The Ultimate 93 Inch Pizza Prep Table Guide

Share

Picture this: it's the middle of your Friday night rush. Orders are pouring in, the printer is screaming, and every single second is precious. In that controlled chaos, a 93 inch pizza prep table isn't just a piece of equipment—it's your command center. It's the engine that keeps a high-volume pizzeria humming along, offering the massive workspace and refrigerated storage you need to keep things flowing.

Why the 93 Inch Pizza Prep Table Is Your Kitchen's MVP

Think of your prep station as the heart of your kitchen's assembly line. The way it's designed has a direct line to your speed, consistency, and, let's be honest, your profitability. For any shop that pumps out a serious number of pies, the 93-inch model is the undisputed Most Valuable Player.

This size just hits a perfect sweet spot. It gives you an enormous work surface plus all the refrigerated storage you could ask for. You get enough room for multiple chefs to work together without constantly bumping elbows—a game-changer during peak hours. That kind of collaborative space means your workflow is smooth, with zero bottlenecks from stretching the dough to sprinkling on the last topping.

Understanding Prep Table Variations

While we’re zeroing in on the 93-inch pizza prep table, it helps to see where it fits in the wider family of stainless steel stations. Not all tables are built the same; they’re engineered for very specific jobs.

- Standard Work Tables: These are the basics. Just a simple, flat stainless steel top. They're fantastic for general tasks like chopping veggies or mixing dough, but they don't have any built-in refrigeration.

- Sandwich and Salad Prep Tables: These units have a refrigerated rail for holding pans of cold ingredients, but the cutting board is much narrower—usually around 10-12 inches deep. The whole setup is optimized for building sandwiches and salads, making it easy for a chef to reach every single ingredient.

- Pizza Prep Tables: Here’s the key difference: an extra-deep cutting board, often 19 inches or more. This massive surface is specifically made to handle large pizza doughs. It gives your crew all the space they need to stretch, top, and build pies without feeling cramped. The refrigerated rail is also raised, keeping ingredients out of the way but still perfectly chilled and right at your fingertips.

A well-chosen prep table isn't just a purchase; it's a strategic investment in operational excellence. The right model can dramatically reduce ticket times, improve product consistency, and minimize food waste by keeping ingredients at optimal temperatures.

The sheer demand for equipment like the 93 inch pizza prep table says a lot about its value in the food service world. The global market for these tables was valued at roughly USD 1.5 billion in 2023 and is on track to grow significantly. This growth just highlights how critical efficient, high-capacity prep stations are in any modern commercial kitchen. You can dig deeper into these market trends and what they mean for restaurant owners.

Choosing Your Perfect Prep Station

Walking into the world of commercial prep tables can feel a bit like visiting a car dealership. You’ve got your sleek sports cars and your rugged off-road trucks. Both get you from A to B, but they’re built for completely different jobs. Prep tables are the same—they’re engineered for very specific tasks.

Getting a handle on these differences is the key to picking a station that actually helps your kitchen flow instead of getting in the way. It's about more than just size; it’s about matching the equipment's design to what you do day in and day out.

Pizza Prep Tables vs. Sandwich Prep Tables

The biggest fork in the road is choosing between a table made for pizza and one built for sandwiches or salads. At a glance, they might seem pretty similar, but their core designs are tailored to entirely different ways of working. A 93-inch pizza prep table, for example, is a serious piece of equipment designed for one thing: cranking out a high volume of pies.

A major giveaway is the depth of the cutting board. Pizza prep tables have an extra-deep work surface, usually 19 inches or more. That huge space is absolutely essential for stretching large pizza doughs, giving your cooks plenty of real estate to sauce and top everything without making a mess.

On the other hand, sandwich and salad tables have much skinnier cutting boards, typically around 10 to 12 inches deep. This is a more ergonomic setup for building smaller items, as it lets staff easily reach over the board to the ingredient rail. Sure, you could make a sandwich on a pizza table, but it would feel like trying to parallel park a bus in a spot meant for a compact car.

Another smart design choice on pizza prep tables is the raised refrigerated rail. It keeps cold pans of toppings elevated and out of the main work zone. This prevents stray flour or sauce from getting into your ingredients while keeping everything perfectly chilled and easy to grab.

This kind of specialized design is what makes the pizza-making process so smooth. To see one in action, check out our in-depth review of the Atosa 93-inch pizza prep table, which breaks down all its features.

The Critical Role of Stainless Steel

Once you’ve settled on the type of table, the next thing to look at is the material. In a commercial kitchen, there’s no substitute for stainless steel. It’s tough, hygienic, and stands up to corrosion. But not all stainless steel is created equal—the "grade" makes a huge difference in how long your table will last.

You'll mainly come across two grades in kitchen equipment:

- 304 Stainless Steel: This is the gold standard for any surface that touches food. It has more nickel, giving it top-tier resistance to corrosion from the salts and acids in food. It’s the perfect material for the tabletop and ingredient rail.

- 430 Stainless Steel: This is a more budget-friendly grade often used for the body, legs, and shelves. It’s still plenty durable, but it’s not quite as corrosion-resistant as 304 steel. It's a solid choice for the structural parts of the table that aren't in constant contact with food.

Think of it like building a house: you use top-of-the-line waterproof materials for the roof (like 304 steel for food zones) and standard, sturdy materials for the internal frame (like 430 steel for the body).

Why Steel Gauge Matters

You’ll also hear the term "gauge," which is just a measure of the steel's thickness. It works backward, which can be a little confusing: the lower the gauge number, the thicker and stronger the steel. For a busy commercial kitchen, a lower gauge is almost always the right call.

A table built from 16-gauge steel will take a beating far better than one made from a thinner 18-gauge or 20-gauge steel. For a beast like a 93-inch pizza prep table that's going to see constant action, investing in a lower gauge is a no-brainer. It means your station can handle the daily grind without denting or warping, protecting your investment for years.

Anatomy of a High-Performance Pizza Prep Table

What really makes one prep table better than another? When you get down to it, it’s not just about the shiny stainless steel top. The real magic happens with the features working together under the hood. To truly appreciate a top-tier 93-inch pizza prep table, you have to look past the surface and see the components that make your daily grind smoother and your investment last longer.

Think of it like this: a basic sedan and a high-end SUV both get you from A to B. But the SUV is built for tougher jobs and has all the bells and whistles for a better experience. A high-performance prep table is the SUV of your kitchen—loaded with features that boost efficiency and pay for themselves over time.

Core Components That Define Quality

The heart of any refrigerated station is its cooling system. This is one of the biggest differences between a budget model and a premium one. High-end tables almost always use a forced-air refrigeration system. This system uses fans to push cold air everywhere inside, from the main cabinet to the ingredient rail. The result? When the doors swing open during a crazy dinner rush, the temperature bounces back fast.

Another feature that seems small but makes a huge difference is the self-closing doors. In a busy kitchen, it’s easy for someone to accidentally leave a door ajar. Self-closing doors (especially those that stay open at 90 degrees) stop cold air from escaping. That means less work for your compressor and lower energy bills—a simple but powerful tool for food safety and efficiency.

The table below breaks down the key features that truly define a quality 93-inch pizza prep table. It shows what you should be looking for and why each component is so important for a busy kitchen.

Essential Features of a 93 Inch Pizza Prep Table

| Feature | Description | Impact on Kitchen Operations |

|---|---|---|

| Forced-Air Refrigeration | Uses fans to evenly distribute cold air throughout the unit, including the rail. | Ensures consistent temperatures and quick recovery, keeping ingredients fresh and safe during peak hours. |

| Self-Closing Doors | Doors that automatically shut, often with a stay-open feature at 90 degrees. | Prevents energy waste, reduces strain on the compressor, and maintains food-safe temperatures effortlessly. |

| Digital Temperature Controls | An external digital display for monitoring and adjusting internal temperatures. | Allows for at-a-glance temperature checks without opening the unit, ensuring strict food safety compliance. |

| Epoxy-Coated Shelving | Heavy-duty wire shelves coated with a protective layer of epoxy or PVC. | Resists rust and corrosion from spills and moisture, leading to a longer lifespan and better hygiene. |

| Raised Pan Rail | An elevated section designed to hold ingredient pans at an ergonomic height. | Keeps toppings chilled and within easy reach, speeding up the pizza-making process significantly. |

Each of these features is engineered not just to keep things cold, but to make your entire workflow more intuitive and productive.

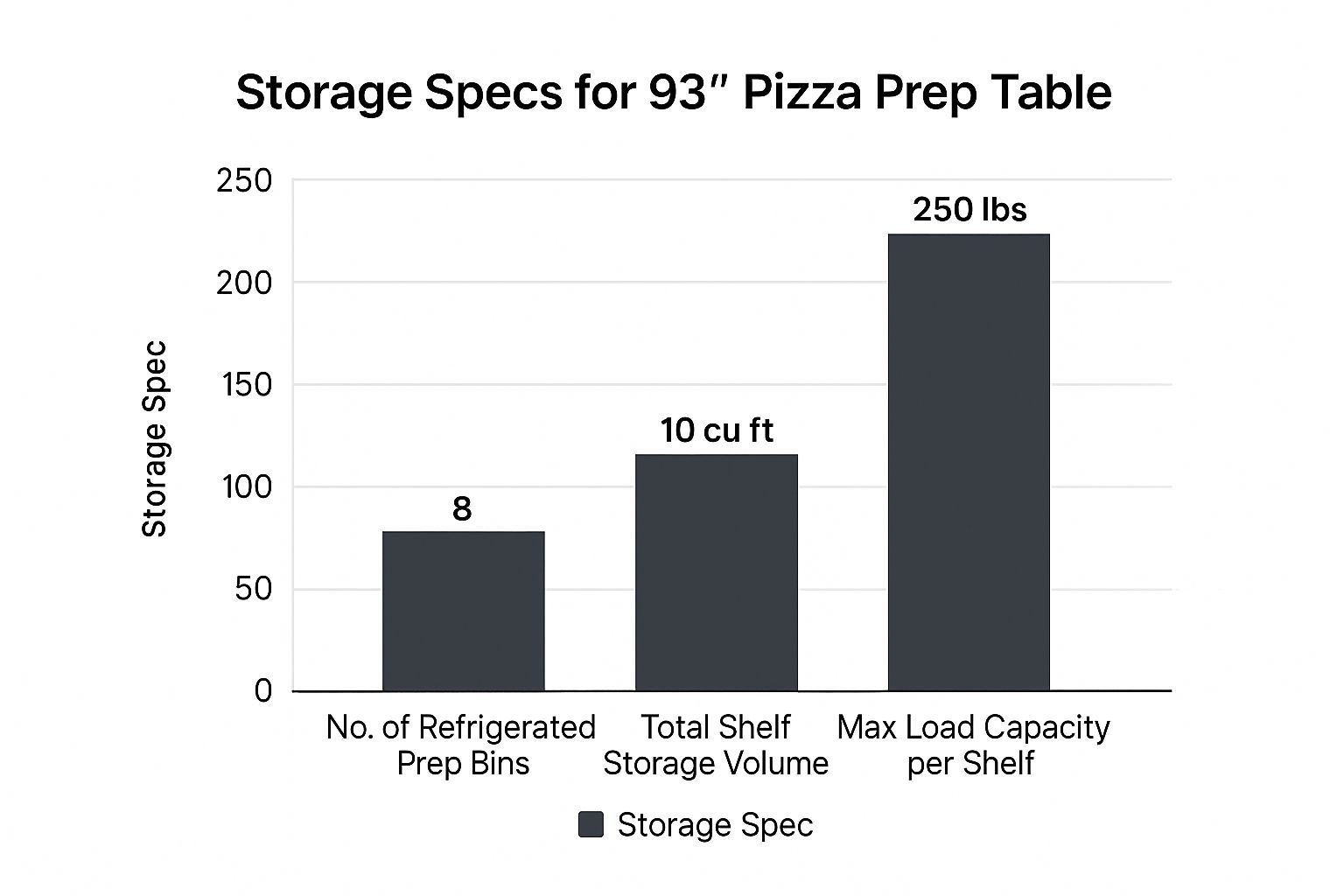

This setup is clearly built for high-volume work, giving you plenty of room for all your toppings, a large refrigerated cabinet, and strong shelves to keep everything organized.

Features That Streamline Your Workflow

Beyond the core mechanics, other features directly improve how your team operates. For food safety, you can't compromise on temperature. That’s why modern units feature digital temperature controls with an easy-to-read external display. Your chefs can see and adjust the temperature in a second without ever opening the door, making sure every ingredient stays safely between 33°F and 41°F.

Heavy-duty shelving is another unsung hero. Look for shelves coated in epoxy or PVC. This coating protects them from the rust and corrosion that inevitably comes with spills and moisture. Adjustable shelves are also a game-changer, letting you customize the space to fit anything from bulky dough boxes to large sauce buckets. It turns a potentially chaotic cabinet into a model of efficiency.

A great prep table doesn’t just keep things cold; it actively helps your kitchen run smoother. Every feature, from the digital controls to the durable shelving, is engineered to remove small points of friction that can add up to major delays during peak service.

The 93-inch size is so popular because it hits that sweet spot between workspace and storage. These tables typically give you 12 to 24 cubic feet of refrigerated storage, perfectly balancing the need for fresh ingredients with the demands of a busy commercial kitchen. It's no surprise that refrigerated prep tables are the top choice for pizzerias—they speed up service and make it easier to meet strict food safety rules.

Choosing the right table means looking at the whole package. For a more detailed look at what to consider before you buy, our comprehensive prep tables buying guide has more expert tips.

Does Your Kitchen Need a 93-Inch Prep Table?

The 93-inch pizza prep table is an absolute powerhouse. It's the kind of workhorse built for serious, high-volume pizzerias. But just because it’s big and impressive doesn't mean it's right for your shop. Getting a unit this size is a major decision, one that really depends on an honest look at your kitchen's daily grind.

Before you even think about committing, you need to look past the shiny specs and ask some real-world questions. How many pies are you actually slinging during your busiest rush? Can your current layout even handle a station that's nearly eight feet long? And where do you genuinely see your business in the next couple of years? Answering these honestly is the first step toward making a smart buy that won't give you buyer's remorse later.

This isn't about getting the biggest piece of gear on the market; it's about finding the smartest tool for the job you actually have.

Assessing Your True Production Volume

The number one thing to consider is your output. Plain and simple. A 93-inch table is designed for scale, letting multiple cooks work shoulder-to-shoulder without tripping over each other. It’s perfect for pizzerias that are slammed with orders all night long.

Let's look at two very different kitchens:

-

The Neighborhood Pizzeria: This spot is a local favorite, maybe selling 30-40 pizzas during the Friday night peak. It's busy, for sure, but a single talented chef can probably keep up using a smaller 60 or 72-inch table. A 93-inch beast in this kitchen would just be an expensive, space-hogging ornament.

-

The Bustling City Chain: This location is a machine, pumping out over 100 pizzas an hour with a dedicated assembly line of two or three people. For them, a 93-inch prep table isn't a want—it's a need. That massive workspace is the only thing keeping ticket times down and orders flowing.

The real trick is to base your decision on sustained peak volume, not just a few crazy nights. If your kitchen is constantly hitting a wall where workspace is the main bottleneck, then upgrading to a 93-inch model makes a lot of sense.

This lines up with what we're seeing across the industry. Recent market data shows the pizza prep table market is expected to hit nearly USD 4.92 billion by 2033, growing at a brisk CAGR of about 11.9%. This kind of growth, which is faster than many other commercial appliance categories, points to a huge demand for high-capacity solutions like the 93-inch model. If you're interested, you can dive deeper into the data on the growing pizza prep table market to see these trends for yourself.

Analyzing Space and Kitchen Workflow

Once you've confirmed the volume, you have to think about the physical reality of your kitchen. A 93-inch table is huge, and it needs more than just a spot on the floor. You have to factor in breathing room for ventilation, space for refrigerator doors to swing open, and clear pathways for your crew to move.

Before you even start browsing, grab a tape measure. Make sure you can leave at least 3-4 inches of clearance at the back and on the sides. That space is crucial for the refrigeration system to work properly. If you cram it against a wall, the compressor will overheat, driving up your energy bills and shortening the life of your equipment.

You also have to map out your kitchen's flow. Where's the dough station in relation to the prep table? How far is the oven? Squeezing a giant table into the wrong spot can completely wreck your kitchen's rhythm, creating more headaches than it solves. The goal is a seamless line from dough to oven, with the prep table as the central hub. If a 93-inch table makes that journey awkward and inefficient, a smaller unit is the smarter play.

Protecting Your Investment with Smart Maintenance

Think of your new 93 inch pizza prep table as a serious piece of equipment—it's an investment that's going to be the workhorse of your kitchen. Like any high-performance machine, it needs the right care to keep it running smoothly and avoid those nightmare breakdowns that kill a busy service.

This isn't about adding complicated chores to your closing list. It's about smart, simple habits. A few minutes of preventative care each day will save you a world of hurt, preventing hours of downtime and costly emergency repair calls later on.

Daily and Weekly Maintenance Routines

The key to keeping your prep table in top shape is consistency. Simple daily tasks are your best defense against the most common equipment problems and hygiene headaches. These should become second nature, just like wiping down the line at the end of the night.

Daily Checklist:

- Wipe Down All Surfaces: At closing, grab a soft cloth and a mild detergent to clean every stainless steel surface, inside and out. Always wipe with the grain of the steel to keep it looking sharp and avoid scratches.

- Clean the Cutting Board: Pull the cutting board off the unit. Give it a thorough wash with soap and hot water, then sanitize it properly. Let it air dry completely before putting it back.

- Check for Spills: Wipe up any spills inside the refrigerated base right away. This prevents sticky, hard-to-clean messes and protects the interior from potential corrosion.

Weekly tasks go a bit deeper, hitting the spots that are crucial for performance but don't need daily attention.

Weekly Checklist:

- Inspect Door Gaskets: Run your hand along the rubber seals on the doors. You're looking for any cracks, tears, or spots where they've become hard and brittle. A bad seal leaks cold air, forcing your compressor to work overtime and driving up your energy bill.

- Rotate and Sanitize Pans: Take all the ingredient pans out of the rail. Wash, sanitize, and dry them completely before you refill them and put them back.

- Deep Clean the Interior: Empty out the refrigerated cabinet. Give the inside walls and shelves a good scrub with a food-safe sanitizer to keep things fresh and clean.

Consistent maintenance isn't a chore; it's an operational strategy. A well-maintained prep table uses less energy, holds temperatures more reliably, and lasts significantly longer, providing a better return on your initial investment.

Monthly and Quarterly Deep Cleaning

Your monthly and quarterly to-do list is all about the mechanics of your 93 inch pizza prep table. These steps are absolutely essential for keeping your cooling system efficient and heading off the most common reasons for a total system failure.

One of the most critical jobs is cleaning the condenser coils. These coils are what release heat from the refrigeration system. Over time, they get caked with a mix of dust, grease, and flour, which acts like a blanket, insulating them and making the compressor work way too hard.

A clean condenser can cut your unit's energy use by as much as 10-15%. To clean them, unplug the unit first. Then, use a stiff brush or a vacuum attachment to gently remove all the gunk. Doing this simple task every one to three months is the single best thing you can do to prolong the life of your compressor.

For a deeper dive into caring for different finishes and equipment, check out our complete guide to restaurant stainless steel tables.

Quick Troubleshooting for Common Issues

Even with the best maintenance plan, things can still go wrong. Knowing how to spot and fix minor issues can save a service from grinding to a halt over a small problem.

- Unit Isn't Cooling Properly: Before you pick up the phone to call a technician, check the basics. Is it plugged in? Are the condenser coils dirty? Are the doors sealed tightly? Sometimes, just overloading the cabinet with warm product can make the temperature rise temporarily.

- Water Leaking on the Floor: This is almost always a clogged condensate drain line. A quick clean-out with a pipe cleaner or a shot of compressed air can usually clear it right up.

When you empower your team with these maintenance and troubleshooting skills, you make them partners in protecting your investment. This proactive mindset ensures your 93 inch pizza prep table stays the reliable, efficient heart of your pizza operation.

Frequently Asked Questions

Jumping into the world of commercial kitchen equipment always kicks up a few questions, especially when you’re looking at a big investment like a 93-inch pizza prep table. We’ve pulled together the most common questions we get from pizzeria owners to give you clear, straight-to-the-point answers. This should help you feel confident you're making the right call.

What Is the Difference Between a Pizza Prep Table and a Work Table?

They might both be made of that same gleaming stainless steel, but a pizza prep table and a regular work table are built for two totally different jobs.

Think of a standard work table as your kitchen's blank canvas. It’s a simple, flat surface that’s perfect for general tasks like portioning dough balls or chopping up a box of onions. It gives you a tough, hygienic workspace, but that's where its features end.

A pizza prep table, however, is a purpose-built workstation. It's an all-in-one assembly line, integrating refrigeration right into the unit with a refrigerated rail for all your topping pans and a spacious refrigerated cabinet down below. The whole design is about keeping every essential ingredient perfectly chilled and right at your fingertips.

Can I Use a Pizza Prep Table for Sandwiches and Salads?

You absolutely can, but it’s not always the best tool for the job. There’s a key ergonomic trade-off you need to think about: the cutting board.

A 93-inch pizza prep table comes with an extra-deep cutting board, usually 19 inches or even more. That massive surface area is a must-have for stretching and topping large pizza skins.

While you can definitely build a sandwich on it, it can feel a little awkward. A dedicated sandwich prep table has a much narrower cutting board, typically around 10-12 inches deep. This slimmer design lets your staff easily reach over the board to grab ingredients from the rail. So, for a mixed menu, a pizza table offers great versatility. But if you're running a high-volume sandwich or salad line, a dedicated unit is going to be much faster and more comfortable for your team.

What Kind of Warranty Should I Look For?

A solid commercial warranty is non-negotiable. It's your safety net and a huge clue about how much faith the manufacturer has in their own equipment. For a big piece of gear like a refrigerated prep table, you should be looking for a warranty that covers a few different things.

- Parts and Labor: Find a warranty that gives you at least 1 year of coverage for both parts and labor. This will protect you from surprise costs for most problems that might pop up early on.

- Compressor: This is the big one. The compressor is the heart of the whole refrigeration system and the most expensive part to fix or replace. A good warranty will give you 5 years of coverage specifically for the compressor.

Don't skim over the warranty details. It provides serious peace of mind and protects your investment from expensive repairs down the road.

How Much Electricity Does a 93 Inch Pizza Prep Table Use?

Energy use can definitely vary from one model to another, but a typical 93-inch pizza prep table will generally use somewhere between 8 and 12 kilowatt-hours (kWh) per day.

If you want to keep your utility bills in check, keep an eye out for models that are Energy Star certified. These units have been independently tested and proven to be about 20% more energy-efficient than standard models. Over the life of the table, that adds up to hundreds of dollars saved on your electricity bill.

What Are the Installation and Clearance Requirements?

Getting the installation right is critical for your prep table's performance and lifespan. Most units are designed to plug into a standard electrical outlet, but you absolutely must check the specific voltage and amperage requirements from the manufacturer to avoid any electrical problems.

Even more important is ventilation. The refrigeration system needs room to breathe so it can get rid of heat properly.

Plan on leaving at least 2 to 3 inches of clear space around the back and sides of the unit. If you push the table right up against a wall, you'll trap heat and force the condenser to work way too hard. This leads to poor cooling, system overheating, and eventually, a dead compressor.

Before your new table shows up, grab a tape measure and make sure you have the space. It’s a simple step that makes a huge difference in the health and efficiency of your equipment.

Ready to find the perfect prep station for your kitchen? At PrepTables.com, we offer a wide selection of high-quality pizza prep tables, including powerful 93-inch models designed for maximum efficiency and durability. Explore our collection and upgrade your workflow today.