A Guide to Commercial Convection Ovens

Share

Ever wonder how a professional kitchen churns out perfectly golden pastries and evenly roasted meats, time after time? The secret isn't some complicated culinary technique; it's the smart technology humming away inside a commercial convection oven. At its core, this machine solves a fundamental problem that plagues traditional ovens: uneven heat.

Decoding the Magic Behind Convection Cooking

Think about the difference between a still, hot summer day and a breezy one. On a still day, the heat feels intense, but step into the shade and it's much cooler. A conventional oven is like that still day, using stationary heating elements that create "hot spots" and "cold spots." This is exactly why you find yourself constantly rotating baking sheets halfway through.

A commercial convection oven, on the other hand, is that breezy day. It adds a fan into the mix, actively circulating hot air all around the oven cavity. This constant motion gets rid of those inconsistent temperature zones, wrapping your food in a consistent blanket of heat.

The Key Components Working in Harmony

The incredible efficiency of a convection oven comes down to a few key parts working together seamlessly. This system is designed to distribute heat perfectly, which is what leads to those superior cooking results.

- The Internal Fan: This is the heart of the whole operation. Usually found at the back of the oven, the fan is what pulls in hot air and pushes it all around the food, making sure every surface cooks at the same rate.

- The Heating Element: Just like in a conventional oven, you have heating elements (either gas or electric) that create the heat. The big difference is that the fan takes this heat and actively spreads it around.

- The Exhaust System: This is an often-overlooked hero. This vent helps pull moisture and steam out of the oven, which is crucial for getting that crispy skin on a chicken or a perfect brown on roasted vegetables.

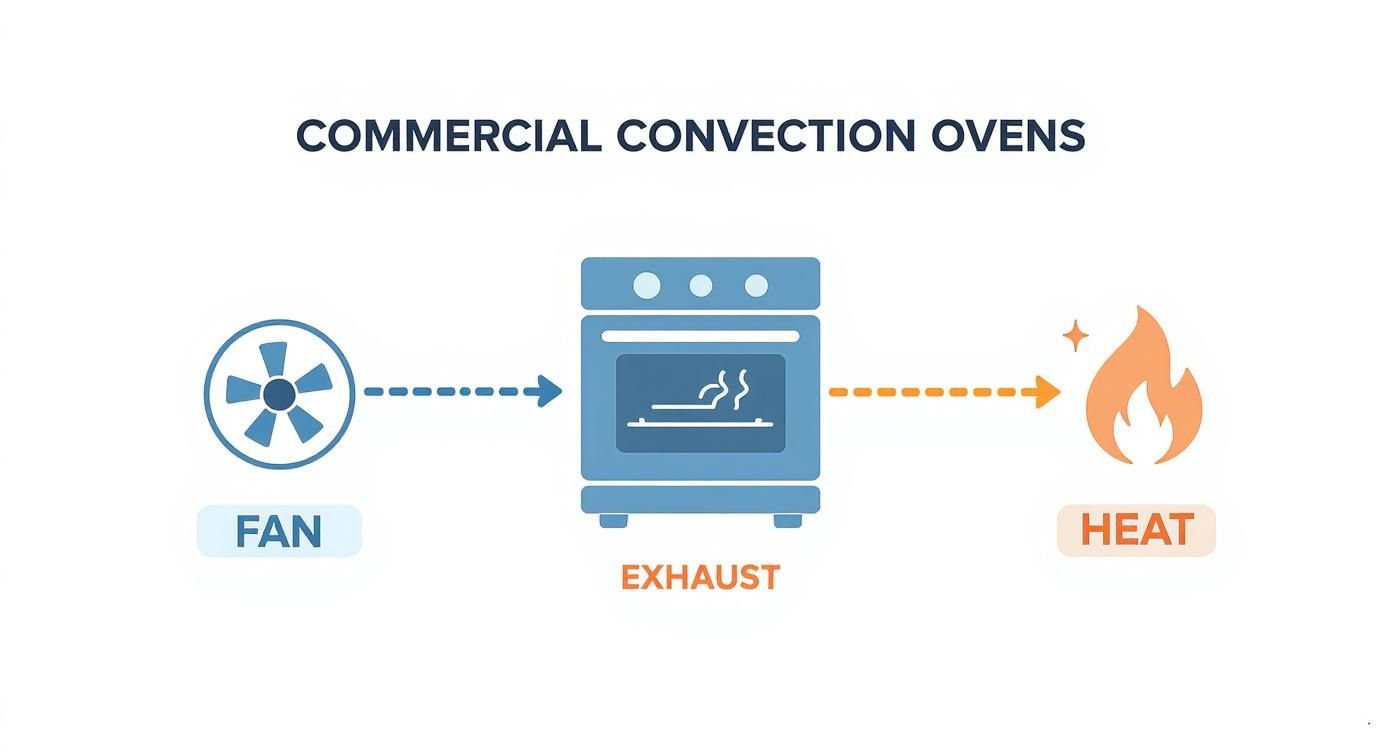

This concept map breaks down how the core components—the fan, exhaust, and heat source—work together to create a better cooking environment.

As you can see, it’s the synergy between these parts, especially the fan-driven air circulation, that really defines the oven’s performance and makes it so efficient.

Faster Cooking Times and Better Results

That constant movement of hot air does more than just cook evenly—it cooks faster. By keeping the air in motion, a commercial convection oven can slash cooking times by up to 25% and often lets you cook at a lower temperature. In a busy commercial kitchen where every minute counts, that's a huge advantage.

To put it simply, here’s a quick look at how the two oven types stack up.

Convection vs Conventional Ovens at a Glance

This table offers a snapshot of the operational differences and performance outcomes between these two cooking methods.

| Feature | Commercial Convection Oven | Conventional (Radiant) Oven |

|---|---|---|

| Heat Distribution | Fan circulates hot air for even cooking. | Relies on natural heat radiation, creating hot/cold spots. |

| Cooking Speed | Up to 25% faster. | Slower, standard cooking times. |

| Browning/Crisping | Superior browning and crisping due to dry, moving air. | Less consistent browning; can result in moist or soggy textures. |

| Batch Capacity | Can use all racks simultaneously with consistent results. | Often requires rotating pans; lower racks may cook slower. |

| Energy Efficiency | Generally more efficient due to shorter cooking times. | Less efficient as it takes longer to cook. |

The key takeaway is that the fan-driven technology in a convection oven is what gives it a clear edge in a professional setting.

By eliminating hot spots, a commercial convection oven allows chefs to utilize every rack simultaneously, dramatically increasing batch capacity without sacrificing quality. This means more consistent products and a more efficient workflow.

The demand for this kind of efficiency is clear when you look at the market. The broader commercial oven market was valued at $14.46 billion in 2024 and is expected to climb to $21.20 billion by 2030. This growth really highlights how much the foodservice industry relies on efficient cooking technology like the commercial convection oven. You can discover more insights about the convection oven market trends and their future growth.

Ultimately, understanding how a convection oven works is all about appreciating the power of moving air. It turns a simple heating box into a precision tool that delivers consistent browning, crispier textures, and faster output—all things that are absolutely essential for any successful professional kitchen.

Exploring the Different Types of Convection Ovens

Shopping for a commercial convection oven feels a lot like walking onto a car lot. You're hit with a dizzying array of options, and it’s clear each model is built for a different job. You wouldn't try to haul a ton of bricks in a compact car, and you wouldn't rely on a tiny countertop oven to feed a packed restaurant.

Getting to know the main categories is the first step. It’s how you’ll find the perfect kitchen workhorse that can keep up with your business without breaking a sweat. The first way we can break them down is by size, which ties directly into how much food you need to pump out.

Sizing Up Your Options: From Countertop to Full-Size

The oven's footprint is one of the biggest decisions you'll make. It has to fit your physical kitchen space and your production demands. Get this right, and you'll avoid major bottlenecks during your busiest hours.

-

Full-Size Ovens: These are the titans of the commercial kitchen. Built for high-volume places like bustling restaurants, big hotels, and university cafeterias, these ovens are all about capacity. A standard full-size model can hold multiple full-size sheet pans (that’s the big 18"x26" ones), letting you cook massive batches at once. They are true floor models, so they need a good amount of space and proper ventilation.

-

Half-Size Ovens: Here's your middle ground. Half-size ovens strike a great balance between capacity and footprint, making them a go-to for smaller eateries, cafes, and caterers. They fit half-size sheet pans (18"x13") and are often stackable, which means you can double your cooking power without eating up more floor space. That modular design is a lifesaver for businesses that are still growing.

-

Countertop Ovens: When space is the ultimate luxury—think food trucks, coffee shops, or concession stands—a countertop convection oven is your answer. These compact powerhouses give you all the even-cooking magic of their bigger siblings but in a much smaller package.

There's a real and growing demand for these smaller units. The commercial countertop convection oven market, valued at $240 million in 2025, is on track to hit $335 million by 2031. That's a solid compound annual growth rate of 5.7%, showing just how vital these space-savers are for smaller food operations.

The Great Debate: Gas Versus Electric

Okay, so you’ve picked a size. Now for the next big question: what’s going to power it? Deciding between a gas and an electric convection oven usually comes down to what your kitchen is already set up for, what utilities cost in your area, and how you like to cook.

Gas Ovens are speed demons. They preheat fast and are a favorite in high-volume kitchens where every second counts. If natural gas is cheap where you are, they can also save you money on operating costs. The trade-off? You need a dedicated gas line, and the heat might not be quite as perfectly even as an electric model.

Electric Ovens, on the other hand, are masters of precision. They are famous for their rock-solid temperature control and incredibly even heat, which is why bakers often swear by them for delicate work. They might take a bit longer to preheat, but installation is simpler—just plug it into the right outlet.

For many bakers, the dry, consistent heat from an electric oven offers total control. It's the secret to getting perfectly uniform results, from the top rack all the way to the bottom.

So, which is best? It really depends on your menu. If you're doing a lot of roasting or high-temp cooking, the raw power of gas is fantastic. If you're baking pastries, cakes, and other delicate items, you’ll love the gentle, steady heat from an electric oven.

Specialized Ovens for Unique Kitchen Needs

Beyond the standard models, you'll find specialized units built for very specific jobs. These ovens pack unique features that solve particular culinary challenges.

-

Bakery-Depth Ovens: Sometimes called deep-depth ovens, these are designed with bakers in mind. They’re built to hold full-size sheet pans either side-to-side or front-to-back. That flexibility is a game-changer in a bakery, making loading and unloading way more efficient. To learn more about picking the right gear, check out our guide on commercial ovens for bakery operations.

-

Combi Ovens: Think of these as the Swiss Army knife of ovens. A combi oven blends convection heat with steam injection, letting you bake, roast, steam, and poach all in one piece of equipment. That control over humidity opens up a whole new world, from crusty artisan breads to unbelievably juicy roasts. They're a big investment upfront, but a combi can easily replace several other machines, freeing up precious kitchen real estate.

By thinking through the size, power source, and any special features you might need, you can cut through the noise and find a commercial convection oven that’s a perfect fit for your kitchen's workflow and menu.

The Role of Stainless Steel Prep Tables in the Kitchen

Bringing a commercial convection oven into your kitchen is a strategic move, but its efficiency depends heavily on the workflow around it. This is where stainless steel prep tables become essential partners. They provide the durable, sanitary surfaces needed for everything from chopping vegetables to assembling dishes before they enter the oven.

The real magic of a well-equipped kitchen lies in how seamlessly each station works together. A sturdy prep table next to your convection oven creates an efficient zone, minimizing steps and maximizing output.

Understanding Different Types of Prep Tables

Not all prep tables are created equal. They come in various configurations, each designed to meet specific kitchen demands. The most common material is stainless steel, prized for its durability, resistance to rust and corrosion, and ease of cleaning.

- Standard Work Tables: These are the versatile workhorses of the kitchen. Available in a wide range of sizes, they offer a simple, flat surface for general prep tasks. Many feature an undershelf for storing equipment or ingredients, maximizing vertical space.

- Tables with Backsplashes: A small but crucial feature, a backsplash prevents ingredients and liquids from splashing onto walls, making cleanup easier and improving overall sanitation. These are ideal for placement against a wall, especially in wet prep areas.

- Sandwich and Salad Prep Tables: These specialized units are designed for high-speed assembly lines. They feature refrigerated wells or pans on top to keep ingredients like lettuce, tomatoes, and cheeses chilled and within easy reach. The refrigerated base provides additional cold storage for backup supplies.

- Pizza Prep Tables: Similar to sandwich tables, these are optimized for pizza making. They typically have a wider, refrigerated rail to accommodate larger pans of toppings and a durable cutting board surface for rolling out dough. The refrigerated cabinet below is designed to hold dough boxes at the perfect temperature.

This wide array of options allows you to create a customized and highly efficient workspace.

Unlocking Unbeatable Consistency and Quality

A dedicated and well-organized prep station is key to achieving consistent results. When your ingredients are properly stored and easily accessible, your kitchen staff can work faster and with greater accuracy. A sandwich prep table ensures every sandwich gets fresh, crisp lettuce, while a pizza prep table keeps cheese and pepperoni at a safe, cool temperature.

This level of organization directly supports the quality of food coming out of your commercial convection oven.

- Streamlined Workflow: Ingredients are prepped and ready, allowing dishes to go into the oven without delay, ensuring they are cooked perfectly.

- Enhanced Food Safety: Refrigerated prep tables keep perishable ingredients out of the temperature "danger zone," reducing the risk of foodborne illness.

- Increased Durability: Stainless steel can withstand the harsh demands of a commercial kitchen, from heavy knife work to hot pans coming directly out of the oven.

This commitment to an organized prep area removes guesswork and empowers your team to deliver high-quality, dependable results with every single order.

Supercharge Your Kitchen's Output

Combining an efficient commercial convection oven with the right prep tables is a total game-changer for workflow. Imagine a pizzeria where the dough is proofed, topped, and loaded into the oven in a seamless line. Or a deli where sandwiches are assembled on a refrigerated line and passed to a countertop convection oven for toasting.

This synergy massively boosts your capacity, letting you produce more food in the same amount of time.

A busy bakery can use a large stainless steel table for kneading and shaping dough right next to their bakery-depth convection oven. A high-volume restaurant can set up multiple prep stations to keep the flow of dishes moving smoothly during the dinner rush.

This jump in productivity directly impacts your bottom line. It means you can serve more people, take on bigger catering gigs, and run a much tighter ship during your busiest hours. The oven is the engine, but the prep tables are the assembly line that feeds it, proving that their value goes way beyond just a simple surface; they streamline your entire operation.

How to Choose the Right Convection Oven

Stepping into the market for a commercial convection oven can feel a little daunting. Let's be honest, this isn't just another piece of equipment—it's a critical investment. The right oven becomes the workhorse of your kitchen, defining your efficiency, consistency, and how much you can produce.

To make a smart choice, you need a game plan. It all starts with the practical stuff: space and volume. Before you even glance at a single model, get out the tape measure and figure out your available footprint. A beast of a full-size floor unit might be impressive, but it's worthless if it kills your kitchen's workflow.

At the same time, get real about your production needs during your busiest rushes. Are you a small cafe baking a few dozen pastries a day? Or are you a high-volume catering operation that needs to roast hundreds of pounds of meat? Matching the oven’s capacity to your actual demand is the first and most important step to avoiding bottlenecks.

Aligning Power Source with Your Kitchen

Once you’ve got a handle on the size, the next big question is how you're going to power it. The choice between a gas or electric commercial convection oven often comes down to what utilities you have and your local energy costs. But each type has its own personality that can affect your food.

- Gas Ovens are all about raw power and getting up to temperature fast. They're a favorite in high-volume kitchens for a reason. If you already have a gas line and natural gas is affordable in your area, they can be cheaper to run in the long run.

- Electric Ovens are the masters of precision. They are celebrated for their incredibly even heat distribution and tight temperature control. This makes them the go-to for bakeries and pastry chefs who need absolute consistency for delicate items like cakes and meringues.

Don't forget about ventilation. Gas ovens almost always need a proper ventilation hood to handle the byproducts of combustion. Some electric models might not, but it all depends on local codes and what you’re cooking. To make sure you're compliant, our guide on commercial kitchen ventilation requirements is a great place to start.

Manual Simplicity vs Digital Precision

How you interact with your oven every day really matters. The choice between manual dials and a digital screen often comes down to your menu's complexity and your team's comfort level.

Manual controls, with their simple knobs for time and temperature, are incredibly reliable and easy to train new staff on. They are perfect for kitchens doing simple, repetitive tasks where you don't need fancy, multi-stage cooking programs.

Programmable digital controls, on the other hand, deliver precision like nothing else. You can save recipes, program cooking cycles with multiple stages, and ensure every single batch comes out identically, no matter who's running the oven. This is a game-changer for businesses that need to maintain strict consistency across multiple locations.

Essential Features That Drive Performance

Beyond the basics, a few key features can really elevate an oven from a simple hot box to a valuable kitchen asset.

Look for features that solve specific problems for your menu. A steam injection function is non-negotiable for an artisan bread bakery, while a multi-speed fan is a must-have for a kitchen producing both hearty roasts and delicate soufflés.

Here are a few things to keep an eye out for:

- Multi-Speed Fans: A high-speed fan is great for getting a beautiful brown crust on a roast, but it can flatten a delicate cake. A two-speed or variable-speed fan gives you the control to dial back the airflow for more sensitive baking.

- Steam Injection: This feature is crucial for getting that perfect, crackly crust on artisan breads. It also introduces moisture that helps keep large roasts juicy and tender.

- Easy-to-Clean Interior: Look for models with coved (rounded) stainless steel corners and rack guides that you can pop out. These simple design choices eliminate places for grime to hide and make daily cleaning much faster, saving you a ton in labor costs over the life of the oven.

Choosing a new oven is a big financial step, and you're not alone. The global convection ovens market is projected to expand from $1.66 billion in 2024 to $2.59 billion by 2035, showing just how essential this equipment is. When you're looking at such a significant investment, it's smart to know your funding options. For a great overview of financing kitchen gear like a new oven, check out this helpful Restaurant Equipment Financing Guide. By carefully thinking through your space, power source, controls, and must-have features, you can confidently pick an oven that will be a reliable partner in your kitchen's success for years.

Essential Cleaning and Maintenance Practices

A commercial convection oven is the workhorse of any serious kitchen. Just like a high-performance engine, it needs consistent care to keep running at its best. If you neglect maintenance, you're not just risking a hygiene issue—you're hurting your cooking performance, wasting energy, and shortening the oven's lifespan.

The best way to protect your investment is with a simple, consistent cleaning routine. Think of it this way: a quick daily wipe-down is like brushing your teeth; it stops bigger problems from ever starting. A deeper weekly clean is like a professional dental cleaning, getting into all the spots you might normally miss.

Your Daily Maintenance Ritual

The most effective upkeep starts with small, daily habits. These tasks only take a few minutes at the end of a shift, but they make a massive difference in preventing stubborn, baked-on grease. Staying on top of this makes the weekly deep clean far less of a chore.

- Wipe Down the Interior: After the oven cools to a safe temperature, grab a damp cloth and a mild, food-safe detergent. Wipe down all the interior surfaces to catch any fresh spills before they have a chance to harden into a baked-on mess.

- Clean the Door Glass: Use a good, non-abrasive glass cleaner on both sides of the oven door. This simple step ensures you can actually see what you're cooking without opening the door and letting all that precious heat escape.

- Clear Out Debris: Take a quick look at the bottom of the oven for any fallen crumbs or food bits. Sweep them out. If you don't, they'll just burn during the next use, creating smoke and bad odors.

The Weekly Deep Clean

Once a week, you'll want to set aside a little more time for a more thorough cleaning. This is your chance to tackle the areas that a daily wipe-down can’t reach, especially the hardworking components of the oven.

- Soak the Racks: Pull the oven racks out and let them soak in a tub with warm water and a commercial-grade degreaser. Once the grime has loosened, give them a scrub with a non-abrasive brush, rinse them well, and let them air dry completely before putting them back.

- Clean the Fan Area: Carefully wipe down the fan baffle—that's the panel covering the fan. If the manufacturer says it's okay, clean the fan blades too. A clean fan is non-negotiable for the even air circulation a commercial convection oven is known for.

- Inspect Door Gaskets: Check the rubber or silicone seal around the door for any cracks, tears, or brittleness. A tight seal is absolutely crucial for holding temperature and being efficient. If it's damaged, replace it immediately to stop heat from leaking out.

Monthly and Long-Term Health Checks

Beyond the regular cleaning, a few quick checks each month can help you spot mechanical issues before they turn into major failures. This is all about preventative care and listening to your equipment.

Think of this as a wellness check for your oven. Keeping all your kitchen equipment in prime condition is just good business. For a wider view on this, check out our guide on commercial kitchen equipment maintenance.

To make this straightforward, here’s a simple checklist you can follow.

Your Convection Oven Maintenance Checklist

This structured approach keeps your oven sparkling and ensures it delivers the consistent, high-quality results your customers expect. Breaking tasks down makes maintenance a simple habit instead of a dreaded chore.

| Frequency | Task | Purpose |

|---|---|---|

| Daily | Wipe down the interior with a mild detergent. | Prevents grease and food buildup before it hardens. |

| Daily | Clean the inside and outside of the door glass. | Ensures clear visibility to monitor food without heat loss. |

| Daily | Sweep out any crumbs or food debris. | Avoids burning, smoke, and unpleasant odors. |

| Weekly | Remove and soak oven racks in a degreaser. | Dissolves tough, baked-on grime for easier cleaning. |

| Weekly | Clean the fan baffle and accessible fan blades. | Maintains optimal airflow for even cooking. |

| Weekly | Inspect the door gasket for damage or wear. | Ensures a tight seal to maintain temperature and efficiency. |

| Monthly | Calibrate the thermostat. | Guarantees accurate cooking temperatures and food quality. |

| Monthly | Listen for unusual noises from the fan motor. | Catches potential mechanical issues before they fail. |

Following these simple but structured practices will keep your commercial convection oven performing at its peak. It’s a small time investment that protects your kitchen's productivity and your bottom line.

Frequently Asked Questions

Stepping into the world of commercial convection ovens can bring up a few questions. We’ve put together some straightforward answers to the most common queries, helping you get the most out of your new equipment right away.

How Do I Convert Recipes for a Convection Oven?

This is usually the first question on everyone's mind. Since a commercial convection oven is much more efficient, you can't just follow the time and temperature from a standard recipe.

A good rule of thumb is to lower the cooking temperature by 25°F (around 15°C). So, if your recipe calls for 375°F in a conventional oven, you’ll want to set your convection oven to 350°F. You’ll also need to keep a closer eye on the clock; start checking for doneness about two-thirds of the way through the original bake time. A lasagna that usually takes an hour might be perfectly bubbly and brown in just 45 minutes.

When Should I Not Use the Convection Fan?

That fan is a powerhouse, but it’s not right for every single dish. The circulating air can be a bit too much for delicate batters and custards, causing them to set unevenly or get strange ripples on top.

It's best to switch the convection setting off when baking things like:

- Delicate Cakes and Custards: The moving air can disturb the surface of thin batters, which is bad news for soufflés, cheesecakes, and flan.

- Quick Breads and Soufflés: These need a calm, even heat to rise properly. The fan's force can make them collapse or bake with a lopsided top.

- Braising or Slow Cooking: For recipes that depend on slow, moist heat—like a pot roast in a Dutch oven—the fan will dry things out way too quickly.

In these cases, just use your oven’s standard bake mode without the fan. You'll get much better results.

Does a Commercial Convection Oven Need a Hood?

Whether you need a ventilation hood comes down to your oven’s power source and, most importantly, your local health codes. As a general rule, gas convection ovens always require a hood. They produce combustion byproducts like carbon monoxide that absolutely must be vented outside.

Electric models offer a bit more flexibility. An electric commercial convection oven might not need a hood if you're only baking pastries or bread that won't create much grease or smoke. However, if you plan on roasting meats or cooking anything greasy, a hood is almost certainly required to handle the vapor. The best advice? Always check with your local health and fire departments to make sure you're compliant.

Your oven is a long-term investment. Don't risk its performance or safety by guessing on ventilation. Always consult local codes and a professional installer to ensure your setup is safe and efficient.

What Is the Difference Between a Convection Oven and a Combi Oven?

This is a really common point of confusion. While they both use fans to move heat around, they are built for different jobs.

A standard commercial convection oven is a master of dry-heat cooking. It’s perfect for roasting, baking, and getting a beautiful brown crust on things. Some models even have a steam-injection feature, which is fantastic for creating crusty artisan breads.

A combi oven is a completely different beast. It’s a multi-functional unit that can cook with convection heat, steam, or a precise combination of both. This means it can do everything a convection oven can do, plus steam, poach, braise, and even cook sous-vide. Think of a convection oven as a specialist for dry heat, while a combi oven is a versatile all-in-one that can replace several other pieces of kitchen equipment.

At PrepTables.com, we know that having the right equipment is the foundation of any great kitchen. Take a look at our complete collection of commercial cooking equipment, including tough and reliable commercial convection ovens built to handle the demands of any professional operation.