What Temperature Refrigerator And Freezer For Safe Food Storage

Share

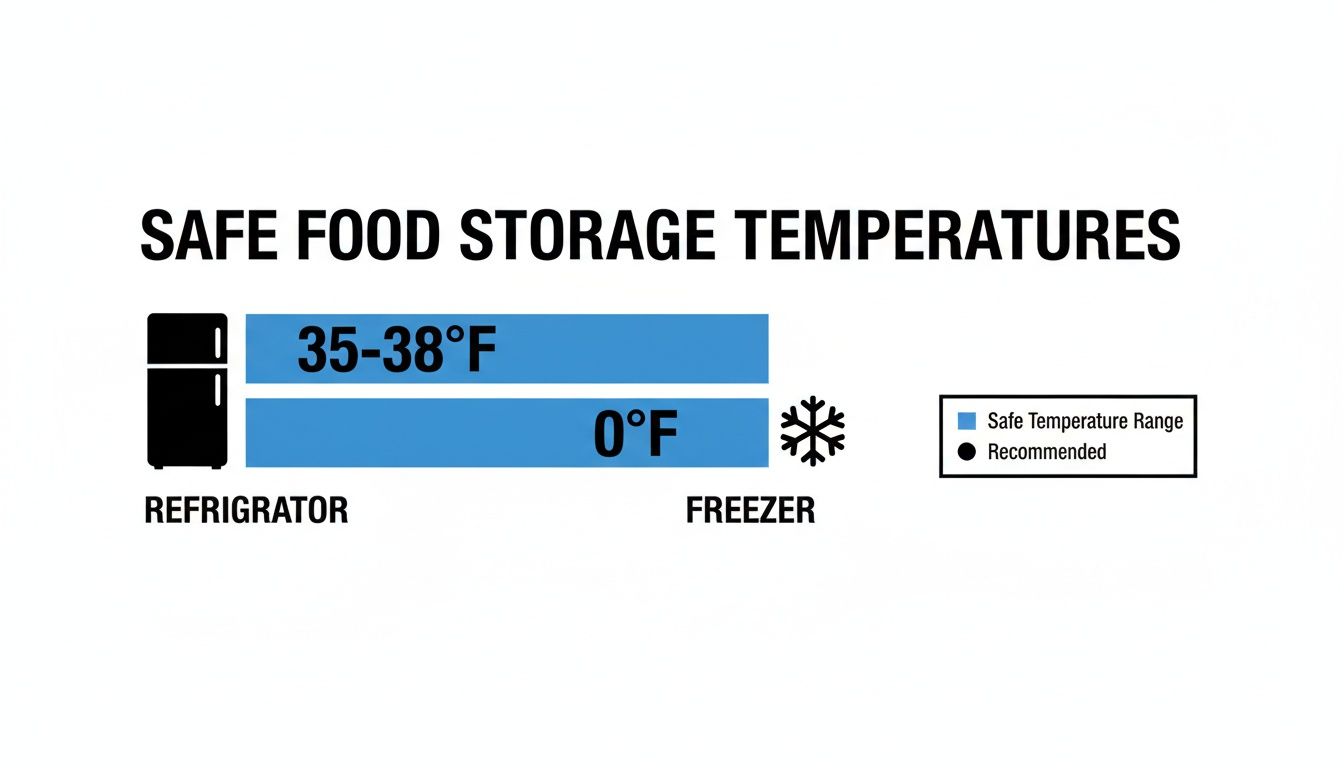

When it comes to food safety, temperature isn't just a number—it's everything. For any commercial kitchen, the golden rule is to keep your refrigerator set between 35°F and 38°F (that's 2°C to 3°C) and your freezer at or below 0°F (–18°C).

These aren't just suggestions; they're the critical thresholds that keep your ingredients safe and your business running smoothly.

Recommended Refrigerator And Freezer Temperatures

Think of your refrigerator as hitting the 'pause' button on bacteria. When you keep it in that sweet spot, microbial growth slows to a crawl, which means your food stays fresh longer. But let that temperature creep up, even by a few degrees, and you've effectively pressed 'play.' Spoilage kicks into high gear.

This is why nailing your temperature settings is a non-negotiable cornerstone of a well-run kitchen.

In the fast-paced environment of a professional kitchen, holding that tight 35°F to 38°F (2°C to 3°C) range can be the difference between serving fresh, quality dishes and dealing with costly waste. Improper refrigeration is a major contributor to foodborne illness, leading to lost inventory, damaged reputations, and health risks. Keeping your equipment dialled in is your first line of defense.

If you want to dive deeper into this topic, we've covered more in our guide on food safety temperature control.

The Ideal Temperature Zones For Food Safety

It's helpful to think of your refrigerator and freezer as having two very different, but equally important, jobs. The refrigerator's role is to keep perishable items cool and safe for short-term use. The freezer, on the other hand, is there to completely halt biological processes for long-term storage.

This simple infographic breaks it down visually, showing the clear line between cooling and freezing.

As you can see, these are distinct, non-negotiable zones. Sticking to them is what ensures you get the best of both worlds: safety and quality. That optimal refrigerator range is especially crucial for slowing down bacterial growth in high-risk items like meats, dairy, and prepped produce.

For a quick and easy reference, here's a breakdown of the temperatures you should be aiming for in your commercial units.

Recommended Commercial Refrigerator and Freezer Temperatures

This table offers a clear guide to the optimal temperature ranges needed to maintain food safety and quality across your commercial refrigeration equipment.

| Unit Type | Optimal Fahrenheit Range (°F) | Optimal Celsius Range (°C) | Primary Purpose |

|---|---|---|---|

| Reach-In Refrigerator | 35°F – 38°F | 2°C – 3°C | Short-term storage of perishables. |

| Walk-In Cooler | 35°F – 38°F | 2°C – 3°C | Bulk short-term storage. |

| Prep Table/Bain-Marie | 33°F – 41°F | 1°C – 5°C | Keeping ingredients cold during service. |

| Reach-In Freezer | 0°F or below | -18°C or below | Long-term frozen storage. |

| Walk-In Freezer | 0°F or below | -18°C or below | Bulk long-term frozen storage. |

Keeping this chart handy can help your whole team stay on the same page, ensuring that every piece of equipment is doing its job to protect your inventory.

Why Precise Freezer Temperatures Are Non-Negotiable

If a refrigerator just slows things down, think of your freezer as the ultimate pause button for your inventory. It's designed to bring all those biological processes to a dead stop. Keeping that freezer at a consistent, rock-solid temperature isn't just a "best practice"—it's the core of protecting the quality, safety, and cash value of your food.

The magic number for any commercial freezer is 0°F (–18°C). This isn't just some random figure; it's based on pure food science. At this temperature, the water inside your ingredients freezes completely solid, which slams the brakes on the microbial activity that leads to spoilage. It effectively locks in the nutrients, flavor, and texture you paid for, preserving everything for the long haul.

The High Cost of an Unsteady Temp

When a freezer's temperature yo-yos up and down, it kicks off a vicious cycle of partial thawing and refreezing. This is what creates the dreaded freezer burn. Tiny ice crystals form on the food's surface, sucking out moisture and destroying its cellular structure. What you're left with is a product that's dry, tough, and tasteless—and it usually ends up straight in the bin.

For any business that relies on bulk frozen goods, like a pizzeria managing dough or a cafeteria stocking up on proteins, that waste is pure profit down the drain. A steady temperature is your only defense.

A stable 0°F (–18°C) environment is your best defense against product degradation. Fluctuations not only spoil food but also force the freezer's compressor to work harder, increasing energy consumption and leading to premature equipment failure.

Meeting the Demands of Specialty Items

While 0°F (–18°C) is the gold standard, some items are a bit more high-maintenance. Take ice cream, for example. It's at its best when stored at a frigid –20°F (–29°C). Any warmer, and you risk large ice crystals forming, which gives it that gritty, unpleasant texture nobody wants. Knowing the specific quirks of your inventory is key to optimizing storage and serving up a top-notch final product.

Commercial freezers, whether they're undercounter units or massive walk-ins, are built for this kind of rigor. They're engineered to hold a steady temperature somewhere between -10°F and 0°F (-23°C to -18°C), a range that stops over 99% of microbial growth in its tracks. For managers of pizzerias and cafeterias, that precision is everything. A deviation of just 5°F (-15°C) can actually double the damaging thaw-refreeze cycles, effectively cutting a product's shelf life in half. You can dive deeper into how these standards developed and changed the food industry by exploring the history of refrigeration. This is the kind of unwavering consistency that protects both your inventory and your bottom line.

Understanding Your Commercial Refrigeration Equipment

Knowing the ideal temps for your fridge and freezer is the first step. The real test? Applying that knowledge to the specific gear in your kitchen. This is where food safety truly comes alive.

Commercial refrigeration isn't a one-size-fits-all game. Every unit is built for a different job, from holding bulk inventory to giving your line cooks instant access to prepped ingredients. Grasping these differences is the secret to keeping consistent, safe temperatures across your entire operation.

Think of it like this: a massive walk-in cooler is the bank vault for your food inventory—it's all about long-term, stable cold storage. A refrigerated prep table, on the other hand, is the cashier's drawer, built for speed and constant access during the controlled chaos of a dinner rush. Both must stay cold, but their designs serve two totally different functions.

Differentiating Key Refrigeration Units

Every piece of equipment in your kitchen has a role to play. A busy deli counter has very different needs than a food truck with barely enough room to turn around, which is why there are so many specialized options out there. For a much deeper dive, our guide to the different types of commercial refrigerators breaks it all down.

Here’s a quick look at the most common units you'll find:

- Walk-In Coolers and Freezers: These are the titans of kitchen storage. They’re designed to hold bulk ingredients at a rock-solid temperature, making them perfect for big operations like hospitals or school cafeterias that need to store cases of produce or boxes of frozen meat.

- Reach-In Refrigerators and Freezers: These are the daily workhorses. More accessible than walk-ins, these upright units keep your most frequently used items right where you need them, whether that's near a prep station or on the main cooking line.

- Undercounter Units: Squeezing every inch of utility out of your space is key. These compact fridges and freezers fit perfectly under countertops, making them a favorite for tight kitchens, bars, and food trucks.

The Role of Stainless Steel Prep Tables

Refrigerated prep tables are where smart design meets practical function. They combine a durable stainless steel work surface with built-in refrigeration, keeping ingredients safely chilled right where you need them. For salad bars, sandwich shops, and pizzerias, these units are absolutely essential.

A refrigerated prep table isn't just a cold box with a cutting board on top; it's a food safety system. The best ones have specialized airflow channels that push a constant curtain of cold air over the food pans. This is what keeps your ingredients out of the "danger zone," even when the lids are being opened constantly.

There are several types of stainless steel prep tables, each designed for specific kitchen workflows:

- Sandwich Prep Tables: These units feature a deep, refrigerated well for holding large pans of cold cuts, cheeses, and vegetables, along with a cutting board that runs the full length of the table. The focus is on easy access to a wide variety of ingredients for quick assembly.

- Pizza Prep Tables: Similar to sandwich tables, but pizza prep tables have a raised rail to hold smaller ingredient pans at an ergonomic height. This design makes it easy for chefs to top pizzas quickly. They also typically have a wider cutting board surface to accommodate large pizza doughs.

- Standard Prep Tables (Worktop Refrigerators): These offer a solid, flat stainless steel top for general prep work, with refrigerated cabinets below. They are perfect for kitchens that need extra refrigerated storage and workspace in one footprint.

- Mega Top Prep Tables: A variation on the sandwich table, mega tops include an extra row of food pans, providing more ingredient capacity in the same amount of space. This is ideal for establishments with extensive menus.

Choosing the right equipment for your kitchen’s workflow isn't just about efficiency—it's a critical part of your food safety plan.

Accurately Measure And Monitor Kitchen Temperatures

Setting the dials on your refrigerator and freezer is just the starting point. Real food safety comes from keeping a constant, accurate watch on those temperatures. Just relying on the built-in dial is a bit like guessing your speed on the highway—you might be in the right ballpark, but you don't have the precision you need for serious quality control and compliance.

To really master temperature tracking, you need the right tools and a solid routine. When you get this down, monitoring stops being a chore and becomes a natural part of your kitchen's rhythm, protecting both your inventory and your reputation.

The Right Tools and Techniques for Accuracy

To get a true reading of what’s happening inside your unit, you'll need an independent, NSF-certified thermometer. These are built for the rigors of commercial use and calibrated for accuracy. The thermostat that comes with your fridge only tells you the air temperature at one specific spot, which can be pretty misleading.

For the most precise measurement, just follow these simple steps:

- Placement is Key: Don't just hang the thermometer on a random shelf. For the fridge, stick it in a glass of water. In the freezer, wedge it between two frozen packages. This approach measures the temperature of the food, not just the air that swings up and down every time the door opens.

- Wait for Stabilization: Give the thermometer at least 5-8 hours to settle in. This ensures you get a stable, accurate reading, not just a snapshot in time.

- Check Multiple Spots: Temperatures can be surprisingly different from one part of a unit to another. Test a few areas—near the door, way in the back, top shelf, bottom shelf—to find any warm or cold spots.

Going through this process gives you a real-world picture of what your ingredients are actually experiencing. That way, you can adjust your settings with complete confidence.

Creating a Consistent Monitoring Schedule

Checking temperatures randomly is better than nothing, but a structured logging system is your best defense against problems. A simple log sheet taped to each unit is an incredibly powerful tool. It builds accountability and helps you spot equipment issues early.

Your temperature log is more than just a piece of paper; it's a historical record of your equipment's performance. Consistent logging helps you spot gradual temperature creeps that signal a failing compressor or a worn-out door gasket before a catastrophic failure occurs.

Your routine should absolutely include checks at key moments: first thing in the morning, right before the lunch or dinner rush, and at closing.

Modern wireless monitoring systems can take this a giant step further. They provide 24/7 data and can shoot an alert straight to your phone if a temperature ever wanders out of the safe zone. This kind of tech can save you thousands of dollars in spoiled product by catching a problem the second it starts.

Getting the Most Out of Your Prep Tables: Temperature & Efficiency

Refrigerated prep tables are the workhorses of any high-volume kitchen. But getting them to hold the right temperature consistently isn't just a "set it and forget it" task. To truly optimize these units for both food safety and energy efficiency, you need a combination of smart daily practices and routine maintenance. When you get it right, that simple piece of equipment becomes a true cornerstone of your kitchen's success.

Think of the cold air inside your prep table like a river. If you block its path with overstuffed food pans, you create stagnant pools where the temperature can creep up into the danger zone. Proper food pan arrangement is a game-changer. Avoid piling ingredients high and always leave small gaps between the pans. This simple step allows cold air to circulate freely and evenly, keeping everything at a safe, consistent temperature.

This is especially critical for specialized units like sandwich prep tables and pizza prep tables, which are built for specific workflows. Many of the best models feature 'cold wall' technology, where refrigerant lines are embedded right into the walls surrounding the food wells. This design creates a constant blanket of cold, but it only works if you do your part—keep those lids closed whenever you're not actively pulling ingredients.

Maximizing Performance and Slashing Waste

Consistent maintenance is the real secret to a long, efficient life for any refrigerated prep table. A few simple habits can prevent expensive breakdowns and keep your utility bills from spiraling out of control.

- Clean Condenser Coils Regularly: The condenser coils, usually at the back or bottom of the unit, are what dissipate heat. When they get caked with dust and grease, the compressor has to work overtime, wasting energy and putting the whole system at risk of failure. A quick brushing once a month can make a massive difference.

- Inspect and Clean Door Gaskets: Those rubber seals around the doors and lids are your first line of defense, keeping cold air in and warm kitchen air out. If they're cracked, torn, or dirty, you're literally paying to cool your kitchen. Wipe them down daily and check to make sure they're creating a tight seal.

- Don't Block Air Vents: Internal fans are what move the cold air around. If you block the vents with storage boxes or oversized containers, you'll create warm spots and force the unit to run constantly to catch up.

How Precise Temperatures Impact Your Bottom Line

Keeping your prep tables at the correct temperature is about more than just food safety—it's about protecting your profits. The whole history of refrigeration started with preventing disease, but today, it's a major driver of economic efficiency. Early designs aimed for around 32°F (0°C), and modern technology has refined this to a science. Consider this: a tiny 1°C increase in temperature can allow bacteria to double every 20 minutes. For a busy sandwich shop, that could easily lead to $5,000 a year in spoiled ingredients alone. You can learn more about the evolution of refrigeration temperatures and see how it shapes modern food service.

Investing in a high-quality prep table pays for itself over time. Features like thicker insulation and powerful, efficient compressors don't just hold temperatures more reliably—they also cut down on daily energy use, which directly lowers your operating costs.

Properly maintained commercial refrigerated prep tables are a non-negotiable asset for any serious kitchen. By combining smart daily habits with a consistent maintenance schedule, you can ensure your ingredients stay fresh, your team works efficiently, and your business stays both profitable and compliant.

Troubleshooting Common Temperature Problems

Even the most bulletproof commercial refrigeration units can have an off day. When you notice the temperature display slowly creeping into the danger zone or see frost forming in weird places, that’s your unit telling you something’s wrong.

Catching these signs early is crucial. A quick fix can be the difference between a minor adjustment and a dumpster full of spoiled inventory—not to mention avoiding a catastrophic equipment failure down the road.

Often, the cause is something surprisingly simple, like a blocked air vent or a tired-out door gasket. But sometimes, it points to a deeper mechanical issue that needs a pro. The key is knowing how to read the signs and connect them to the right cause.

Diagnosing Common Temperature Issues

Before you pick up the phone to call a technician, a little detective work can often solve the problem right then and there. Most temperature headaches trace back to a handful of usual suspects. It can also be helpful to understand the basic principles behind any cooling system. For a different perspective, reading about troubleshooting a cooling system that isn't performing as expected offers some great parallels for diagnosing refrigeration issues, even though it's focused on HVAC.

To help you get straight to the root of the issue, we've put together a quick guide for the most common problems you'll run into.

Troubleshooting Common Refrigeration Temperature Issues

This table is your go-to guide for diagnosing and fixing the frequent hiccups that can throw off your commercial refrigerator and freezer temperatures, helping you stay on top of food safety.

| Symptom | Potential Cause | Solution |

|---|---|---|

| Unit is too warm | Blocked air vents, dirty condenser coils, or a worn-out door gasket letting warm air in. | Check that nothing is blocking internal vents, clean the coils, and inspect the gasket for a tight seal. |

| Excessive frost buildup | The door is being left open too long, or the door gasket is failing, allowing moist air to enter. | Minimize door opening times and replace any cracked or hardened gaskets immediately. |

| Temperature fluctuates | The unit is overloaded, or items are placed too close to the thermostat, giving it false readings. | Avoid overpacking shelves to allow for proper airflow and keep items away from the thermostat sensor. |

| Compressor runs constantly | Dirty condenser coils, a faulty gasket, or the unit is set to an unnecessarily low temperature. | Clean the coils, check the door seal, and make sure the thermostat is set to the recommended range. |

By keeping an eye out for these symptoms and knowing the likely culprits, you can handle most temperature issues quickly and efficiently, keeping your equipment running smoothly and your food safe.

Frequently Asked Questions About Refrigerator And Freezer Temperatures

Even when you've got your temperature logs down pat, questions are bound to pop up in the heat of a busy kitchen. Here are some quick answers to the common things we hear from professionals about keeping their refrigerators and freezers at the right temp.

How Long Can a Commercial Refrigerator Door Stay Open?

There's no magic number, but the goal is always to keep the door shut as much as possible. A solid rule of thumb is to aim for less than 30 seconds each time you open it. Every second the door is open, the compressor has to kick into overdrive to cool things back down, which burns energy and puts your food at risk.

What Is the Food Temperature Danger Zone?

The "danger zone" is the temperature range between 41°F and 135°F (5°C and 57°C). This is the sweet spot where bacteria just love to multiply, and they do it fast. Keeping your cold food stored below 41°F isn't just a suggestion—it's one of the most critical rules in food safety.

If you're looking for ways to extend shelf life beyond just temperature control, you might also look into methods like Modified Atmosphere Packaging (MAP). You can learn more about this technology with tools like the Oxybaby MAP Tester for food preservation.

Can You Use a Residential Refrigerator Commercially?

Putting a home refrigerator in a professional kitchen is a bad idea, and in most places, it's a health code violation. Your fridge from home just doesn't have the muscle. It lacks the powerful compressor, heavy-duty insulation, and quick temperature recovery needed for a commercial environment with constant door openings and high heat.

Think of a commercial-grade unit as an investment in food safety and compliance. It’s built to take a punch—recovering its temperature in seconds during a busy dinner rush. A residential model would simply fail, putting your entire inventory on the line.

How Often Should You Calibrate Kitchen Thermometers?

You need to trust your thermometers, so regular calibration is a must. A good best practice is to calibrate them at least once a week, and always after they've been dropped. The ice point method is the easiest way: just stick the probe in a cup of ice water and make sure it reads 32°F (0°C). If not, adjust it.

At PrepTables.com, we provide the durable, NSF-certified refrigeration and prep equipment you need to maintain precise temperatures and keep your kitchen running safely and efficiently. Explore our full range of commercial-grade solutions today at https://preptables.com.