Choosing a Stainless Steel Lab Table

Share

Walk into any serious lab, commercial kitchen, or medical facility, and you'll see one thing in common: stainless steel. A stainless steel lab table isn't just a piece of furniture; it's the industry standard for any environment where cleanliness and durability are non-negotiable. Its non-porous surface is a fortress against bacterial growth, making it an essential tool for high-demand, sterile work.

Why Stainless Steel Is the Standard for Clean Workspaces

When you're setting up a professional workspace, picking the right surfaces is far more than an aesthetic choice. It's a foundational investment in safety, efficiency, and compliance. So, what makes stainless steel the undisputed champion for environments where sanitation is everything?

The secret is in its DNA. Stainless steel is an alloy, a mix of iron, chromium, and often nickel. This blend creates a passive, non-reactive layer on the surface—an invisible shield that delivers two massive benefits:

- Exceptional Corrosion Resistance: This layer protects the table from rust, chemical spills, and the harsh cleaning agents that would eat away at lesser materials.

- Hygienic Surface: The material is completely non-porous. That means there are no microscopic nooks or crannies for bacteria, mold, or other pathogens to hide and multiply.

Durability Meets Practicality

Beyond being sterile, stainless steel is just plain tough. It handles high impacts, heavy loads, and extreme temperatures without warping or cracking. You can set a hot beaker or a heavy centrifuge right on it without a second thought. This blend of brawn and cleanability is exactly why it's the go-to in demanding settings.

As labs and kitchens lean more into modular and ergonomic setups, steel's role has only grown. The global laboratory furniture market, where stainless steel tables are a cornerstone, was valued at around USD 2.1 billion in 2023 and is still climbing. This trend underscores the industry's deep reliance on materials that are not only durable but also easy to clean and maintain under rigorous conditions. You can discover more insights about laboratory furniture market trends and see just how central stainless steel has become.

At the end of the day, a stainless steel table isn't just furniture. It's a foundational tool that supports reliable, repeatable, and safe work, day in and day out.

Understanding these core advantages is the first step. Now, let’s dig into how different grades and thicknesses of steel affect performance so you can pick the perfect table for your specific needs.

Understanding Stainless Steel Grades And Gauges

The real muscle and longevity of a stainless steel lab table come down to the specific material it’s made from. Not all stainless steel is created equal, and knowing the difference between grades and gauges is absolutely essential for making a smart investment that actually fits your work environment.

At its heart, stainless steel is the go-to material in professional settings for a reason: it's tough, hygienic, and incredibly resistant to corrosion. It’s so vital that the global stainless steel market was valued at USD 163.7 billion in 2024 and is expected to keep growing, a testament to its critical role everywhere from healthcare to food service.

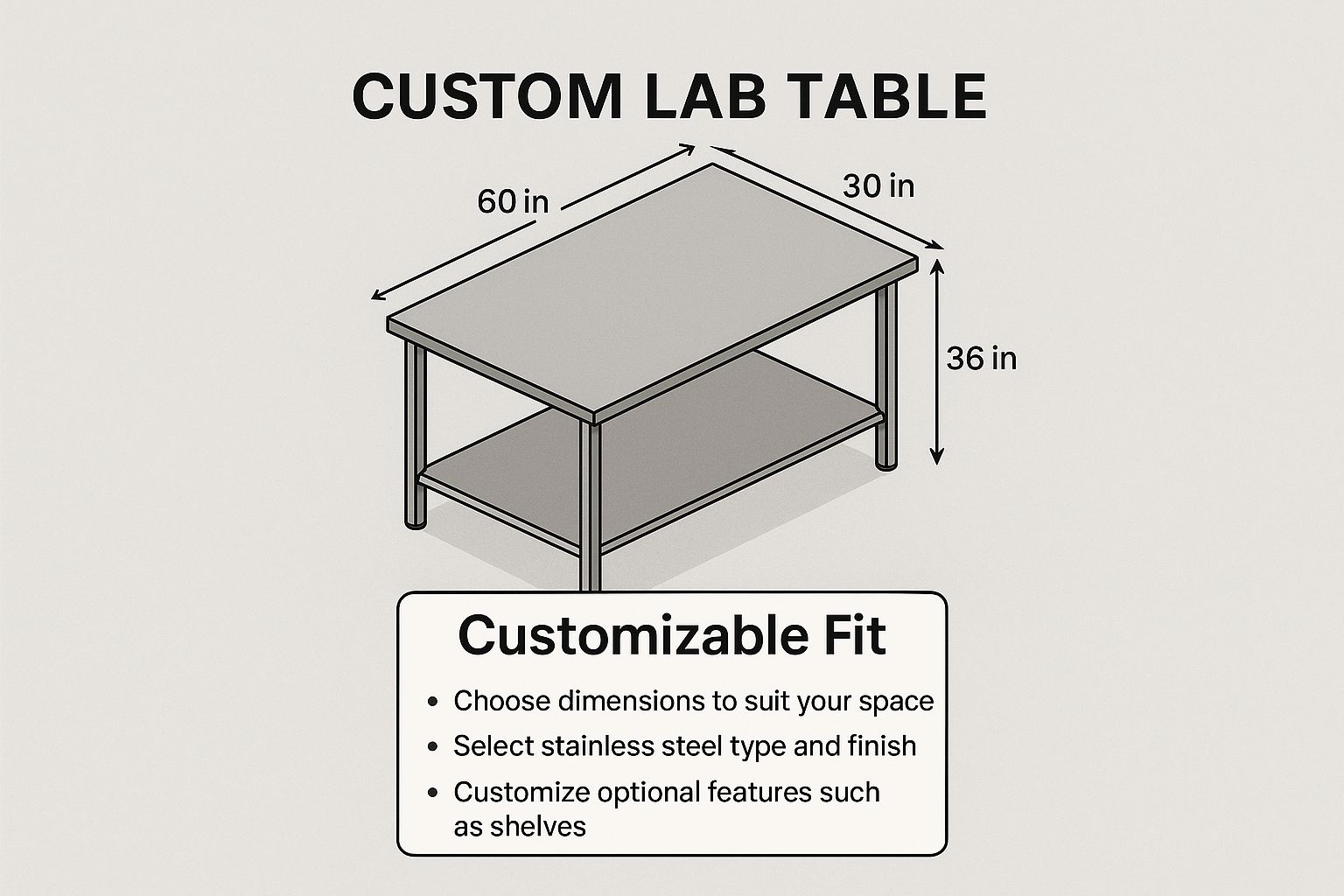

This blueprint gives you an idea of how a stainless steel table can be designed for a specific space.

What the image really drives home is that beyond just the material, getting the dimensions right is what creates a truly efficient, custom-fit workspace.

Decoding Steel Grades 304 vs 430

The "grade" of stainless steel tells you about its chemical makeup and, by extension, its performance. For most lab and prep tables, you'll be choosing between two main options:

-

304 Grade: You'll often hear this called "food-grade" steel, and it's the top choice for almost any lab or kitchen. It has more chromium and nickel, creating a powerful shield against rust and corrosion. If your table will ever see moisture, chemicals, or acidic substances, 304 grade is the reliable standard.

-

430 Grade: This is your more budget-conscious, magnetic alternative. It still holds up well against corrosion, but its lower nickel content makes it a bit more vulnerable in wet environments or around harsh chemicals. It’s a solid pick for dry storage areas, packaging stations, or any light-duty work where moisture isn't a daily concern.

If you want to get even more granular on material specs, check out our guide on commercial stainless steel tables.

Making Sense Of Steel Gauge

"Gauge" is simply the thickness of the steel. The key thing to remember is that it works on an inverse scale—the lower the gauge number, the thicker and stronger the steel.

Think of it like this: a 14-gauge table is a heavyweight champion, built to withstand heavy equipment and high-impact work. An 18-gauge table is more of a middleweight contender, perfect for general prep and lighter tasks.

Choosing the right gauge is all about balancing what you need it for with what you want to spend.

-

14-Gauge: This is the heavy-duty option. It’s built for industrial labs, butcher shops, or any place where you’re mounting hefty equipment or doing intense physical work. You’re paying for maximum durability here.

-

16-Gauge: A great all-around choice, 16-gauge offers a fantastic mix of strength and cost. It's the workhorse you see in many kitchens for general food prep, standard lab work, and assembly lines.

-

18-Gauge: As the most common and economical option, 18-gauge steel is more than enough for light-duty prep, simple lab tasks, and general utility work. You still get all the hygienic benefits of stainless steel for everyday applications.

This table provides a quick reference to help you decide.

Stainless Steel Grade and Gauge Selection Guide

This quick comparison will help you choose the right stainless steel grade and gauge based on your specific application and environmental conditions.

| Specification | Grade 304 | Grade 430 | 14-Gauge | 18-Gauge |

|---|---|---|---|---|

| Best For | Wet/corrosive environments | Dry, low-moisture areas | Heavy-duty, high-impact work | General purpose, light-duty tasks |

| Corrosion Resistance | Excellent | Good | N/A (depends on grade) | N/A (depends on grade) |

| Cost | Higher | Lower | Highest | Lowest |

| Durability | High | Moderate | Maximum | Standard |

| Common Use Cases | Food prep, chemical labs | Dry storage, packaging | Butcher blocks, equipment stands | Prep stations, utility tables |

Ultimately, matching the grade and gauge to your daily tasks ensures you get a table that performs well and lasts for years to come.

Finding the Right Table Type for Your Workflow

A simple, flat-top bench is a workhorse, but it’s really just the starting point. When you start looking at stainless steel tables, you’ll find a whole world of configurations designed to streamline your work. Picking the right setup is about optimizing your entire process, whether you're in a high-tech lab or a busy commercial kitchen. The right table becomes an active part of your workflow, cutting down on clutter and making everyone more efficient. Let's break down the most common variations.

Core Configurations for Labs and Kitchens

The most popular modifications are all about adding storage, protection, or mobility. These might seem like small tweaks, but they can make a huge difference in your day-to-day operations by keeping your space organized and flexible.

-

Tables with Backsplashes: An integrated backsplash is a simple feature with a massive payoff. That small raised edge at the back stops liquids, ingredients, and small items from falling behind the table. It protects your walls and makes cleanup infinitely faster.

-

Tables with Undershelves: Storage is almost always in short supply. A stainless steel table with an undershelf literally doubles your storage capacity without taking up any more floor space. It’s the perfect spot for stashing bulk supplies, equipment, or containers, keeping your main work surface clear for the task at hand.

-

Mobile Tables on Casters: In any dynamic environment, flexibility is everything. A table on casters (wheels) can be moved around effortlessly. You can reconfigure the room, transport materials, or just roll it out of the way for a deep clean. If your lab or kitchen layout needs to adapt, a mobile table is a must-have.

Think of these features as practical solutions to common problems. A backsplash solves cleanup headaches, an undershelf beats back the clutter, and casters give you the freedom to change your setup whenever you need to.

Specialized Tables for Food Preparation

While labs benefit from core designs, the food service world has engineered highly specialized stainless steel prep tables. These units often integrate refrigeration to streamline specific culinary tasks, boosting efficiency and ensuring food safety.

Sandwich Prep Tables

A sandwich prep table is a game-changer for delis, cafés, and quick-service restaurants. This all-in-one station combines a cutting board work surface with a refrigerated base below. The defining feature is the refrigerated "cold rail" on top, which holds pans of ingredients like meats, cheeses, and vegetables at a safe temperature. This design allows a chef to assemble orders in one spot, maximizing speed and consistency during busy periods.

Pizza Prep Tables

Similarly, a pizza prep table is built specifically for pizzerias. These tables feature a wide, often marble or refrigerated steel top, ideal for stretching dough. Above the work surface is a raised, refrigerated rail that keeps toppings like sauce, cheese, and pepperoni within easy reach. The integrated design minimizes movement in a hot kitchen and ensures every ingredient remains fresh and compliant with food safety standards. For any high-volume pizzeria, this specialized table is an essential tool.

Key Features That Impact Safety and Performance

Once you've zeroed in on the right type of stainless steel lab table, it's time to sweat the small stuff. These are the details that really separate a decent table from a great one—the features that directly affect its safety, stability, and how it performs day in and day out. Trust me, skipping over these can lead to a lot of headaches later.

NSF Certification: More Than Just a Sticker

One of the most critical things to look for is NSF certification. This isn't just a fancy label; it’s your guarantee that the table meets tough public health and safety standards.

An NSF-certified table is built for sanitation. We're talking smooth, crevice-free welds and surfaces that are a breeze to clean and sanitize, which is crucial for preventing bacterial growth. In any food service or sterile lab environment, this certification is absolutely non-negotiable. If you want to dive deeper, you can learn more about what NSF certification means and why it's so important. For any work involving food, medicine, or sterile processes, that NSF mark is your peace of mind.

Construction and Stability

How a table is put together has a massive impact on its stability over the long haul. You’ll generally find two types of construction, and each has its own clear pros and cons.

-

Welded Construction: These are the tanks of the lab world. They arrive fully assembled with the legs welded directly to the top, creating a super-rigid unit that can handle serious weight without a hint of wobble. The catch? They're bulky and a pain to move, especially into tight corners or up stairs.

-

Knock-Down (Bolt-On) Construction: These tables show up in a box and you put them together. They are way easier to transport and get into place, but the bolted connections can loosen up over time and will need a good tightening now and then. They're a solid choice if you need portability or are looking to save a bit, but they just don't offer the same rock-solid feel as a welded table.

Think about where you'll be using it. For a permanent, heavy-duty station holding sensitive equipment, a welded table is the way to go. But for a more flexible setup or a lab with tricky access, a knock-down table makes a lot more sense.

The focus on hygiene and safety has only intensified in recent years, especially after COVID-19. This has driven up demand for furniture that’s not just tough, but also easy to keep sterile. In 2021, the global laboratory furniture market was valued at a whopping USD 930.6 million, and you can bet stainless steel tables were a huge piece of that pie.

Practical Features for Daily Use

Beyond the big-ticket items like certification and construction, a few smaller features make a huge difference in day-to-day use and safety.

Adjustable Feet: Let's be honest, floors are almost never perfectly level. Adjustable bullet feet are a must-have. They let you level the table by twisting each foot, getting rid of that dangerous wobble that could ruin an experiment or cause a spill.

Bullnose Edges: Look for tables with rounded, smooth edges, often called "bullnose" or "safety" edges. Sharp, square corners are a recipe for disaster in a busy lab—they’re notorious for snagging clothes and causing injuries.

Load Capacity: Always, always check the manufacturer's specified load capacity. This number tells you the maximum weight the table can safely hold. Don't just think about your main piece of equipment; add up the weight of everything you might pile on top. A table rated for 500 lbs might seem like enough, but it could be totally inadequate for a heavy centrifuge or industrial mixer.

How to Care for Your Stainless Steel Table

Getting a stainless steel lab table is a real investment. But that legendary durability isn't just automatic—it comes from proper, consistent care. That’s what ensures it'll last for decades, keeping its professional look and hygienic, non-porous surface.

The most important thing to remember is what stainless steel loves and what it hates. The metal gets its strength from a passive oxide layer on its surface, which is what protects it from rust. Your whole goal is pretty simple: protect that layer at all costs.

Daily Cleaning and Maintenance

When it comes to daily cleaning, less is definitely more. All you really need is a soft microfiber cloth, some warm water, and a mild, pH-neutral detergent. This gentle approach is more than enough to handle most of the daily grime without damaging the table's protective layer.

Here's a pro tip: always wipe in the direction of the grain—you'll see those faint lines on the surface. Wiping with the grain helps prevent those tiny, almost invisible micro-scratches that can make the finish look dull over time. After you wash it, dry the surface right away with a clean, lint-free cloth. This stops water spots and mineral buildup, which can be a real pain to remove later.

It’s a common myth that you need harsh chemicals for a truly clean surface. In reality, the most damaging mistake you can make is reaching for chlorine-based cleaners like bleach. Chlorine aggressively attacks the steel's protective layer, leading to ugly and irreversible pitting and corrosion.

Tackling Tough Stains and Protecting the Surface

In a busy lab or kitchen, you're bound to run into tougher messes—fingerprints, chemical residue, or dried-on spills. For those situations, you need something a bit stronger, but still safe. A non-abrasive stainless steel cleaner can work wonders on stubborn spots without scratching up the surface.

To keep your table looking its best and head off any future problems, stick to these best practices:

- Avoid Abrasives: Whatever you do, don't use steel wool, scouring pads, or abrasive powders. These tools can actually embed tiny iron particles into the surface, which will eventually rust and completely ruin the finish.

- Neutralize Spills Quickly: If a chemical spill happens, rinse the area immediately with deionized water. For acids or bases, make sure you follow your lab’s specific safety protocol for neutralization.

- Use Protective Barriers: Prevent scratches from heavy equipment by placing rubber or silicone mats underneath. And for any cutting tasks, using a dedicated cutting board is non-negotiable to protect the surface below.

For a deeper dive into cleaning agents and specific techniques, you can learn more about how to clean stainless steel in our comprehensive guide. Following these simple steps will make sure your stainless steel lab table remains a functional and professional centerpiece of your workspace for years to come.

Common Questions About Stainless Steel Lab Tables

When you’re about to invest in a stainless steel table, a few final questions always seem to pop up. Getting those answered clearly is the last step to making sure you're getting a table that works for you right now and holds up for years to come.

Let's walk through the most common queries so you can wrap up your decision with total confidence.

Can I Put Hot Items Directly on the Surface?

You sure can. One of the best things about stainless steel is its incredible heat tolerance. Go ahead and place hot pans, lab beakers, or equipment straight out of the autoclave directly on the surface. You won’t have to worry about scorching, melting, or leaving a mark.

Is it indestructible? Not quite. If you were to apply extremely high, prolonged heat to a very thin gauge of steel, you might see some minor warping over many years. But for the day-to-day hustle of a busy lab or kitchen, it’s just not a practical concern. This durability is exactly why it’s the go-to for high-temperature work.

Is NSF Certification Really Necessary?

If your table is going anywhere near food prep, medical tasks, or any kind of sterile lab environment, then yes, NSF certification is non-negotiable. Health codes often mandate it, and it's your guarantee that the table is designed for easy, complete sanitation—which is everything when it comes to preventing contamination.

Now, if you’re just using it for general industrial work or dry storage where hygiene isn’t the top priority, you might not be required to have it. Even so, that NSF seal is a powerful signal of a high-quality, professionally built piece of equipment.

How Do I Prevent Scratches on My New Table?

Stainless steel is tough as nails, but it's not completely scratch-proof. A little preventative care goes a long way in keeping that finish looking smooth. The golden rule is to never drag heavy equipment with rough bottoms across the surface. And in a kitchen, using a cutting board is an absolute must—no exceptions.

For lab work, think about placing a protective rubber or silicone mat down in your high-use areas. If you do get a few minor scratches (it happens!), they can often be buffed out with a non-abrasive stainless steel polish. But honestly, preventing them in the first place is always the winning strategy.

The most crucial takeaway is understanding the material's limits. While tough, stainless steel's longevity relies on proper use—avoiding abrasive pads, harsh chemicals like bleach, and direct cutting on the surface will keep it pristine for years.

What Is the Real Difference Between 304 and 430 Grade Steel?

It really all boils down to corrosion resistance. Grade 304 stainless steel is made with a good amount of nickel, which gives it fantastic protection against rust and corrosion. This makes it the clear winner for wet environments or places where it’ll be exposed to chemicals or acidic foods.

Grade 430 steel, on the other hand, doesn't have that nickel content. It’s a more budget-friendly option, but it’s best saved for completely dry applications where moisture is never an issue. For pretty much any professional lab or kitchen, 304 is the smarter, more reliable long-term investment.

Ready to find the perfect stainless steel table for your workspace? Explore the extensive collection at PrepTables.com and discover durable, NSF-certified options designed for any professional environment. Find your ideal fit today at https://preptables.com.