Your Complete Guide to a Sink with Drainboard

Share

Think of a sink with a drainboard as more than just a place to wash things. It’s a complete, single-unit workstation that marries a sink basin with a built-in, sloped surface. This all-in-one design is a game-changer for hygiene and workflow, acting as the command center for washing, rinsing, and drying in any serious kitchen.

Why a Sink with a Drainboard is Your Kitchen's Unsung Hero

Picture a central hub that keeps water from making a mess of your counters, gives you a dedicated spot for prep or drying, and just makes the whole kitchen run smoother. That's what an integrated drainboard does. It’s not just a sink—it's a smart piece of equipment built for efficiency.

You can think of the drainboard as a built-in 'landing zone' that bridges the gap between washing, prepping, and drying. This guide will cover it all, from picking the right material to why NSF certification is a must-have, so you can choose a unit that truly becomes the workhorse of your kitchen.

The Power of Integrated Stainless Steel Prep Tables

A sink on its own is useful, but when you integrate it into a stainless steel prep table, you create a real productivity hub. This setup combines your washing and prep areas into a single, seamless surface, which drastically cuts down on how much your staff has to walk around. No more carrying wet ingredients across the kitchen floor—everything happens in one place, which is a huge win for both speed and safety.

These integrated tables come in a few different flavors:

- Standard Work Tables with Sinks: This is the most common version. You get a big, flat stainless steel surface with one or more sink basins built right in. It’s super flexible for general prep, whether you're chopping produce or portioning out meat.

- Tables with Undershelves: For extra storage, many tables come with one or two shelves underneath. This is perfect for keeping pots, pans, and containers close by, making things even more efficient.

- Mobile Prep Tables: Some tables are put on casters, so you can move them around and change your kitchen layout whenever you need to. That kind of adaptability is a lifesaver for caterers or kitchens that switch up their service style.

In a commercial kitchen, every saved step is money in the bank. A sink built into a prep table means staff aren't walking back and forth between washing and assembly stations. This slashes prep time and makes the entire operation more efficient.

Specialized Prep Stations: Sandwich and Pizza Tables

If your menu is highly specialized, a prep table designed for one specific purpose is the ultimate efficiency tool. These units are built from the ground up to support a particular type of food assembly, creating an all-in-one production line.

Here are two of the most popular variations:

- Sandwich Prep Tables: These units combine a work surface, a sink, and refrigerated compartments underneath to hold ingredients like meats, cheeses, and veggies. This all-in-one station lets a chef wash produce, assemble sandwiches, and grab chilled ingredients without taking a single step.

- Pizza Prep Tables: Similar to sandwich tables, these have refrigerated rails for toppings and a big, flat workspace for dough. The integrated sink is right there for handwashing or cleaning tools, which is crucial for food safety during a dinner rush.

These specialized units are the pinnacle of workflow optimization, evolving the simple sink-with-a-drainboard idea into a productivity powerhouse.

Boosting Kitchen Efficiency and Hygiene

A sink with an integrated drainboard is so much more than just a place to let dishes dry. Think of it as the central nervous system for your kitchen's wet work—a strategic tool that boosts both your workflow and your food safety standards. From washing produce to air-drying heavy pots, this single piece of equipment can completely change how your kitchen operates.

Let's break down the three biggest wins a drainboard setup brings to the table in any professional kitchen.

The first thing you'll notice is a huge leap in hygiene. We’ve all seen it: those annoying puddles of water that gather on countertops next to a busy sink. That standing water is a magnet for bacteria, creating a serious health risk right where you prepare food.

A drainboard stops this problem before it even starts. The sloped, grooved surface is designed for one job: to guide every last drop of water directly into the sink bowl. This keeps your counters dry, clean, and sanitary, which is a massive help in preventing cross-contamination.

Streamlining Your Kitchen Workflow

Beyond just keeping things clean, a drainboard creates a clear, logical path for work. It’s like having a mini assembly line built right into your sink area. You get a natural flow from dirty to clean, whether you’re prepping vegetables or washing down equipment.

This dedicated space prevents that familiar, chaotic pile-up of wet items around a standard sink. Instead of throwing a towel down on the counter or using a separate rack, you have a designated, self-draining zone ready to go.

A drainboard system establishes a clear landing and drying zone, cutting down on wasted steps. Your team can move from washing to rinsing to drying in a straight line, without any backtracking. This directly translates to faster prep times and a much more organized kitchen.

A well-placed sink is a cornerstone of kitchen design. To really get the most out of it, it helps in understanding the kitchen work triangle, which helps you place your sink, stove, and fridge in the most efficient layout.

Maximizing Your Counter Space

In any kitchen, whether it's a massive restaurant or a tiny food truck, counter space is gold. A sink with a drainboard is a fantastic space-saver because it rolls several functions into one unit.

It combines your sink basin, a wet prep area, and a drying rack into a single, seamless piece of equipment. This frees up precious counter real estate that would otherwise be eaten up by bulky drying racks or cutting boards you've set aside for messy tasks.

This isn't just about saving space; it's about reducing clutter and making the whole environment safer and more organized. In fact, this push for efficiency is a major trend in the commercial kitchen world. Integrated sinks with drainboards are driving demand as more buyers focus on hygiene and workflow. By 2025, the global stainless-steel sink market was valued at around USD 1,385.46 million, and sinks with drainboards were one of the fastest-growing categories. Buyers are actively looking for these kinds of smart, clutter-busting solutions for their kitchens. When you choose a sink with a drainboard, you’re not just buying equipment—you’re investing in a smarter, safer, and more productive kitchen.

Finding the Right Configuration for Your Workspace

Picking the right sink configuration is a bit like choreographing a dance in your kitchen. When it’s right, everything just flows. The perfect setup becomes a natural part of your workspace, gets rid of bottlenecks, and helps your team move faster and smarter. From compact single-drainboard units to sprawling prep tables, the best choice really comes down to your daily operations, your floor plan, and the specific jobs your kitchen crew tackles all day long.

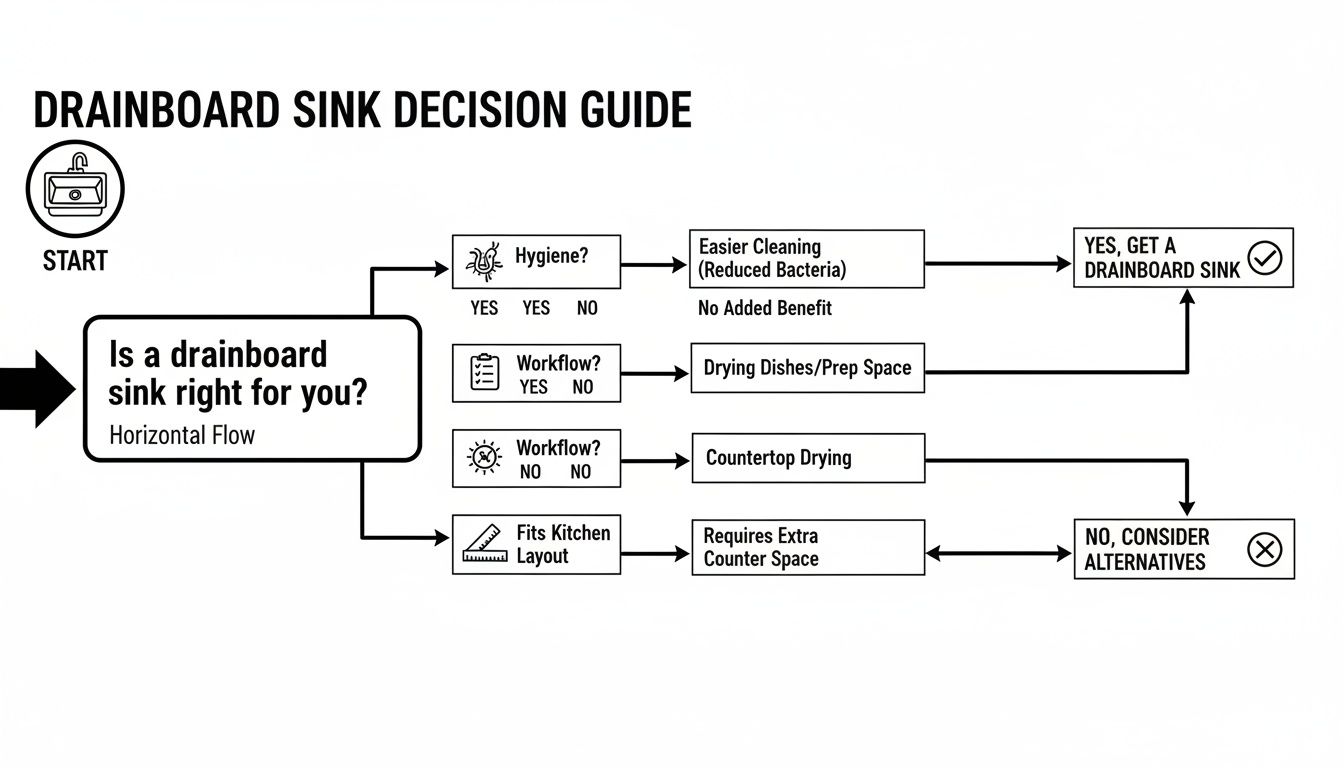

This quick decision tree can help you figure out if a sink with a drainboard is the right move for your kitchen based on what matters most.

The main takeaway here is pretty clear: if keeping things clean, moving efficiently, or making the most of your space are high on your list, an integrated drainboard sink is an option you should be looking at seriously.

To help you narrow down the options, this table breaks down the most common configurations and where they shine.

Comparing Sink and Drainboard Configurations

Use this table to find the ideal sink with drainboard configuration based on your kitchen's primary tasks, available space, and workflow.

| Configuration Type | Best For | Primary Advantage | Space Requirement |

|---|---|---|---|

| Single Drainboard | Small kitchens, linear dishwashing or prep workflows. | Defines a clear "dirty" to "clean" path without taking up too much room. | Compact to Medium |

| Double Drainboard | High-volume kitchens, multitasking, food prep and drying. | Creates a self-contained "wet zone" for multiple simultaneous tasks. | Medium to Large |

| Integrated Prep Table | All-purpose kitchens needing combined washing and prep space. | Merges tasks into one station, reducing movement and improving safety. | Medium to Large |

| Specialized Prep Station | Sandwich shops, pizzerias, or specific-menu restaurants. | Ultimate workflow optimization for a single, repetitive assembly line. | Varies, but usually large |

Each of these setups solves a different problem. The key is matching the configuration to the unique rhythm of your kitchen.

Single vs. Double Drainboard Sinks

Your first big decision is whether to go with a single or double drainboard. A single drainboard sink has one grooved surface, either on the left or right side of the basin. This is the go-to for kitchens with a clear, straight-line workflow. Say your dish pit moves from dirty drop-off on the left to clean drying on the right—a right-sided drainboard just makes sense.

On the flip side, a double drainboard sink, with surfaces flanking the basin, is built for the chaos of high-volume work where multiple things are happening at once. You can have pots and pans air-drying on one side while using the other as a landing spot for freshly rinsed vegetables. This setup gives you a complete, self-contained "wet zone," keeping water-related jobs in one spot and freeing up precious counter space somewhere else.

The choice between a left or right drainboard should come down to your team's dominant hand and the natural flow of your kitchen. Getting this right can cut down on awkward reaching and twisting, making the daily grind a lot more comfortable.

Unlocking Versatility with Integrated Prep Tables

A sink with a drainboard is useful on its own, but its real potential shines when it's integrated into a larger stainless steel prep table. This setup creates a complete, self-sufficient workstation, cutting down on wasted movement and boosting output in a fast-paced commercial kitchen.

These tables aren't one-size-fits-all; they’re designed for specific jobs. The most common configuration is a standard stainless steel work table with one or more sink bowls built right into the surface, giving you a seamless area for both wet and dry tasks.

But the true power move is opting for specialized prep tables built for high-volume, assembly-line work.

Specialized Tables for Peak Performance

Beyond the basic models, specialized prep tables with integrated sinks are designed for specific culinary roles. They turn a simple washing area into a full-blown production line.

Picture a busy sandwich shop. A sandwich prep table brings together a cutting board, a small sink for quick rinses, and refrigerated compartments right below. All the ingredients—meats, cheeses, veggies—are kept at a safe temperature just inches away. An employee can build an entire order without ever leaving their station.

Likewise, a pizza prep table is basically a command center for a pizzaiolo. It has a large surface (often marble or steel) for stretching dough, refrigerated rails for toppings, and an integrated sink. This design keeps the workflow tight, ensuring pizzas are built and fired off with maximum speed—a must-have during a dinner rush. These specialized tables aren't just equipment; they're purpose-built systems designed to make every single movement count.

Decoding Stainless Steel Gauges and Grades

When you pick out a sink with drainboard, you're doing more than just buying a basin and a slanted surface. You're choosing the very material that will face down constant water, harsh cleaning chemicals, and the daily beating of a busy kitchen.

Not all stainless steel is the same, and getting a handle on the difference between grades and gauges is the secret to making a smart purchase that lasts. These aren't just technical terms; they're the real measure of a sink's toughness and long-term value.

The Importance of Steel Grade

Think of the stainless steel grade as its recipe. The specific ingredients in that recipe determine how well it fights off rust and corrosion. For any place that handles food, 304-grade stainless steel is the absolute king. It’s made with both chromium and nickel, creating a powerful shield against rust from water, acidic foods like tomatoes, and all those cleaning agents you use.

Choosing the right grade is a make-or-break decision for the life of your sink. You might see other grades out there, like 430 stainless steel, but they're missing the key ingredient—nickel—that makes 304-grade so tough in wet environments. A 430-grade sink might look like a deal upfront, but it’s far more likely to develop ugly rust spots over time, making it a poor choice for a sink that's always working.

For a sink, 304-grade isn't just a good idea; it's the professional standard. It ensures your investment won't buckle under the pressure of a commercial kitchen, protecting both your equipment and your hygiene standards.

Understanding Stainless Steel Gauge

If the grade is the recipe, then the gauge is how thick the steel is. It’s a simple idea with a rule that feels a bit backward at first: the lower the gauge number, the thicker and stronger the steel. This thickness is directly tied to how well the sink can shrug off dents, dings, and the rattling from heavy pots or a rumbling garbage disposal.

Here’s a quick look at the gauges you’ll see for commercial sinks:

- 16-Gauge: This is the heavyweight champion. It's incredibly thick, super durable, and perfect for the most intense kitchens where heavy pots and equipment are constantly being dropped in. It also does a better job of deadening sound and resisting dents from those inevitable bumps.

- 18-Gauge: This is the go-to choice for a huge range of commercial kitchens. It strikes that perfect balance between being tough enough for daily abuse and being a bit more budget-friendly. It’s a reliable workhorse that won’t let you down.

You might see thinner gauges like 20 or 22, but frankly, they're too flimsy for a real commercial setting. They belong in a home kitchen, not a professional one. For a deeper dive into how different steel types compare, check out our complete guide on understanding stainless steel grades.

By insisting on a sink made from 16 or 18-gauge 304-grade stainless steel, you’re getting a piece of equipment built to perform, not just to look good. It's an investment in durability that pays you back over years of reliable service, standing strong against the kind of wear and tear that would wreck a lesser sink in months. When you look past the price tag and focus on these critical specs, you give yourself the power to choose a sink that will truly be a long-lasting asset for your operation.

Installation, Plumbing, and Must-Have Accessories

You've picked out the perfect sink with drainboard. That's a huge step, but the job isn't done until it's properly installed and kitted out. Think of this part as building the support system for your kitchen's new workhorse. Getting the installation, plumbing, and accessories right doesn’t just make the sink work—it unlocks its full potential.

Whether you go with a freestanding model for placement flexibility or a drop-in style for a seamless look, how you install your sink makes a massive difference in day-to-day use.

Choosing Your Installation Style

First things first: how will the sink fit into your workspace? Each mounting style has its own pros and cons, depending on your kitchen's layout and how you handle cleanup.

- Freestanding Sinks: These are the all-in-one champs. Standing on their own legs, they don’t need a countertop for support. This makes them incredibly versatile, easy to install, and a dream to clean around—a major win for maintaining strict hygiene.

- Wall-Mounted Sinks: By fixing the sink right to the wall, you keep the floor completely clear. Mopping and sweeping become effortless, which helps keep the whole area cleaner. It's a fantastic choice for tight spaces where you can't afford to have obstacles on the floor.

- Drop-In Sinks: Also known as top-mount sinks, these are designed to be lowered into a pre-cut hole in a countertop. The rim of the sink rests on the counter, making for a straightforward and stable installation that works with almost any countertop material.

Here's a pro tip that's easy to miss: make sure the drainboard has a slight, gentle slope toward the sink basin. This is absolutely critical. Without it, water will pool up or spill onto your counters, which completely defeats the purpose of having the drainboard in the first place.

Essential Plumbing Considerations

Good plumbing is the lifeblood of your sink station. If you get these details right from the start, you'll save yourself a ton of headaches from leaks, clogs, and nasty smells down the road. The two main things to focus on are the faucet and the drain.

For a dishwashing station, a high-pressure, commercial-grade pre-rinse sprayer is a total game-changer. It blasts away stubborn food scraps in seconds, seriously cutting down on cleaning time. If it's a prep sink, a gooseneck faucet is your best bet, giving you plenty of clearance to fill big stockpots.

The drain is just as important. A properly installed P-trap is non-negotiable. That little U-shaped pipe holds a bit of water that acts as a seal, stopping sewer gases from creeping into your kitchen. Also, make sure every connection is sealed tight with plumber's tape to prevent leaks. To get a closer look at all the pieces involved, check out our guide to the parts of a stainless steel sink drain.

Must-Have Accessories for Full Functionality

The right gear can turn a good sink into a great one. These add-ons are designed to solve common kitchen frustrations and make your workflow smoother.

Think about these essential upgrades:

- Tall Backsplashes: An integrated backsplash, usually 6-10 inches high, is your best defense against water splashing all over the walls. It prevents moisture damage and makes cleanup a breeze.

- Adjustable Legs: For freestanding sinks, adjustable bullet feet are a must. They let you level the sink perfectly on uneven floors, which guarantees stability and proper drainage. You can also set the sink at a comfortable height for your staff.

- Heavy-Duty Basket Strainers: Clogs are the enemy of any busy kitchen. A quality basket strainer catches all the food gunk before it goes down the drain, saving you from expensive plumbing bills. It's no surprise that market research estimates the sink drain market will hit roughly USD 5.0 billion by 2025—everyone needs reliable drainage.

Maintaining Your Sink for Peak Performance

Think of your stainless steel sink and drainboard as a long-term investment in your kitchen’s efficiency. These things are built like tanks, meant to handle years of relentless use. But like any good tool, a little regular upkeep is what keeps it performing at its best, ensuring it not only lasts but also blows past health and safety standards. It's less of a chore and more of a simple routine to protect its integrity and keep it looking professional.

A big part of this is understanding why things like NSF certification are so important. That seal isn’t just for show; it's a promise that the sink’s design and materials are non-porous, a breeze to clean, and fight off corrosion. This is your first line of defense against bacterial growth and a cornerstone of food safety.

Creating a Simple and Effective Cleaning Schedule

When it comes to fighting off grime, consistency is everything. A simple, regular maintenance plan will keep your sink looking brand new without eating up your valuable time.

Here’s a practical routine that works:

- Daily: At the end of every shift, just give the sink a good rinse with warm water and a mild detergent. Use a soft cloth or sponge and always wipe with the grain of the steel—this little trick helps you avoid tiny scratches. Rinse it all down and wipe it dry to prevent those annoying water spots.

- Weekly: Once a week, go a bit deeper. A dedicated stainless steel cleaner or even a simple paste made from baking soda and water works wonders for lifting stubborn residue or slight discoloration. Just like the daily clean, rinse and dry it completely when you're done.

- Monthly: Take a moment once a month to check on the behind-the-scenes stuff. Look over all the plumbing connections for any slow drips and make sure the basket strainers are free of any gunk.

Preventing Scratches, Rust, and Water Spots

Even the toughest 16-gauge steel needs a bit of help to stay looking sharp. The usual suspects—scratches, rust, and water spots—are actually pretty easy to prevent if you know what you're doing. For a full rundown on the best techniques, check out our guide on https://preptables.com/blogs/prep-tables/how-to-clean-stainless-steel.

Rule number one: stay away from abrasive stuff like steel wool or scouring pads. They'll leave permanent scratches on the surface. Also, keep harsh chemicals like bleach far away, as they can eat through the steel's protective layer and open the door for corrosion.

A pro-level technique for bringing back a sink's protective shield is called passivation. It sounds complex, but it's really just treating the steel with a mild acid (like citric acid) to get rid of any stray iron particles on the surface, which are usually what cause rust spots. Doing this periodically can seriously extend the life and shine of your sink.

Finally, don't let drain issues fester. A slow drain means standing water, which is a recipe for grime and bad smells. If a plunger isn't cutting it, you might need to call in the pros for hydro jetting services for stubborn clogs. Staying on top of both cleaning and plumbing will ensure your sink remains a hygienic, reliable workhorse for years to come.

Got Questions? We've Got Answers.

We've covered a lot of ground, but you might still have a few questions rolling around. Let's tackle some of the most common ones we hear from chefs and kitchen managers. Getting these last details ironed out will help you choose the right sink with complete confidence.

Can I Choose Which Side the Drainboard Is On?

Yes, you can. Most sinks come with options for a left-side, right-side, or even double drainboard setup. It all comes down to your kitchen's flow.

Think about your dishwashing station. You want a smooth path from the dirty dish drop-off to the drying rack. For food prep, you’ll probably want the drainboard right next to your main counter, creating an unbroken workspace.

What Is the Difference Between 304 and 430 Grade Stainless Steel?

The real difference comes down to durability and how well it stands up to rust. 304-grade stainless steel is the gold standard in commercial kitchens. It has nickel in it, which makes it incredibly resistant to corrosion from water, cleaning chemicals, and acidic foods.

Grade 430 is a more budget-friendly option without nickel. It’s less resistant to rust, making it better for dry equipment. For a sink that’s constantly wet, 304-grade is the only smart long-term investment.

Choosing 304-grade steel for your sink isn't just a preference—it's a professional requirement for food service environments. It ensures your equipment can withstand the daily rigors of a commercial kitchen while upholding critical hygiene standards. This choice protects your investment against premature rusting and damage.

How Do I Clean My Stainless Steel Sink to Meet Health Codes?

Keeping your sink up to code is all about a simple, consistent routine. For daily cleaning, just use a mild detergent, warm water, and a soft cloth. Always wipe along the grain of the steel to avoid tiny scratches. Once you're done, give it a good rinse and dry it completely to prevent water spots.

When it's time to sanitize, use a food-safe solution and follow the directions. Here's what's really important: never use abrasive pads like steel wool or harsh chemicals like bleach. These will strip away the steel's protective layer and open the door to rust and corrosion.

Ready to upgrade your kitchen with a durable, efficient, and NSF-certified sink with a drainboard? Explore the complete collection at PrepTables.com and find the perfect configuration to streamline your workflow today. Visit us at https://preptables.com to get started.