Your Guide to the Atosa 67 Pizza Prep Table

Share

In the controlled chaos of a busy pizzeria, every single second counts. The Atosa 67 pizza prep table is designed to be the command center for speed and efficiency, acting as your kitchen's undisputed workhorse to tackle the biggest headaches of high-volume pizza making. This specialized unit keeps every ingredient, from cheese to pepperoni, perfectly chilled and always within arm's reach, making your workflow incredibly smooth during peak hours.

Your Pizzeria's Ultimate Workhorse

Picture your kitchen during the Friday night rush. Orders are pouring in, and your team is moving like a blur. Without the right equipment, this is where things can quickly spiral out of control. An Atosa 67 pizza prep table, however, turns that potential chaos into a well-oiled machine.

This isn't just a stainless steel surface with a fridge slapped underneath; it's a fully integrated system. Its entire design is purpose-built to eliminate wasted steps. Instead of your chefs running back and forth to a separate refrigerator, every essential topping is held at a food-safe temperature in the refrigerated rail, sitting directly above the massive prep area.

Built for Speed and Quality

The deep cutting board gives you plenty of room to stretch and top even the largest pizza doughs without ever feeling cramped. This thoughtful design means a single employee can assemble pizzas much faster, which directly cuts down on ticket times and makes for happier customers. It's all engineered to boost your output without ever sacrificing the quality of the final pie.

The demand for efficient kitchen solutions like the Atosa 67 is driving serious growth in the commercial food equipment market. In fact, the pizza prep table market alone was valued at roughly USD 1.5 billion in 2023 and is expected to climb to around USD 2.3 billion by 2032. That's a huge jump, and it shows just how vital these stations have become for pizzerias and fast-food joints all over the world.

A well-organized prep station is the beating heart of a profitable pizzeria. By bringing all your ingredients and workspace into one spot, units like the Atosa 67 can shave minutes off the prep time for each pizza. Over a single shift, that adds up to major labor savings and a real boost to your revenue.

The Foundation of Kitchen Hygiene

Beyond pure speed, the Atosa 67 is a cornerstone of food safety. Its stainless steel construction isn't just tough enough to handle constant use; it's also non-porous and incredibly easy to sanitize, helping you meet—and even exceed—local health code standards.

The powerful, consistent refrigeration in both the top rail and the undercounter storage ensures that your sensitive ingredients are always kept out of the temperature "danger zone." This is crucial for protecting both your customers and your restaurant's hard-earned reputation. If you're looking to dive deeper into the different types of stations out there, our comprehensive prep tables buying guide offers some fantastic insights.

Ultimately, putting an Atosa 67 in your kitchen is an investment in consistency, safety, and the long-term profitability of your pizzeria.

A Closer Look at the Atosa 67’s Features and Specs

To really get why the Atosa 67 pizza prep table is such a workhorse, we need to go beyond the surface and dig into the nitty-gritty details. These are the specific features and components that elevate it from just another piece of equipment to the central hub of a busy pizza kitchen. Knowing these specs helps you see not just what it does, but exactly how it will slot into your daily operations.

The first thing you think about with any new equipment is space. Where will it go? The Atosa 67 is smartly designed to give you a huge workspace without eating up your entire kitchen floor. Its dimensions strike that perfect balance between a large, functional prep area and a footprint that’s manageable in a commercial setting.

From a practical standpoint, this unit is built to make your life easier. The refrigerated base has plenty of storage, and the top rail is made to hold standard food pans perfectly. This simple, thoughtful design means every topping is chilled, organized, and right where you need it, which is a massive help for speeding up assembly and keeping things moving during the dinner rush.

Core Components That Drive Performance

The real muscle behind the Atosa 67 is its high-quality guts. These are the parts humming away behind the scenes, delivering the consistent, reliable cooling your pizzeria counts on. At its core is a heavy-duty Embraco compressor, a name that commands respect in commercial refrigeration for its sheer durability and efficiency.

Think of the compressor as the engine of your prep table. A cheap one might sputter and struggle during a Friday night rush, causing temperature swings that put your food at risk. The Embraco unit, however, is built for the chaos of a real kitchen. It handles the constant opening and closing of doors with ease, quickly recovering to maintain a stable, food-safe temperature. That’s peace of mind when you need it most.

Atosa’s focus on quality is clear when you look at the parts they choose. By using top-tier components like Embraco compressors and Dixell controllers, they build equipment that doesn’t just pass inspection—it gives you long-term confidence and reliability.

Another game-changing feature is the Dixell digital temperature control. This isn't some vague "colder-warmer" dial; it’s a precision tool. It lets you set and monitor the internal temperature with pinpoint accuracy, ensuring your cheese, pepperoni, and veggies are held in that critical sweet spot between 33°F and 40°F. This isn't just about meeting health codes—it's about preserving the fresh taste and texture of your ingredients.

Specifications That Matter

To put it all into perspective, here's a quick rundown of the key technical specs for the Atosa 67 pizza prep table.

Atosa 67 Pizza Prep Table Key Specifications

This table breaks down the essential details, showing what each feature is and, more importantly, what it means for your kitchen.

| Feature | Specification | Benefit |

|---|---|---|

| Dimensions | 67" W x 33" D x 44" H | Provides a large prep surface and substantial storage without an overwhelming footprint. |

| Compressor | Heavy-Duty Embraco | Ensures reliable, consistent cooling and energy efficiency, reducing operational costs. |

| Refrigerant | R290 Hydrocarbon | An environmentally friendly choice with zero ozone depletion potential and superior thermal efficiency. |

| Temperature Control | Dixell Digital Controller | Offers precise temperature management for optimal food safety and ingredient quality. |

| Doors & Gaskets | Self-Closing with Magnetic Gaskets | Doors stay shut to conserve energy, and gaskets create a tight seal to maintain cold temperatures. |

| Construction | Stainless Steel Interior & Exterior | Delivers exceptional durability and is easy to clean and sanitize, promoting excellent hygiene. |

As you can see, these features are designed to work in concert. For example, the self-closing doors and their tight magnetic gaskets stop cold air from escaping. This means the Embraco compressor doesn't have to work as hard, which saves you money on your energy bill. The stainless steel build isn't just tough; it makes the daily wipe-down quick and effective.

To learn even more about what makes this model a great investment, check out our in-depth guide to the Atosa pizza prep table. It’s this complete package of smart design and quality parts that truly makes the Atosa 67 a top contender for any serious pizzeria.

Comparing Stainless Steel Prep Tables

Not all prep tables are created equal, and knowing the differences is key to optimizing your kitchen's workflow. While many specialized units exist, the foundation for most is durable, hygienic stainless steel. Understanding the various types helps you appreciate why a specialized model like the Atosa 67 pizza prep table is essential for certain tasks.

The Foundation: General Work Tables

The most basic and versatile option is the general stainless steel work table. It's essentially a blank slate—a flat, sturdy surface used for everything from chopping vegetables to plating dishes. These tables are the unsung heroes in many kitchens, defined by their simplicity and strength. They don't have built-in refrigeration, but their flexibility makes them indispensable. For a deeper dive, you can explore various restaurant stainless steel tables.

The Specialist: Sandwich Prep Tables

A step up in specialization is the sandwich prep table, also known as a salad prep table. These units integrate refrigeration into the design, featuring a refrigerated base, a cutting board, and a chilled rail on top to hold food pans. The defining feature of a sandwich prep table is its relatively narrow cutting board, typically around 10 to 12 inches deep. This is perfect for assembling sandwiches, subs, and salads where ingredients are arranged in a linear fashion.

The Powerhouse: The Pizza Prep Table

This brings us to the main event: the pizza prep table, a powerhouse designed specifically for high-volume pizza making. The Atosa 67 pizza prep table is a prime example of this category. It takes the concept of the sandwich table and re-engineers it for the unique demands of pizza production. The most noticeable difference is the extra-deep cutting board, often 19 inches or more. This massive workspace is crucial for stretching and topping large pizza doughs without making a mess.

Another key distinction is the raised ingredient rail. Unlike a sandwich table where the rail is flush with the cutting board, a pizza prep table's rail is elevated. This brilliant design keeps topping pans accessible but out of the way, providing a clear, unobstructed area for working with dough.

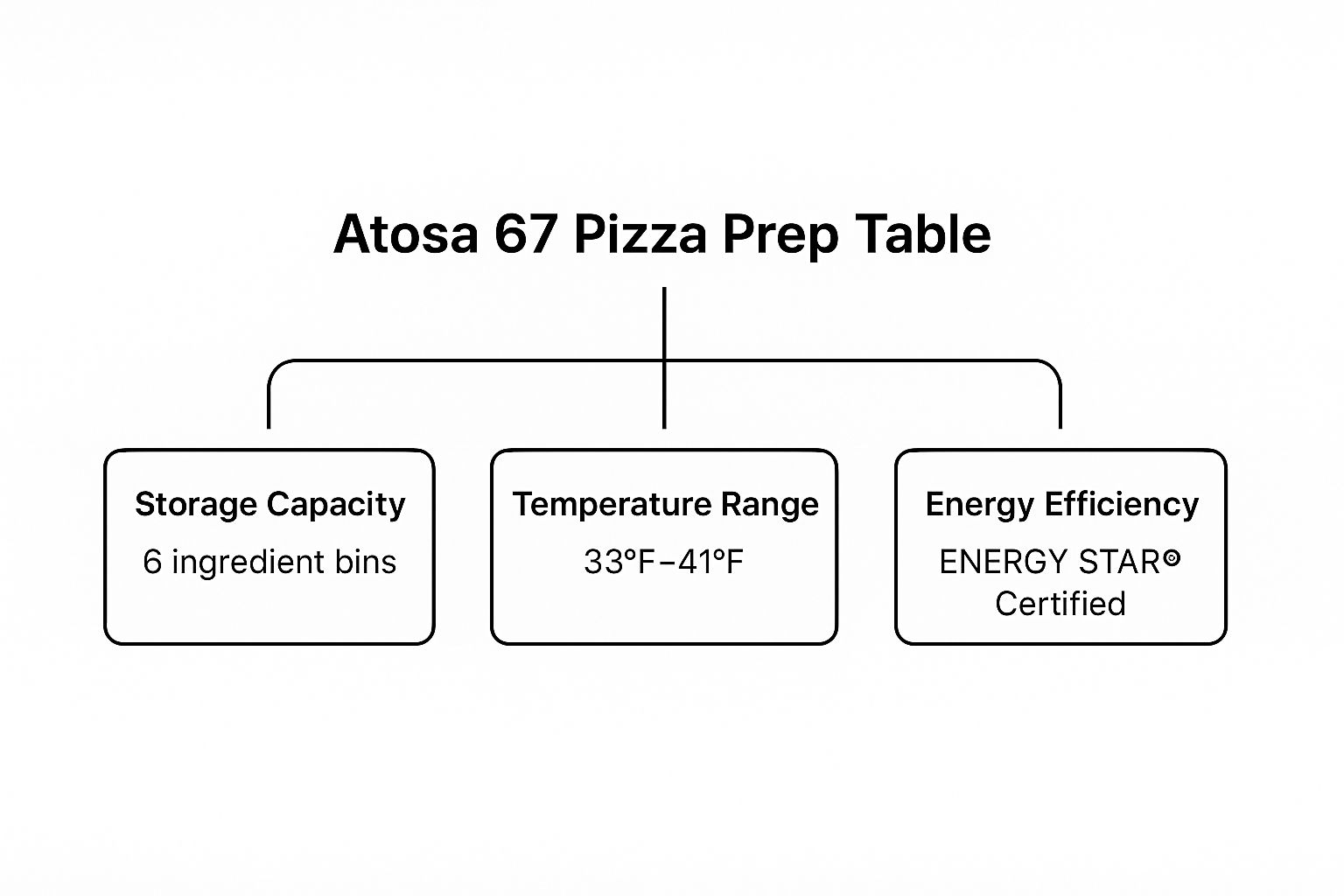

This image below does a great job of showing some of the key features that make the Atosa 67 such a capable machine.

You can see how everything from its storage capacity to its precise temperature control is built for the intense demands of a busy pizzeria. This whole category of equipment exists for a reason—people love pizza! In fact, the U.S. Bureau of Labor Statistics projected a 10% growth for the restaurant industry between 2019 and 2029, a trend largely pushed by our craving for fresh, made-to-order meals. That demand is what fuels the need for smart, efficient tools like the Atosa 67.

So, while all these tables are made from trusty stainless steel, they're designed for very different jobs. A general work table gives you flexibility, a sandwich prep table is built for speed with smaller items, and a pizza prep table gives you the dedicated space and features you need to crush a dinner rush. The Atosa 67 is a perfect example of the latter—it’s a problem-solver, engineered to handle the specific headaches pizzerias face day in and day out.

Boosting Your Kitchen's Efficiency and Food Safety

In any busy kitchen, the line between a smooth service and pure chaos is razor-thin. What often makes the difference? Workflow and food safety. These are precisely the two areas where the Atosa 67 pizza prep table was built to shine. This isn't just another piece of stainless steel; it's a strategic investment designed to crank up your kitchen's speed while reinforcing its hygiene.

Think about a typical Friday night rush. Without the right setup, your pizza maker is a blur of wasted movement. They're grabbing dough from one cooler, walking over to a counter to stretch it, then dashing across the kitchen to a different fridge for toppings. Every single step adds precious seconds to each order, creating a bottleneck that brings the whole operation to a crawl.

This constant back-and-forth doesn't just kill your ticket times; it's a food safety nightmare waiting to happen. Every time that reach-in door swings open, cold air rushes out, forcing the compressor to work overtime to get back to temperature. This constant strain can lead to temperature swings that put your ingredients at risk.

Transforming Workflow with Integrated Design

Now, let's replay that same Friday night, but with the Atosa 67 in place. Your pizza maker is planted in one spot. They stretch the dough on the huge 19-inch deep cutting board, spread the sauce, and then just reach up to the refrigerated rail for cheese, pepperoni, and veggies. Everything they need is right there, all within arm's reach.

This kind of smart, integrated design creates what experts call an economy of motion. It completely gets rid of those unnecessary steps, slashing prep time. A process that used to involve minutes of frantic movement is now done in under a minute, without ever taking a step. Suddenly, one person can handle the workload of two, a game-changer during your busiest hours.

By putting every part of the pizza-making process into one central station, the Atosa 67 turns a series of disjointed chores into a smooth, continuous flow. This is the secret behind how high-volume pizzerias pump out orders without ever compromising on quality.

And this isn't just about moving faster. It’s also about cutting down on the physical and mental stress on your team. A calmer kitchen is a safer, more productive kitchen, which often leads to happier staff and less turnover.

A Fortress of Food Safety

More than just a workflow machine, the Atosa 67 pizza prep table is a fortress for food safety. The biggest threat in any kitchen is poor temperature control, which allows bacteria to multiply on sensitive ingredients. The Atosa 67 tackles this head-on with powerful, consistent refrigeration.

- Refrigerated Rail: The top rail holds all your go-to toppings, keeping them constantly chilled. This makes sure that ingredients like cheese, cooked meats, and chopped veggies never hit the temperature "danger zone" (41°F to 135°F), even when you're slammed.

- Undercounter Storage: Down below, the refrigerated base offers plenty of space for backup ingredients. You can keep extra dough, sauce, and toppings perfectly cold and ready to go, all without ever leaving the station.

This dual-zone cooling is driven by a rock-solid system that holds a steady temperature between 33°F and 40°F. That unwavering consistency is your best line of defense against foodborne illness and is absolutely essential for passing health inspections. Add in the easy-to-clean stainless steel surfaces and self-closing doors, and you have a unit that makes sanitation simple and effective.

At the end of the day, investing in an Atosa 67 is about more than just making pizzas faster. It's about building a smarter, safer, and more profitable kitchen. It protects your customers, empowers your staff, and guards your hard-earned reputation.

Installation and Maintenance Best Practices

You've made a smart move getting an Atosa 67 pizza prep table—it’s a serious piece of equipment for any kitchen focused on efficiency and food safety. To make sure it pays you back for years to come, proper installation and a little bit of routine care are absolute musts. Getting this right from day one will extend its life, keep it running like a champ, and save you from those dreaded emergency service calls.

It helps to think of your prep table like a high-performance car. It needs the right environment and regular tune-ups to deliver its best. The very first step is finding the perfect parking spot for it in your kitchen.

The Initial Setup Your Guide to Proper Installation

How you install this unit sets the stage for its entire lifespan. If you rush through it, you're setting yourself up for poor cooling, extra wear and tear on the components, and maybe even a premature breakdown. It’s worth taking the time to do it right.

1. Location is Everything: This is all about ventilation. The refrigeration system works hard and creates heat, and it needs room to breathe. You’ll want to place the unit at least four to six inches away from any walls or other big appliances. And definitely keep it away from heat sources like your ovens or fryers—placing it too close makes the compressor work overtime.

2. A Level Foundation: You might not think it matters, but an unlevel surface is a quiet killer of efficiency. It can throw the self-closing doors out of alignment, which lets cold air sneak out and warm air creep in. Grab a level and make sure the unit is perfectly flat, adjusting the casters until it is. This one small check ensures the door gaskets get a tight, energy-efficient seal.

3. Dedicated Power: Your Atosa 67 is a powerful beast and needs its own steady supply of electricity. Plug it directly into a dedicated circuit that matches its NEMA 5-15P plug. Whatever you do, don't use an extension cord or share the outlet. That can cause voltage drops and trip your breakers, which is a great way to damage the compressor.

4. Initial Startup: Before you even think about loading it with your precious ingredients, let the unit run completely empty for at least 24 hours. This break-in period gives the whole system time to settle down and reach its ideal temperature, which is usually between 33°F and 40°F. Use a separate, reliable thermometer to double-check the temp before you stock it up.

A common mistake we see is people pushing a prep table right up against a wall to save a few inches of floor space. This basically chokes the condenser coil, forcing the unit to struggle to stay cool. The result? Higher energy bills and a compressor that's going to die way sooner than it should.

Routine Maintenance for Lasting Performance

Once your Atosa 67 pizza prep table is humming along, a simple maintenance routine will keep it in peak condition. These tasks are easy, don't take much time, and make a world of difference for performance and hygiene.

A consistent cleaning schedule is your number one defense against equipment problems and, just as importantly, health code dings.

- Daily Cleaning: At the end of every shift, give all the stainless steel surfaces, the cutting board, and the door gaskets a good wipe-down with a mild soap and warm water. This stops food gunk from building up and keeps things sanitary.

- Weekly Deep Clean: Once a week, pull out all the food pans and shelves to get a deeper clean. Really focus on the door gaskets, making sure to clean inside the folds where crumbs can get trapped and break the seal.

- Quarterly Coil Cleaning: The condenser coil is like the radiator in your car; if it gets clogged with dust, flour, and grease, the compressor will overheat. Every 90 days, unplug the unit, and use a stiff brush and a vacuum to gently clean the coil’s fins. If your kitchen has a lot of flour in the air, you’ll probably want to do this every month.

By taking these straightforward installation and maintenance steps, you’re ensuring your Atosa 67 pizza prep table will be a reliable workhorse in your kitchen. This proactive approach doesn't just protect your investment; it protects your food quality and your business’s reputation.

Frequently Asked Questions

When you're looking to invest in a real workhorse for your kitchen, like the Atosa 67 pizza prep table, you're bound to have some questions. It's a specialized piece of equipment, and understanding exactly how it stacks up against other gear is the key to feeling confident in your choice.

We've pulled together the most common questions we hear from chefs and owners. Our goal is to give you clear, straight-up answers so you can see precisely how this table can benefit your kitchen's workflow.

What Is the Difference Between a Pizza Prep Table and a Sandwich Prep Table?

This is a fantastic question because it gets right to the heart of why using the right tool for the job matters so much. While they might look similar at a glance, pizza prep tables and sandwich prep tables are engineered for very different kinds of food assembly. The two biggest differences are the depth of the cutting board and the setup of the ingredient rail.

A sandwich or salad prep table is built for making subs, paninis, and salads. Its cutting board is fairly narrow, usually just 10 to 12 inches deep, which is all you need to assemble ingredients in a line. The ingredient pans on these units are typically level with the work surface, making it easy to slide items down the line.

The Atosa 67 pizza prep table is a completely different animal, built from the ground up to handle big, round pizza doughs.

- Deep Cutting Board: It boasts a much deeper cutting board, often 19 inches or more. This massive workspace gives your crew plenty of room to stretch, toss, and top a large pizza without the dough flopping over the edge and making a mess.

- Raised Ingredient Rail: The ingredient rail is smartly elevated above the main prep surface. This design keeps all your toppings within easy reach but completely out of the way of the main dough-working area. It’s an unobstructed canvas for creating your pizza base.

Honestly, trying to make a big pizza on a narrow sandwich table is just an exercise in frustration. The Atosa 67’s purpose-built design completely eliminates that struggle, making it the obvious choice for any serious pizzeria.

How Often Should I Clean the Condenser Coil on My Atosa 67?

Taking care of your equipment is the best way to protect your investment, and when it comes to the Atosa 67, cleaning the condenser coil should be at the top of your list. Think of the coil as the lungs of the refrigeration system—if it gets clogged, the whole unit struggles to breathe.

As a general rule, you should clean the condenser coil at least every 90 days.

But remember, that's just a starting point. Every kitchen is different. If your pizzeria has a lot of airborne flour, grease, or dust—and most do—you'll want to clean it more often, probably every 30 to 60 days. A dirty coil forces the compressor to work overtime just to keep things cool, which drives up your energy bills and can lead to expensive breakdowns. A quick, regular cleaning is the single best thing you can do to keep your unit running efficiently for years.

Can I Use the Atosa 67 for More Than Just Pizza?

Absolutely! While it was born to make pizza, the Atosa 67 pizza prep table is far from a one-trick pony. Its core strengths—a huge prep surface and powerful, reliable cooling—are incredibly valuable for all sorts of kitchen tasks.

That massive workspace and refrigerated base are perfect for prepping other large-scale menu items, like:

- Calzones and strombolis

- High-volume wrap and salad production

- Gourmet flatbreads

- Assembling large catering trays

In short, if you have any high-volume job that demands a generous work area while keeping lots of ingredients perfectly chilled, this unit is a fantastic asset. Its solid build and strong cooling system make it a valuable player in any busy commercial kitchen, not just a pizzeria.

What Kind of Electrical Outlet Does the Atosa 67 Need?

Getting the electrical setup right is non-negotiable for safety and performance. The Atosa 67 is designed for a standard commercial kitchen environment and usually ships with a NEMA 5-15P plug. This is just your everyday three-prong plug that fits into a normal 115V wall outlet.

However, it's not quite that simple. We strongly recommend plugging the Atosa 67 pizza prep table into a dedicated circuit. If you have it sharing an outlet with other power-hungry appliances like a microwave or a large mixer, you risk tripping the breaker or causing voltage drops. Those fluctuations can seriously damage the compressor over time. Before you plug anything in, always double-check the unit's data plate or owner's manual to confirm the specific electrical needs and ensure a safe, stable power source.

Ready to transform your kitchen's efficiency and food safety? The Atosa 67 pizza prep table is the reliable, purpose-built solution your pizzeria needs to handle the rush. Explore our full range of professional-grade equipment at PrepTables.com and equip your team for success. https://preptables.com