast the oil gets back to the right temperature after you drop in cold food. A fast recovery time is what keeps you from falling behind during a massive rush.

A commercial range with burners gives you the flexibility to sauté, simmer, and boil. It’s vital for any truck serving soups, sauces, pasta, or more complex dishes that require a few different pots and pans going at once. Not every truck needs a full range, but for those that do, it becomes the central hub of the whole operation.

Your menu is the ultimate blueprint for your cooking line. Don't invest in a six-burner range if you only sell grilled sandwiches. Match the appliance to the task to maximize both your limited space and your budget.

Gas vs. Electric: Powering Your Production

The choice between propane (gas) and electric appliances is a fundamental one you have to make.

-

Gas (Propane) Equipment: This is what you’ll see most often for the heavy hitters—griddles, charbroilers, and fryers. Propane gives you powerful, instant heat and really precise temperature control, plus it doesn't bog down your generator. The trade-off is that you need professionally installed gas lines, proper ventilation, and you have to be diligent about safety checks.

-

Electric Equipment: You'll typically find electric power in smaller countertop units, warmers, or specialty appliances. They’re usually easier to install and some health inspectors see them as being a bit safer. The big downside is the massive electrical load they put on your generator. A food truck can easily need 5,000-7,000 watts just for its main cooking gear, and you’ll want another 30-50% of capacity on top of that just to handle the power surge when they start up.

Ventilation: A Non-Negotiable Safety System

It doesn't matter what cooking equipment you pick; a commercial-grade ventilation system is absolutely mandatory. A proper hood and exhaust fan system is designed to pull heat, smoke, and grease-filled vapor right out of your truck. This isn't just about keeping things comfortable. It’s a critical fire safety requirement. Grease buildup in a kitchen without good ventilation is a huge fire hazard waiting to happen.

Health and fire codes are incredibly strict about this. You have to install a system that’s correctly sized for your cooking line and meets all your local regulations. This is one area where cutting corners can get your business shut down before you even sell your first taco.

Choosing Reliable Refrigeration and Cold Storage

Let's be honest, your refrigeration system is the unsung hero of your food truck. It’s the life support for your entire inventory. Think about it—this is the one piece of equipment working 24/7 to guarantee food safety, keep your ingredients fresh, and prevent thousands of dollars of product from ending up in the trash. Picking the right cold storage isn't just about keeping things chilly; it's about protecting your investment and your reputation.

When you're outfitting your truck, you absolutely cannot cut corners on refrigeration. A residential fridge might look tempting on paper because of the price tag, but it’s just not built for this life. Those units can't handle the constant vibrations from being on the road or the intense heat blasting out of a commercial kitchen. Commercial-grade units, however, are built tough. They have powerful compressors that bounce back fast after the door swings open a dozen times during a rush, making sure everything stays safely at or below 40°F.

Under-Counter Refrigerators and Freezers

In a food truck, space is gold. Under-counter refrigerators and freezers are your best friends when it comes to making the most of every last inch. These compact workhorses slide right under your prep counters, putting ingredients exactly where you need them. This kind of setup is what creates a smooth, efficient workflow, cutting down on the frantic running around between prepping and cooking.

An under-counter fridge is perfect for the stuff you grab all the time—sauces, prepped veggies, cheese. Then, a matching under-counter freezer can hold your backup proteins, fries, or other specialty items you don't need to access every five minutes. Just be sure to measure twice and buy once, paying close attention to the unit’s dimensions and which way the door swings so it doesn't block a walkway.

Refrigerated Prep Tables

If your menu is all about sandwiches, salads, tacos, or pizzas, a refrigerated prep table isn't just a nice-to-have; it's a total game-changer. These are brilliant hybrid units that give you a durable stainless steel work surface on top, with built-in refrigerated wells and under-counter cold storage below. Everything you need is chilled and right at your fingertips, which will dramatically slash your assembly and service times.

You'll generally run into two main types:

- Sandwich/Salad Prep Tables: These have shallow refrigerated wells designed to hold standard food pans. You can load them up with lettuce, tomatoes, meats, and other toppings. They almost always come with a cutting board running the full length of the unit, creating the perfect assembly line.

- Pizza Prep Tables: These are similar, but they feature a deeper, raised rail to hold bigger pans for all your pizza toppings. The workspace is usually deeper, too, giving you plenty of room to stretch out and build pies in one spot.

The right prep table can completely transform how fast you get food out the window. If you're looking to get into the nitty-gritty, you can learn more about the benefits of commercial refrigerated prep tables and figure out the perfect fit for your menu.

Calculating Your Cold Storage Needs

Trying to figure out how much refrigeration you need can feel like a shot in the dark, but it’s a calculation you have to get right. Too little space, and you're stuck making constant restocking trips or, worse, running out of key ingredients during a dinner rush. Too much space, and you've just sacrificed valuable prep or cooking real estate for a big, empty box.

Start with your menu. List every single refrigerated and frozen ingredient you'll need for a busy service. Estimate the volume for each item, and then tack on a buffer of about 20-30%. This cushion will cover you for those unexpectedly huge crowds or special events and give you a solid baseline for the total cubic footage you need.

Food trucks are a different beast; they demand specialized kitchen gear built to maximize tight spaces while meeting strict food safety rules. As gourmet food trucks continue to explode in popularity, manufacturers have really focused on energy efficiency and multi-functionality. This is especially true for refrigeration, where units have to hold safe temperatures on limited power—a non-negotiable requirement under health codes. You can find more insights on this trend in the food truck market report on grandviewresearch.com.

Designing Your Ideal Food Prep Stations

The secret to a killer food truck isn't just the food—it's the workflow. And that all starts with your prep station. Think of it as your command center, the spot where speed, cleanliness, and organization have to come together seamlessly. The foundation for any real mobile kitchen is the humble but essential stainless steel prep table, a key piece of the puzzle when outfitting the necessary appliances for a food truck.

There's a good reason stainless steel is the industry standard. It’s non-porous, meaning bacteria has nowhere to hide, which makes cleanup a breeze and keeps health inspectors happy. It's also tough as nails, ready to handle the constant bumps and rattles of a kitchen on the move without getting beat up.

Standard Stainless Steel Work Tables

The most basic and flexible option you have is the standard stainless steel work table. It’s your blank canvas, giving you a solid, sanitary surface for all the chopping, mixing, and plating you can throw at it.

Most of these tables come with options to help you squeeze every last inch of utility out of your space. The most valuable feature is easily the undershelf. This simple addition literally doubles your storage without taking up more precious floor space, making it perfect for stashing mixing bowls, bulk ingredients, or smaller appliances.

To really get the most out of your setup, think vertically. Add wall-mounted shelves right above your prep tables. This keeps your go-to spices, tools, and containers within arm's reach, clearing your main work surface for the real action. When you're picking a table, pay attention to the steel gauge. A lower number like 16-gauge means thicker, tougher steel that’s built for heavy-duty work.

Specialized Prep Tables: Sandwich and Pizza Stations

If your menu is all about speed and customization—sandwiches, salads, bowls, or pizzas—a plain flat table just won’t do. You need a specialized workstation. These genius pieces of equipment combine a work surface, refrigerated storage, and ingredient wells into one compact unit, creating a powerful assembly line.

-

Sandwich Prep Tables: Born for deli-style menus, these tables feature refrigerated wells on top designed to hold food pans of toppings, proteins, and veggies. A cutting board runs the full length of the unit, providing a dedicated assembly space. Underneath, a standard under-counter fridge keeps backup ingredients chilled and close by. This all-in-one design lets one person build an entire order from scratch in a single spot, massively boosting speed and consistency.

-

Pizza Prep Tables: Just like a sandwich joint needs its station, a pizza truck needs a purpose-built setup. A pizza prep table is engineered to make the entire pizza-making process smooth. It’s similar to a sandwich table but with key differences: a deep, raised rail holds bigger, deeper pans for sauce and cheese, and the main work surface is often deeper and made of a cold material like marble to prevent dough from sticking. The refrigerated base underneath provides easy access to dough boxes and other bulk items.

A dedicated prep table isn't a luxury; it's a workflow multiplier. By putting every necessary ingredient at an employee's fingertips, you can slash order assembly times by half, which is crucial during a lunch rush when every second counts.

Choosing between a standard work table and a specialized refrigerated unit comes down to your menu. A simple, versatile work table is great for general prep, but if your core product involves assembling multiple fresh ingredients, a sandwich or pizza prep table will be the best investment you make in your truck's efficiency. Matching your prep table to your menu is what turns a simple surface into a high-performance machine.

Whether you need a versatile stainless steel work table or a specialized refrigerated unit, PrepTables.com has the professional-grade equipment to build the backbone of your food truck kitchen. Explore our extensive selection to find the perfect prep station that boosts your efficiency and workflow. https://preptables.com