Blast Chiller Commercial: Essential Guide to Choosing the Right Unit

Share

Think of a blast chiller commercial unit as a time machine for your food. Its main job is to pull the heat out of cooked food fast, locking in that just-made freshness, flavor, and texture. But most importantly, it's about safety. This isn't just a beefed-up freezer; it’s a specialized piece of gear designed to stop bacterial growth cold.

What Is a Commercial Blast Chiller and Why Is It Essential?

A commercial blast chiller is a purpose-built refrigeration machine that blasts food with high-speed, intensely cold air. The whole point is to get food through the temperature "danger zone"—between 140°F and 40°F—as quickly as humanly possible. This is the temperature window where nasty bacteria like Salmonella and Listeria really take off and multiply.

You can't just shove a hot stockpot into a standard walk-in cooler. That’s a classic rookie mistake. It warms up the whole cooler, putting all your other food at risk and forcing the compressor to work itself to death. A blast chiller handles this process in its own insulated environment, cooling food down safely and efficiently without messing with the rest of your inventory. It’s a critical piece of the puzzle for any well-run kitchen and a cornerstone of solid cold chain management.

The Three Pillars of Blast Chilling

When you bring a blast chiller into your kitchen, the benefits really stack up across three key areas that directly affect your business's reputation and bottom line.

-

Enhanced Food Safety: By crashing temperatures in minutes, not hours, blast chillers slam the brakes on bacterial growth. This ensures your food not only meets but flies past HACCP safety guidelines. Most units can take food from a piping hot 194°F down to a safe 37°F in just 90 minutes.

-

Superior Food Quality: Ever notice how food gets mushy after being frozen and thawed? That’s because slow freezing creates large, jagged ice crystals that tear up the food's cellular structure. Blast chilling is so fast it creates tiny micro-crystals, which preserves the original texture, flavor, and nutrients of everything you cook.

-

Operational Efficiency: This is where the magic really happens for your workflow. Blast chillers make the "cook-chill" method possible, letting you cook huge batches during quiet periods. You can then chill and store these items for days, ready to be reheated for service. This dramatically cuts down prep times during the dinner rush and slashes food waste.

A blast chiller isn't an expense; it's an an investment in consistency, safety, and a smarter workflow. It gives chefs the power to perfectly preserve their creations, from delicate sauces to dense roasts, guaranteeing every dish served is as fantastic as the moment it came off the line.

It's no surprise that more and more kitchens are catching on. The global market for commercial blast chillers was valued at USD 1.5 billion in 2024 and is expected to hit USD 2.8 billion by 2033. That kind of growth tells you just how essential this equipment has become for any food service operation serious about quality. You can see more on this trend in this detailed report.

Understanding Blast Chiller Cooling Cycles

A commercial blast chiller's real power isn't just about raw speed; it’s about intelligent control. Think of it less like a simple freezer and more like a high-performance cooling engine with different gears for different jobs. These "gears" are its cooling cycles, each one a specialized mode designed to handle various food types with absolute precision.

Instead of a one-size-fits-all deep freeze, a blast chiller uses jets of high-velocity, super-cooled air to pull heat out of food uniformly. This whole process is carefully managed to preserve the integrity of the dish, preventing the kind of damage that standard freezing causes. The real magic happens when you choose the right cycle for the right food.

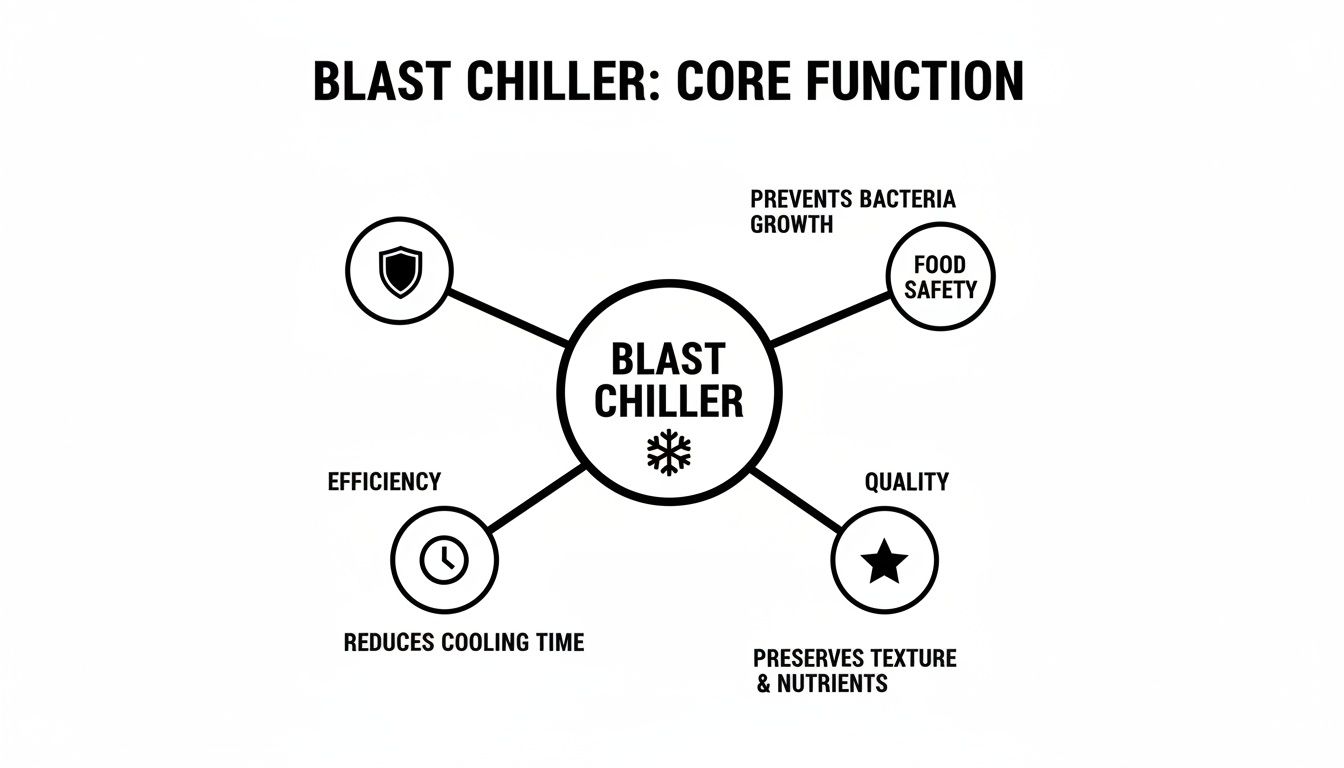

This diagram breaks down the core functions of a blast chiller, showing how it supports food safety, quality, and overall kitchen efficiency.

As you can see, these three benefits are all connected. Rapid cooling is the central process that makes everything else possible.

Soft Chilling For Delicate Foods

The soft chilling cycle is the most gentle of the cooling modes. It uses air temperatures that hover just above freezing, typically around 32°F (0°C), to slowly and carefully lower the food's internal temperature. This careful approach prevents ice crystals from forming on the surface of your most delicate items.

Picture a bakery that just pulled a batch of rich, creamy cheesecakes from the oven. Hitting them with a hard freeze would completely ruin their silky texture. With soft chilling, the temperature is brought down gradually, protecting the delicate structure of things like custards, mousses, cooked vegetables, and light fish fillets.

Hard Chilling For Dense and High-Fat Items

When you need sheer cooling power for dense or high-fat foods, you switch to the hard chilling cycle. This mode is the real workhorse of the blast chiller, blasting frigid air as low as 0°F (-18°C) to rapidly cool items straight from the oven or stovetop.

Its main goal is to get food through the temperature danger zone as fast as humanly possible. This cycle is perfect for things like:

- Large batches of dense soups, stews, and chili.

- Thick cuts of meat like a prime rib or big pork roasts.

- Lasagnas and other heavy, deep-dish casseroles.

A high-volume catering company, for example, would use hard chilling to safely cool large hotel pans of roasted chicken right after cooking. This locks in both safety and quality for their next big event.

Shock Freezing For Long-Term Preservation

Finally, the shock freezing cycle takes rapid cooling to its absolute extreme. This function is designed to take food from piping hot all the way down to a deep freeze—typically 0°F (-18°C) at its core—in under four hours. It does this by blasting the food with air that can get as cold as -40°F (-40°C).

The incredible speed of shock freezing creates microscopic ice crystals. Unlike the large, destructive crystals formed in a conventional freezer, these tiny micro-crystals don't rupture the food's cell walls. This is key to preserving texture, moisture, and nutritional value when you eventually thaw it.

This makes it the best method for preserving seasonal produce, raw proteins, or prepared meals for long-term storage. An ice cream shop could use shock freezing to set freshly churned batches in an instant, creating a much smoother and creamier final product.

To help you visualize which cycle to use and when, here’s a quick comparison.

A Comparison of Blast Chiller Cooling Cycles

| Cycle Type | Target Temperature | Ideal For (Examples) | Primary Benefit |

|---|---|---|---|

| Soft Chilling | Air at ~32°F (0°C) | Cheesecakes, custards, cooked vegetables, light fish, delicate sauces | Prevents surface ice crystals, protecting delicate textures. |

| Hard Chilling | Air at ~0°F (-18°C) | Dense soups, thick meat roasts, lasagnas, high-fat foods | Rapidly moves food through the temperature danger zone for maximum safety. |

| Shock Freezing | Air at ~-40°F (-40°C) | Raw proteins, seasonal produce, batch-prepped meals, ice cream | Creates micro-crystals, preserving texture, flavor, and nutrients for long-term storage. |

Blast chillers excel by offering these distinct modes, letting you handle everything from delicate pastries to dense roasts with incredible efficiency. For delis and bakeries, where undercounter models fit seamlessly with compact prep tables, these units are invaluable for preserving product integrity. The soft chill cycle, for instance, drops temperatures to 37°F without ice crystal formation, which helps retain up to 95% moisture and flavor compared to slow cooling methods. You can find out more about how these specialized cycles impact food quality in this market research report.

Key Specifications for Choosing Your Blast Chiller

Picking the right blast chiller commercial unit is a huge decision. It's not just another piece of equipment; it directly affects your kitchen's speed, safety, and even your bottom line. This isn't a one-size-fits-all situation—the perfect model really depends on your menu, how much food you're pushing out, and the space you have to work with. Let's get into the specs so you can find a machine that’s a true partner in your kitchen.

Before you even think about chilling cycles or temperature ranges, you have to look at the physical realities of your kitchen. It's just like choosing prep tables to fit your layout; a blast chiller has to slide right into your workflow without causing a bottleneck. The unit's construction is the foundation of that decision.

Durable Construction and Specialized Prep Tables

Any reliable kitchen is built on high-quality stainless steel, and that goes double for equipment that handles rapid temperature swings. For a blast chiller, always look for units with NSF-certified stainless steel construction. That certification is your guarantee that the material is tough, non-porous, and easy to sanitize—all critical for stopping cross-contamination and staying on the right side of the health inspector.

This need for tough, specialized surfaces is something we see all over the kitchen, especially with prep tables. Just as a blast chiller is a specialized cooling tool, different prep tables are designed for specific tasks to maximize workflow. Understanding these specialized work surfaces helps put the blast chiller’s role in a high-efficiency kitchen into perspective.

- Standard Stainless Steel Prep Tables: These are the all-rounders and the workhorses of any commercial kitchen. Available in various gauges (thicknesses), they offer a simple, durable, and easy-to-clean surface for general tasks like chopping, mixing, and plating. Their versatility means they can be placed almost anywhere, supporting the entire food preparation process.

- Pizza Prep Tables: Built specifically for high-volume pizzerias, these units are a perfect example of specialized equipment. They combine a refrigerated rail on top for holding toppings at safe temperatures with a wide, flat work surface below, often made of marble or stainless steel, for stretching dough and assembling pies. This integrated design streamlines the entire pizza-making process.

- Sandwich Prep Tables: Similar in concept to pizza tables, these are designed for delis, cafes, and sandwich shops. They feature refrigerated ingredient pans for deli meats, cheeses, and condiments, along with a built-in cutting board. This creates a compact, all-in-one station that allows staff to build sandwiches and salads with speed and efficiency.

A well-run kitchen is all about harmony. A small blast chiller sitting next to a sandwich prep table lets a deli cool down a big batch of house-roasted turkey in minutes, building top-tier food safety right into the prep line.

Capacity From Countertop to Roll-In

Once you've got construction sorted, the next big thing is capacity. This is usually measured in pounds (lbs) or by how many standard food pans it can hold. You need to choose based on your busiest days, not your average ones. A small café might just need to chill a few pans of pastry cream, but a big hotel kitchen could be processing hundreds of pounds of food for a single event.

The market for smaller units is blowing up right now. Countertop blast chillers are a game-changer for tight spaces like food trucks and delis. This niche was valued at USD 1,199.4 million in 2025 and is expected to hit USD 1,643.5 million by 2035. That growth is coming from restaurants and hotels—exactly the kind of places that need compact, NSF-certified gear. You can explore more about this market trend on Future Market Insights.

To figure out what you need, here’s a quick rundown of the common sizes:

- Countertop Models: Small, compact, and perfect for kitchens with limited space or small-batch needs. They usually hold 3-5 pans.

- Reach-In Models: These look a lot like your standard commercial fridge and offer a big jump in capacity, typically holding 5 to 15 trays. This is the sweet spot for most restaurants.

- Roll-In Models: These are the heavyweights, built for massive operations like industrial kitchens, catering companies, and hospitals. You can wheel an entire rolling rack of food pans right inside, making it incredibly efficient for huge batches.

Temperature Ranges and Capabilities

Last but not least, check the unit's temperature specs. All blast chillers cool food, but their power and features can be very different. The big question is whether you need a machine that just chills or one that can also shock freeze.

A standard blast chiller is engineered to take food from a piping hot 194°F (90°C) down to a safe 37°F (3°C) in about 90 minutes. That’s its main job and it's absolutely essential for any cook-chill system.

A blast chiller/freezer, sometimes called a shock freezer, does it all. It can run the standard chilling cycle, or it can hit your food with a powerful freeze, taking it from 194°F (90°C) all the way down to 0°F (-18°C) in around 240 minutes. This kind of versatility is priceless for preserving food long-term, letting you freeze seasonal ingredients at their peak or prep huge batches of menu items well in advance. If you want the most flexibility, a combination unit is the way to go.

Integrating Blast Chillers into Your HACCP Plan

Think of a commercial blast chiller as more than just a piece of equipment; it's one of your strongest partners in food safety. It's the muscle behind a solid Hazard Analysis and Critical Control Points (HACCP) plan, a system designed to spot potential food safety risks and stop them before they start.

HACCP is all about controlling risk, and in any kitchen, temperature is the biggest variable. This is where a blast chiller steps in. It directly tackles the most critical point for cooked foods: cooling them down fast. Its whole job is to push food through the temperature danger zone so quickly that harmful bacteria simply don't have a chance to multiply.

Halting Bacteria Growth with Speed and Precision

The foundation of any good HACCP plan is prevention, not reaction. A blast chiller is the perfect tool for this because it removes all the guesswork from the cooling process. It guarantees that every single batch, whether it's a big pot of soup or a tray of roasted chicken, reaches a safe temperature in a predictable, recordable timeframe.

Most health codes, which follow FDA guidelines, require hot foods to be cooled from 135°F (57°C) to 70°F (21°C) within two hours. Then, they must go from 70°F (21°C) down to 41°F (5°C) or colder in the next four hours. A blast chiller can knock out that entire process in as little as 90 minutes, easily beating those safety minimums.

A blast chiller basically creates a biological firewall. By cutting down the time food spends in the danger zone, it stops pathogens cold. This protects your customers' health and, just as importantly, your business's reputation.

This kind of precise control is a game-changer. If you want to dive deeper into the full certification process, our guide on what HACCP certification is is a great resource for any modern kitchen.

Data Logging for Simplified Compliance and Audits

One of the biggest headaches of maintaining a HACCP plan is the paperwork. Health inspectors need to see proof that you're following your safety rules every single day. Modern blast chillers turn this chore into an automatic, error-proof process.

Many new blast chiller models are built with compliance in mind and come loaded with smart features:

- Integrated Food Probes: You stick these probes right into the food, giving you an exact core temperature reading through the whole chill cycle. This confirms the inside is just as cold and safe as the outside.

- Data Logging Capabilities: The machine automatically records everything—start time, end time, and the temperature curve from beginning to end. You can usually download this data with a USB stick or over Wi-Fi.

- Printable Reports: Some units can even print out detailed reports for each cycle. This gives you an instant, physical record to pop right into your HACCP logbook.

This automated record-keeping gives you undeniable proof that you’ve met your critical control points. When the health inspector shows up, you can just hand them the digital logs or printed reports. It shows total compliance with confidence and turns your blast chiller from a simple appliance into an essential risk management tool.

How a Blast Chiller Changes Your Kitchen's Entire Rhythm

A blast chiller commercial unit is more than just a piece of cooling equipment; it completely rewrites the script for how your kitchen operates. Think of it as the key that unlocks a much smarter, less frantic way of working called the "cook-chill" method.

This whole strategy is about breaking the stressful cycle of cooking every single dish to order right in the middle of the dinner rush.

Instead of that chaotic scramble, you can cook big, beautiful batches of your best-selling items during the calmer morning hours. As soon as they're done, they go straight into the blast chiller, which locks in their freshness and quality in a way no other appliance can. When service gets crazy, those perfectly prepped components are ready to be quickly reheated and served, meaning every plate goes out looking and tasting fantastic.

This simple shift takes a massive amount of pressure off your line cooks. It cuts down on food waste from prepping too much and makes sure the last customer of the night gets a meal that's just as good as the first. The blast chiller essentially becomes the heart of a proactive kitchen, not a reactive one.

The Blast Chiller as Your Workflow's Central Hub

Picture your kitchen's workflow like an assembly line. A blast chiller is like a strategic pause button on that line—a checkpoint where you can stop production without losing an ounce of quality or compromising safety. That pause gives you an incredible amount of control.

For more on how different pieces of equipment fit together, this guide on optimizing kitchen space and flow is a great resource. A blast chiller is a major part of that puzzle.

Let's look at how this plays out in the real world:

- Pizzerias: Imagine prepping gallons of your signature marinara and pre-cooking pounds of sausage and bacon first thing in the morning. Blast chill them, and they're perfectly preserved and ready to go. When the Friday night pizza rush hits, you’re just assembling, not scrambling to cook toppings from scratch.

- Catering Companies: For caterers, prepping in advance isn't a luxury; it's survival. A blast chiller lets them safely prepare multi-course meals—from chilled appetizers to braised meats—days before an event. This is how they pull off flawless execution for hundreds of guests.

- Restaurants and Cafes: Any restaurant can use this. Think about blast chilling batches of soup, braised short ribs, or even delicate panna cotta. Everything is ready to be finished and plated the moment an order comes in.

When you separate the cooking process from the service time, you transform your kitchen. It stops being a frantic sprint and turns into a well-orchestrated relay race. Each step is done calmly and correctly before handing off perfectly prepped ingredients to the next station.

Putting the Cook-Chill Method to Work

Getting started with the cook-chill workflow is surprisingly simple, and you’ll see the benefits almost immediately. The whole system boils down to three steps: cook, chill, and reheat.

Here’s what that process looks like with a blast chiller:

- Prepare and Cook: Cook your food just like you always do—meats, sauces, vegetables, you name it. The only difference is you’re making larger, more efficient batches based on what you expect to sell.

- Rapidly Chill: As soon as the food comes off the heat, get it into the blast chiller. The machine will power it down to a safe 37°F. Once it’s chilled, you can move it to a regular fridge and it will hold its quality for up to five days.

- Rethermalize and Serve: When an order ticket comes in, you just pull the chilled components, reheat them to the correct temperature, and plate them. The dish tastes like it was just made from scratch because, in a way, it was.

This method is a game-changer. It lets you manage inventory with incredible accuracy, nearly eliminates the risk of running out of a popular dish, and keeps your quality consistently high. Best of all, it makes your kitchen a much calmer, more organized, and more productive place to be.

Installation, Maintenance, and Common Pitfalls to Avoid

Bringing a new blast chiller commercial unit into your kitchen is a huge leap forward for food safety and workflow. But to really get the most out of that investment, you have to nail the installation and stay on top of maintenance. Getting these fundamentals right from day one is the secret to a long, productive life for your machine.

The setup process is way more than just plugging it in. These are serious pieces of refrigeration equipment with very specific needs.

Setting Up for Success

First off, let's talk about airflow. A blast chiller’s whole job is to pull heat out of food and push it out into the room. If you shove it into a tight corner with no breathing room, that hot air gets trapped. This makes the condenser work overtime, spiking your energy bills and setting the stage for a breakdown. Always, always follow the manufacturer's specs for clearance on the back and sides.

Next up, utilities.

- Electrical: These units are power-hungry. You absolutely need a dedicated circuit and the right outlet to handle its voltage and amperage. An extension cord isn't a workaround; it's a fire hazard that can fry your compressor.

- Drainage: All that rapid cooling creates a lot of condensation that has to go somewhere. Most chillers need a direct line to a floor drain, so factor that into your placement plans.

A solid setup is your foundation. You can actually learn a lot by looking at how other complex cooling systems are maintained—many of the same principles apply. For example, there's a lot of overlap with these essential HVAC maintenance tips for efficiency.

Your Routine Maintenance Checklist

Just like your range or your mixer, your blast chiller needs consistent, routine care. The best way to prevent expensive, emergency repairs is to create a simple maintenance schedule and stick to it. This is a core idea we cover in our big guide on commercial kitchen equipment maintenance.

Think of maintenance as a health checkup for your machine. A few minutes of preventive care each week can save you from a major headache—and a huge repair bill—later on.

Here’s a quick-start schedule to build on.

Essential Blast Chiller Maintenance Checklist

This routine maintenance schedule will help keep your commercial blast chiller running efficiently and extend its operational life.

| Frequency | Task | Why It Matters |

|---|---|---|

| Daily | Wipe down interior and exterior surfaces. Clean the door gaskets. | Prevents bacterial buildup and ensures a tight door seal, which saves energy. |

| Weekly | Clean the condenser coil with a stiff brush or vacuum. | A clean coil expels heat more efficiently, reducing strain on the compressor. |

| Monthly | Calibrate the temperature probes. | Ensures your HACCP data is accurate and that food is being cooled to safe temperatures. |

Following these simple steps will make a massive difference in your machine's performance and longevity.

Common Mistakes That Cost You Money

Even with a perfect setup and a great maintenance routine, simple user errors can sabotage your blast chiller's performance. Steering clear of these common slip-ups is key.

One of the biggest culprits is overloading the chiller. Every machine has a maximum capacity for a reason. Jam it too full, and the cold air can’t circulate properly. This leads to much longer chilling times and hot spots where food isn't getting cooled safely.

Another one we see all the time is improper food placement. Don't just stack sheet pans right on top of each other. You have to leave space between them so air can flow freely around every surface of the food. That's how you get everything to cool down quickly and evenly.

Finally, make sure you're selecting the correct cooling cycle. Using a powerful "hard chill" cycle on a delicate custard, for instance, will completely ruin its texture. Match the cycle to the food.

Frequently Asked Questions About Commercial Blast Chillers

Jumping into the world of commercial kitchen equipment always kicks up a few questions. When it's time to talk about a blast chiller commercial unit, getting the details straight helps you make a purchase you can feel good about. Here are some quick, clear answers to the questions we hear most from chefs and kitchen managers.

What Is the Real Difference Between a Blast Chiller and a Freezer?

Think of it this way: a freezer's job is to keep already frozen food frozen. It’s a long-term holding pen, plain and simple.

A commercial blast chiller, on the other hand, is all about speed. It’s a rapid cooling machine designed to take hot food—like a sauce just off the stove at 160°F—and drop its temperature down to a food-safe 37°F in about 90 minutes. That incredible speed is the whole point, making it a game-changer for food safety and quality.

Will Using a Blast Chiller Change My Food's Taste or Texture?

Actually, it does the opposite. When you use a blast chiller the right way, it protects and even improves the quality of your food, especially when you compare it to slow freezing in a regular freezer.

The super-fast cooling process creates tiny, harmless micro-crystals of ice that don't damage the food's cellular structure.

Slow freezing creates large, jagged ice crystals that literally shred food cells. That’s what causes that mushy, watery texture when you thaw something out. A blast chiller helps your food keep its original moisture, texture, and flavor much more effectively.

How Do I Choose the Right Size Blast Chiller for My Business?

Always base your decision on your kitchen's peak production, not your average Tuesday. Think about the absolute maximum amount of food you'll need to chill or freeze at once, whether it’s for your busiest dinner service or a massive catering event.

For example, if you’re a caterer who needs to cool 250 lbs of protein for a wedding, you need a model that can handle that load, plus a little extra. Just as important, make sure the unit’s internal racking is built for the pan sizes you already use every day, like full-size hotel pans. That's how you ensure it fits right into your workflow without any headaches.

Ready to take control of your kitchen's efficiency and food safety? Explore our complete collection of commercial blast chillers and other essential equipment at PrepTables.com. Find the perfect unit to match your needs by visiting https://preptables.com today.