Top 67 Inch Pizza Prep Table | Perfect for Your Pizzeria

Share

When you're running a high-volume pizzeria, the 67-inch pizza prep table is the heart of your operation. It’s not just a counter; it's a dedicated station that brilliantly combines a large workspace with refrigerated storage. This setup is designed from the ground up for pure efficiency, letting your crew build pizzas fast and keep them consistent. It’s a strategic piece of equipment that speeds up orders and keeps your food safety on point.

Why a 67 Inch Pizza Prep Table Is Your Kitchen’s MVP

Picture the Friday night rush. Tickets are flying, and your team is in overdrive. The secret to handling that chaos without breaking a sweat is a smooth, organized workflow. That's exactly where a 67-inch pizza prep table shows its true value, turning a potentially frantic process into a well-oiled machine. Think of it as the command center for your entire pizza line.

This particular size really hits the sweet spot for most pizzerias. You get plenty of room to stretch dough, slather on sauce, and load up toppings without eating up your entire kitchen floor. A smaller table can easily become a bottleneck, while anything bigger might just be overkill for many shops. The 67-inch size gives one or two chefs enough elbow room to work together comfortably.

Integrated Design for Peak Performance

So what makes these tables so incredibly effective? It's their smart, all-in-one design. They bring together three crucial kitchen components into a single unit, which means less running around and more time saved on every single order.

- Refrigerated Base: The fridge underneath keeps all your backup ingredients—extra cheese, dough balls, sauce—chilled and right where you need them. This simple feature stops your chefs from having to walk back and forth to a separate walk-in, keeping the workflow tight and focused.

- Ingredient Rail: Up top, a refrigerated pan rail holds all your essential toppings like pepperoni, mushrooms, and onions at a safe, cool temperature. This layout is perfect for building pizzas assembly-line style.

- Durable Cutting Board: A deep, full-length cutting board gives you a massive workspace. It’s designed to be wide enough to handle even the largest pizza skins, which is a key feature that sets it apart from a standard prep table.

By combining refrigeration, storage, and a dedicated work surface, a pizza prep table creates an ergonomic work triangle in a single footprint. This efficiency is a game-changer for reducing ticket times and improving order accuracy.

The demand for this kind of efficiency is clear when you look at the market. The global pizza prep tables market was valued at around USD 1.5 billion in 2023 and is expected to grow quite a bit. This growth just proves how vital these units have become for any modern pizzeria that cares about speed and quality. You can dive deeper into these trends by checking out detailed industry reports.

Navigating the World of Commercial Prep Tables

When you're outfitting a commercial kitchen, the surfaces you choose can literally make or break your workflow. Not all prep tables are created equal, and understanding the various types of stainless steel prep tables available is the first step toward building an efficient, high-performance workspace. From basic work tables to highly specialized refrigerated units, each serves a distinct purpose.

The Different Types of Stainless Steel Prep Tables

The term "prep table" covers a wide range of equipment. At the most fundamental level, you have the standard stainless steel work table. This is the jack-of-all-trades in any kitchen—a simple, durable, and hygienic flat surface perfect for general tasks like chopping vegetables, portioning meats, or plating dishes. Their strength lies in their simplicity and versatility, but they lack integrated features like cooling.

For operations where ingredients must be kept at specific temperatures, you move into the category of refrigerated prep tables. These units are a leap forward in efficiency, combining a work surface with built-in cold storage. Within this category, tables are further specialized for specific foods. The two most common types are:

- Sandwich/Salad Prep Tables: Designed for speed and assembling smaller food items, these tables feature a refrigerated rail for toppings and a cutting board, typically 8-10 inches deep.

- Pizza Prep Tables: Engineered for high-volume pizza production, these feature a much deeper cutting board (often 16-19 inches) to accommodate large pizza skins and a raised refrigerated rail designed to hold larger pans of high-use ingredients like cheese and sauce.

Choosing the right type is critical, as a mismatch can create significant bottlenecks in your service. For a detailed breakdown, it's worth consulting a comprehensive buying guide for prep tables that outlines these important differences.

A classic mistake is thinking a sandwich prep table can do the job of a pizza prep table. Sure, both keep things cold, but their core designs—especially the cutting board depth and pan setup—are engineered for completely different products and prep styles.

Sandwich Prep Tables vs. Pizza Prep Tables

It helps to think of a sandwich prep table as a sprinter. It’s built for speed and agility, handling smaller, lighter ingredients. These units usually have a shallower cutting board, maybe 8 to 10 inches deep. This narrow workspace is perfect for assembling sandwiches, subs, and salads where the "canvas" is much smaller.

A 67 inch pizza prep table, on the other hand, is the marathon runner. It’s built for endurance, high volume, and handling much larger items. The single biggest difference is its extra-deep cutting board, which often measures between 16 and 19 inches.

This extra depth is absolutely essential for a pizzeria. It gives you the space you need to stretch out a large pizza dough, add sauce, and pile on toppings without the dough flopping over the edge. Trying to make a 16-inch pizza on a 10-inch deep cutting board would be a messy, inefficient nightmare that slows down your entire line.

Here’s a quick rundown of the key differences:

- Cutting Board Depth: A pizza prep table’s board is nearly twice as deep as a sandwich table's, giving it the room needed for large pizza skins.

- Ingredient Pans: Pizza tables are set up to hold larger, full-size pans (like 1/3-size pans) in the rail, which is ideal for high-volume toppings like shredded cheese and pepperoni. Sandwich tables often use smaller 1/6-size pans for smaller amounts of sliced veggies and meats.

- Workflow Design: A pizza table is laid out for a linear, assembly-line process for making large, flat items. A sandwich station is optimized for smaller, more detailed assemblies.

At the end of the day, while both are refrigerated workhorses, their designs serve very specific purposes. For any serious pizzeria, a specialized 67 inch pizza prep table isn't just a nice-to-have—it's an essential tool engineered for the unique demands of making the perfect pie.

Decoding The Must-Have Features For Your Prep Table

Choosing a 67 inch pizza prep table is a lot like picking the engine for your pizzeria's race car. The right components make all the difference between winning a busy dinner rush and falling behind. Understanding the key features is your roadmap to selecting a unit that will perform under pressure and become a true workhorse in your kitchen.

Beyond just its size, the heart of any prep table is its refrigeration system. This is what keeps your ingredients fresh, safe, and ready to go. Modern units almost always use forced-air refrigeration, which constantly circulates cold air throughout the main cabinet and the top pan rail. Think of it like a convection oven, but for cooling; it gets rid of warm spots and makes sure every topping, from mozzarella to mushrooms, stays at a consistent, food-safe temperature. This is a massive improvement over older, less reliable cold-wall designs.

Another critical feature to look for is an ENERGY STAR rating. Don't mistake this for just a sticker; it's a guarantee of efficiency. An ENERGY STAR certified prep table can be 10-20% more energy-efficient than standard models. That translates directly into lower monthly utility bills and a smaller carbon footprint for your business.

Construction And Materials Matter

The long-term durability of your prep table really comes down to its construction—specifically, the grade of stainless steel it's made from. While all stainless steel might look the same at first glance, there are crucial differences you need to know about. You'll generally run into two main types:

- 304-Grade Stainless Steel: This is the gold standard for any surface that touches food, like the tabletop and the interior. It has more chromium and nickel, which makes it exceptionally resistant to rust and corrosion, especially from acidic ingredients like tomato sauce or vinaigrettes.

- 430-Grade Stainless Steel: This is a more budget-friendly option you'll often find on the exterior sides and back of a unit. While it's still durable, it's more likely to rust over time, particularly in the humid, demanding environment of a commercial kitchen.

For the best long-term value, investing in a table with a 304-grade stainless steel top and interior is a smart move. It will save you from dealing with costly corrosion and help you maintain a hygienic prep surface for years to come.

The right combination of refrigeration, energy efficiency, and high-quality materials ensures your prep table isn't just a purchase, but a long-term investment in your kitchen's productivity and safety.

Storage And Accessibility

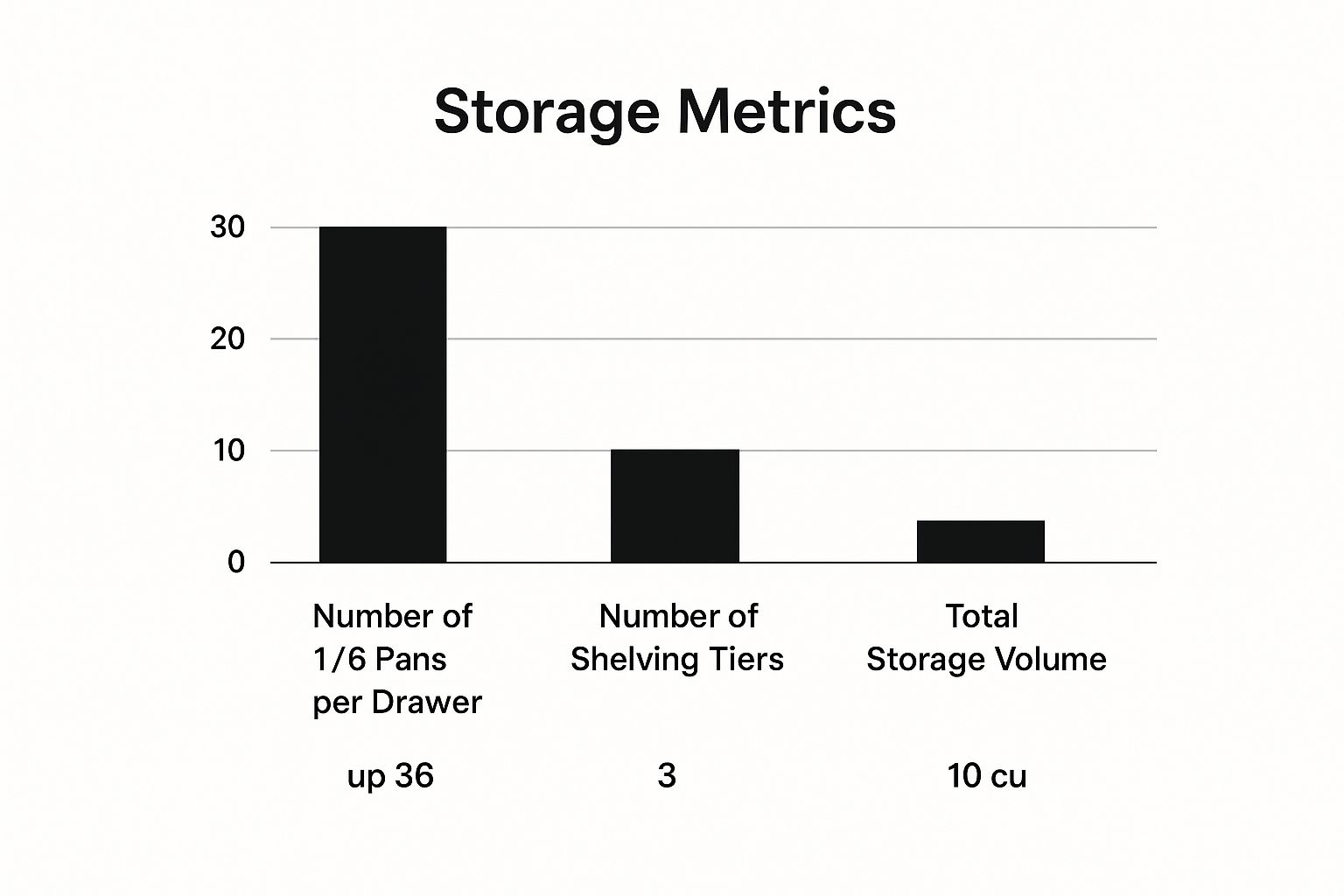

The final piece of the puzzle is figuring out the best setup for storage and access. A 67 inch pizza prep table has to be as practical as it is powerful. You'll need to decide between drawers and doors for the refrigerated base.

Drawers are fantastic for organization, letting you separate different doughs or ingredients into their own pans. This can be a huge time-saver during a busy service. On the other hand, traditional cabinet doors offer more flexible, open storage space that's perfect for bulkier items like blocks of cheese or large sauce containers. For a deeper dive into a model that balances these features well, check out our review of the Atosa 67" pizza prep table.

When you're trying to figure out which features matter most, a side-by-side comparison can make the decision much clearer. This table breaks down what you should be looking for in a 67-inch unit.

Feature Comparison for a 67 Inch Pizza Prep Table

| Feature | What to Look For | Why It Matters for Your Pizzeria |

|---|---|---|

| Refrigeration Type | Forced-air refrigeration system | Ensures consistent cooling across all ingredient pans, preventing spoilage and maintaining food safety. |

| Energy Efficiency | ENERGY STAR certification | Reduces your monthly utility bills by up to 20% and lowers your environmental impact. A smart long-term financial choice. |

| Material (Top/Interior) | 304-grade stainless steel | Offers the best resistance to rust and corrosion from acidic foods like tomato sauce, ensuring durability and hygiene. |

| Material (Exterior) | 430-grade stainless steel | A cost-effective option for non-contact areas, but look for a 304-grade exterior if your budget allows for maximum longevity. |

| Storage Configuration | Doors vs. Drawers | Drawers are great for organizing portioned ingredients, while doors provide flexible space for bulk items. Choose based on your workflow. |

| Refrigerated Capacity | 18-24 cubic feet | Provides ample cold storage directly at the point of use, minimizing trips to the walk-in cooler and speeding up production. |

Thinking through each of these points will help you narrow down the options and find a prep table that’s perfectly suited to the way your kitchen operates.

From a design standpoint, 67 inch pizza prep tables hit a sweet spot, balancing a generous workspace with a manageable footprint. By carefully evaluating each of these features, you can confidently choose a prep table that will meet the unique demands of your pizzeria for years to come.

Why NSF Certification and Steel Quality Are Non-Negotiable

In a bustling commercial kitchen, things like food safety and equipment durability aren't just buzzwords on a checklist. They're the absolute bedrock of your operation. When you're looking at a 67-inch pizza prep table, you'll see terms like "NSF certified" and different steel grades thrown around. Let's break down what they actually mean, because understanding them is the key to a smart, lasting investment.

Think of an NSF certification as the ultimate seal of approval for your kitchen's hygiene. The National Sanitation Foundation (NSF) is a trusted, independent group that puts commercial kitchen equipment through the wringer to make sure it meets strict public health standards.

An NSF stamp on your prep table means it’s been rigorously tested and approved. It's a guarantee that the materials are non-porous and resist corrosion, and the whole unit is designed to be cleaned easily and completely. This design is crucial for stopping harmful bacteria in its tracks.

This isn't just a fancy sticker. It's your peace of mind and your proof to a health inspector that your gear is up to code. A prep table without that certification can be a major red flag during an inspection, potentially costing you in fines or violations.

Understanding Stainless Steel Grades

The metal your prep table is made from is every bit as important as its certifications. Stainless steel is the go-to for a reason, but here's the catch: not all stainless steel is created equal. The "grade" of the steel is what dictates how tough it is, how well it fights off rust, and ultimately, how long it will survive in your kitchen.

You’ll mainly see two common grades: 300-series and 400-series.

- 300-Series (Specifically 304-Grade): This is the gold standard for any surface that touches food. It has more chromium and nickel, which makes it a champion at resisting rust and corrosion. Acidic stuff like tomato sauce or vinaigrettes? No problem for 304-grade steel.

- 400-Series (Specifically 430-Grade): This is a more budget-friendly option, and you'll often find it on the exterior sides or back of a unit—places that don't directly contact food. It's still durable, but it's more likely to start showing rust over time, especially in a steamy, humid kitchen.

For a hard-working 67-inch pizza prep table, springing for a model with a 304-grade stainless steel top and interior is a very wise move. It might cost a little more upfront, but it's an investment that pays off by protecting your table from breaking down prematurely, giving you a hygienic and dependable workhorse for years.

How Steel Quality Connects to All Prep Tables

This whole conversation about steel quality isn't just for pizza tables. It applies across the board, from basic worktops to other specialized refrigerated units. For a simple work surface, you'll want a high-quality grade across the entire top to handle whatever prep you throw at it. You can check out a wide range of durable restaurant stainless steel tables to see how materials and construction vary.

With refrigerated units like sandwich and pizza prep tables, the stakes get even higher. A sandwich prep table needs top-tier steel to stand up to all the different dressings and condiments. A pizza prep table is in a constant battle with acidic tomato sauce, making 304-grade steel an absolute must-have for the worktop and ingredient rail to keep pitting and rust away. At the end of the day, choosing the right steel is choosing how long your equipment will last.

Optimizing Your Kitchen Layout and Workflow

A 67 inch pizza prep table is a beast in the kitchen, but just plopping it against an empty wall won't unlock its full power. Where you place this unit is a strategic move that dictates your kitchen's entire rhythm, from how comfortable your staff is to how quickly orders fly out the door. Think of it as an investment—you want it working with you, not against you.

First things first, grab your tape measure. This isn't just about making sure the table's 67-inch width fits. You absolutely need to leave enough breathing room—think at least 4 to 6 inches of clearance around the back and sides. The refrigeration condenser has to have proper airflow to do its job. If you suffocate it, you're just asking for an overworked unit, higher energy bills, and eventual equipment failure.

And don't forget about the human element. Think about the flow of people and ingredients. Will the refrigerated doors swing open and block a walkway or slam into other equipment? Is there enough room for two people to work back-to-back during the Friday night rush without tripping over each other? These little details aren't so little when you're in the weeds.

Ergonomics: The Key to a Productive Pizza Line

Once you've mapped out the physical space, it's time to think about ergonomics. This is all about setting up the workspace to fit your team, reducing physical strain and cranking up their output. A long shift hunched over a low table is a recipe for back pain and fatigue, which tanks morale and slows everyone down. Most prep tables have a standard height of around 35-36 inches, a detail you’ll definitely want to confirm.

The real magic happens when you create an efficient "work triangle." This connects three critical spots in your kitchen:

- Ingredient Storage: The walk-in or reach-in fridges where your core supplies live.

- Prep Table: The command center for building every pizza.

- Oven: The final stop before the pizza hits the box.

When your 67 inch pizza prep table is perfectly positioned to shorten the distance between these points, you create a seamless workflow. Your crew can grab dough, top it, and slide it into the oven with almost no wasted motion.

Ergonomics isn't a luxury; it's about engineering speed and consistency right into your process. When the ingredient rail is within easy reach and the refrigerated base is well-organized, your team can build pizzas faster and with far fewer mistakes.

A Smart Investment in a Thriving Market

Fine-tuning your kitchen workflow isn't just a minor operational tweak; it’s a critical business decision, especially in a crowded market. The pizza industry in the United States is a massive $50.1 billion market with over 74,000 businesses vying for a piece of the pie. For the independent pizzerias that make up the heart of this industry, efficiency is the name of the game.

It's really no wonder that 36.8% of operators are putting their money into high-quality pizza prep tables—they know it directly impacts their speed and bottom line. If you want to dive deeper into the numbers, check out the latest 2025 Pizza Industry Trends Report.

At the end of the day, taking the time to thoughtfully plan your kitchen layout around your 67 inch pizza prep table is a move that pays dividends every single shift. It saves your valuable staff from physical wear and tear, eliminates wasted steps, and turns your pizza line into a well-oiled machine.

Keeping Your Prep Table Running Like New

Think of your 67-inch pizza prep table as the unsung hero of your kitchen. It's on the front lines every single day. Since it's a major investment, you want it to be a reliable workhorse for years to come, not a source of emergency repair bills.

The secret? A simple, consistent maintenance plan. You don't need anything complicated. By breaking down the essential jobs into daily, weekly, and monthly tasks, you can keep your unit in peak condition without adding a huge burden to your team's workload. This is your playbook for protecting that investment and ensuring food safety.

The Essential Cleaning Schedule

A clean prep table is non-negotiable for food safety. Following a set schedule means every nook and cranny gets the attention it needs, which stops bacteria in its tracks and actually extends the life of your equipment.

Daily Routine (End of Shift)

- Sanitize All Surfaces: This is the big one. Give the cutting board, the entire stainless steel top, and the inside of the refrigerated base a thorough wipe-down with a food-safe sanitizer. Always follow the sanitizer's instructions for proper dwell time.

- Clean Ingredient Pans: Pull every food pan from the rail. They need to be completely washed, rinsed, and sanitized before you even think about refilling them for the next service.

- Wipe Down Gaskets: Use a cloth with warm, soapy water to clean the door or drawer gaskets. Little bits of food and grime build up here, causing the seals to dry out, crack, and eventually fail.

Weekly Deep Clean

Once a week, it's time to go a little deeper. Pull out all the shelving from the refrigerated cabinet for a proper cleaning. This is also the perfect opportunity to hunt down any hidden spills or grime that might have been missed during the daily wipe-downs.

A clean work environment isn't just about looking good—it's the foundation of food safety. Consistent cleaning is a core part of upholding public health standards and earning your customers' trust, bite after bite.

Preventative Maintenance to Avoid Downtime

Beyond the daily scrubbing, a little preventative care is what will really save you from those expensive, middle-of-a-rush repair calls. The single most important task is cleaning the refrigeration system's "lungs"—the condenser coils.

Over time, these coils get choked with a nasty mix of grease, flour, and dust from the kitchen air. When a coil gets clogged, it can't breathe out heat properly. This forces the compressor to work overtime, hiking up your energy bill and leading to an inevitable, costly burnout.

Monthly Condenser Coil Cleaning

- Disconnect Power: Safety first. Always unplug the entire unit before you start.

- Locate the Coils: You'll usually find the condenser coils behind a grille on the back or side of the prep table.

- Brush and Vacuum: Grab a stiff-bristled brush (never a wire one, as it can damage the delicate fins) and gently loosen all the caked-on dust. Use a vacuum with a brush attachment to suck up all the debris you've knocked loose.

Aim to clean the coils at least every 90 days. But if you're in a high-volume pizzeria with lots of flour in the air, you should really be checking and cleaning them monthly. This one simple habit can dramatically improve your table's efficiency and prevent the #1 cause of refrigeration failure.

Troubleshooting Common Headaches

Even the best-maintained equipment can have an off day. Knowing how to spot the early warning signs of common problems can often save you a service call and a lot of frustration.

- Temperature Fluctuations: If your unit is struggling to stay cold, the very first thing to check is the condenser coil. A dirty coil is almost always the culprit. Next, run your hand along the door gaskets to feel for any obvious drafts, and look for rips or gaps.

- Failing Gaskets: A gasket that doesn't create a tight seal is a huge energy waster, making your compressor run non-stop. Test it with the "paper trick." Close the door on a slip of paper—if you can pull it out with zero resistance, it's time to order a new gasket.

- Water Leaking Inside: Seeing a puddle inside the cabinet? This usually means you have a clogged drain line. Find the drain hole inside the unit and gently clear any food debris or blockages with something flexible, like a pipe cleaner.

Frequently Asked Questions About Pizza Prep Tables

Investing in a 67-inch pizza prep table is a big step for any pizzeria, so it's only natural to have a few questions. Getting straight, practical answers is the key to making sure you choose a unit that will really pull its weight in your kitchen. Here, we'll walk through some of the most common things buyers ask, giving you the clear information you need to make your final choice.

Electrical and Placement Needs

Do I need a special electrical outlet for a pizza prep table?

This is an excellent question and one we hear all the time. The good news is that most commercial pizza prep tables, including the 67-inch models, are built for convenience. They typically come with a standard NEMA 5-15P plug, which is the same one you find on household appliances and fits any normal 115V wall outlet in North America.

But here's the crucial part: you need to look at the unit's amperage draw on its spec sheet. Always plug the prep table into a dedicated circuit that can handle its electrical load. If you share the circuit with other heavy-duty equipment, you risk tripping the breaker right in the middle of a dinner rush.

Multi-Purpose Use and Design Differences

Can I use a pizza prep table for sandwiches and salads too?

You absolutely can, but it's worth thinking about the ergonomics. The biggest difference between a pizza prep table and a sandwich prep table is the depth of the cutting board. Pizza tables have those extra-deep boards, usually 16 to 19 inches, which give you plenty of room to stretch out large doughs.

Trying to assemble a small sub or salad on that massive surface can feel a bit clumsy and slow you down. A dedicated sandwich prep table has a much narrower board, often just 8 to 10 inches deep, which is tailor-made for that kind of work. So while the pizza table gives you more flexibility, a specialized table is often more efficient for its specific job.

What's the difference between a raised rail and a mega top table?

This all comes down to how many toppings you need to keep chilled and within arm's reach.

A standard raised rail holds a single row of ingredient pans, perfect for basic pizza menus. A "mega top," however, is designed for high-volume topping variety, holding two or even three rows of pans in a larger refrigerated housing.

A standard raised rail table gives you a single row for your ingredient pans. It’s the perfect setup for shops with a core menu of classic pizzas.

A “mega top” table, on the other hand, is built for kitchens that go big on customization. It expands that refrigerated rail to hold two or even three rows of pans. This dramatically boosts your on-the-line ingredient capacity without taking up more floor space. If your customers love building their own creations with tons of toppings, the mega top is definitely the way to go.

Essential Maintenance Questions

How often should I clean the condenser coils?

This is one of the most important maintenance jobs for any piece of refrigerated equipment. For the average commercial kitchen, cleaning the condenser coils every 90 days is a great rule of thumb.

However, if your kitchen has a lot of grease, flour, or dust in the air, you’ll want to do it more often—probably once a month. Keeping those coils clean is non-negotiable for efficient cooling, lower energy bills, and a longer life for your compressor.

Ready to upgrade your kitchen’s efficiency and performance? PrepTables.com offers a premium selection of 67-inch pizza prep tables and other commercial equipment designed for durability and workflow optimization. Find the perfect prep table for your pizzeria today!