Your Essential Guide to Hot Holding Cabinets

Share

Think of a hot holding cabinet as your kitchen’s secret weapon—the perfect waiting room for your perfectly cooked food. It’s a specialized, insulated unit built to keep dishes at a precise, food-safe temperature without actually cooking them any further. In short, it locks in the quality, texture, and flavor of your food from the moment it leaves the pan to the moment it hits the plate.

Why a Hot Holding Cabinet Is Your Kitchen's MVP

In a pro kitchen, timing isn’t just important—it’s everything. The hot holding cabinet is the unsung hero that closes the gap between prep and service, making sure every dish arrives just as the chef intended. This isn't just about keeping food warm; it's about holding onto that peak freshness and, crucially, keeping it safe.

Picture a chaotic dinner rush. Orders are flying in, all with different cook times. A perfectly seared steak is ready, but the roasted vegetables need another five minutes. Without a holding cabinet, that steak starts getting cold. With one, the chef can slide the finished items in, turning a frantic scramble into a smooth, controlled flow.

Protecting Your Customers and Your Bottom Line

Food safety is the one area where there are absolutely no shortcuts. A hot holding cabinet's main job is to keep food out of the temperature "danger zone"—that notorious range between 40°F and 140°F where bacteria throw a party. By holding food consistently above 140°F (60°C), these cabinets are a critical defense against foodborne illness and a key part of staying compliant.

But it’s not just about safety; this piece of gear is a massive boost to your finances. It cuts down on food waste by giving prepared dishes a much longer shelf life. Instead of tossing out food that’s gone cold or lost its texture, you can hold it for service, saving both your ingredients and your profits. This efficiency is why the global food holding equipment market keeps expanding. In fact, the market was valued at around USD 5.2 billion in 2025 and is projected to hit nearly USD 7.2 billion by 2035. You can dig deeper into this growing market over at FutureMarketInsights.com.

Here's a quick look at how these cabinets work for your business.

Core Functions of a Hot Holding Cabinet

| Function | Primary Benefit | Impact on Business |

|---|---|---|

| Temperature Maintenance | Keeps food above the 140°F "danger zone" to inhibit bacterial growth. | Prevents foodborne illness, ensures regulatory compliance, and protects your reputation. |

| Quality Preservation | Maintains food texture, moisture, and flavor without overcooking. | Delivers a consistent, high-quality product to customers every single time. |

| Workflow Management | Allows chefs to cook in batches and hold items until needed for service. | Reduces ticket times, decreases staff stress during peak hours, and improves kitchen efficiency. |

| Waste Reduction | Extends the viable life of prepared dishes, preventing them from being discarded. | Lowers food costs, increases profit margins, and supports sustainability efforts. |

These core functions come together to make the holding cabinet one of the most valuable players in any commercial kitchen.

Enhancing Kitchen Efficiency

A well-used holding cabinet unlocks the power of batch cooking. Your team can prep large quantities of popular dishes—think roasted chicken, mashed potatoes, or signature soups—during the slower periods. When the dinner rush slams the kitchen, those items are hot, fresh, and ready for plating. Ticket times drop, and happy customers get their food faster.

A hot holding cabinet isn't just a box that keeps food warm. It's a strategic tool that buys you time, protects your product, and streamlines your entire service process from the kitchen line to the customer's table.

The ripple effect of this efficiency is huge. It leads to a more organized kitchen, less stress for your crew, and a reliably great dining experience for every guest. By mastering the art of holding, you give your kitchen the power to perform at its peak, even when the pressure is on.

Decoding the Different Types of Holding Cabinets

Picking the right hot holding cabinet isn't a one-size-fits-all situation. The perfect unit for a massive hotel banquet would be serious overkill for a food truck, and a small café cabinet wouldn't last a minute in a high-volume kitchen. The first step is to get a handle on the basic differences in how they're built and where they fit into your workflow.

The biggest split comes down to how a cabinet is constructed and where it will live in your kitchen. Some are built to move, while others are permanent fixtures designed to streamline your line.

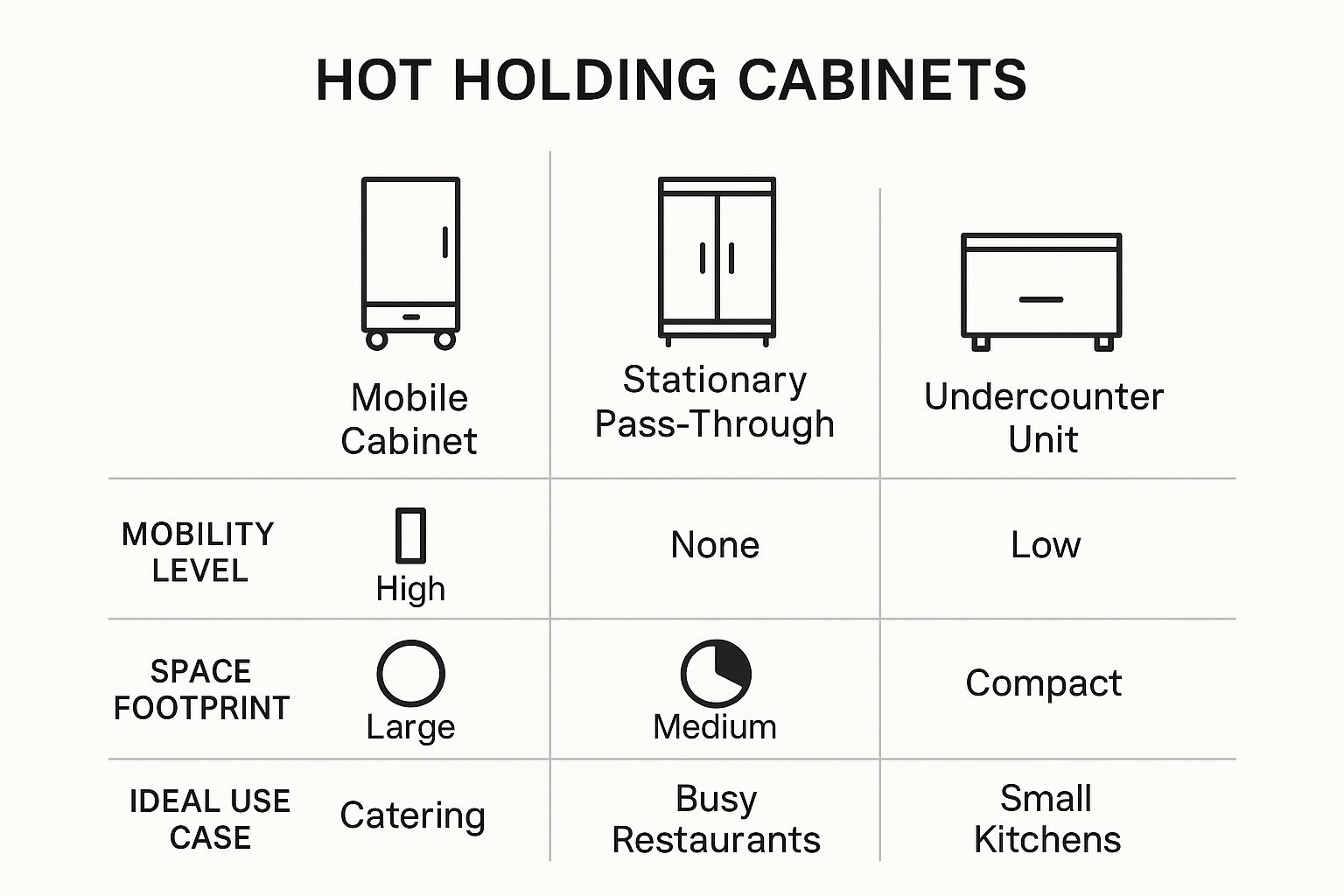

This infographic gives a great visual breakdown of three of the most common hot holding cabinet styles you'll encounter.

As you can see, each type is really tailored for a specific job, striking a different balance between mobility, footprint, and function.

Categories Based on Form and Function

Mobile Cabinets, which you'll often hear called transport cabinets, are the workhorses for caterers and event spaces. They're built on sturdy casters, allowing you to load them up in the kitchen and roll them right out to the service area. This keeps food perfectly hot and safe all the way to the guest.

Stationary Pass-Through Cabinets are designed for busy kitchens that have a clear line separating the prep area from the service area. With doors on both the front and back, cooks can load freshly prepared food from their side, and servers can grab it from the other. It’s a brilliant way to create a smooth, efficient flow and keep service staff out of the hot line.

Undercounter Cabinets are lifesavers in kitchens where every last inch of floor space counts. These compact units slide right under a standard countertop, giving you vital holding capacity without messing up your kitchen layout. They're perfect for smaller spots like cafes or for dedicating a holding space to a specific station on your line.

The Technology Powering Your Cabinet

Beyond the physical build, the heating technology inside is what really dictates how the cabinet performs and what kind of food it's good for. You're mainly looking at two different approaches: controlling dry heat versus actively managing humidity.

-

Dry Heat Cabinets: Think of these as the classic "hot box." They're the simplest type of hot holding cabinet, using a basic heating element to keep the inside warm. They're cost-effective, but they're best for holding things for a shorter time, especially foods that do well in a dry environment like anything breaded or fried.

-

Humidity-Controlled Cabinets: These are the more sophisticated option. By adding moisture into the cabinet, they do a much better job of preserving the quality of delicate foods. They stop things from drying out, which is a game-changer for holding roasted meats, steamed veggies, and sauces for longer periods.

Here's the key takeaway: for a lot of food, managing humidity is just as crucial as managing temperature. A cabinet with humidity control gives you way more flexibility and protects the texture and quality of a much bigger chunk of your menu.

For kitchens that need absolute precision, some models have advanced features that work almost like a high-tech food warmer table. If you want to dive deeper into how these different heating systems compare, check out our guide on the benefits of a food warmer table.

Making the Right Choice for Your Menu

At the end of the day, the best hot holding cabinet for you comes down to what you're cooking.

A pizzeria that needs to hold crispy-crust pizzas might be perfectly happy with a simple dry heat cabinet. But a fine-dining spot holding a beautiful prime rib absolutely needs a humidity-controlled unit to keep it juicy and perfect. Always think about your menu first, and let that guide you to the technology that will best protect the food you work so hard to create.

Must-Have Features Before You Invest

Choosing a new hot holding cabinet can feel like just comparing spec sheets. But the features that really count go way beyond the basic dimensions and capacity. Making a smart investment means looking at the parts that will actually affect your day-to-day operations, your energy bills, and ultimately, your food quality.

This is your buyer's checklist. We’re going to break down the critical features that separate a reliable workhorse from a source of daily frustration. These are the details that make sure you get a return on your investment for years to come.

The Foundation of Performance Insulation and Construction

Think of a holding cabinet's insulation like the walls of a really good thermos. High-quality foam or fiberglass insulation is what keeps the internal temperature stable without constantly kicking the heating element on. This translates directly to better energy efficiency and lower utility costs over the life of the unit.

Poor insulation means the cabinet has to work overtime. That leads to temperature swings that can ruin food safety and quality. It’s a feature you can’t see, but its impact is huge. A well-insulated cabinet is the cornerstone of consistent performance and saving money.

Just as important is the overall build quality. Look for durable, food-grade stainless steel. This stuff is not only tough enough for a busy kitchen but is also non-porous and easy to clean, which is critical for hygiene. Also, check the door gaskets—the rubber seals around the door. A tight seal stops heat from escaping, which is another key part of being energy efficient.

Precision at Your Fingertips Temperature and Humidity Controls

The control system is the brain of your hot holding cabinet. It’s the difference between a perfectly held prime rib and a dried-out disaster. Your main choices are old-school analog dials or modern digital panels, and that choice makes a big difference.

Precision is non-negotiable in food holding. Digital controls, often accurate to within 2°F, offer a level of reliability that older analog systems, which can fluctuate by as much as 10°F, simply cannot match.

Analog controls are simple and cheaper upfront, but they aren't very precise and often need to be recalibrated. Digital controls, on the other hand, let you set the exact temperature and give you clear readouts. It takes all the guesswork out of food safety. This level of control is why the global heated holding cabinet market, valued at around USD 3.5 billion in 2023, is growing so fast as chefs demand better tech. You can find more in-depth analysis on this expanding market at Dataintelo.com.

Let's put the two control types side-by-side to see how they stack up.

Feature Comparison Analog vs Digital Controls

When you're deciding between control systems, it helps to see the key differences clearly. This table breaks down what you can expect from each type.

| Feature | Analog Controls | Digital Controls |

|---|---|---|

| Precision | Less precise, often with a +/- 10°F variance. | Highly precise, typically accurate to within a few degrees. |

| Ease of Use | Simple knobs are intuitive but lack specific temperature settings. | Clear digital readouts allow for exact temperature and humidity inputs. |

| Consistency | Can be prone to temperature swings and requires manual checks. | Maintains a very stable environment with minimal fluctuation. |

| Advanced Features | Basic temperature control only. | Often includes humidity control, timers, and programmable settings. |

As you can see, digital controls offer a significant advantage in almost every area that impacts food quality and operational ease.

For foods that dry out easily, like roasted meats or steamed veggies, humidity control is a must-have. A cabinet that lets you manage both heat and moisture will keep food tasting and looking fresh for much longer.

Features That Enhance Daily Workflow

Beyond the core tech, several practical features can make a huge difference in your kitchen's daily grind.

-

Adjustable Shelving: Look for cabinets with shelf slides or racks you can move around or take out. This flexibility lets you configure the inside to hold everything from shallow sheet pans to deep hotel pans, making the most of your space.

-

Door Type: Solid doors are the best for insulation and keeping heat in. However, glass doors give you great visibility, so staff can check inventory at a glance without opening the door and letting all the heat out. Your choice depends on whether efficiency or visibility is more important.

-

Interior Lighting: Good interior lighting might seem like a small detail, but it’s incredibly useful. It helps staff see what’s inside, making it faster to grab the right items during a busy service. This reduces mistakes and keeps the door closed more often.

By carefully thinking about these must-have features, you move beyond just the price tag to see the true long-term value of a hot holding cabinet. The right mix of solid construction, precise controls, and user-friendly design will make it a reliable and profitable tool in your kitchen.

The Role of Stainless Steel Prep Tables in Your Workflow

Long before a dish is perfectly held in a hot holding cabinet, it starts its journey on a prep table. These surfaces are the command centers of an efficient kitchen, and choosing the right type is crucial for a smooth workflow. Stainless steel is the industry standard for a reason: it's durable, hygienic, and easy to sanitize. Let’s explore the various types available.

Standard Work Tables: The Kitchen's All-Purpose Hub

The most common type is the standard stainless steel work table. It offers a simple, sturdy surface for a huge range of tasks, from chopping vegetables and butchering meat to plating finished dishes. Many come with an undershelf, which is invaluable for storing equipment and ingredients, keeping the main work surface clear and organized. A clutter-free prep area is the first step toward efficient service, ensuring food gets to the hot holding cabinet on time.

Sandwich and Salad Prep Tables: The Cold Line Champions

For delis, cafes, and restaurants with a heavy focus on cold items, specialized sandwich and salad prep tables are essential. These refrigerated units combine a countertop work surface with a series of cold wells on top, keeping ingredients like sliced meats, cheeses, and fresh vegetables chilled and within easy reach. This design drastically speeds up assembly time and ensures food safety by maintaining the cold chain right up until the moment of service.

Pizza Prep Tables: The Specialist for Perfect Pies

Pizzerias and Italian restaurants rely on pizza prep tables, which are engineered specifically for crafting pies. These units feature refrigerated rails for toppings and often include refrigerated drawers designed to hold and proof dough at the perfect temperature. A wide, durable cutting board runs the length of the table, providing ample space to stretch dough and assemble pizzas efficiently. Some high-end models even offer marble or granite surfaces that stay naturally cool, which is ideal for working with sticky dough.

A well-organized prep table is the starting point of an efficient kitchen. When every tool and ingredient has its place, the entire process—from initial prep to final holding—becomes faster, safer, and less stressful for your team.

A chaotic prep station leads to mistakes and poor timing, which undermines the quality of the food you're trying to preserve in your holding cabinet. By choosing the right stainless steel prep table for your menu, you build a foundation for efficiency that benefits the entire kitchen.

Best Practices for Flawless Food Holding

Getting the perfect hot holding cabinet is only half the battle. How you use it is what really separates the pros from the amateurs. If you master a few key practices, your cabinet transforms from a simple hot box into a strategic tool that guarantees impeccable food quality and safety, shift after shift. Think of these daily strategies as your playbook for flawless execution.

The absolute number one rule? Always preheat your cabinet. You wouldn't throw a cake into a cold oven, and you should never put hot food into a cold holding unit. If you do, the food's temperature will plummet right into the unsafe "danger zone," where bacteria have a field day.

Give your unit a good 30-45 minutes to get up to temp before you put anything inside. This makes sure the cabinet is ready to maintain heat from the get-go, not just slowly warm things back up.

Arranging Food for Optimal Performance

How you load food into the cabinet makes a huge difference. The most common mistake I see is overcrowding. When you cram pans together, you choke off the airflow, creating hot and cold spots that wreck both food safety and quality. A well-organized cabinet lets hot air move freely around every single pan.

It’s like building a campfire—you need space between the logs for the heat to circulate. Just leave at least an inch of space between pans on all sides. It's a simple step, but it ensures a consistent temperature throughout the entire unit, holding every dish perfectly.

A hot holding cabinet should be a fortress against the temperature "danger zone" (40°F to 140°F). Proper preheating and consistent temperature checks are not just best practices—they are non-negotiable requirements for food safety.

By focusing on these operational details, you turn holding food from a guessing game into a precise science. The result is that every plate you serve is both delicious and safe for your customers.

Setting Temperature and Humidity for Success

Different foods need different holding environments. A one-size-fits-all approach just doesn't work; you'll end up with soggy fried chicken and dried-out roasts. The real key is to match the cabinet's settings to your specific menu.

- For Crispy Foods: Things like fried chicken or french fries need a dry, hot environment. Keep the humidity settings low to preserve that satisfying crunch and stop them from going limp.

- For Moist Foods: On the other hand, roasted meats, steamed veggies, and sauces need humidity to keep their texture and moisture. You can use a pan of water or adjust the cabinet's humidity controls to keep them from drying out.

This is exactly why the hot holding cabinet market is so important. These commercial units are a critical investment for any serious foodservice operation, with the market valued at an estimated USD 1.2 billion in 2024 and only expected to grow. They’re the unsung heroes that ensure food stays safe and tastes great. You can find more market insights on VerifiedMarketReports.com.

Essential Cleaning and Maintenance Routines

A hot holding cabinet is a serious investment in your kitchen's quality and food safety. Like any other piece of hardworking equipment, it needs regular care to keep it performing at its best. Think of consistent cleaning and preventative maintenance not as chores, but as essential routines that protect your gear, keep things hygienic, and head off expensive breakdowns before they happen.

If you let things slide, you'll start seeing inaccurate temperatures, higher energy bills, and just plain unsanitary conditions. A little bit of attention every day prevents that sticky buildup of grease and food particles that can really do a number on the internal components over time. It’s the foundation of reliable performance.

Daily Cleaning Checklist

A quick wipe-down at the end of each day is non-negotiable. This simple habit stops grime from hardening into a much bigger, more annoying job down the road.

- Power Down and Cool Off: Safety first. Always unplug the unit and let it cool down completely before you start cleaning.

- Remove Racks and Shelves: Pull out all the removable interior parts. Give them a good wash in a commercial sink with a food-safe detergent, then rinse and let them air dry.

- Wipe Interior Surfaces: Grab a soft cloth and a mild, food-safe cleaner to wipe down the entire interior—walls, floor, and the inside of the door.

- Clean the Exterior: Don't forget the outside. Wipe down the cabinet, paying special attention to the handle and controls where grime tends to build up.

This daily reset ensures your hot holding cabinet is fresh and ready for the next service.

Weekly and Monthly Maintenance Tasks

Beyond the daily wipe-down, setting aside a few minutes each week and month for deeper checks will keep your cabinet running like a champ. It's all about spotting potential issues before they turn into real problems. A proactive approach is always, always better than a reactive repair.

For a bigger picture on keeping all your kitchen gear in top shape, it's a great idea to adopt a comprehensive yearly appliance maintenance checklist.

Weekly Tasks:

- Inspect Door Gaskets: Take a close look at the rubber seal around the door. You're searching for any cracks, tears, or signs that it's getting brittle. A damaged gasket lets precious heat escape, forcing the unit to work overtime and wasting energy.

- Deep Clean the Interior: Give the inside a more thorough cleaning. If you have some stubborn, stuck-on residue, a non-abrasive scrub brush can be your best friend here.

A well-maintained door gasket is one of the most critical components for energy efficiency. A tight seal can reduce energy consumption by ensuring the heating element doesn't have to cycle on as frequently.

Monthly Checks:

- Calibrate the Thermostat: Pop an oven-safe thermometer inside and see if the cabinet's temperature display is telling the truth. If it’s off by more than a few degrees, you might need to call in a pro for calibration.

- Check Heating Elements: Just give the heating elements a quick visual inspection. Look for any obvious signs of damage or buildup that could cause problems.

These simple routines are a key part of a larger strategy for getting the most life out of your equipment. To dive deeper, check out our complete guide on commercial kitchen equipment maintenance for a full-circle view of asset care.

Common Questions About Hot Holding Cabinets

Even after you get the hang of your hot holding cabinet, some questions always seem to pop up during the daily grind. Here are some quick, straightforward answers to the most common queries we hear.

Can I Cook Food in a Hot Holding Cabinet?

Absolutely not. A hot holding cabinet is designed for one thing only: keeping already cooked food at a safe temperature, which means staying consistently above 140°F (60°C). It just doesn't have the intense heating power needed to cook raw food safely from scratch.

Trying to cook in a holding cabinet is a recipe for disaster. It will let food sit in the temperature "danger zone," creating the perfect breeding ground for nasty bacteria. Think of your cabinet as a cozy waiting room for your food, not the oven itself.

How Do I Stop Food from Drying Out?

This is a classic kitchen challenge, but it's totally manageable. The best fix is to use a cabinet that has humidity controls built right in, letting you add moisture to the air. If you have a simpler dry-heat model, an easy trick is to place a hotel pan of water on the bottom shelf to create a little steam.

Also, don't forget the basics: keep your food covered with lids or foil. This simple step is a game-changer for trapping moisture. Lastly, try to minimize how often you open the door—every time you do, you're letting precious heat and humidity escape.

The core difference between a proofing and a holding cabinet lies in their temperature and humidity ranges. A proofing cabinet uses low heat and high humidity for rising dough, while a holding cabinet uses high heat to keep cooked food safe.

What Is the Difference Between a Proofing and a Holding Cabinet?

They might look similar on the outside, but their jobs are completely different. A proofing cabinet is a baker's best friend. It creates a warm, moist environment (usually around 80°F to 115°F) that's perfect for helping bread and other doughs rise, or "proof."

A hot holding cabinet, on the other hand, runs at much higher temperatures to keep cooked food hot, safe, and ready to serve. While some fancy combo units exist, your standard holding cabinet is definitely not the right tool for proofing dough.

How Often Should I Check Food Temperatures Inside?

To be absolutely sure about food safety, you need to check the internal temperature of your food with a good, calibrated thermometer at least every two hours. This regular check confirms that everything is staying safely above that critical 140°F (60°C) line.

This isn't just a good idea; it's a vital part of any Hazard Analysis and Critical Control Points (HACCP) plan. It's how you guarantee you're serving food that's not just delicious, but safe. To really stay on top of your kitchen's hygiene, think about adding your cabinet's cleaning schedule to your ultimate kitchen deep cleaning checklist.

Ready to streamline your kitchen's workflow and ensure food safety? Explore the wide selection of professional-grade hot holding cabinets and other essential equipment at PrepTables.com. Find the perfect solution for your needs at https://preptables.com.