Top Prep Table for Restaurant – Choose Your Ideal Model

Share

A prep table for a restaurant is more than just a place to chop vegetables; it's the heart of your kitchen's daily operations. Think of it as the central workstation for every culinary task, providing a durable, clean surface for mixing, prepping, and plating. This unsung hero truly dictates your kitchen's workflow, safety, and speed, making your choice here one of the most critical you'll make.

The Different Types of Prep Tables

Imagine your prep table as the command center for your entire kitchen. It’s not just a slab of metal; it’s the stage where raw ingredients start their journey to becoming the dishes your customers rave about. The wrong table can cause serious bottlenecks and even safety hazards, but the right one makes every single process smoother and faster. Understanding the various types available is the first step toward creating a kitchen that just flows.

From the classic workhorse to specialized refrigerated units, each type serves a unique purpose designed to maximize efficiency for a specific set of tasks.

Standard Stainless Steel Work Tables

This is your jack-of-all-trades, the foundational block you build a great kitchen on. The standard stainless steel work table is the most common and versatile option out there for a reason. It's a blank canvas, perfect for general tasks like dicing onions, butchering proteins, or portioning out ingredients for the line. Chefs love these tables for their no-nonsense design and rugged, dependable space for any prep work that doesn't need to be kept cold.

Pizza Prep Tables

Built specifically for the art of pizza making, these tables are engineered to streamline the entire process. They feature an extra-deep work surface to give you plenty of room to stretch large doughs. At the back, a raised, refrigerated rail holds all your toppings, from pepperoni to peppers, keeping them chilled and within arm's reach. Below, the refrigerated cabinet is perfectly designed for storing dough boxes and backup ingredients. It’s an all-in-one station that creates a powerful pizza production line.

Sandwich and Salad Prep Tables

These units are built for one thing: speed. They typically feature a cutting board that runs the length of the table, right next to a series of chilled wells designed to hold food pans. This is where you keep your lettuce, tomatoes, cheeses, and sliced meats. This setup lets a cook assemble custom orders in seconds without ever having to walk away, which is key for consistency and speed during a lunch rush in delis, cafes, and quick-service restaurants.

By keeping chilled ingredients right where the prep happens, specialized units like pizza and sandwich tables slash ticket times and seriously cut down on the risk of foodborne illness. They are a must-have for any restaurant that's serious about freshness and speed.

Navigating Stainless Steel Work Tables

Stainless steel prep tables are the backbone of any serious commercial kitchen. But when you start shopping, you’ll run into terms like "gauge" and "series" that can feel like a whole new language. Getting a handle on what they mean is the secret to picking a table that will actually survive the daily chaos of a busy restaurant.

Let's break down what these specs really mean for your kitchen.

Think of stainless steel as having different recipes. The two most common ones you'll see are 304 series and 430 series. The big difference is in their key ingredients—specifically, how much nickel they contain.

-

304 Series Stainless Steel: This is the good stuff. It’s the top choice for any prep table for restaurant use because it has more nickel, giving it fantastic resistance to rust and corrosion. If you're going to be working with acidic foods like lemons or tomatoes, or the table will constantly be wet or exposed to harsh cleaners, you want 304 series.

-

430 Series Stainless Steel: This is your more budget-conscious pick. It has less nickel, so it's a bit more susceptible to corrosion over time. That said, it's still a tough, food-safe material that's perfectly fine for general use, like an equipment stand or a place to store dry goods where it won’t be getting soaked all day.

Understanding Steel Gauge and Durability

Besides the type of steel, you'll see a number called the "gauge." This tells you how thick the steel is, but it works backward from what you'd expect: the lower the gauge number, the thicker and stronger the steel. A lower gauge means a tougher table that won’t dent or warp when you slam down heavy equipment.

-

14-Gauge: This is the tank. It’s the thickest, most heavy-duty option you can get. This is what you need for a butcher shop, a high-volume spot where you're pounding out cutlets, or for holding a massive mixer that runs all day.

-

16-Gauge: This is the industry standard for a reason. It hits the sweet spot between durability and price, making it a reliable workhorse for almost any general prep task, from chopping veg to plating.

-

18-Gauge: This is the lightest and most economical option. It’s still a solid table, but it’s best for lighter-duty work. Think holding small appliances, storing things on the undershelf, or as a utility table that doesn’t see heavy action.

Choosing the right gauge is all about matching the table's strength to the job you have in mind. Don't waste money on a 14-gauge for light prep, but definitely don't try to put a 50-pound slicer on an 18-gauge table.

Practical Design Elements to Consider

The little details in a table's design can make a huge difference in your daily workflow. The edges, for instance, come in different styles. A bullnose edge is rounded and smooth, which is a lifesaver in a tight kitchen—it’s much safer for staff who are moving fast. A squared edge is flat, which is perfect for pushing tables right up against a wall or lining them up seamlessly with other equipment.

The undershelf is another feature you'll want to think about. Most tables have one for extra storage, but they aren't all the same. A stainless steel undershelf is tough and a breeze to clean. A galvanized steel one is cheaper but won't resist rust as well, so it's best for storing dry goods only. If you want to get into the nitty-gritty, you can learn more about finding the perfect stainless steel work table in our detailed guide.

Specialized Stainless Steel Configurations

While a simple flat-top table is a kitchen must-have, some operations need something more specialized. That’s where you find tables engineered to combine workspace with other essential functions, streamlining specific tasks.

The two most common examples are pizza prep tables and sandwich prep tables. These are basically stainless steel work tables with built-in refrigeration. A pizza table will have a wide, deep cutting board surface for stretching dough, with a refrigerated rail up top to hold all your toppings. Underneath, a refrigerated cabinet keeps extra dough balls and ingredients cold.

A sandwich or salad prep table works the same way, with a long cutting board next to a line of refrigerated wells designed to hold food pans. This setup keeps your lettuce, meats, cheeses, and veggies chilled and right at your fingertips, making it incredibly fast to build custom orders. These specialized units are the ultimate prep stations for high-volume service.

Diving Into Specialized Refrigerated Prep Tables

When your menu is all about fast assembly and peak freshness, a simple stainless steel surface just won't cut it. This is where specialized refrigerated prep tables come in. Think of them as all-in-one workstations that brilliantly merge a tough work surface with built-in cold storage. These units are engineered from the ground up to kill wasted motion, keeping your team humming and your ingredients perfectly chilled, even when the dinner rush hits its peak.

Picture a slammed deli during lunch hour. Without a refrigerated prep table, a cook is constantly running back and forth to the main walk-in—grabbing lettuce, then tomatoes, then cheese, then meats. Every trip eats up precious seconds and opens the door for food to enter the temperature danger zone. A refrigerated prep table gets rid of this chaotic dance by putting everything right at their fingertips.

These specialized units are the ultimate weapon for any kitchen that churns out made-to-order food. By consolidating prep and storage, they slash ticket times, cut down on food waste by holding ingredients at ideal temps, and make sure every single dish is built with consistent, safe components. Let's break down the two heavy hitters in this category.

The Powerhouse Pizza Prep Table

For any pizzeria worth its salt, a dedicated pizza prep table is an absolute must-have. It’s the command center where dough, sauce, cheese, and toppings all come together. These tables are specifically designed to fit the unique rhythm of pizza making, creating a smooth production line from start to finish.

A standout feature is the extra-deep work surface. Unlike a standard table, a pizza prep table gives you a ton of real estate—often 19 inches deep or more—to stretch and spin large doughs without feeling boxed in. This generous workspace is a game-changer for speed and consistency.

Right above the work surface, you'll find a refrigerated topping rail. This raised, chilled section holds a bunch of food pans, keeping everything from pepperoni and mushrooms to onions and olives at a safe, constant temperature. This setup lets a pizza maker build pies in rapid-fire succession without ever taking a step.

Underneath the countertop, a refrigerated cabinet provides bulk cold storage. This area is perfectly set up to hold dough boxes, backup sauce containers, and extra cheese, making sure the station stays locked and loaded through a busy shift.

The demand for these specialized tables is skyrocketing. The global market for pizza prep tables was valued at USD 1.75 billion in 2024 and is expected to climb to a staggering USD 4.92 billion by 2033. This growth mirrors the worldwide boom of pizza chains and delivery services, proving just how essential these units are in today's pizzerias.

The Efficient Sandwich and Salad Station

Much like its pizza-focused cousin, the sandwich and salad prep table is built for two things: speed and organization. These units are the backbone of delis, cafes, and any spot serving a high volume of custom-built sandwiches, wraps, or salads. Their entire design is centered on one core idea: keep a wide variety of fresh ingredients chilled and ready to go.

The defining feature of a sandwich station is its long, narrow cutting board that runs right alongside a series of refrigerated wells. These wells are made to hold standard-sized food pans (often called hotel pans), creating a cold buffet of every ingredient you need. It allows a cook to move right down the line, adding lettuce, tomatoes, pickles, deli meats, and cheeses with incredible efficiency.

Here’s a quick look at how these features work together in the real world:

- The Cutting Board: Usually made from a durable, food-safe polymer, it gives you a dedicated spot for slicing bread and assembling the final product.

- The Cold Wells: This refrigerated "rail" can hold anywhere from eight to twenty or more pans, depending on how long the table is. This means you can support an extensive menu with tons of ingredient choices.

- The Refrigerated Base: The cabinet below offers extra cold storage for backup ingredients, dressings, and condiments, which means fewer trips to the walk-in cooler.

A well-organized sandwich prep table is like a perfectly tuned assembly line. By keeping every component chilled and at the cook's fingertips, it empowers staff to fulfill custom orders with incredible speed and accuracy, ensuring every customer gets exactly what they ordered, fast.

For a deeper dive into how these systems function and what to look for when buying, check out our complete guide on commercial refrigerated prep tables. This resource breaks down the mechanical components and helps you match a unit to your specific menu needs.

Ultimately, both pizza and sandwich tables are more than just equipment; they are strategic investments in your kitchen's workflow, safety, and consistency.

Features That Make or Break a Prep Table

When you're outfitting a kitchen, choosing a prep table isn't just about finding a flat surface. The real magic is in the details—the specific features that will either make your kitchen a well-oiled machine or a source of constant headaches. Think of it as the difference between a tool that works for you and one you're always fighting against.

Getting these practical details right from the start is your pre-purchase checklist. From storage and mobility to cleanliness and safety, every feature plays a part in the table's long-term value. Nailing these choices now saves you time, money, and a lot of frustration down the line.

Undershelf Storage: Solid vs. Wire

The space under your prep table is prime real estate. You'll generally have two choices for an undershelf: solid or wire. The best option for you depends entirely on what you'll be storing down there.

- Solid Undershelves: These give you a flat, stable surface, perfect for holding smaller items like spice containers or ingredient boxes that could easily tip or fall through a wire rack. They’re a breeze to wipe down, but they can collect a bit more dust.

- Wire Undershelves: These are great for promoting air circulation, a big plus in a hot kitchen. They're ideal for storing produce like potatoes and onions that need good airflow. Spills fall right through, which means less puddling on the shelf but more cleaning for the floor underneath.

The Non-Negotiable Backsplash

A backsplash is that small raised lip, usually just a few inches high, that runs along the back of the table. It might look minor, but its effect on kitchen cleanliness is massive. It's the simple barrier that stops ingredients, liquids, and utensils from disappearing into that impossible-to-clean gap between the table and the wall.

This one feature keeps messes contained on the work surface, speeding up cleanup and preventing food scraps from building up in hidden spots—a huge red flag for health inspectors. If your table is going against a wall, a backsplash is an absolute must.

Add a Little Flexibility with Casters

Not every prep table for restaurant use needs to be bolted to the floor. Choosing a model with casters (which are just heavy-duty wheels) introduces a level of flexibility that can be a game-changer. A mobile prep table can be rolled out of the way for deep cleaning, shifted around to fit a new workflow, or even brought out for special catering events.

For kitchens with constantly changing layouts or strict cleaning schedules, casters turn a stationary piece of equipment into a versatile, mobile workstation. Just make sure they have locks to keep the table firmly in place when you're working.

Sizing It Up for a Smooth Workflow

One of the easiest mistakes to make is getting the wrong size prep table. If it's too big, it becomes an obstacle, blocking walkways and disrupting the kitchen's flow. If it's too small, your chefs will be cramped for space and their efficiency will tank.

Before you even think about buying, get out a tape measure. Carefully measure your space, and don't forget to account for things like door swings and how your team moves around. A solid rule of thumb is to leave at least 36 inches of clearance for main walkways. As you plan the purchase, looking into equipment financing for small business can be a smart move to get the gear you need without tying up all your capital.

Why NSF Certification Is a Big Deal

If you spot an "NSF" logo on a prep table, that's a good thing. It means NSF International has tested and certified it to meet strict public health and safety standards. This isn't just a friendly suggestion—it’s a requirement for most local health departments.

An NSF-certified table is your guarantee that it's made from food-safe materials, designed for easy and thorough cleaning, and built to prevent bacteria from finding a place to hide. That little logo is your peace of mind, assuring you the table is safe for a commercial kitchen and will fly through health inspections.

Prep Table Feature Comparison for Your Restaurant

Still weighing your options? This table breaks down the key features across the most common prep table types. It’s a quick way to see which one lines up best with what your kitchen truly needs.

| Feature | Standard Stainless Steel Table | Sandwich/Salad Prep Table | Pizza Prep Table |

|---|---|---|---|

| Work Surface | Open, flat stainless steel | Integrated cutting board, refrigerated wells | Deep, wide cutting board, refrigerated rail |

| Refrigeration | None | Refrigerated base and top rail | Refrigerated base and top rail |

| Backsplash | Optional, but highly recommended | Typically included | Typically included |

| Storage | Undershelf (solid or wire) | Refrigerated cabinets/drawers | Refrigerated cabinets/drawers |

| Best For | General prep, mixing, non-perishables | Assembling sandwiches, salads, burritos | Assembling pizzas, calzones, flatbreads |

| Mobility (Casters) | Often optional | Often included or optional | Often included or optional |

| NSF Certification | Essential for commercial use | Essential for commercial use | Essential for commercial use |

Choosing the right features from the get-go ensures your prep table becomes a seamless part of your kitchen's rhythm, rather than an obstacle to work around.

Maximizing Your Investment with Proper Care

Think of a quality prep table as a long-term asset for your restaurant. Just like any crucial tool in your kitchen, its lifespan and performance hinge on how well you take care of it. Protecting that investment starts the moment you unbox it with proper installation and carries through with a consistent maintenance routine. This isn't just about making your equipment last longer; it's about upholding the highest standards of food safety and keeping your kitchen running like a well-oiled machine.

The first thing you’ll want to do is get it perfectly level. This can be tricky, especially on notoriously uneven kitchen floors. Most commercial prep tables come with adjustable bullet feet for this exact reason. Grab a level, place it on the surface, and twist the feet up or down at each corner until it's perfectly balanced. An unstable table is more than just an annoyance—it's a safety hazard that puts unnecessary strain on the frame.

Maintenance for Refrigerated Models

If you've got a refrigerated prep table, care goes beyond just the surface. These units are the workhorses keeping your ingredients chilled and safe, and their refrigeration systems need a little TLC to avoid expensive breakdowns. The compressor is the heart of the unit, and it needs to breathe.

Always leave at least a few inches of clearance around the ventilation grilles. If the airflow is blocked, the compressor has to work overtime, which means higher energy bills and a much shorter lifespan for the unit. Make it a weekly habit to clean the condenser coils. These coils are magnets for dust and grease, but a quick brushing is all it takes to keep them clean and running efficiently.

Stainless Steel Cleaning Protocols

Stainless steel is tough and known for its resistance to corrosion, but it's not indestructible. The secret to keeping it looking great is a simple, consistent cleaning schedule. For daily wipedowns, all you need is a soft cloth, warm water, and a mild detergent. Always remember to wipe in the direction of the steel's grain—this little trick helps you avoid creating tiny scratches on the surface.

To keep rust at bay and maintain a hygienic surface, stay away from harsh abrasives like steel wool. Also, avoid any cleaners that contain chlorine, as they can eat away at the protective layer of the steel. Sticking to a strict cleaning schedule will do more than just extend your prep table's life; it will also help you avoid costly restaurant health code violations.

For a deeper dive into equipment upkeep, check out our guide to commercial kitchen equipment maintenance.

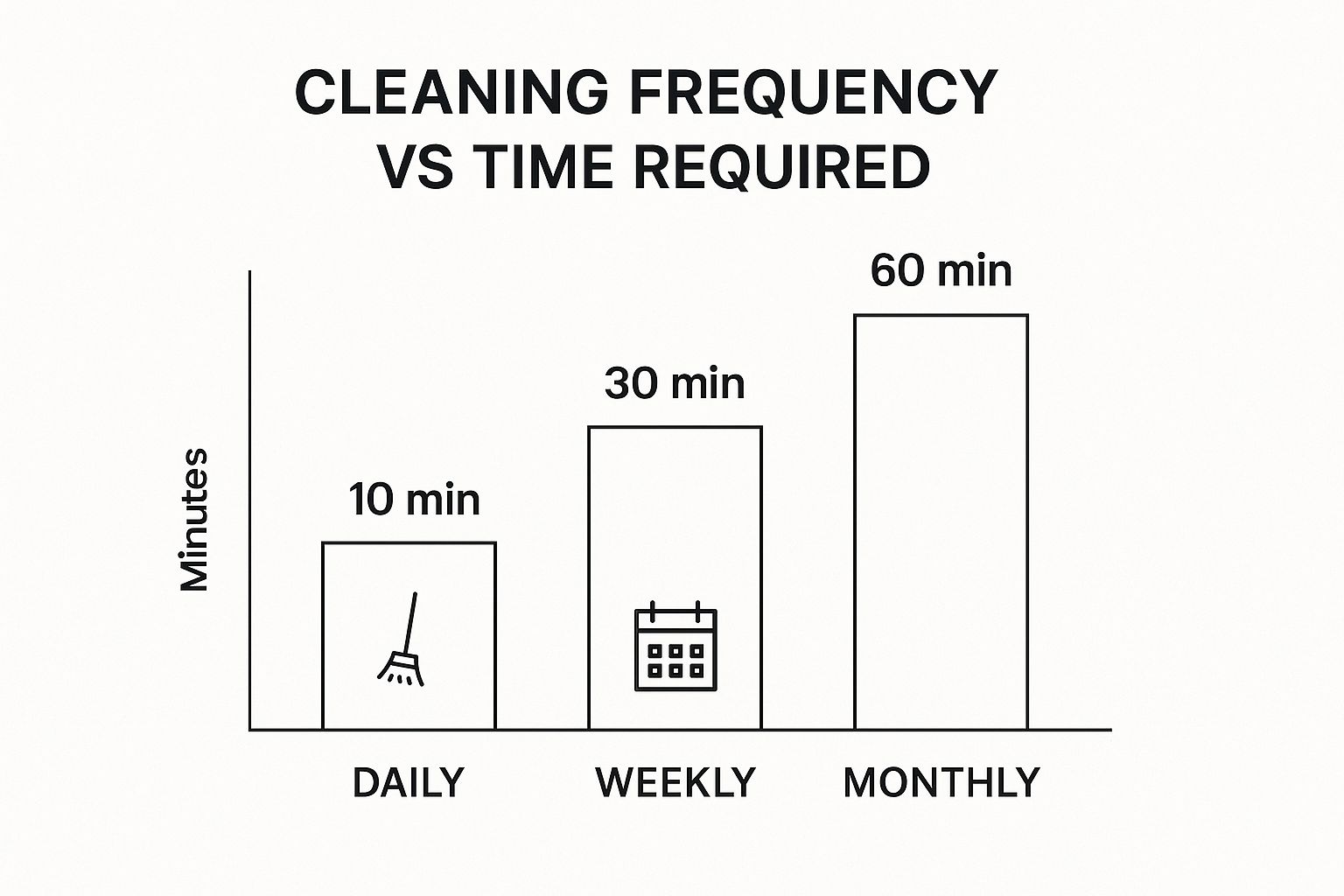

To make things easy, here’s a simple checklist you can share with your team:

-

Daily:

- Wipe down all surfaces with a food-safe sanitizer at the start and end of every shift.

- Clean up spills right away to stop them from sticking and staining.

-

Weekly:

- Brush the condenser coils on refrigerated units to get rid of any dust buildup.

- Check and tighten any loose nuts or bolts on the legs and undershelves.

-

Monthly:

- Give the stainless steel surfaces a deep clean and polish with a designated cleaner.

- Inspect the gaskets on refrigerated doors for cracks or tears. A bad seal lets cold air escape and wastes energy.

Your Top Prep Table Questions, Answered

Picking the right prep table for your restaurant can feel like a pop quiz you didn't study for. With all the different options, features, and lingo, it’s easy to get overwhelmed. Let's clear up some of the most common questions so you can make your final choice with confidence.

Think of this as your cheat sheet. We'll sort through the key details that make the difference between a great investment and a future headache. By the end, you'll know exactly what your kitchen needs.

What Is the Best Stainless Steel Gauge for My Kitchen?

The "best" steel gauge really comes down to the job at hand. Gauge is just a measure of the steel's thickness, and the rule is pretty simple: the lower the number, the thicker and tougher the steel.

-

14-Gauge: This is the tank. You'll want 14-gauge for any heavy-duty work like butchering, pounding out meats, or holding up massive equipment like a 60-quart mixer. It’s built to take a constant beating without denting or warping.

-

16-Gauge: This is the industry go-to and the sweet spot for most kitchens. It strikes the perfect balance between durability and price, making it ideal for all your general prep work—chopping, mixing, and assembling food day in and day out.

-

18-Gauge: This is your light-duty player. It's perfect for holding smaller appliances, storing dry goods on an undershelf, or for use as a utility table that won't see a lot of heavy action.

Don't waste money on a 14-gauge table for light tasks, but more importantly, don't risk putting your heavy mixer on a flimsy 18-gauge surface. Just match the gauge to the grind.

Do I Really Need an NSF Certified Prep Table?

Short answer: yes, you absolutely do. NSF (National Sanitation Foundation) certification is your guarantee that the table meets strict public health and safety standards. It’s not just some sticker; it’s a must-have for passing most local health inspections.

An NSF-certified table is built from the ground up to be non-porous, a breeze to clean, and resistant to bacteria. If you skip this, you’re risking a failed health inspection, which could mean fines or even getting shut down. It's simply not negotiable for a commercial kitchen.

This certification means every little detail, from the welds to the fasteners, is designed to keep food particles and germs from getting trapped. It's a cornerstone of a clean, compliant kitchen.

Pizza vs. Sandwich Tables: What Is the Real Difference?

While they both look like refrigerated prep stations, they’re actually engineered for two very different workflows. The real differences are in the work surface and the topping rail design, each tailored to a specific menu.

A pizza prep table has a much deeper work surface, usually 19 inches or more. That extra real estate is essential for stretching out large pizza doughs. The refrigerated rail is also raised higher, which helps contain bulky pizza toppings and stops them from spilling onto your dough.

On the other hand, a sandwich prep table has a narrower cutting board that runs right alongside the refrigerated wells. This setup is all about a straight-line assembly process—perfect for building sandwiches, salads, or burritos as you move down the line. The wells are usually flush with the counter for quick, easy scooping. These efficient stations are getting more popular every year; the global market for food prep tables hit about USD 1.18 billion in 2023 and is expected to climb to USD 1.62 billion by 2029. You can dive deeper into this trend over at Arizton Advisory & Intelligence.

Should I Choose a Table With or Without a Backsplash?

This one is simple: it all depends on where you plan to put the table. If your prep table is going to live against a wall, then a backsplash is non-negotiable.

That little raised edge at the back of the table is a lifesaver. It stops food, liquids, and utensils from disappearing into that impossible-to-clean gap between the table and the wall. This one small feature makes cleanup way faster and prevents grime and bacteria from building up where health inspectors love to look. If your table is set up as an island in the middle of the kitchen, you can skip the backsplash.

Ready to find the perfect prep table that meets your kitchen's every need? At PrepTables.com, we offer a huge selection of NSF-certified stainless steel work tables, specialized pizza and sandwich stations, and commercial refrigeration solutions. Explore our durable, high-quality equipment today at https://preptables.com and build the efficient, safe, and productive kitchen you've always wanted.