Food Contact Surfaces: Essential Safety & Cleaning Tips

Share

Let's get down to brass tacks. What exactly is a food contact surface? It's any surface that food touches directly. Think beyond the obvious, like cutting boards and prep counters. We're also talking about the inside of your ice machine, the blades on a meat slicer, and every single utensil. Getting a handle on these surfaces is the absolute cornerstone of a safe, hygienic kitchen.

Finding the Perfect Prep Table for Your Needs

In any professional kitchen, the prep table is mission control. It’s where the magic happens, turning raw ingredients into finished dishes. Having the right one isn't just a convenience; it can make or break your workflow, safety, and efficiency. Think of it less like a piece of furniture and more like one of the most critical food contact surfaces in your entire operation.

While you'll see tables made from various materials, stainless steel is the undisputed champion for these high-traffic areas. Its non-porous surface is a fortress against bacteria, and it's tough enough to handle the daily grind. But not all stainless steel tables are created equal—different designs are engineered to solve very specific kitchen problems.

The Classic Stainless Steel Work Table

This is the old reliable, the workhorse you’ll find in just about every commercial kitchen, from a high-end restaurant to a neighborhood food truck. The standard stainless steel work table is loved for its simple design, do-it-all versatility, and pure toughness. When you're picking one out, a couple of key features can make a huge difference in your day-to-day work and long-term hygiene.

A backsplash is one of those simple but brilliant features. It’s a raised edge along the back that stops food and liquids from splashing all over your walls. Even better, it closes that pesky gap between the table and the wall, which is a favorite hiding spot for grime and bacteria.

The edge of the table matters, too. A bullnose edge is rounded and smooth, which is a lot more comfortable (and safer) for staff who are leaning against it all day. On the other hand, a square edge lets you push multiple tables right up against each other, creating one long, seamless workspace without any gaps for food to get stuck in.

Specialized Prep Tables for High-Volume Tasks

Moving beyond the all-purpose table, you get into specialized units built to make specific, repetitive jobs faster and safer. These tables are smart—they bring everything a chef needs for a particular station into one compact area. This cuts down on wasted steps and keeps ingredients at safe temperatures.

A well-designed prep table isn't just a surface; it's a strategic tool. By integrating refrigeration and storage directly into the workspace, specialized tables reduce the time food spends in the temperature "danger zone," minimizing the risk of bacterial growth and ensuring compliance with health codes.

Two of the most common specialized tables are game-changers for any spot making a lot of sandwiches or pizzas.

Sandwich Prep Tables: The Assembly Line Powerhouse

Picture a station where every single ingredient for building the perfect sandwich is right at your fingertips. That's a sandwich prep table. These units are true assembly-line powerhouses, built from the ground up for speed and food safety.

Their design usually features:

- A Refrigerated Base: The bottom half is a reach-in cooler, giving you plenty of cold storage for backup meats, cheeses, and veggies.

- An Integrated Cutting Board: A tough cutting board, often made of high-density polyethylene, runs along the front, giving you a dedicated food contact surface for assembly.

- A Refrigerated Rail: Right behind the cutting board is a chilled well that holds multiple food pans. This is where you keep your toppings—lettuce, tomatoes, onions, pickles—perfectly cold and ready to go.

This all-in-one setup means your crew can build sandwiches at lightning speed without ever walking over to a separate fridge. It drastically cuts prep time and keeps every temperature-sensitive ingredient safely chilled.

Pizza Prep Tables: Built for Dough and Toppings

Pizza prep tables work on the same concept but are fine-tuned for the unique flow of a pizzeria. The process of making a pizza—stretching dough, saucing it, and piling on toppings—needs a completely different layout.

You'll notice a few key differences:

- Wider Refrigerated Rails: The chilled wells are usually wider and deeper to hold big pans of cheese, pepperoni, and all the other popular pizza toppings.

- Dough-Friendly Surfaces: Many of these tables have marble or granite countertops. These stones are fantastic food contact surfaces for dough work because they stay naturally cool, which stops the dough from getting warm and sticky.

- Raised Rails: The topping rail is often raised to a more ergonomic height, so the pizza maker can easily grab ingredients while working on the dough below.

By organizing the space for the specific steps of pizza making, these tables help pizzerias keep their quality consistent, crank out orders faster, and maintain the highest food safety standards.

Choosing the Right Materials for Your Surfaces

Picking the right material for your food contact surfaces is a lot like choosing the right tires for a race car. It directly impacts performance, safety, and how long your equipment will last. Not just any material can stand up to the hustle of a professional kitchen. The best ones all share a few key traits: they're non-porous, corrosion-resistant, and incredibly easy to sanitize.

This is exactly why stainless steel is the undisputed king in commercial kitchens. Its smooth, non-absorbent surface gives bacteria absolutely nowhere to hide, which makes cleaning and sanitizing a breeze. It also stands up to rust and corrosion from acidic foods and harsh cleaning chemicals, meaning it won't break down over time and will stay a safe, durable workspace for years.

Understanding Stainless Steel Grades

When you start looking at equipment, you'll see numbers like 304 and 430 attached to stainless steel. These aren't just random digits—they’re grades that tell you about the metal’s makeup and how it will perform. Think of it like the difference between regular and premium gas; both get the job done, but one is built for higher performance.

Here’s what you need to know:

-

304 Stainless Steel is the true industry workhorse. It’s the most common grade you'll find for food contact surfaces because it contains more chromium and nickel, giving it top-tier resistance to rust and corrosion. This makes it perfect for sinks, prep tables, and any surface that gets hit with a lot of moisture or acidic ingredients like lemon juice or tomato sauce.

-

430 Stainless Steel is a more budget-friendly choice. It’s still durable and perfectly food-safe, but it has less nickel, making it a bit less resistant to corrosion over the long haul. You’ll often find it used for table legs, shelving, or the outside of equipment where direct, constant contact with corrosive stuff isn't a big concern.

The choice often comes down to balancing your budget with the table's intended use. For that main prep table that’s going to see heavy, all-purpose action, 304 grade is the superior investment for both hygiene and durability.

The right material isn't just a recommendation; it's a foundational element of your food safety program. A non-porous surface like 304 stainless steel actively prevents the absorption of bacteria, liquids, and food particles, which is the first line of defense against cross-contamination.

Specialized Materials for Specific Tasks

While stainless steel definitely runs the show, a few other materials have carved out important roles for specific jobs where their unique properties give them an edge. These materials get the green light from health departments because they meet the same core standards of being durable and easy to clean.

For instance, cutting boards are almost always made from high-density polyethylene (HDPE). This tough, plastic-like material is non-absorbent and won't dull your knives. Unlike wood, which can trap bacteria in its grain, HDPE can be sent right through a commercial dishwasher for total sanitization.

The one major exception for wood in professional kitchens is hard maple for butcher blocks. Under very strict health code rules, this specific type of dense, closed-grain wood is allowed because its natural properties can help slow down bacterial growth when it's properly cared for. Still, you'll usually only see it used for direct meat-cutting tasks.

Comparing Common Food Contact Surface Materials

To make sense of your options, it helps to see how these materials stack up against each other. Each one has its place in a well-equipped kitchen, and knowing the pros and cons will help you make smarter purchasing decisions.

| Material | Key Characteristics | Common Uses | Pros | Cons |

|---|---|---|---|---|

| 304 Stainless Steel | High chromium/nickel content; non-porous and smooth. | Prep tables, sinks, countertops, equipment surfaces. | Excellent corrosion resistance, highly durable, easy to sanitize. | Higher initial cost compared to other grades. |

| 430 Stainless Steel | Lower nickel content; magnetic. | Equipment exteriors, table legs, shelving, dry-storage areas. | More affordable, durable for non-corrosive uses. | Less resistant to rust and acidic foods over time. |

| HDPE | High-density plastic; non-absorbent and durable. | Color-coded cutting boards, food storage containers. | Prevents cross-contamination, gentle on knives, dishwasher safe. | Can be scored by knives, requiring eventual replacement. |

| Hard Maple | Dense, closed-grain hardwood. | Butcher blocks for direct meat cutting. | Self-healing surface, gentle on knife edges. | Porous if not maintained, requires special cleaning, not dishwasher safe. |

Ultimately, the best choice depends entirely on the job at hand. A stainless steel workhorse is essential, but specialized materials like HDPE are just as critical for maintaining a safe and efficient workflow.

The Impact of Material Choice on Contamination

The material you choose has a direct, measurable effect on how well you can control contamination. Any surface that's porous, cracked, or scratched can quickly turn into a breeding ground for dangerous pathogens.

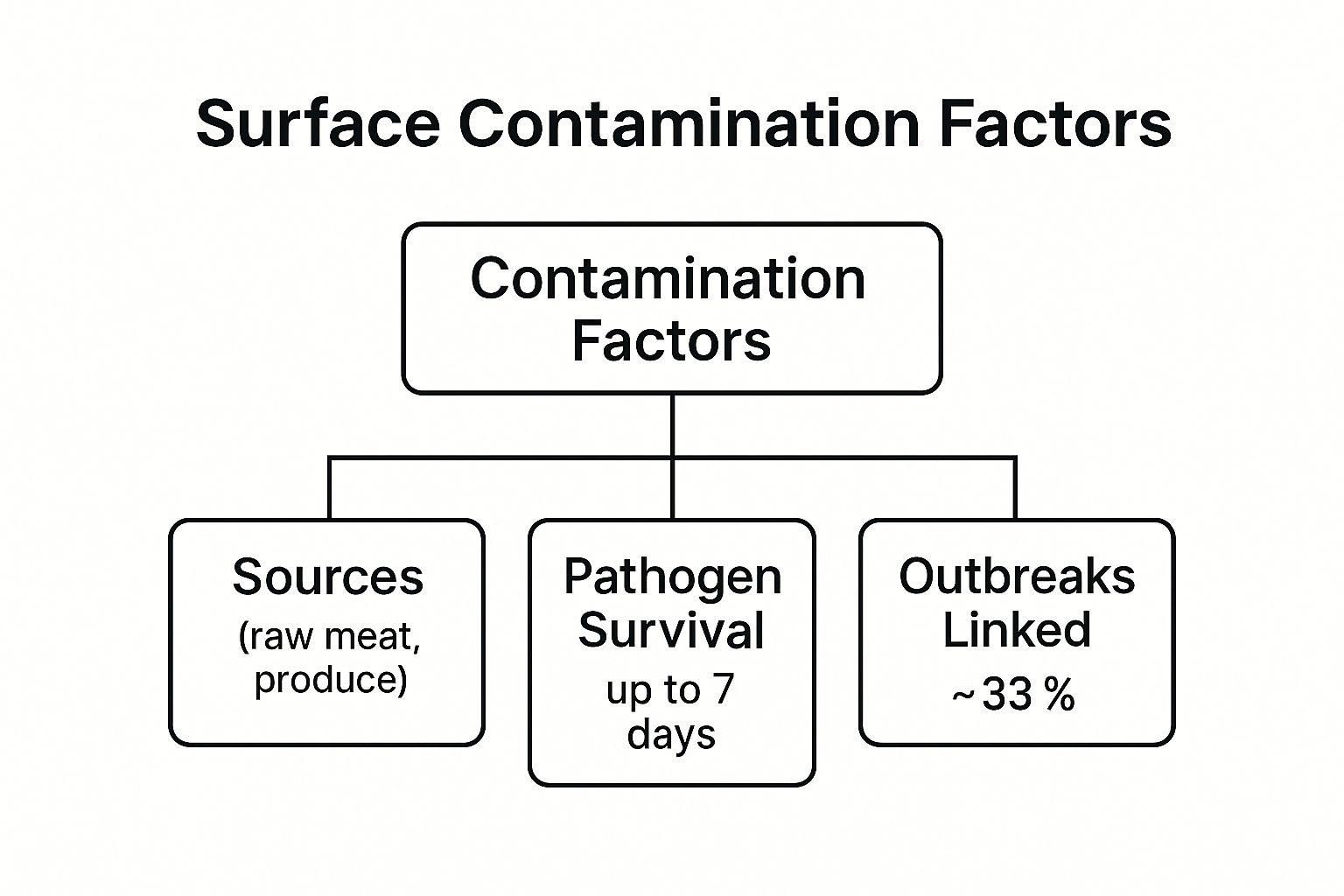

This image really drives home the main factors that contribute to surface contamination in a kitchen.

It’s a clear visual reminder of how easily germs can spread and stick around, which is why picking materials that can be cleaned effectively over and over again is so critical. Making smart purchasing decisions from the start is a cornerstone for any restaurant that wants to uphold the highest standards. To get a better look at specific equipment, you can explore this guide to restaurant stainless steel tables.

The Bigger Picture of Food Contact Surfaces

The principles of safe food contact surfaces don't just stop at the kitchen door. They’re a critical part of the entire global food supply chain, from farm to fork. While a chef worries about a prep table, the exact same safety standards are applied on a massive scale in the food packaging industry.

Here, materials like plastics, metals, and paper are the first line of defense, protecting food as it makes its long journey to the consumer.

This connection is more important now than ever. Think about the rise of ready-to-eat meals and the explosion of food delivery services—these trends have massively increased the need for reliable, hygienic packaging. Every single container, wrapper, and carton has to act as a temporary food contact surface. It must be just as non-toxic and non-absorbent as the stainless steel table in a professional kitchen.

The Growing Importance of Safe Packaging

The scale of the packaging industry is immense. Every packaged item on a grocery store shelf, from a plastic-wrapped block of cheese to a can of tomatoes, relies on materials that meet strict food-safe criteria. They have to prevent chemical leaching, block out contaminants, and maintain the food's quality from the processing plant all the way to a home pantry.

And this demand is only getting stronger. The global food packaging market, which covers all food contact surfaces from paper to glass, was valued at around USD 391.5 billion in 2025. Projections show it rocketing to nearly USD 661.2 billion by 2035, pushed by the popularity of meal kits and online grocery shopping. You can see more on these market trends and how they impact packaging from the experts at Future Market Insights.

This growth shines a light on a crucial point: the integrity of these surfaces is non-negotiable for public health on a global scale. One failure in packaging can lead to widespread contamination, making the choice of safe materials an enormous responsibility for food producers.

Innovations in Packaging Materials

Just like with kitchen equipment, the packaging world is always evolving, with a huge focus on both safety and sustainability. Manufacturers are constantly developing new materials that are not only safe for direct food contact but are also friendlier to the environment.

These innovations often focus on:

- Bio-based plastics: Made from renewable sources like cornstarch, these materials offer a compostable or biodegradable alternative to traditional plastics.

- Active packaging: This is smart packaging that does more than just hold the food. It might have elements that absorb oxygen to stop spoilage or even release antimicrobial agents to extend shelf life.

- Improved barrier coatings: New, super-thin coatings for paper and cardboard can provide the same moisture and grease resistance as plastic linings but with a much smaller environmental footprint.

The real challenge for the packaging industry is a constant balancing act. They have to ensure the material is a perfectly safe food contact surface, meet consumer demands for convenience and sustainability, and keep costs low enough for mass production.

Ultimately, understanding food packaging gives you the full picture of food safety. The same core principles that guide your choice of a cutting board are being applied to billions of containers worldwide. Whether it’s a stainless steel work surface or a recyclable plastic clamshell, the goal is always the same: to provide a safe, inert, and cleanable surface that protects food at every step.

Mastering Your Cleaning and Sanitizing Process

In a professional kitchen, a surface that looks clean isn't always safe. Wiping away visible crumbs and spills is just the first step. To really protect your customers—and your reputation—you have to master the critical difference between cleaning and sanitizing your food contact surfaces.

Think of it this way: cleaning is like sweeping the floor to get rid of the dirt you can see. Sanitizing is like mopping it afterward with disinfectant to kill the germs you can't.

Cleaning is the physical act of removing food scraps, grease, and grime. It's the essential first step that clears the way for the real work. Sanitizing, on the other hand, is the chemical process that kills or reduces invisible pathogens like bacteria and viruses down to safe levels. You simply can't sanitize a dirty surface, which makes this two-part punch non-negotiable for food safety.

The Five-Step Process for Safe Surfaces

To ensure every food contact surface is both spotless and safe, your staff needs a consistent, five-step method they can follow every single time. This isn't just a friendly suggestion; it's the bedrock of food safety in any commercial kitchen. Skipping even one step can compromise the entire process and put your diners at risk.

The process is straightforward and easy to train:

- Scrape: Get all the loose food and leftovers off the surface. A simple scraper or brush works wonders for clearing away any large debris.

- Wash: Use hot, soapy water and a clean cloth or brush to scrub everything down. This breaks down grease and any stubborn, stuck-on food.

- Rinse: Give the surface a good rinse with clean, clear water to wash away all the soap and the grime you just loosened up.

- Sanitize: Apply your sanitizing solution across the entire surface. This is the step that actually kills the germs.

- Air-Dry: Let the surface air-dry completely. Whatever you do, don't use a towel—it can reintroduce the very contaminants you just worked so hard to eliminate.

Understanding Your Sanitizing Tools

Not all sanitizers are created equal, and using them correctly is absolutely vital. The two most common types you’ll find in commercial kitchens are chlorine (bleach) and quaternary ammonium compounds, often called "quats". Each has its own specific rules for concentration and contact time to be effective.

The effectiveness of a sanitizer depends entirely on two factors: the right concentration and sufficient contact time. Too little of either, and you’re just wasting time and product without actually killing harmful pathogens.

For example, a standard chlorine solution needs a concentration of 50-100 parts per million (ppm) and has to sit on the surface for at least 30 seconds. Quats often require a higher concentration, around 200 ppm, and might need a contact time of 60 seconds or more. Always read the manufacturer’s instructions and use test strips to make sure your solution is mixed correctly. Keeping these surfaces in top shape is a key part of any good maintenance plan. For a deeper dive, check out our guide on commercial kitchen equipment maintenance.

Critical Timing for Cleaning and Sanitizing

Knowing how to clean is just as important as knowing when. In a busy kitchen, having clear rules on timing is what prevents cross-contamination and bacterial growth. These aren't flexible guidelines; they're hard-and-fast rules that protect public health.

There are two primary timing rules to hammer home with your team:

- Between Tasks: Surfaces must be cleaned and sanitized whenever you switch between different food types. The most critical switch is going from raw foods (like chicken or beef) to ready-to-eat foods (like salad greens or sandwich toppings). This is how you stop dangerous pathogens from hitching a ride onto food that won't be cooked.

- The Four-Hour Rule: Any food contact surface that's in continuous use has to be stopped, cleaned, and sanitized at least once every four hours. This rule is based on how quickly bacteria can multiply to dangerous levels at room temperature. Sticking to this timeline is a fundamental requirement of pretty much every health code out there.

Here's the rewritten section, crafted to sound completely human-written and natural, following the provided style guide.

How Automation Is Changing Food Handling

The future of food safety is looking more and more hands-off. Automation is stepping onto the scene in a big way, pushing human contact to the side and seriously upping the game on hygiene. As the food processing world keeps moving forward, technology is tackling some of the oldest safety challenges, creating a whole new category of specialized food contact surfaces.

This shift is all about getting things right every single time. It's most obvious when you look at the rise of food-grade robotic systems. These aren't your sci-fi movie robots; they're purpose-built machines designed to handle everything from delicate pastries to fresh produce without ever introducing contaminants. The real magic is in their specialized grippers, which are essentially the new hands on the assembly line.

The Rise of Food-Grade Robotic Grippers

Think of a robotic gripper as the smartest, safest utensil you've ever seen. These components are painstakingly engineered to be the one and only point of contact between the machine and the food. We're not talking about simple mechanical claws here—these are sophisticated food contact surfaces made from materials like stainless steel and special polymers that won't corrode, absorb moisture, or give germs a place to hide.

Their seamless design gets rid of all the tiny cracks and crevices where bacteria love to set up camp, which has always been a headache with traditional equipment.

This move to automation is picking up speed fast. The global market for these food-grade grippers was valued at around USD 348 million in 2024 and is expected to jump to USD 550 million by 2031. That kind of growth tells you everything you need to know—it's a direct result of rising labor costs and the constant pressure to meet tough hygiene rules. If you want to dig into the numbers, the analysts at Intellect Market Research have a lot more data on this booming market.

Key Drivers Pushing the Industry Forward

So, what's behind this big push? A few powerful forces are changing how we think about and manage food contact surfaces.

- Enhanced Hygiene and Safety: Automation cuts down on direct human handling, which is one of the biggest culprits for cross-contamination. You can clean and sanitize a robotic system with a level of precision that’s nearly impossible to match by hand.

- Rising Labor Costs: With payroll getting more expensive every year, automated systems are starting to look like a very smart long-term investment for cutting overhead and boosting efficiency.

- Demand for Consistency: Customers and regulators want the exact same quality and safety in every single product. Robots nail repetitive tasks perfectly, making sure every item is handled the same way and eliminating simple human error.

By taking the unpredictability of human touch out of the equation, automated systems create a much more controlled and reliable environment. This opens the door to a level of consistency and food safety that just wasn't possible on a massive scale before.

At the end of the day, automation is a massive leap forward. These robotic systems and their specialized grippers are completely redefining what a food contact surface can be—smarter, safer, and more efficient than ever.

Frequently Asked Questions

Running a kitchen means you're constantly juggling a million details, and the rules around food contact surfaces can definitely throw a few curveballs. Getting straight answers is crucial for keeping your operation safe, clean, and on the right side of the health inspector. Here are a few of the most common questions we hear from operators.

Can I Use a Wooden Cutting Board in My Commercial Kitchen?

This is a classic question, and the short answer is: probably not. While some very specific exceptions might exist in local health codes for things like a traditional butcher's block (think dense hardwoods like maple), wood is generally a no-go for everyday use.

The reason is simple: wood is porous. It acts like a sponge, soaking up moisture and bacteria deep into its grain. Once that happens, it's nearly impossible to get it truly sanitized. For the daily grind of a commercial kitchen, you need non-absorbent materials like high-density polyethylene (HDPE) or composite boards. They can be properly scrubbed, sanitized, and often run through a high-temp dishwasher, which wood just can't handle.

What Is the Four-Hour Rule for Cleaning Surfaces?

The "four-hour rule" is one of those non-negotiable food safety cornerstones. It mandates that any food contact surface being used continuously with foods that require temperature control must be completely cleaned and sanitized at least every four hours.

That four-hour window isn't just a random number; it’s based on how quickly dangerous bacteria can multiply to unsafe levels at room temperature. If your crew is slicing, dicing, and prepping for a long stretch, they have to hit pause every four hours to run through the full clean-and-sanitize procedure.

Think of this rule as your frontline defense against foodborne illness. Sticking to it religiously is one of the most powerful ways to stop pathogen growth dead in its tracks on your prep line.

How Do I Know if Equipment Is Officially Food-Safe?

The simplest, most reliable way to know if a piece of equipment is built for a commercial kitchen is to look for a certification mark. These marks come from third-party organizations that test products to make sure they're safe. In the U.S., the gold standard you'll see everywhere is the NSF International mark.

When a prep table, sink, or storage container has that NSF logo, it means it's been through the wringer. It's been tested to ensure the materials are non-toxic, non-absorbent, and tough enough to resist corrosion. More importantly, it’s been designed so you can actually clean it properly, with no weird crevices where bacteria can hide. Always look for that certification when buying new gear—it’s your best guarantee of compliance and safety. For a deeper dive, you can check out our complete food safety sanitation guidelines.

At PrepTables.com, we only stock NSF-certified equipment because we know it's built for the demands of a real kitchen. We focus on durability and hygiene to help you meet the highest safety standards. Find the right compliant prep tables and gear for your operation at https://preptables.com.