Restaurant Kitchen Equipment List: Must-Have Gear for Pros

Share

When you start putting together a complete restaurant kitchen equipment list, you’re talking about everything from the big-ticket items down to the small but essential tools. This means your preparation tables, all your cooking equipment like ranges and fryers, your refrigeration units, every shelf and rack for storage solutions, and your warewashing stations.

The secret to a functional kitchen isn't just buying stuff; it's mapping all that equipment to your specific menu and the natural flow of work.

Building Your Kitchen From The Ground Up

Outfitting a commercial kitchen is much more than a shopping spree. It’s about building a single, efficient system. Before you even think about buying a single spatula, you need to trace the journey your food will take, from the moment it arrives on the delivery truck to the second it lands on the customer's plate.

This "workflow-first" mindset is what separates the pros from the amateurs. It stops bottlenecks before they start, cuts down on cross-contamination risks, and lets your team move with purpose. Every great restaurant is built on this kind of logical foundation.

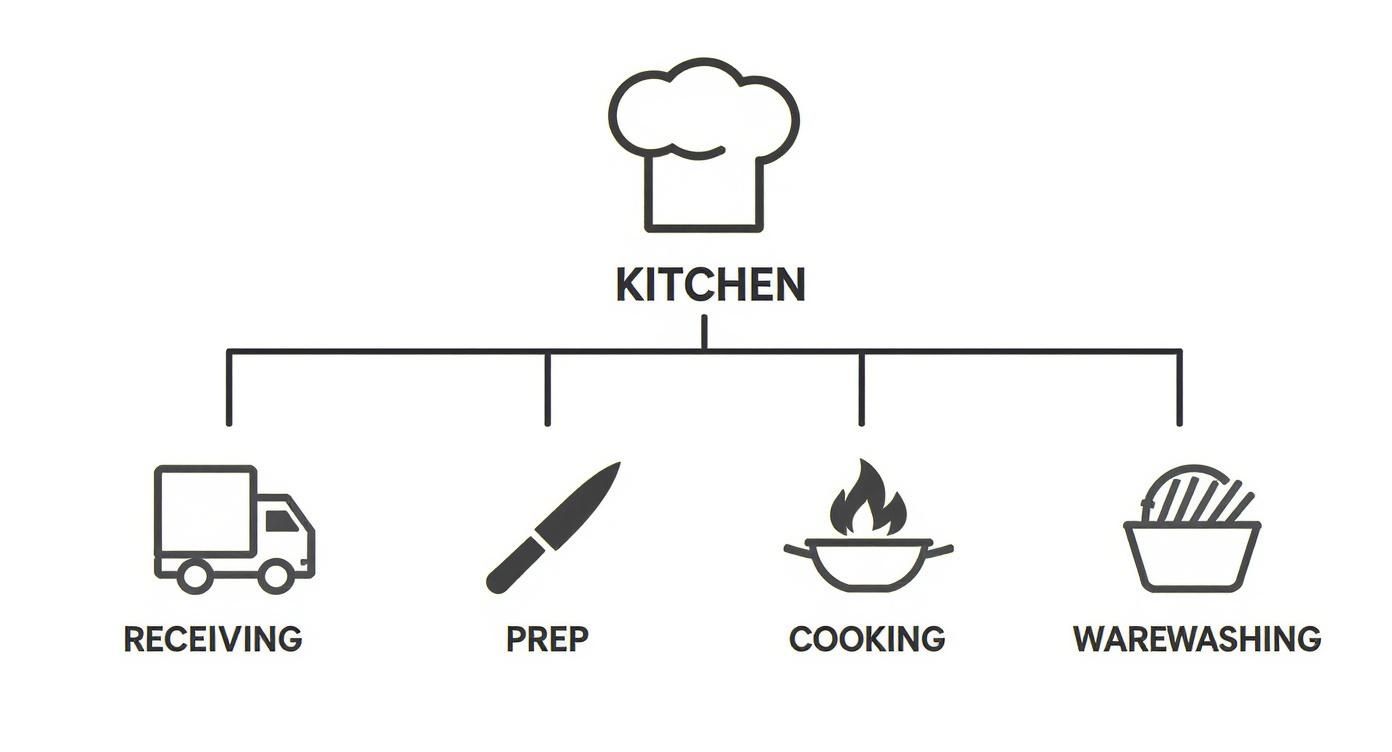

This diagram breaks down the four main zones that form the backbone of any professional kitchen's workflow.

Thinking about your kitchen in these distinct zones helps you see exactly how ingredients and people should move. It’s the blueprint for a smooth, high-functioning operation, ensuring you go from raw ingredients to plated dishes without tripping over each other.

Planning Your Kitchen Layout

The very first step in drafting your equipment list is designing the layout. A smart layout makes sure every station has what it needs without getting in the way of another. Think about the path: from the receiving area (ingredients in), to prep stations (ingredients processed), to the cooking line (dishes made), and finally to the warewashing area (cleanup).

But before you get too deep into planning, you have to deal with the red tape. Understanding the local commercial building permit requirements is a non-negotiable first step. Getting this right from the start saves you from expensive and frustrating changes down the line.

Understanding The Market And Your Needs

The demand for solid kitchen equipment is booming right along with the restaurant industry itself. The global market was valued at a whopping USD 92.89 billion and is expected to hit USD 206.07 billion by 2035. That growth tells you one thing: investing in durable, efficient equipment isn't a luxury, it's how you stay in the game.

A restaurant’s success is often determined before the first meal is ever served. The quality and layout of your kitchen equipment directly impact speed, consistency, and safety—the very pillars of the guest experience.

At the end of the day, your menu is the ultimate guide for your equipment list. A classic steakhouse is going to need heavy-duty charbroilers and griddles. A bakery, on the other hand, can't function without high-capacity mixers and convection ovens. Go through your menu item by item and list out every single piece of gear needed to make it, and make it fast. This strategy ensures you only spend money on what you actually need to execute your vision.

Designing Your Food Preparation Stations

The prep station is where the magic really begins. This is the heart of your kitchen, the spot where your culinary vision starts taking shape, transforming raw ingredients into the building blocks of every dish on your menu. And right in the middle of it all is the single most essential tool in any commercial kitchen: the stainless steel prep table.

Think of your prep tables as the foundation for your chefs. Just like a shaky foundation can bring down a house, a flimsy or poorly chosen work surface can kill your kitchen's flow, create safety hazards, and grind service to a halt. That’s why picking the right one is such a critical step.

Choosing Your Stainless Steel Workhorse

There's a reason stainless steel is the undisputed king of commercial kitchens. It’s non-porous, which means it doesn't give bacteria and germs a place to hide, making it incredibly hygienic and a breeze to sanitize. It's also built like a tank, tough enough to handle the daily grind of chopping, pounding, and constant scrubbing without a hint of rust or wear.

But not all stainless steel is the same. You need to get familiar with two key specs—gauge and grade—to make a smart buy.

-

Steel Gauge (Thickness): This number tells you how thick the steel is. It's a bit counterintuitive, but a lower gauge number means thicker, tougher steel. For most restaurant jobs, you're looking at either 18-gauge or 16-gauge. An 18-gauge table is a solid, budget-friendly pick for lighter work, like putting together salads or plating desserts. But for the heavy-duty stuff—butchering large cuts of meat, holding heavy equipment, or kneading massive batches of dough—a 16-gauge table is what you want for its superior strength and resistance to dents.

-

Steel Grade (Composition): This is all about what the steel is made of. The two you’ll see most often are 430 and 304. Type 430 is a good, affordable option that’s perfectly fine for most dry environments. But if your prep area gets a lot of moisture or is exposed to corrosive stuff like salt and acidic foods, Type 304 stainless steel is the gold standard. It has chromium and nickel mixed in, giving it the best corrosion resistance you can get.

Choosing the right stainless steel work table is a foundational decision. It directly impacts your kitchen's hygiene, efficiency, and long-term durability. This isn't just a tabletop; it’s an investment in a smoother, safer operation.

For a deeper dive into what makes a great table, our complete guide on choosing a stainless steel work table breaks down all the details you need to select the perfect surface for your kitchen. Getting this right means you’ll have a table that works hard for you for years to come.

Specialized Prep Tables For High-Speed Assembly

A standard flat-top table is a must-have, but some menus demand equipment built specifically for speed. Two of the most common are pizza and sandwich prep tables. These are basically hybrid units that mash up a refrigerated base with a dedicated workspace right on top.

These units are all about workflow. By keeping every ingredient perfectly chilled and literally at your fingertips, they stop chefs from having to run back and forth to the walk-in. Those saved seconds add up fast on every single order.

Sandwich Prep Tables

Picture the chaos of a lunch rush at a sandwich shop. That's exactly what a sandwich prep table (or "sandwich unit") is built for. It has a refrigerated base below to hold all your bulk items like meats, cheeses, and veggies.

The top is laid out for pure efficiency, with a cutting board running along the front and a "cold rail" of chilled food pans set in behind it. This setup lets a cook stand in one spot and churn out dozens of sandwiches an hour, all while keeping ingredients at the perfect temperature. It's the ultimate assembly line.

Pizza Prep Tables

In the same way, a pizza prep table is designed from the ground up for making pizzas at top speed. These tables usually have a wider and deeper work surface—often marble or another material that stays cold—to give you plenty of room for stretching large doughs.

The refrigerated rail on a pizza table is raised and angled towards the chef, making it easy to grab toppings like pepperoni, mushrooms, and cheese. The refrigerated base underneath is set up to hold extra ingredients and dough trays. For a pizzeria, where saving a minute on each pizza can mean hundreds more in sales during a dinner rush, this integrated design isn't a luxury—it's a necessity.

Equipping Your Commercial Cooking Line

If your prep stations are the heart of the kitchen, the cooking line is its fiery soul. This is where all the action happens. The sizzle of a burger hitting the griddle, the roar of a deep fryer, and the intense, shimmering heat from the range all work together to turn meticulously prepped ingredients into the dishes your customers crave. Picking out the right cooking equipment isn't just about filling up space; it's about matching your firepower perfectly to what your menu demands.

The gear you choose for your line is a direct reflection of your restaurant's entire concept. A high-end steakhouse is going to sink serious cash into powerful charbroilers. A small bakery, on the other hand, will care more about high-capacity convection ovens. Every single piece of equipment on that line needs to earn its spot, especially when you're in the weeds during a dinner rush and every second counts.

The Foundational Cooking Workhorses

At the core of almost every cooking line are the essentials—the pieces that do the bulk of the heavy lifting day in and day out. Think of these as the versatile, hard-working anchors of your kitchen.

- Commercial Ranges: This is the classic, quintessential piece of cooking equipment. A commercial range gives you a cooktop up top and an oven down below. You can get them in gas or electric, with all sorts of burner setups, flat tops, or even griddle tops to fit exactly how your team cooks.

- Convection Ovens: A convection oven isn't like your standard home oven. It uses fans inside to circulate hot air, which means food cooks faster and much more evenly. That makes them absolutely critical for bakeries and any high-volume kitchen that needs perfect, consistent results for roasting and baking.

- Griddles and Charbroilers: A flat-top griddle is your best friend for breakfast items like pancakes and eggs or diner staples like burgers and cheesesteaks. For those picture-perfect grill marks and that smoky flavor on steaks and chicken, you need a charbroiler with its distinct grates.

Specialized Equipment for Signature Dishes

Once you have the basics covered, your specific menu will start calling for more specialized tools. These are the units designed to handle very specific jobs with speed and precision, taking the guesswork out of tricky or repetitive cooking tasks.

For instance, an Italian spot focused on pasta would be completely lost without a dedicated pasta cooker. This machine keeps a huge volume of water at a constant rolling boil, letting chefs drop multiple orders of different pasta types at once without the water temperature crashing.

In the same way, a pub or fast-casual joint famous for its wings and fries absolutely needs a reliable deep fryer. Commercial fryers are built to get back up to temperature in a flash, making sure every single batch comes out golden and crispy, even during the busiest Friday night rush. Investing in the right specialized equipment is what lets you deliver consistent quality on your most popular dishes.

Your cooking line is a direct investment in your menu's success. The right combination of general and specialized equipment prevents bottlenecks, ensures food quality, and empowers your culinary team to perform at their best when the pressure is on.

The market for this gear speaks for itself. The global commercial cooking equipment market was valued at USD 13.3 billion in 2025 and is expected to more than double to USD 26.5 billion by 2035. This boom is all about restaurants hunting for more efficient appliances to keep up with customer demand. You can dig into these insights on the commercial cooking market to see the trend.

Planning for Capacity and Workflow

When you're building your restaurant kitchen equipment list, two things are absolutely critical for the cooking line: capacity and ventilation. You have to figure out your peak volume to make sure your equipment can handle the stress. An undersized griddle or a fryer with only one basket can bring your whole kitchen to a grinding halt on a packed Saturday night.

Just as important is your commercial kitchen ventilation system, which includes the hood and the fire suppression setup. This isn't just about keeping the kitchen comfortable; it's a non-negotiable legal requirement for safety and air quality. The cooking equipment you buy will directly impact the size and power of the ventilation system you'll need, so you have to plan these two things together to build a safe, efficient, and powerful cooking line.

Mastering Refrigeration And Storage Systems

Think of your cold storage as the bank vault for your inventory. It’s where you protect your most valuable assets—your ingredients. Get it right, and you safeguard food safety, maintain ingredient quality, and keep costs under control.

This isn't just about keeping things cold. It’s about creating a seamless, organized flow from the delivery truck to the prep station. From massive walk-in units holding bulk product to the small under-counter fridges on the line, every piece has a job. Proper storage is absolutely non-negotiable.

Choosing The Right Refrigeration Units

Every restaurant's refrigeration needs are different, which is why there are so many types of units. The choices you make here will have a direct impact on your kitchen’s efficiency and your ability to nail those food safety standards.

-

Walk-In Coolers and Freezers: These are the heavy lifters of your cold storage, built for holding bulk inventory. Your walk-in cooler handles large quantities of produce, dairy, and meat, while the freezer is for all your long-term frozen goods. Their main purpose is to hold huge volumes at a steady, safe temperature.

-

Reach-In Refrigerators and Freezers: You’ll see these upright units placed strategically near prep and cooking stations. They give chefs quick access to ingredients they need right now, preventing a trip to the walk-in and saving precious time during a service rush.

-

Under-Counter and Worktop Refrigerators: These compact units are workhorses, built right into prep stations to maximize space and efficiency. They give line cooks immediate access to prepped items like sauces, garnishes, and proteins, exactly where they need them.

Ensuring Food Safety And Quality

The single most critical job of any commercial refrigerator is to maintain a consistent temperature. Even small fluctuations can invite bacterial growth, spoil food, and cost you serious money. This is why you can’t cut corners with professional-grade equipment. For a deeper dive, check out our guide on selecting the perfect commercial refrigerator for your kitchen.

Every single time a refrigerator door opens, cold air pours out and you waste energy. Investing in equipment with strong seals, efficient compressors, and good insulation is a direct investment in food safety and lower utility bills. A tiny 1°F increase in temperature can slash the shelf life of some produce by as much as 10%.

When you're shopping for units, always look for the NSF (National Sanitation Foundation) certification. This seal is your guarantee that the equipment is designed for easy cleaning and sanitizing, which helps you meet health codes and prevent cross-contamination. To really double down on temperature control and energy savings, especially for doors that are opened constantly, look into the benefits of air curtains.

Essential Dry Storage Solutions

Beyond the cold stuff, a well-organized dry storage area is vital for non-perishables like flour, sugar, canned goods, and spices. Using the right shelving system is your first line of defense against pests, moisture, and damaged inventory.

-

Metro Shelving (Wire Shelving): This is the industry standard for a reason. The open-wire design promotes air circulation to prevent moisture buildup and lets you see your entire inventory at a glance. Always go for durable, corrosion-resistant finishes like chrome or epoxy-coated steel.

-

Dunnage Racks: These low, heavy-duty platforms are a health code must-have in many places. They get bulk items—like 50-pound bags of flour or cases of produce—safely off the floor. This protects your inventory from pests and moisture and makes cleaning underneath a breeze.

Optimizing Your Warewashing And Sanitation Workflow

Let's be blunt: a clean kitchen isn't just a nice-to-have, it's the absolute foundation of a successful restaurant. Your warewashing and sanitation area is the engine room of this whole operation, making sure your team has clean, safe tools to work with from open to close. A smooth workflow here is what stops a mountain of dirty dishes from forming and bringing your service to a grinding halt.

It all starts with picking the right commercial dishwasher. These aren't just beefed-up versions of your home machine; they're high-powered sanitation units built to meet demanding health codes and handle an incredible volume of work. The right one for you really comes down to your restaurant's size and how many covers you do a night.

Selecting The Right Commercial Dishwasher

As you put together your restaurant kitchen equipment list, you’ll run into a few main types of dishwashers, and each one is built for a different kind of kitchen pace.

-

High-Temp vs. Low-Temp Models: High-temperature machines are the workhorses that use a booster heater to get the final rinse water up to at least 180°F. This searing heat is what kills the bacteria—no chemicals needed. Low-temperature models, on the other hand, run cooler at about 120-140°F and rely on chemical sanitizers in the final rinse. They use less energy, but you'll have a recurring cost for the chemicals.

-

Door-Type vs. Conveyor Machines: A door-type, or rack, dishwasher is a perfect fit for most small to medium-sized spots. You slide one rack in at a time, and it gets the job done efficiently. But for the big leagues—hotels, busy cafeterias, and high-volume restaurants—a conveyor machine is a must. These are beasts that automatically pull multiple racks through different washing and rinsing chambers, cleaning hundreds of dishes an hour without breaking a sweat.

The Essential Three-Compartment Sink

No matter how powerful your dishwasher is, every single commercial kitchen is required by the health department to have a three-compartment sink. It’s your go-to for manually washing all the pots, pans, and oversized items that just won't fit in the machine.

Think of a properly set up three-compartment sink as your first line of defense against cross-contamination. Each basin has a specific job: the first is for hot, soapy water (Wash), the second is for clean rinse water (Rinse), and the third holds a chemical sanitizing solution (Sanitize).

Nailing this simple Wash-Rinse-Sanitize process is non-negotiable for passing health inspections and keeping your kitchen truly clean. For a deep dive into setting it up perfectly, check out our guide on the 3-bay commercial sink—it covers everything you need to know.

Completing Your Sanitation Station

Beyond the dish pit, a few other pieces of gear are absolutely vital for a clean and compliant kitchen. You need dedicated handwashing stations, fully stocked with soap and paper towels, within easy reach of every food handler. A grease trap is another one that’s not optional; it’s a legal requirement in most places to keep fats and oils from wrecking the city's sewer lines.

Finally, a dedicated mop sink and organized storage for your cleaning chemicals and tools keep your sanitation tasks contained and safely away from food prep zones. All these pieces work together to create a bulletproof system for food safety. This focus on sanitation is only getting more critical, especially as the global commercial kitchen equipment market is expected to grow by USD 41.81 billion by 2029, pushed by new tech and higher food safety standards. You can read more about these commercial kitchen market trends to see what's coming next.

Essential Smallwares And Safety Equipment

If the big appliances are the skeleton of your kitchen, then the smallwares are the muscles doing the heavy lifting every single day. We're talking about the hundreds of smaller items that are just as vital to your success as a six-burner range or a walk-in freezer. Get this part wrong, and even the best-equipped kitchen can grind to a halt during a busy service.

A complete equipment list has to nail the fundamentals. It all starts with a full battery of professional-grade pots and pans—think sauce pots, stock pots, sauté pans, and plenty of sheet pans. And high-quality chef's knives, paring knives, and serrated knives? They’re basically an extension of your chef's hands. Absolutely non-negotiable.

Core Utensils And Preparation Tools

Beyond the main cookware, your crew needs a whole arsenal of utensils to actually execute the menu. These are the tools they’ll reach for at nearly every stage of prep and cooking.

Your shopping list for essential smallwares should definitely include:

- Mixing Bowls: You can never have enough. Get a variety of stainless steel sizes for everything from tossing salads to marinating proteins.

- Measuring Tools: For consistent results and keeping food costs in check, complete sets of measuring cups and spoons are a must.

- Basic Utensils: Make sure you're well-stocked with the basics. Whisks, tongs, spatulas, ladles, and slotted spoons are the workhorses of the line.

- Cutting Boards: A color-coded system is the industry standard for preventing cross-contamination. Red for raw meat, green for produce, blue for fish—you know the drill.

- Food Storage Containers: Go for clear, tough, NSF-certified containers. Ones with tight-fitting lids are key for keeping ingredients fresh and your walk-in organized.

Mandated Safety And Sanitation Gear

A safe kitchen is a fast kitchen, and some safety gear isn't just a smart idea—it's the law. This equipment protects your staff, your space, and your business from accidents that are entirely preventable. Trust me, a fire or a bad injury will cost you a lot more than the upfront investment in proper safety equipment.

A well-run kitchen cares just as much about safety as it does about ticket times. A fire suppression system and a first-aid kit are every bit as important as your most expensive oven. Think of them as the silent partners in your operation.

Your safety checklist needs to cover a few key items to stay compliant. A professionally installed fire suppression system is almost always required above your cook line. On top of that, you'll need several multi-purpose (Class ABC) fire extinguishers mounted in easy-to-grab spots.

Finally, a fully stocked first-aid kit is mandatory for dealing with the minor cuts and burns that are just part of life in a kitchen. And don't skimp on non-slip floor mats, especially in high-traffic, wet zones like the dish pit. Slips and falls are one of the most common accidents in restaurants. These smallwares and safety items are truly the unsung heroes of a smooth, successful service.

Common Kitchen Equipment Questions Answered

Stepping into the world of commercial kitchen equipment always kicks up a few questions. Let's walk through some of the most common ones operators face to help you make smarter buys that fit your budget and your kitchen's reality.

Should I Buy New Or Used Restaurant Kitchen Equipment

This one really comes down to your budget and what piece of equipment you're looking at. For the absolute workhorses—your refrigeration units or cooking ranges—buying new is almost always the best bet. You get a full warranty and the peace of mind that comes with peak performance right out of the box. You can't afford for these critical pieces to fail.

On the other hand, used equipment can offer some serious savings, especially for durable items with few moving parts. Think about things like stainless steel tables, sinks, or shelving. You can often find these in fantastic shape for a fraction of the cost. A word of caution: always get a professional to inspect any used mechanical equipment before you pull the trigger, and just know it probably won't come with a warranty.

What Are The Most Important Certifications For Kitchen Equipment

When you're shopping, keep an eye out for two key certifications. These aren't just about checking a box for the health inspector; they're about ensuring the safety of your staff and customers.

- NSF (National Sanitation Foundation): This seal of approval means the equipment is built to strict public health standards. In simple terms, it's designed to be cleaned and sanitized easily and effectively, leaving no room for nasty stuff to hide.

- UL (Underwriters Laboratories): The UL mark is all about safety from electrical and fire hazards. You'll find it on gas and electric equipment, certifying that it has met rigorous safety tests.

Pretty much every health department in the country will require both NSF and UL certifications for your equipment. Trying to skirt these rules is a recipe for failed inspections and having to buy everything all over again.

How Do I Choose The Right Equipment Size And Capacity

Don't just eyeball it. Sizing your equipment correctly depends on three things: your menu, your projected sales, and the actual physical space you have to work with.

Start by breaking down your menu to see which dishes you expect to sell the most and what gear you'll need to pump them out. Then, dig into your business plan's sales projections to figure out what your busiest hours will look like—this helps you buy equipment that can keep up without creating a bottleneck. Finally, get out the tape measure and map out your floor plan. You need to make sure everything fits while still leaving enough room for your team to move safely and efficiently.

At PrepTables.com, we provide the durable, certified, and perfectly sized equipment you need to build an efficient and successful kitchen. Explore our extensive selection of NSF-certified prep tables, refrigeration, and cooking equipment at https://preptables.com.