Your Complete Guide to Sandwich Refrigerated Prep Tables

Share

Think of a sandwich refrigerated prep table as the command center for any kitchen that values speed. It’s more than just a cold box with a counter; it’s a purpose-built workstation where organization, food safety, and efficiency all come together to slash assembly times. This single piece of gear keeps all your key ingredients chilled, organized, and literally at your fingertips.

Exploring Different Stainless Steel Prep Tables

From a local deli to a five-star restaurant, stainless steel tables are the unsung heroes of every commercial kitchen. They’re the durable, hygienic surfaces we rely on for everything. But when you build refrigeration directly into these workstations, they become specialized powerhouses that can totally transform your kitchen’s productivity and food safety. Getting to know the different types is the first real step in streamlining your kitchen’s flow.

These units aren't just refrigerators with a cutting board slapped on top. They are intelligently designed pieces of commercial kitchen equipment built for specific jobs. The whole idea is to cut down the number of steps a chef has to take between the walk-in and the assembly line, which is a lifesaver during a chaotic dinner rush.

To help you get a quick handle on what's out there, here’s a simple breakdown of the main types of refrigerated prep tables and what they do best.

Prep Table Types at a Glance

| Table Type | Primary Use | Key Feature | Ideal For |

|---|---|---|---|

| Sandwich/Salad Table | Assembling sandwiches, wraps, salads | Standard-depth cutting board, top pan rail | Delis, cafes, sandwich shops, fast-casual |

| Pizza Prep Table | Stretching dough, topping pizzas | Extra-deep cutting board, raised pan rail | Pizzerias, Italian restaurants, food trucks |

| Mega Top Table | Holding extra ingredients for complex items | Extra row of pans on top (more capacity) | High-volume salad bars, burrito/bowl concepts |

| Worktop Refrigerator | General prep, holding overflow ingredients | Solid, flat work surface (no pan rail) | Any kitchen needing extra cold storage + workspace |

This table gives you a starting point, but let's dive into the specifics of the most common models you'll encounter.

Sandwich and Salad Prep Tables

The classic sandwich refrigerated prep table is probably the one you see most often. It’s built with a refrigerated cabinet underneath for storing bulk items and a top section designed to hold rows of standard-sized food pans. These pans keep everything from sliced turkey and provolone to lettuce, tomatoes, and sauces perfectly chilled and right in front of the action.

A built-in cutting board, which usually runs the entire length of the unit, gives you an immediate workspace for lightning-fast assembly. This setup is the absolute gold standard for delis, cafes, and any spot that builds sandwiches, wraps, or salads to order. The whole design is engineered to create a smooth, linear workflow.

The real magic of this design is how it consolidates your workflow. By keeping ingredients chilled and ready in one spot, you can dramatically cut down prep times and deliver a more consistent product every single time.

Pizza Prep Tables

Pizza prep tables look similar at first glance, but they are engineered for a completely different menu. The most obvious difference is a much deeper cutting board, often 16 to 20 inches deep, which gives you plenty of room to stretch out dough and add toppings. That extra space is critical for handling large pizza skins without making a mess or feeling boxed in.

You'll also notice the pan rail on a pizza table is usually raised and angled toward the chef. This smart, ergonomic touch makes it way easier to grab handfuls of cheese, pepperoni, and other toppings on the fly. The refrigerated base is also set up differently, often designed to hold bulk dough boxes and large containers of sauce.

Comparing Different Commercial Prep Tables

Not all stainless steel prep tables are created equal. Choosing the right one is a lot like picking the perfect tool for a specific job in your kitchen. They all combine a refrigerated base with a workspace, sure, but their designs are tweaked for different menus, and that directly impacts your kitchen’s speed and efficiency.

Think of it this way: a standard sandwich prep table is like a sprinter, built for quick, linear tasks. A pizza prep table, on the other hand, is more of a marathon runner, kitted out for endurance and much larger, more complex creations. Getting this choice right from the start is a huge deal. Let's break down the key differences to help you find the perfect match for your operation.

The Classic Sandwich and Salad Prep Table

This is the workhorse of the industry. The sandwich refrigerated prep table is the backbone of countless delis, cafes, and fast-casual spots. Its design is a masterclass in efficiency, with a standard-depth cutting board running the length of the unit, sitting right next to a rail of chilled ingredient pans.

This setup creates a natural assembly line where everything—from sliced turkey and provolone to fresh lettuce and tomatoes—is right at your fingertips. It’s all about minimizing wasted movement, which lets your team build sandwiches, wraps, and salads with impressive speed. The refrigerated cabinet below gives you plenty of space for backup ingredients, so you can restock on the fly during a lunch rush without skipping a beat.

Mega Top Prep Tables for Maximum Variety

Take the classic sandwich table and give its ingredient capacity a serious upgrade. That’s a mega top prep table in a nutshell. These units are built for kitchens with massive menus or just plain crazy-high volume. What sets them apart is an extra third row of pans, which bumps up the number of available chilled ingredients by as much as 50%.

That extra real estate is a game-changer for businesses that thrive on customization, like build-your-own salad bars, burrito shops, or gourmet sandwich joints. By keeping more ingredients at the ready, mega tops cut down on how often you need to restock during peak hours, which keeps the line moving and your customers happy.

Pizza Prep Tables: A Category of Their Own

Sure, you could technically make a sandwich on a pizza prep table, but you’d be missing the whole point of its highly specialized design. These units are engineered from the ground up to handle the unique workflow of making pizza.

Here are the key things that make a pizza prep table different:

- Extra-Deep Work Surface: They have a much deeper cutting board, often 16 to 20 inches, giving you plenty of room to stretch dough and build large pizzas without making a mess.

- Raised Pan Rail: The ingredient rail is lifted and angled toward the chef. This smart, ergonomic design makes it way easier to grab handfuls of cheese, pepperoni, and other bulky toppings in a hurry.

- Specialized Refrigeration: The refrigerated base is usually set up to hold big dough boxes and bulk containers of sauce and cheese.

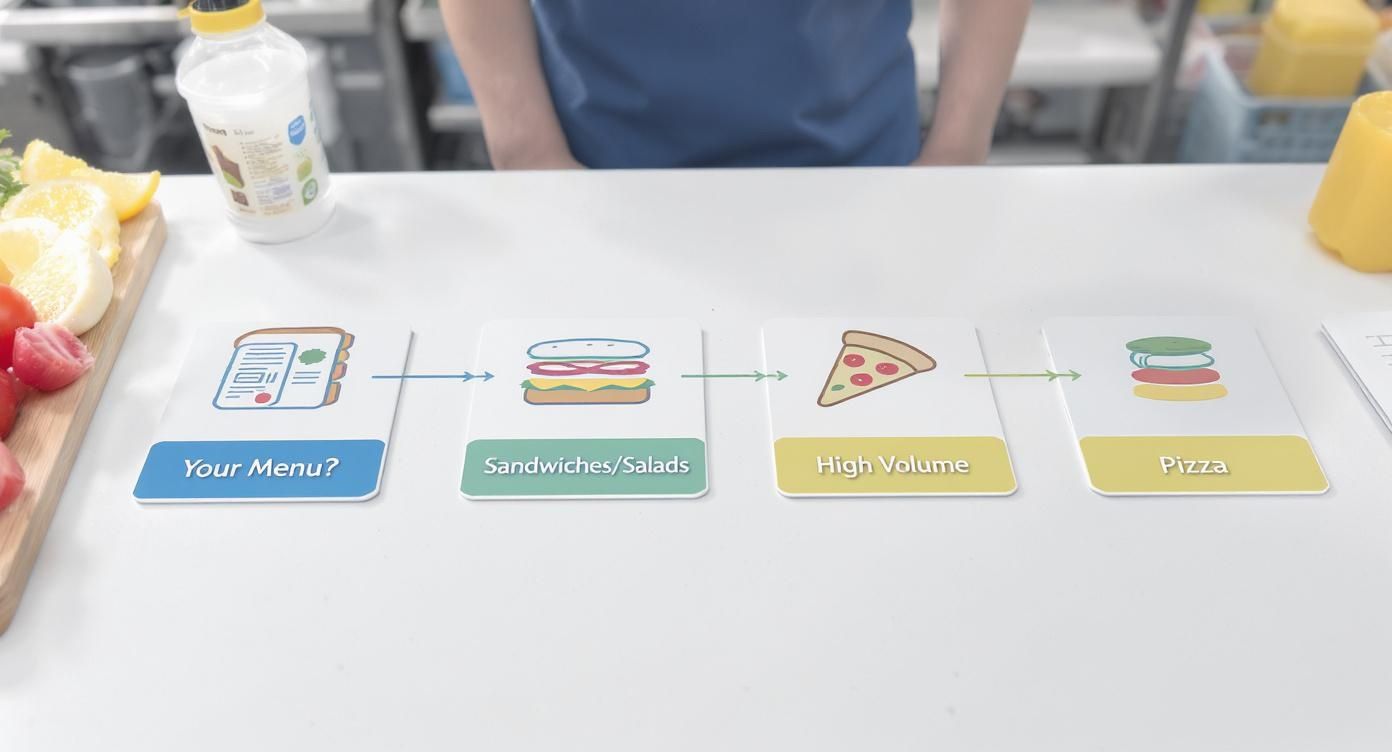

To help you picture which prep table fits your menu, this simple guide can point you in the right direction.

As the graphic shows, your menu—whether it's focused on sandwiches, pizza, or high-volume custom orders—should be the main thing driving your decision.

The global market for these tables is huge, with the sandwich prep table segment alone valued at around USD 1.2 billion. Standard sandwich tables make up about 45% of that, but mega tops are quickly gaining ground in high-volume kitchens. Pizza prep tables are also becoming more common, while medium-sized units account for roughly 48% of global sales, hitting that sweet spot between capacity and kitchen footprint.

Picking the right table is a foundational part of setting up any food service business. As you weigh the different types, it's helpful to see how they fit into a broader essential coffee shop equipment list to make sure you have all your bases covered. For a deeper look into the world of these essential units, check out our guide on commercial refrigerated prep tables.

Diving Into the Core Features That Drive Performance

Look past the shiny stainless steel, and you'll find what really makes a sandwich refrigerated prep table tick. The internal components are the true workhorses—they're what guarantee performance, keep your food safe, and ultimately, make your kitchen hum with efficiency. Getting to know these parts is like a mechanic understanding what’s under the hood of a high-performance car. It empowers you to pick a unit that won’t just get the job done, but will thrive during the busiest lunch rush.

Every detail, from the thermostat's accuracy to the cooling system's design, plays a crucial role. These features directly influence temperature consistency, how much you'll spend on electricity, and even where you can place the unit in your kitchen. Let's break down the essential tech that separates a decent prep table from a great one.

Temperature Control Systems

Rock-solid temperature control is the single most important job of any refrigerated prep table. The ability to hold a steady, food-safe temperature below 40°F (4°C) isn't just a nice feature—it's an absolute must for passing health inspections and serving quality ingredients.

Modern units generally come with one of two types of controls:

- Digital Thermostats: These give you an exact temperature reading on a bright LED screen, so you can set and watch the internal climate with surgical precision. This level of accuracy is key for meeting strict food safety rules and spotting any cooling problems early on.

- Dial Controls: You might see these on older or more basic models. Dial thermostats are simple and generally reliable, but they're more of an estimate. You lose the exactness of a digital system, making it tougher to confirm the precise temperature at a glance.

For nearly any commercial kitchen, a digital thermostat is the way to go. It offers better control and, more importantly, peace of mind.

The Compressor: The Lungs of Your Prep Table

Think of the compressor as the engine—or maybe the lungs—of your refrigeration system. It’s the powerhouse that circulates refrigerant to keep everything chilled. A huge factor in its performance is where it takes in air, or how it "breathes," which directly impacts where you can place the unit.

You'll run into two main designs:

- Front-Breathing Compressors: These units pull air in and push it out through a grille on the front. This design is a lifesaver in tight spaces because it lets you slide the table right up against a wall or between other appliances without starving the compressor for air.

- Rear-Breathing Compressors: As the name suggests, these models need a few inches of open space at the back and sides for proper airflow. They work just fine, but they're far less flexible and can be a headache to position in a crowded kitchen.

Given how precious floor space is in most kitchens, a front-breathing unit is almost always the smarter, more practical choice.

Insulation and Energy Efficiency

Good insulation is one of those invisible features that makes a huge difference to your prep table's performance—and your electric bill. It’s the barrier that keeps cold air in and the hot kitchen air out.

The best tables use high-density, foamed-in-place polyurethane insulation. This stuff is incredibly good at holding a stable internal temperature, meaning the compressor doesn’t have to kick on as often. A well-insulated unit doesn’t just save you money on energy; it also reduces wear and tear, helping the compressor last longer.

Optimizing Your Pan Rail System

The pan rail is mission control for your sandwich or salad line. It's the refrigerated, recessed top section that holds all of your ingredient pans. How you set this area up can make or break your speed and efficiency.

Most rails are built for standard-sized food pans, but the best configuration is the one that fits your menu. For instance:

- 1/6 Size Pans: This is a popular, all-around great choice. It lets you hold a solid variety of common ingredients like lettuce, tomatoes, and cheeses.

- 1/9 Size Pans: If your menu is heavy on different sauces, spreads, or small garnishes like olives and peppers, these smaller pans let you cram more options into the same amount of space.

By mixing and matching pan sizes, you can create a custom layout that puts your most-used items right at your fingertips. This simple step can transform your sandwich refrigerated prep table from a piece of equipment into a perfectly tuned workstation.

How to Choose the Right Size and Capacity

Picking the right sandwich prep table isn’t just about finding a spot for it in your kitchen. It’s about matching the equipment to the beat of your business. Go too small, and your team is scrambling to restock mid-rush, which absolutely kills your ticket times. Go too big, and you’ve just sunk cash and floor space into a stainless steel giant you don't really need.

Think of it like this: a small cafe pumping out a few dozen sandwiches a day needs a zippy scooter, not a semi-truck. In the same way, a high-volume cafeteria needs the industrial muscle of a massive unit to even stand a chance. The most important call you'll make is matching the table's size and capacity to what your kitchen actually does every day.

Compact Units for Small Spaces

Got a food truck, a tiny coffee shop, or a cozy cafe? You know that every single square inch counts. This is exactly where compact, undercounter prep tables come in to save the day. These smaller units, typically running from 27 to 36 inches wide, are built to pack a punch in a minimal footprint.

They offer a surprising amount of utility, giving you critical refrigerated storage and a prep surface without taking over your whole kitchen. An undercounter sandwich refrigerated prep table can slide right under an existing counter, creating an efficient, tidy workstation. While the internal capacity is on the smaller side, usually 6 to 10 cubic feet, it's plenty for operations with a focused menu or lower daily volume.

Mid-Sized Tables: The Industry Standard

For most operations—think busy delis, established cafes, and mid-sized restaurants—the sweet spot is in the 48-inch to 60-inch range. These tables are the versatile workhorses of the industry, striking a perfect balance between serious refrigerated storage and a generous prep surface. They're big enough for two people to work side-by-side without bumping elbows during a rush.

These units generally offer 12 to 18 cubic feet of cold storage, which is more than enough to hold all the backups you need for a full service. There's a reason this size is the industry standard: it can support a healthy menu and a steady stream of customers without the sprawling footprint of the bigger models. This is the go-to for any business that’s outgrown its starter setup and needs gear that can handle a real lunch or dinner service.

Stop. Before you even look at an "add to cart" button, find a tape measure. Don't just measure the spot where the table will live—measure every single doorway, hallway, and tight corner it has to squeeze through on delivery day. Five minutes now can save you a world of pain later.

Massive Models for High-Volume Kitchens

When your entire game is about volume—we're talking large cafeterias, university dining halls, or bustling ghost kitchens—you need equipment that can keep up with a relentless pace. This is the domain of the 72-inch and larger models, including the extra-deep mega tops.

These beasts are built for non-stop demand. They feature gigantic prep surfaces and cavernous refrigerated storage, often pushing past 20 cubic feet. A 72-inch or even a 93-inch table can easily fit multiple chefs, letting you set up a streamlined assembly line to crank out hundreds of orders. Their massive pan rails hold an incredible variety of ingredients, which means less time running to the walk-in and more time getting food out the door.

Why Materials and Build Quality Matter

A commercial kitchen is a battlefield. It’s a chaotic world of heat, steam, and constant motion. Your sandwich refrigerated prep table isn't just another piece of equipment; it's a workhorse that has to survive the daily grind without flinching.

Investing in a unit with solid build quality isn't about looks—it's about food safety, long-term reliability, and getting the best bang for your buck. Think of it like buying a car. You could get a basic model that gets you around, or you could get one with a stronger frame and more durable parts. The second one will handle rough roads, need fewer repairs, and last way longer. It’s the exact same logic for your kitchen gear.

The Critical Role of Stainless Steel

There’s a reason stainless steel is the undisputed king of commercial kitchen materials. It's tough, non-porous, and a breeze to sanitize. But here's the catch: not all stainless steel is created equal. Understanding the different grades is your ticket to choosing a table that will fight off rust and corrosion for years.

The two most common grades you’ll run into are:

- 304 Stainless Steel: This is the good stuff. It's the premium choice for the tops and interiors of high-quality prep tables. With more chromium and nickel in the mix, it has fantastic resistance to rust from salt, acidic foods, and harsh cleaning chemicals.

- 430 Stainless Steel: This is the more budget-friendly option, often used for the sides and back of a unit. It's still durable, but it’s more likely to corrode over time, especially if you’re in a humid climate or it gets exposed to the wrong stuff.

If you really want to get into the nitty-gritty, you can learn more about how stainless steel grades are explained in our detailed guide. For a long-lasting table, a 304-grade top and interior is a smart investment.

Understanding Steel Gauge

Another huge piece of the puzzle is the steel gauge. This is just a fancy term for the thickness of the steel. It's a little backward, but just remember this: a lower gauge number means thicker, stronger steel.

A prep table built with 16-gauge steel is a tank compared to one made from thinner 18-gauge or 20-gauge steel. A thicker gauge gives the unit better structural integrity, meaning it can handle the weight of heavy equipment and survive the inevitable bumps and dings of a busy kitchen without getting dented up.

The global push for better food safety is shaking up the commercial kitchen market. Valued at about USD 1.2 billion, the sandwich and salad prep table market keeps growing because these refrigerated units are simply better at keeping ingredients fresh and hygienic. This trend is driving more and more businesses to invest in certified, high-quality equipment. You can find more insights on this growing market on Verified Market Research.

The Non-Negotiable NSF Certification

If there's one sticker you should absolutely look for on any piece of kitchen equipment, it's the NSF certification. This little mark from NSF International is your proof that the unit has been put through the wringer and meets strict standards for public health and safety.

An NSF-certified sandwich refrigerated prep table is guaranteed to be:

- Easy to Clean: It's designed with smooth, rounded corners and seamless welds so food particles and germs have nowhere to hide.

- Made from Food-Safe Materials: The materials used won't leach nasty chemicals into your food. Simple as that.

- Built for Durability: It's engineered to take a beating in a commercial environment without falling apart.

At the end of the day, choosing a table with a quality build, the right steel, and an NSF certification isn't an expense. It's a foundational investment in your kitchen’s safety, efficiency, and future.

Keep Your Investment Running Smoothly With Proper Maintenance

Think of your sandwich refrigerated prep table as one of the most reliable workhorses in your kitchen. Just like any key player on your team, it needs a little care to perform at its best day in and day out. Good maintenance isn't just about wiping things down; it's a smart strategy to keep it running for years, avoid those dreaded emergency repair calls, and protect your investment.

A simple, consistent routine is all it takes. A well-maintained unit is more than just clean—it's more energy-efficient, keeps your ingredients safer, and ultimately costs you less to own over its lifespan. Let's walk through the easy tasks that make a huge difference.

A Simple Maintenance Playbook

The secret is consistency. When you break down tasks into daily, weekly, and monthly jobs, staying on top of maintenance feels easy instead of overwhelming. To keep everything running like clockwork and catch small problems before they become big ones, think about utilizing pre-start checklist templates to make it part of your daily opening routine.

Daily Tasks (Just 5-10 Minutes):

- Wipe Down Everything: Give all the stainless steel surfaces, door handles, and the cutting board a quick clean with a food-safe sanitizer.

- Catch Spills Fast: Don't let spills sit. Cleaning them up right away inside the refrigerated cabinet prevents sticky messes and keeps things sanitary.

- Check the Door Seals: A quick wipe of the rubber door gaskets ensures they're clean and creating a tight seal.

Weekly Tasks (10-15 Minutes):

- Deep Clean the Inside: Pull everything out of the refrigerated base and give the shelves and interior walls a good, thorough cleaning.

- Inspect the Gaskets: Take a closer look at the door gaskets for any rips or tears and give them a deeper clean to get rid of any grime. A bad seal forces your compressor to work overtime.

- Rotate Your Stock: This is the perfect time to organize your ingredients and follow the "first in, first out" rule to cut down on waste.

The Single Most Important Monthly Task

If you do only one thing every month, make it this: clean the condenser coil. This quick five-minute job can single-handedly prevent the most common—and costly—refrigeration breakdowns.

The coil works like a radiator for your fridge, pushing heat out of the system. But over time, it gets clogged with dust, grease, and all the other gunk floating around a kitchen. When that happens, the compressor has to struggle to keep things cool.

This doesn't just spike your energy bill; it puts a massive strain on the compressor, which can lead to it burning out way too soon. All you need is a stiff-bristle brush and a vacuum to clear the buildup. Do it at least once every 90 days, or even monthly if you're in a high-grease environment like a burger joint.

Thinking beyond the initial price tag is essential. An ENERGY STAR certified unit might cost more upfront, but its lower electricity consumption can lead to hundreds of dollars in savings over its operational life, delivering a much better return on investment.

Frequently Asked Questions

When you're outfitting a commercial kitchen, questions are going to come up. It's only natural. Investing in a core piece of equipment like a sandwich refrigerated prep table is a big decision, and you want to get it right. Here are some of the most common questions we get from kitchen managers and owners, answered straight and to the point.

What Is the Ideal Temperature for a Sandwich Prep Table?

You'll want to keep the refrigerated base at or below 40°F (4°C). That’s the magic number for food safety, stopping harmful bacteria in its tracks and keeping your ingredients fresh and crisp. Thankfully, most modern units have digital thermostats, making it simple to lock in that exact temperature and stay compliant with health codes.

Can I Use a Pizza Prep Table for Making Sandwiches?

You can, but it’s often not the best fit. Pizza prep tables are built with a much deeper cutting board to handle large pizza doughs. This extra depth can make it awkward and inefficient to assemble smaller items like sandwiches. Their raised pan rails are also designed for bulk toppings. For a busy sandwich line, a dedicated sandwich prep table with its flush, accessible cutting board is almost always the more efficient choice.

How Often Should I Clean the Condenser Coil?

At a minimum, you should clean the condenser coil every 90 days. If your kitchen deals with a lot of grease, flour, or dust in the air, stepping that up to a monthly cleaning is a smart move. A clean coil is the key to an efficient refrigerator; it helps the unit cool down faster, uses less electricity, and prevents the compressor from burning out. It’s probably the most important piece of maintenance you can do.

What Is the Difference Between a Standard and Mega Top Prep Table?

It all comes down to how many ingredients you can keep on the line. A standard top prep table typically has enough room for two rows of food pans. A mega top, on the other hand, is built with a larger refrigerated well that holds a third row of pans, boosting your ingredient capacity by roughly 50%. This is a game-changer for shops with big menus or insane lunch rushes, as it means less time spent running to the walk-in to restock.

Ready to find the perfect stainless steel prep table for your kitchen? Explore our extensive collection at PrepTables.com and discover durable, NSF-certified solutions designed to optimize your workflow and elevate your service. Visit us today at https://preptables.com.