A Guide to Commercial Kitchen Shelving

Share

In any kitchen worth its salt, commercial kitchen shelving is the absolute foundation for efficiency and safety. It’s so much more than just a place to put things; it's the organizational backbone that keeps your workflow smooth, your hygiene standards high, and your business profitable. A smart shelving setup is the difference between controlled chaos and, well, just chaos.

Why Your Kitchen Shelving Is Mission-Critical

Think of your commercial kitchen shelving as the quiet hero of your entire operation. It's like a librarian's card catalog—without a logical system, finding what you need becomes a nightmare. A chef needs to be able to grab an ingredient or a tool in a split second, and the right shelving makes that happen. It turns a frantic search into a simple, seamless movement, which directly shaves time off prep and service. This isn't just about making life easier; it's about pure performance.

This kind of strategic organization has a huge impact on food safety, too. Proper shelving is what allows you to actually follow first-in, first-out (FIFO) inventory rules and set aside specific areas for different food groups. When you get items off the floor and keep raw meats away from fresh produce, you're massively cutting down the risk of cross-contamination. That's a non-negotiable for passing health inspections. You can dive deeper into designing a safe and efficient space in our complete guide on commercial kitchen shelves.

The Economic Impact of Smart Storage

The real-world importance of good shelving is obvious when you look at the numbers. The global market for kitchen shelves was valued around USD 30.5 billion and is expected to climb to USD 45.2 billion by 2033. That growth is all about the demand for smarter, more functional storage in both commercial kitchens and homes. You can see more on this growing market over at Verified Market Reports.

Investing in high-quality commercial kitchen shelving is not just an operational expense; it's a strategic decision that directly contributes to a safer, more efficient, and ultimately more profitable kitchen environment.

When you get your storage right from day one, you’re building a solid foundation for your business. The right system pays dividends across the board, leading to some key benefits:

- Improved Workflow: Putting ingredients and gear where they make sense minimizes running around, saving precious seconds on every single order.

- Enhanced Safety and Sanitation: Keeping everything organized and off the floor isn't just a good idea—it's essential for health codes and preventing foodborne illness.

- Maximized Space: Using vertical shelving and other specialized units helps you squeeze value out of every square foot. This is a game-changer in tight kitchens.

- Reduced Food Waste: When you can see everything clearly, it's much easier to track inventory and use products before they go bad.

At the end of the day, your shelving system isn't just passive storage. It's an active player in your business's success, influencing everything from daily operations to your bottom line.

Choosing the Right Shelving Material

Picking the right material for your commercial kitchen shelving is a bit like choosing tires for a truck. You wouldn't use highway tires for a muddy, off-road job, right? The same logic applies here. Your kitchen is a tough environment—full of heat, moisture, and heavy use—and you need materials that can take a beating. Your choice will have a direct impact on how long your shelves last, how easy they are to clean, and your long-term costs.

The whole process starts with a simple look around your kitchen. What does your dry pantry need? It's a world away from the humid, splash-heavy environment of a dishwashing station or the bone-chilling cold of a walk-in freezer. Matching the shelving material to its specific location is the absolute first step in building a storage system that won’t let you down.

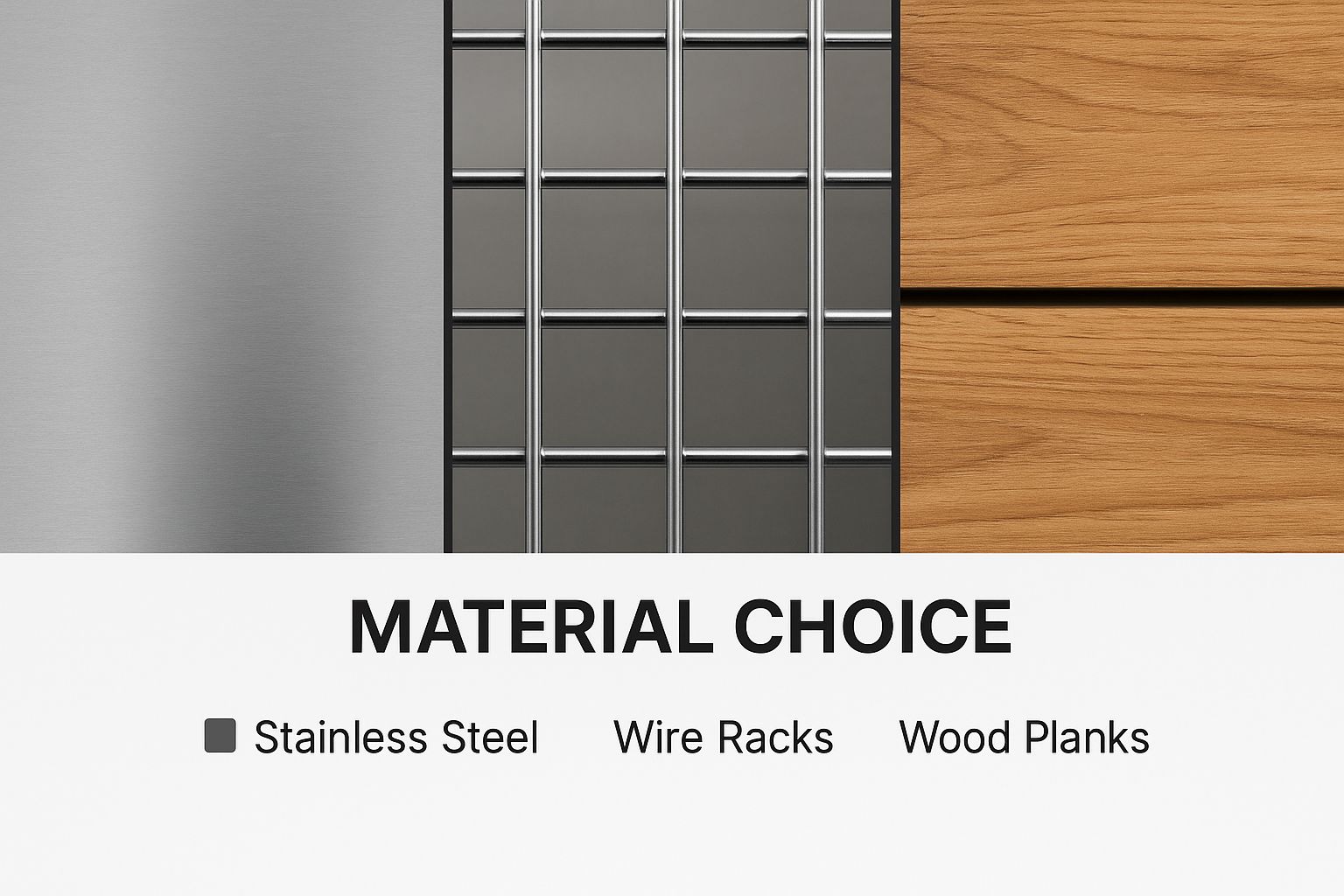

This image shows you the textures and finishes of the most common materials, giving you a quick visual on the core options for your kitchen's storage.

The difference between shiny stainless steel, open-wire shelving, and other finishes isn't just about looks; it's about what each material brings to the table in terms of hygiene, airflow, and raw strength.

Deciding on the right material can feel overwhelming, but breaking it down by pros and cons makes it much clearer.

Commercial Shelving Material Comparison

Here's a quick comparison of the most common materials you'll encounter. Think of this as your cheat sheet for matching the right shelf to the right job.

| Material | Best Use Case | Corrosion Resistance | Durability/Strength | Average Cost |

|---|---|---|---|---|

| Stainless Steel | All-purpose, especially wet areas & prep stations | Excellent (Type 304) to Good (Type 430) | Very High | High |

| Epoxy-Coated Wire | Walk-in coolers, freezers, dishwashing areas | Very High | High | Moderate |

| Polymer | Extreme moisture, freezers, coastal areas | Ultimate | High | Highest |

| Chrome Wire | Dry storage, pantries, inventory rooms | Low | High | Low |

This table lays out the basics, but the real expertise comes from knowing the finer details of each option and where they truly shine—or where they'll fail.

Stainless Steel: The Industry Standard

When you close your eyes and picture a professional kitchen, you're probably seeing stainless steel. There’s a good reason it's the undisputed king of commercial food spaces. It's incredibly tough, non-porous (so bacteria has nowhere to hide), and can handle wild temperature swings without complaining.

But here's the catch: not all stainless steel is created equal. The grade is what really matters.

- Type 304 Stainless Steel: This is the premium stuff. It's often called 18/8 steel because it contains 18% chromium and 8% nickel. That high nickel content is its superpower, giving it top-tier resistance to rust. This makes it a no-brainer for sinks, dish pits, and any surface that’s constantly wet.

- Type 430 Stainless Steel: This is the more budget-friendly cousin because it has no nickel. It's still strong and perfectly food-safe, but it's more likely to corrode if you expose it to acidic foods or harsh chemicals over and over. It's a great, solid choice for dry storage where moisture isn't the main enemy.

Choosing the right grade of stainless steel isn't about being cheap; it's about being smart. Put the tough Type 304 in your wet zones and use the economical Type 430 in dry areas. This way, you optimize your budget without compromising on safety where it counts.

This strategic approach ensures your investment in commercial kitchen shelving really pays off.

Epoxy-Coated Wire Shelving

For those damp and humid spots like walk-in coolers and dish rooms, epoxy-coated shelving is a fantastic contender. It’s built with a strong steel core that’s been dipped in a thick layer of epoxy, creating a protective shield against rust and corrosion.

That epoxy coating—usually green or black—is what seals the metal off from moisture, giving it a huge advantage over basic chrome. Plus, the wire design is great for air circulation. That’s a game-changer in refrigerated spaces for keeping temperatures even and preventing moisture from settling on your produce.

Polymer Shelving for Ultimate Corrosion Resistance

If you need the absolute best defense against rust, polymer shelving is your answer. These units typically combine a steel core for strength with a thick polypropylene (plastic) shell. This plastic armor is completely immune to rust, making it the top pick for walk-in freezers, kitchens in salty coastal air, or anywhere with extreme humidity.

The smooth surface is also a dream to clean and sanitize. Many polymer shelves even have removable plates you can pop off and run through the dishwasher. It’s a feature that makes deep cleaning so much easier and helps you maintain the highest hygiene standards. They might cost more upfront, but their nearly indestructible nature in wet areas means they’ll outlive other materials by years.

Chrome Wire Shelving for Dry Storage

Chrome-plated wire shelving is what you'll see in countless pantries and dry storage rooms, and for good reason. It’s cost-effective, has a clean look, and is plenty strong for holding heavy bags of flour, sugar, and cases of canned goods. The open-wire style also lets air move freely and helps you see your inventory with a quick glance.

But—and this is a big but—you have to know where it belongs. The chrome plating offers very little protection against moisture. If you put it in a walk-in cooler or near a sink, it will rust, and quickly. Chrome shelving is strictly for completely dry environments. Using it in the wrong spot is one of the most common and costly mistakes a kitchen can make.

Finding the Perfect Shelving Configuration

Once you've nailed down the right material for your shelving, the next big question is design. Picking the right setup for your kitchen is a bit like laying out a workshop—you need different surfaces and storage spots for different jobs. Each type of shelf solves a specific problem, and getting the right one in the right place is the secret to a kitchen that just flows.

This isn't just about what fits in the space. It's about making sure air moves freely in your walk-in, stopping small bags of spices from falling through the cracks, and using every single inch of vertical space you have. The right shelving configuration is a cornerstone of a well-run kitchen.

Wire Shelving for Superior Airflow

You’ll find wire shelving in almost every commercial kitchen, and for good reason. That open-grid design is its biggest asset, letting air circulate all around your inventory. This is non-negotiable in places like walk-in coolers and freezers.

Proper airflow means cold air hits every product evenly, keeping everything at a safe temperature and getting rid of warm spots where bacteria can start to grow. It also cuts down on moisture buildup, which is a fast track to spoilage.

But it’s not just for coolers. Wire shelving has a few other tricks up its sleeve:

- Great Visibility: The open design lets you see what you have at a glance. Inventory checks are faster, and your cooks aren't wasting time hunting for that one specific ingredient.

- Fire Code Compliance: This is a big one. Most fire codes demand that sprinkler systems can reach the products on your shelves. Water passes right through wire shelving, which is why it's often required over solid units.

- Budget-Friendly: When you’re outfitting a big storeroom, costs add up. Wire shelving is typically more affordable than solid stainless steel, making it a practical pick for large areas.

Solid Shelving for Containment and Stability

While wire shelving is the king of airflow, solid shelving is the champion of containment. The flat, unbroken surface is perfect for holding onto small or loose items that would slip right through a wire rack—think bags of flour, spices, or small utensils.

Solid shelving is also your best friend for preventing cross-contamination. If you're storing a container of sauce above dry pasta, a solid shelf acts as a safety net. Any accidental drips or spills are caught before they can ruin the inventory below. This makes it the go-to choice for areas above prep tables where sanitation is everything.

Wall-Mounted Shelves for Maximizing Vertical Space

In most kitchens, floor space is gold. Wall-mounted shelves let you tap into all that unused real estate up high, adding storage where a full-sized unit could never go.

You’ll often see them used:

- Above Prep Stations: Keep spices, oils, and small tools right where you need them. It’s a simple change that makes prep work so much faster.

- Over Sinks: This is the perfect spot for cleaning supplies or for letting freshly washed pots air dry.

- In Tight Hallways: A narrow wall shelf can add a ton of storage without getting in the way of foot traffic.

Getting things off the countertops and onto the walls makes your whole workspace feel more organized and less chaotic.

Dunnage Racks for Safe Floor Storage

Health codes are not flexible on this: food can never be stored directly on the floor. That’s where dunnage racks come in. These are low, super-sturdy platforms built to lift heavy, bulky items off the ground—things like 50-pound bags of sugar, cases of canned goods, and boxes of produce.

Dunnage racks are a non-negotiable piece of equipment for food safety. They protect your inventory from pests, moisture, and floor contaminants, ensuring you remain compliant with health and safety regulations.

They are built to handle serious weight, making them the only safe and hygienic way to store your heaviest goods.

High-Density Mobile Shelving for Ultimate Space Savings

For kitchens that are seriously tight on space, high-density mobile shelving is a powerful tool. These systems put standard shelving units on floor tracks, letting you slide them to create an aisle wherever you need it. Instead of having multiple permanent aisles, you just have one that moves.

The result? A massive boost in storage capacity—often by 50% or more—without needing any more square footage. It’s a bigger upfront investment, but it can completely transform a cramped storeroom. This push for efficiency is part of a larger trend; the global commercial kitchen appliances market was valued at USD 99.28 billion and is expected to more than double to USD 219.75 billion by 2034. That growth underscores just how critical smart, space-saving equipment has become. You can dig into the numbers and trends in the full report from Polaris Market Research.

Integrating Prep Tables for Peak Efficiency

Standalone commercial kitchen shelving is a must for your bulk storage, but the real magic happens when you merge that storage with your active workspaces. Your prep tables are the command centers of your kitchen—it's where all the action is. Thinking about how to blend them into your layout is a game-changer. These aren't just countertops; they're dynamic stations that combine storage, prep, and sometimes even cooling into one hyper-efficient hub.

The classic stainless steel prep table is the foundation of it all. These tables are absolute workhorses, giving your team a tough, hygienic surface for all the chopping, mixing, and plating that goes on. But their real value skyrockets when you factor in their built-in storage.

Most tables come with an undershelf, which is just a solid or wire shelf sitting below the main worktop. This one simple feature is a powerhouse. It gives you instant access to mixing bowls, small appliances, or ingredient bins, keeping your main prep surface clear and ready for work.

Types of Stainless Steel Prep Tables

Standard stainless steel prep tables are the backbone of most kitchens, but "standard" doesn't mean one-size-fits-all. They come in several configurations, each designed to solve specific workflow challenges. The most common varieties include:

- Work Tables: These are the most basic and versatile option, providing a simple, flat stainless steel top with an undershelf. They are perfect for general prep tasks, from chopping vegetables to assembling dishes. Key features to look for are a backsplash—a raised edge that prevents spills from hitting the wall—and an open base or cabinet base for different storage needs.

- Equipment Stands: Built to be lower and more robust than a standard work table, these are designed to safely hold heavy countertop equipment like mixers, griddles, or charbroilers. They provide a sturdy, dedicated spot for your gear at an ergonomic working height.

- Specialized Prep Tables: When your kitchen focuses on high-volume items, specialized tables are essential. These units integrate refrigeration directly into the workstation to create an efficient assembly line.

A well-chosen prep table isn't just a piece of furniture; it's an active component of your workflow. The right features, like an undershelf and backsplash, can dramatically reduce wasted movement and improve sanitation, directly contributing to a more efficient and safer kitchen environment.

By selecting the right type of table for each station, you can create dedicated zones that streamline tasks and keep your kitchen running smoothly.

Pizza and Sandwich Prep Tables

If your operation pumps out a high volume of specific items—like sandwiches or pizzas—then specialized prep tables are non-negotiable. These units are engineered for one thing: speed. They build refrigeration right into the prep station, creating a streamlined assembly line that means your cooks aren't constantly walking back and forth to a separate cooler.

The two most common specialized units you'll see are sandwich/salad prep tables and pizza prep tables. Each one is designed with specific features for its unique job.

-

Sandwich and Salad Prep Tables: These units have a refrigerated rail on top that holds a bunch of food pans filled with fresh ingredients like lettuce, tomatoes, cheeses, and meats. Everything stays perfectly chilled and right at your fingertips. Just below the rail is a cutting board for assembly, and the base of the unit is a refrigerated cabinet for all your backup supplies.

-

Pizza Prep Tables: These work on the same principle but are built for the demands of a pizzeria. They usually have a deeper refrigerated rail to fit larger pans of sauce, cheese, and toppings. More importantly, the work surface is often made of marble or another material that stays cold, which is perfect for keeping pizza dough from sticking or getting overworked. The cutting board surface is also much wider to handle large pizza skins.

These specialized tables are the ultimate in ergonomic kitchen design. Everything a cook needs is organized and ready to go, which drastically cuts down the time it takes to get an order out. For a sandwich shop or a pizzeria, this kind of efficiency isn't just a nice-to-have—it's the core of the business model. It means faster ticket times and more customers served during your busiest hours. Choosing the right specialized table turns a simple workstation into a powerful engine for productivity.

Getting to Grips with Load Capacity and NSF Certification

Okay, so we've talked materials and different shelving setups. Now, let's get into two things that are absolutely critical for any professional kitchen: load capacity and NSF certification. This isn't just industry-speak; these concepts are all about keeping your staff safe, your customers healthy, and your business out of trouble.

Think of load capacity like the weight limit on an elevator. Pushing it too far is a huge risk. Every shelf is designed to hold a certain amount of weight, and if you overload it, you're asking for a collapse. That means potential injuries, ruined inventory, and a massive headache. Before you start stacking heavy items like 50-pound bags of flour or cases of canned goods, always, always check the manufacturer's specs.

Why You Can't Ignore NSF Certification

Just as important is that little blue NSF logo. When you spot that on a piece of equipment, it’s a big deal. It's a seal of approval from NSF International, an independent group, showing the product has been through tough testing to meet strict public health and safety standards.

Health inspectors are trained to look for this logo right away.

Seeing the NSF mark tells them the equipment is designed and built specifically for food safety.

For shelving, NSF certification means it's made from non-porous materials that won't trap bacteria. It also means the surfaces are smooth and easy to clean, with no little cracks or crevices for food to get stuck in. This certification gives health inspectors instant confidence that your storage is safe for a commercial kitchen. Want to dive deeper? We break it all down in our guide on what NSF certification truly means.

Simply put, NSF-certified shelving is your front-line defense against cross-contamination and foodborne illness. It is a mandatory requirement in most jurisdictions and a clear indicator that you prioritize hygiene and safety in your operation.

Investing in certified gear isn't just about following the rules—it's about building the solid foundation of safety that every successful kitchen needs.

Global Growth and The Need for Standards

The demand for high-quality, compliant kitchen storage is growing everywhere. Take the Middle East and Africa (MEA) kitchen storage market—it was valued at USD 1,392.3 million and is expected to hit USD 1,983.0 million by 2035. This boom comes from new hotels, resorts, and restaurants that all need top-notch kitchen storage.

This global expansion is exactly why universal standards like NSF are so vital. They create a clear, reliable benchmark for safety and quality that kitchen operators can count on, no matter where they are in the world.

Installation and Maintenance Best Practices

Picking the right commercial kitchen shelving is really only half the job. To get the most out of your investment, proper installation and consistent maintenance are what truly make the difference. A little bit of care will protect your shelves for years, keeping your kitchen safe, hygienic, and running smoothly.

Getting the assembly right from the start is crucial. Before you even begin, check that your floor is perfectly level. An uneven surface can make the whole unit lean, creating a serious tipping hazard once you load it up with heavy pans and ingredients. For wall-mounted shelves, you absolutely have to find and use the wall studs for anchoring. This is non-negotiable if you want real stability and strength.

Building a Simple Maintenance Routine

Once your shelves are securely in place, a simple but consistent maintenance routine becomes your best defense against daily wear and tear. This isn't just about protecting the equipment; it's about upholding critical food safety standards and stopping small problems before they become big ones.

This routine doesn't need to be complicated. A quick weekly wipe-down and a more thorough monthly deep clean can make a world of difference.

Here are the key tasks to build into your schedule:

- Regular Cleaning: For stainless steel, just use a soft cloth and a mild detergent. Always remember to wipe in the direction of the grain to avoid scratching the surface. Dry it completely afterward to prevent water spots and rust.

- Effective Sanitizing: If you have polymer or epoxy-coated shelves in your walk-in coolers, use a food-safe sanitizer after cleaning to kill any bacteria. Many polymer shelf mats are even removable and can be run through the dishwasher, which makes this task a breeze.

- Routine Inspections: At least once a month, give your shelves a quick once-over. Look for any signs of wobble, rust, or damage. Tighten any loose connections you find and take care of any corrosion right away to keep it from spreading.

A proactive maintenance schedule is far more effective than a reactive one. Taking a few minutes each week for cleaning and inspection can prevent costly replacements and ensure your kitchen remains compliant with health codes.

Following these practices will extend the life of your shelving and all your other kitchen gear. For a more detailed guide, check out our article on commercial kitchen equipment maintenance for tips that apply to your entire operation. By making these simple habits part of your routine, you ensure your storage solutions remain a reliable asset, supporting a safe and productive kitchen.

Common Questions About Kitchen Shelving

When you're outfitting a commercial kitchen, a few common questions about shelving always seem to pop up. Getting the right answers is key to building a kitchen that’s not just efficient, but also safe and up to code. Let's walk through some of the most frequent queries we hear from kitchen managers.

What Is the Difference Between NSF Certified and NSF Listed?

This is a great question, and while the terms sound almost identical, there's a small but important distinction.

NSF Certified means a product has been rigorously tested by the independent NSF International to make sure it meets their tough standards for public health and safety. On the other hand, NSF Listed simply means that product shows up in the official NSF online database.

For all practical purposes in your kitchen, both are good to go. When a health inspector sees either designation, they know the equipment is approved for a food service environment. It tells them the surface is non-porous and can be properly sanitized, which is exactly what they’re looking for.

How Can I Maximize Storage in a Small Kitchen?

When your floor plan is tight, you have to think vertically. The only way to go is up.

- Go Vertical: Use the tallest shelving units that your ceiling height will permit. This is the simplest way to instantly tap into unused overhead space.

- Use Wall Shelves: Mount shelving on the walls above your prep tables, sinks, or other workstations. This keeps crucial tools and ingredients right where you need them, without eating up valuable counter space.

- Consider Mobile Systems: If you have the budget, high-density mobile shelving is a game-changer. These systems run on tracks and can nearly double your storage capacity by getting rid of the need for fixed aisles.

Which Shelving Is Best for a Walk-In Freezer?

For a walk-in, you need shelving that can stand up to the constant cold and moisture. No exceptions.

Your best bets are either polymer or epoxy-coated metal shelves. These materials are specifically engineered to fight off rust and corrosion in damp, cold environments. Whatever you do, never put standard chrome shelving in a walk-in freezer. It will break down fast, start to rust, and quickly become a serious safety hazard.

At PrepTables.com, we provide the durable, NSF-approved commercial kitchen shelving and prep tables you need to build a safe and efficient workspace. Explore our full collection of professional-grade equipment at https://preptables.com.