Refrigerator commercial for sale: Your Guide to Best Picks

Share

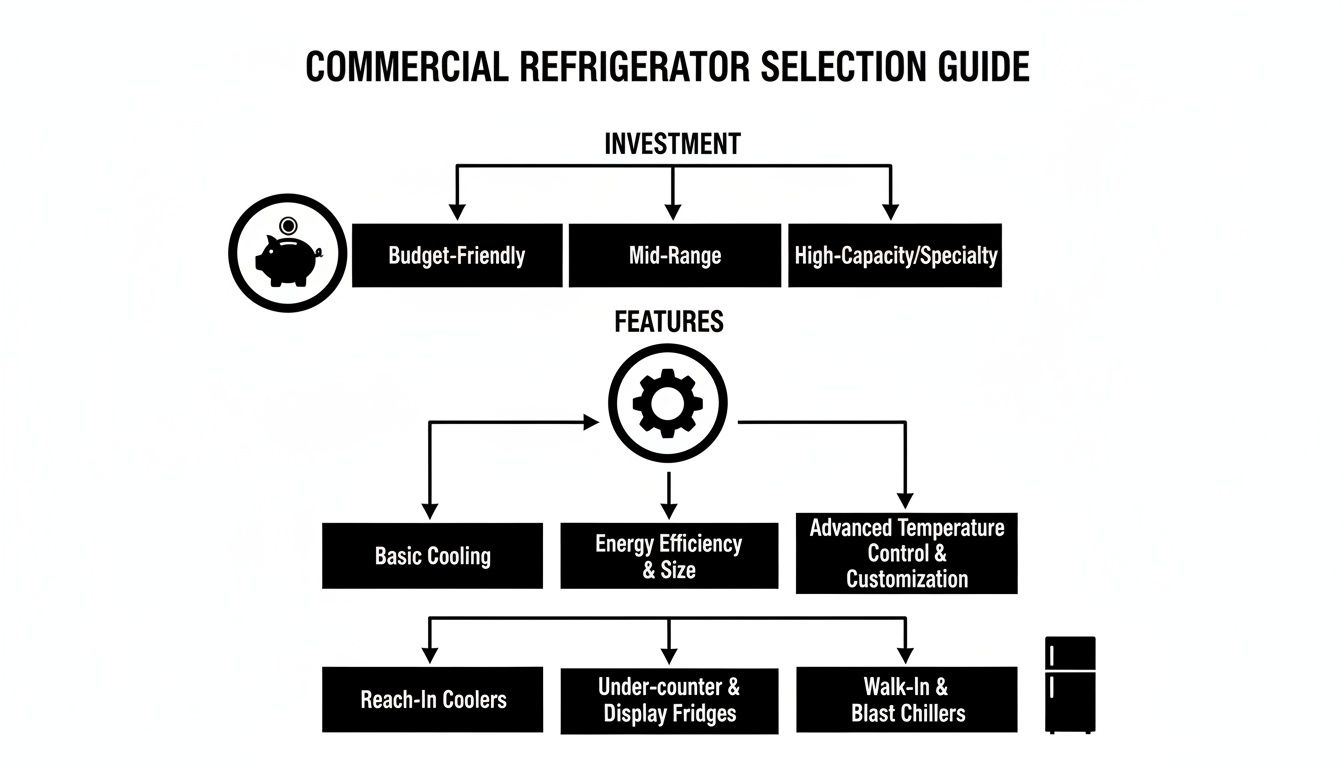

When you're searching for a refrigerator commercial for sale, you're not just buying an appliance. You're making a core investment in your business that touches everything from food safety and kitchen workflow to your monthly power bill. The smartest move you can make is to figure out exactly what you need before you ever start looking at models.

Finding the Right Commercial Refrigerator for Your Business

Choosing a commercial refrigerator is a whole different ballgame than picking one out for your home. It’s a foundational piece of equipment for any food service business. These units are built to take a beating, hold precise temperatures day in and day out, and meet tough health code standards. The sheer number of options can feel like a lot, but if you break it down, it's actually pretty straightforward.

Think of this as your personal roadmap. We'll help you cut through the noise and zero in on a fridge that fits your kitchen and your business like a glove. Whether you're launching a new cafe or overhauling an old kitchen, the goal is the same: find a reliable, efficient workhorse that protects your inventory and keeps things running smoothly.

Key Considerations Before You Buy

Hold off on browsing models and features for just a minute. First, you need to get a clear picture of your operational needs. Nailing this down now will save you from a massive headache later, like buying a unit that's too small for your busy season or one that won't even fit through the kitchen door.

To get your search started on the right foot, think through these key areas:

- Space and Layout: Get out the tape measure. You need to know your available footprint, but don't forget to measure doorways and hallways, too. Think about how the fridge's placement will impact the flow of traffic in your kitchen.

- Capacity Needs: How much food are you storing? Always plan for your busiest days, not your average ones. The last thing you want is to run out of cold storage during a dinner rush.

- Menu and Inventory Type: What you store dictates the kind of refrigeration you need. A bakery's needs are completely different from a butcher shop's or a high-volume pizzeria's.

- Energy Efficiency: That cheaper model might look tempting, but it could cost you a fortune in energy bills over its life. An ENERGY STAR certified model can slash energy use by up to 35%, saving you real money in the long run.

By getting crystal clear on these requirements first, you stop aimlessly searching for a "refrigerator commercial for sale" and start a focused mission to find the perfect tool for your business. This prep work is the single most important step in making a smart investment that will pay off for years.

Exploring Stainless Steel Prep Tables and Specialized Units

Sometimes, standard cold storage just isn't enough. Many modern kitchens need refrigeration that also serves as a functional workspace, and that's exactly where stainless steel prep tables come in. They perfectly merge refrigerated storage below with a tough preparation surface on top, maximizing your kitchen's flow and efficiency.

Think of these units as the ultimate command center for a chef. They are built to keep ingredients chilled and always within arm's reach. This simple design cuts down on how much your staff has to move around, saving precious time during a chaotic dinner rush and keeping sensitive foods at safe temperatures.

The Main Types of Stainless Steel Prep Tables

Stainless steel prep tables are not a one-size-fits-all solution. They come in several varieties, each designed to excel at a specific task. Understanding the differences is key to choosing the right one for your operation. The three main categories you'll encounter are general-purpose work tables, sandwich/salad prep tables, and pizza prep tables.

-

General-Purpose Work Tables: These are the most basic and versatile models. They feature a simple, flat stainless steel top over a refrigerated base. Their large, unbroken work surface is ideal for tasks that require a lot of space, like butchering meat, mixing dough, or plating complex dishes. They are the jacks-of-all-trades in a busy kitchen.

-

Sandwich and Salad Prep Tables: Built for speed and efficiency, these units are a must-have for delis, cafes, and salad bars. They feature a refrigerated rail on top with cutouts designed to hold multiple food-safe pans for ingredients like lettuce, tomatoes, cheeses, and sauces. Most also include a built-in cutting board running the length of the unit, creating a perfect assembly line to build orders quickly.

-

Pizza Prep Tables: While they look similar to sandwich tables, pizza prep tables are engineered specifically for pizzerias. They feature a wider and deeper raised refrigerated rail to accommodate large, round pizza doughs and full-size ingredient pans. The cutting board is also typically much deeper, providing ample space for stretching dough and assembling large pies.

The real magic of a dedicated prep table is speed and safety. By keeping every ingredient below 40°F and directly in the prep zone, these units can slash order assembly times and help you nail food safety compliance, even during the craziest rush.

For a more detailed look, check out our guide on how to choose the right commercial refrigerator for your needs.

Commercial Refrigerator Types at a Glance

| Refrigerator Type | Primary Use Case | Ideal For |

|---|---|---|

| Reach-In | Bulk cold storage, easily accessible | Restaurants, cafes, and any high-volume kitchen |

| Walk-In | Large-scale, long-term cold storage | Large restaurants, catering companies, institutions |

| Undercounter | Compact storage at point-of-use stations | Bars, coffee shops, small prep areas |

| Prep Table | Combined prep surface and ingredient storage | Delis, pizzerias, salad bars, sandwich shops |

| Display/Merchandiser | Showcasing products for customer purchase | Convenience stores, bakeries, grocery stores |

This table should help you quickly identify which category best fits your immediate needs before we dive deeper into key features.

Diving Into Key Features and Essential Certifications

Once you’ve nailed down the right type of refrigerator, it’s time to look under the hood. You need to get familiar with the specific features that drive performance and the certifications that guarantee safety. Two models might look similar on the outside, but it’s the internal components and official ratings that determine how they’ll hold up under pressure.

When you're looking at a refrigerator commercial for sale, these details are what separate a reliable workhorse from a unit that causes constant headaches. Getting this part right means your investment will be sound, compliant, and efficient for years to come.

Core Operational Features

A commercial refrigerator does more than just keep things cold; several features directly impact your daily kitchen operations. A digital thermostat, for instance, gives you precise temperature control—something absolutely essential for food safety. Another game-changer is an automatic defrost cycle, a hands-off system that prevents ice buildup and saves your staff from a tedious maintenance chore.

You’ll also have to choose between solid and glass doors, and the decision has real-world consequences. Solid doors offer much better insulation, which translates to lower energy bills. On the other hand, glass doors let your staff see the inventory at a glance, so they can grab what they need fast without leaving the door open.

Why Compressor Placement Matters

The location of the compressor—the engine of your refrigerator—is a surprisingly critical detail. You'll find two main setups, and each one has distinct advantages depending on your kitchen's environment.

- Top-Mount Compressors: These are perfect for hot environments, like right on a busy cook line. Since heat naturally rises, placing the compressor on top helps it run more efficiently. It also pulls in cleaner air, staying away from the dust and debris on the floor.

- Bottom-Mount Compressors: These are a better fit for cooler, but potentially dustier, areas like basements or prep stations. Their placement makes them much easier to access for cleaning and routine maintenance. Plus, they don't have to work as hard since cool air naturally sinks toward the floor.

Non-Negotiable Certifications for Compliance and Savings

Those little stickers on the unit aren't just for decoration; they are non-negotiable proof of quality, safety, and efficiency. There are two logos you absolutely must look for when buying a commercial refrigerator.

An NSF (National Sanitation Foundation) certification is your guarantee that the unit is built for safe food storage. It means the materials are easy to clean and designed to resist bacterial growth. Operating without NSF-certified equipment is a surefire way to get a health code violation, making this a deal-breaker.

The other essential certification is ENERGY STAR. This label means the refrigerator meets strict energy efficiency guidelines set by the U.S. Environmental Protection Agency. An ENERGY STAR model can dramatically lower your electricity bills, delivering long-term savings that often make up for a higher upfront cost.

The market is already shifting this way, with energy-efficient models projected to make up nearly 50% of all refrigerator sales soon. This shows how both regulations and consumer demand are pushing for lower energy use in commercial and residential kitchens alike. If you want a deeper dive into what makes a unit truly food-safe, you can learn more about what NSF certification is and why it's so vital for your kitchen.

Budgeting and Sourcing Your Commercial Refrigerator

You've picked out the perfect commercial refrigerator... on paper. Now comes the real-world part: figuring out how to actually get it into your kitchen. This is where we shift from specs and features to dollars and cents, building a realistic budget and figuring out where to find a quality unit. A smart strategy here is about getting the best long-term value, not just the lowest price tag today.

Your budget needs to be more than just the number on the price tag. Think about the total cost of ownership. That includes what it's going to cost you in electricity over the years, any potential repair bills, and even shipping fees. Spending a little more upfront on a super-efficient model could easily save you hundreds, if not thousands, over its lifespan.

New Versus Used: Weighing Your Options

One of the first big forks in the road is deciding between a new or a used unit. A brand-new refrigerator is the safe bet. It comes with a full manufacturer's warranty, has all the latest energy-saving tech, and you have the peace of mind knowing you're the first person to use it. For a business that simply can't afford the headache of unexpected equipment failure, this is often the way to go.

On the flip side, a used refrigerator can save you a serious chunk of cash upfront. But this path has its pitfalls. You have to be your own quality control inspector—check the door seals for cracks, listen for any weird noises from the compressor, and make sure it holds its temperature consistently. If you go this route, try to buy from a reputable reseller that offers at least some kind of limited warranty.

Where to Find Your Commercial Refrigerator

Once you've set a budget and decided on new versus used, it's time to start hunting. There are a few solid places to look, each with its own pros and cons.

- Restaurant Supply Stores: These are the specialists. They offer expert advice, a huge selection of new gear, and usually handle the delivery and installation for you.

- Online Marketplaces: Websites that specialize in restaurant equipment are great for finding both new and used units, often with very competitive pricing.

- Equipment Auctions: You can snag an incredible deal at an auction, but it's almost always an "as-is" sale. This is a higher-risk game best played by seasoned buyers who know what to look for.

If you’re placing a large order or need something custom-built, especially from an international brand, finding a reliable sourcing agent can be a lifesaver. This is especially true if you're looking to source from major global hubs.

A critical part of your decision is whether to buy the unit outright or look into financing. For many businesses, holding onto cash is king. It’s worth taking a moment to see if leasing or buying your equipment makes more financial sense for your operation.

What's happening in the global market can also sway your sourcing plan. Right now, the Asia-Pacific region has the largest slice of the global refrigerator market pie, at about 36.34%. Meanwhile, North America is expected to drive around 35% of the market's growth through 2029. These trends impact everything from pricing to what features are available, which is good intel to have when you’re trying to find the best deal.

Common Questions About Buying Commercial Refrigerators

Stepping into the world of commercial refrigeration can feel a bit overwhelming, and it’s natural to have questions. To help clear things up, here are some quick answers to the most common things business owners ask when they’re looking for a new unit.

What Is the Real Difference Between a Commercial and Residential Refrigerator?

The biggest difference boils down to pure power and ruggedness. Think of it this way: a residential fridge is like your family car, while a commercial one is a heavy-duty work truck.

Commercial refrigerators are built with much more powerful compressors. This allows them to cool down incredibly fast and hold a steady temperature, even when the doors are swinging open and shut during a chaotic dinner rush. They're also constructed from tougher materials, like stainless steel, to survive the demanding environment of a professional kitchen. A home unit just can't keep up and won't meet health code standards.

Why Is an NSF Certification So Important?

For any equipment in a commercial kitchen, an NSF certification is non-negotiable. It’s an independent seal of approval, verifying that the refrigerator is designed and built to promote food safety. This means it's made with materials that are non-porous, corrosion-resistant, and easy to clean, preventing bacteria from growing.

Without that NSF stamp, you’re almost guaranteed to fail a health inspection. That could mean fines or even a temporary shutdown. It's your single best guarantee of safety and compliance.

How Often Should I Clean the Condenser Coils?

This is easily one of the most critical maintenance tasks you can do. The condenser coils are what release heat from the unit, but they quickly get clogged with grease, dust, and kitchen grime. When that happens, the compressor is forced to work overtime, jacking up your energy bills and paving the way for a complete system failure.

As a general rule, clean the condenser coils at least every 90 days. If your kitchen produces a lot of grease or airborne flour, like a bakery or a busy fry station, you'll want to do it monthly. A quick brushing is often all it takes to keep things running smoothly.

What Should I Do with My Old Unit?

Getting rid of an old commercial refrigerator isn't as simple as dragging it to the curb. These machines contain refrigerants that can be harmful to the anvironment if they aren't disposed of properly, and local regulations often require professional removal.

When you upgrade, you'll need a plan for your old equipment. For businesses in many areas, your best bet is to look for reliable appliance disposal services that know how to handle this kind of machinery responsibly.

Ready to find the perfect refrigeration solution for your business? At PrepTables.com, we offer a wide selection of NSF-certified and ENERGY STAR-rated commercial refrigerators and prep tables designed for durability and performance. Explore our collection today!