Your Guide to the Right Industrial Baking Oven

Share

An industrial baking oven isn't just another piece of kitchen equipment. It's the high-capacity, heavy-duty heart of any large-scale baking operation, built for one thing: consistent, reliable output. These machines are the powerful engines that drive profitability, turning raw dough into perfectly finished products, whether that’s artisanal bread or mass-produced snack cakes.

Why Your Oven Is The Heart Of Your Bakery

Think of your oven as the central hub of your entire production line. Its performance has a direct ripple effect on everything from product quality and consistency to operational efficiency and, ultimately, your bottom line. It's the cornerstone that supports your bakery's ability to scale, meet growing demand, and maintain the craft that sets your brand apart.

Choosing the right oven is one of the most defining decisions a bakery owner can make. It’s about so much more than just heat. You're investing in a machine that becomes a reliable partner in your growth, empowering you to produce thousands of items with repeatable perfection. This ensures every single customer gets the same great experience, every time.

The Scale of the Baking Industry

The craving for high-quality baked goods isn't just a local trend; it's a global phenomenon. This growing appetite for everything from quick convenience foods to premium artisanal products is fueling major innovation in baking technology. The market numbers tell the story, highlighting just how crucial capable and efficient equipment has become.

The global industrial baking ovens market was valued at approximately USD 1.2 billion in 2023. It’s projected to climb to around USD 1.78 billion by 2032. This growth shows just how critical these ovens are for meeting worldwide consumer demand.

This boom is driven by a few key factors:

- Rising demand for convenience foods: Busy lifestyles have made ready-to-eat baked snacks and meals more popular than ever.

- Increased disposable income: As people's incomes grow, they're more willing to spend on premium and specialty baked goods.

- Urbanization: More people living in cities creates larger, more centralized markets for bakeries to serve.

This expanding market proves that investing in a high-performance industrial baking oven isn't just about keeping up—it's about setting your business up for future success. Understanding the landscape and the technology available is the first step toward making a smart, confident choice. Your oven doesn't just bake; it builds your reputation with every single batch. For a deeper dive, you can get more details on the industrial oven market growth to see how innovation is shaping the industry.

Matching Oven Types to Your Production Needs

Choosing the right industrial baking oven is a bit like casting the lead actor in a play—the one you pick sets the tone for the entire performance. The perfect oven for your bakery depends completely on what you bake, how much you bake, and the space you're working with. Not all ovens are created equal, and each type brings its own unique strengths to the table.

Understanding these differences is the key to matching the right equipment to your business goals. A high-volume bagel factory, for instance, has vastly different needs than an artisanal bakery specializing in delicate sourdough. The technology inside the oven—its core heating and baking mechanism—is what makes it a star for one job and a poor fit for another.

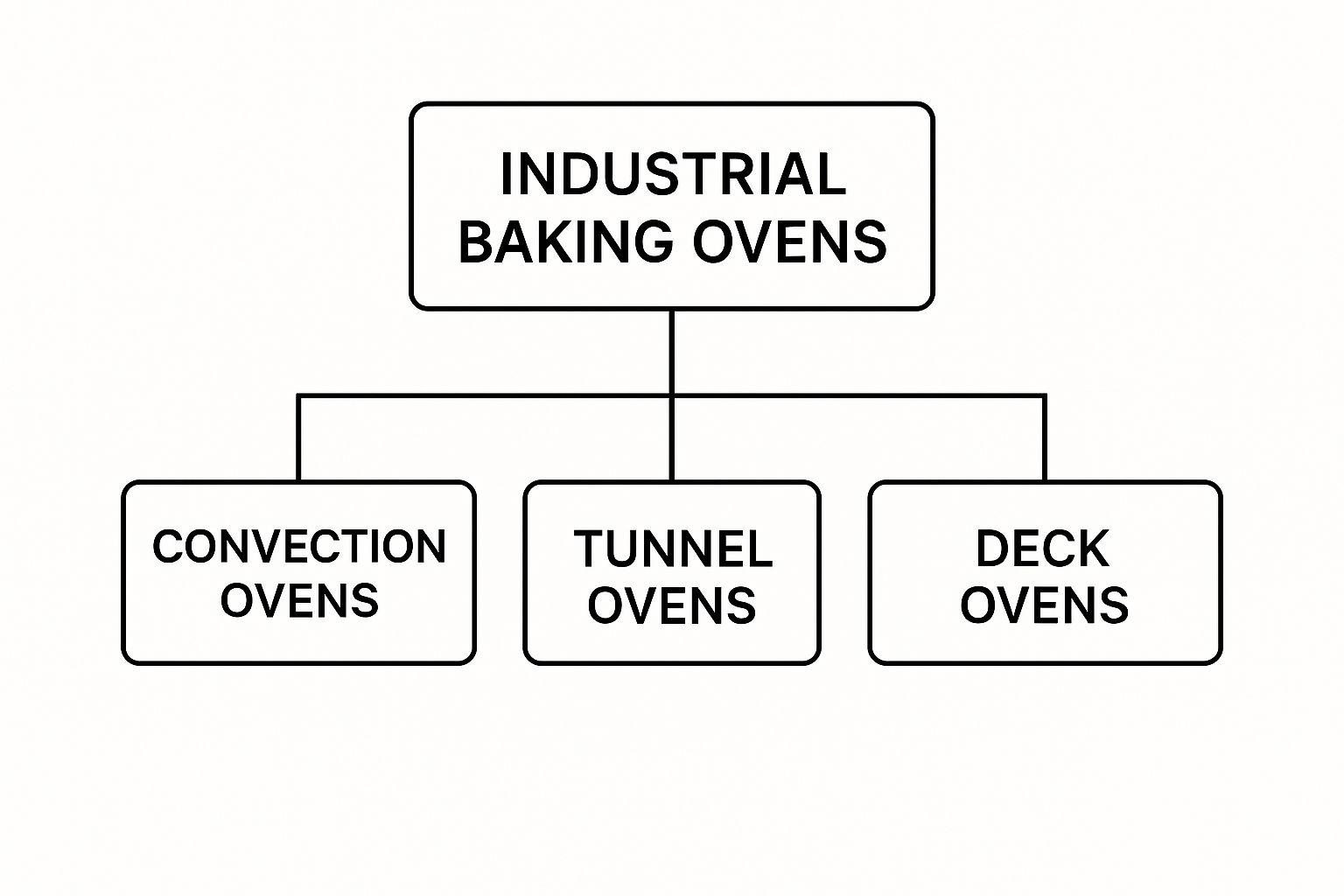

This diagram gives a clear breakdown of the main industrial oven categories.

This shows how the broader category of industrial ovens branches out into specialized types, each built for distinct baking styles and volumes. Let's dig into what makes each of these the right choice for certain production needs.

To help you quickly compare your options, here's a look at how these ovens stack up.

Industrial Baking Oven Types at a Glance

| Oven Type | Baking Mechanism | Best For | Production Scale |

|---|---|---|---|

| Convection | Circulated Hot Air (Fans) | Cookies, Pastries, Muffins | Small to Medium Batch |

| Deck | Radiant & Conductive Heat (Stone/Ceramic Slabs) | Artisanal Breads, Hearth-Baked Pizza | Small to Medium Batch |

| Rack | Rotating Rack with Circulated Hot Air | Diverse Product Batches | Medium to Large Batch |

| Tunnel | Conveyor Belt through Heat Zones | Single, High-Volume Products | Continuous Mass Production |

This table provides a high-level overview, but the real magic is in the details. Let's explore what makes each of these oven types a workhorse in its own right.

Convection Ovens: Masters of Uniform Airflow

Think of a convection oven as the master of perfectly even heat. Unlike a standard oven that just radiates heat from stationary elements, a convection oven uses powerful fans to constantly circulate hot air throughout the baking chamber. This moving air eliminates hot spots and makes sure every item, whether it's on the top rack or the bottom, bakes at the exact same rate.

This makes them the go-to choice for delicate goods that need consistent browning and a uniform texture.

- Cookies: Get a perfectly even color and crispness across the entire batch.

- Pastries: Ensure every flaky layer in your croissants and danishes is cooked through without any burning.

- Muffins and Cupcakes: Achieve a consistent rise and a beautiful golden top on every single one.

Because they are so efficient, convection ovens often bake faster and at lower temperatures than conventional models, which can lead to real energy savings over time. They're incredibly versatile and a true staple in commercial kitchens and smaller bakeries.

Deck Ovens: The Artisanal Hearth-Style Choice

If your bakery’s reputation is built on incredible, crusty bread, then a deck oven is your non-negotiable partner. These ovens are specifically designed to mimic the baking conditions of a traditional brick-lined hearth. They feature large stone or ceramic shelves—the "decks"—that absorb and radiate intense, even heat directly into the bottom of the dough.

A deck oven's primary advantage is its ability to produce an exceptional "oven spring"—the rapid initial rise of bread—and a thick, crispy bottom crust that is impossible to achieve with other methods. This direct, conductive heat is the secret behind world-class artisanal breads and pizzas.

These ovens are absolutely perfect for:

- Artisanal Breads: Sourdough, baguettes, and ciabatta get their signature open crumb and crunchy crust.

- Hearth-Baked Pizza: That stone deck creates the classic crisp-yet-chewy Neapolitan-style crust everyone loves.

While they demand a bit more skill to operate, the superior quality of the final product makes deck ovens the gold standard for any bakery that prizes craft and tradition. The results are truly second to none.

Rack Ovens: Vertical Batch Powerhouses

When you need to bake a diverse range of products in large quantities but are tight on floor space, the rack oven is your answer. These are vertical batch powerhouses. Instead of placing pans on individual shelves, you load an entire rolling rack filled with trays of product directly into the oven.

Once inside, the rack slowly rotates while fans blast hot air, ensuring every single item on every tray gets exposed to uniform heat. This design brilliantly maximizes vertical space and allows for huge, consistent batches. Their versatility is a major plus for businesses with varied menus, from breads and cakes to pastries and even meats. An industrial baking oven like this is a true workhorse.

Tunnel Ovens: Continuous Production Titans

For high-volume, single-product manufacturing, the tunnel oven is king. These are the titans of continuous production. Picture a long tunnel with a conveyor belt running straight through it. Raw products go in one end, travel through multiple, precisely controlled heating zones, and come out perfectly baked at the other.

This assembly-line method is built for massive scale and unbelievable consistency. A study in the Journal of Food Engineering even showed that advanced tunnel ovens can cut bake times by up to 20% without hurting quality. They are the backbone of industrial operations producing items like:

- Packaged cookies and crackers

- Snack cakes

- Industrial bread loaves

- Frozen pizza bases

Of course, a powerful oven needs an efficient workflow feeding it. Just as you match the oven to the product, you have to think about the prep stations that supply it. For a truly seamless process, having the right equipment, like a well-organized prep area, is crucial. This synergy between prep and baking is what creates a genuinely productive operation.

Essential Prep Stations for a Seamless Workflow

A powerful industrial oven is only one piece of the puzzle. An efficient bakery runs on the entire workflow that feeds it, and that journey starts long before anything hits the heat. This is where your prep stations, especially high-quality stainless steel tables, become the true backbone of a clean, organized, and productive kitchen.

An industrial baking oven can push out thousands of items an hour, but it’s useless if your prep line is lagging. Stainless steel work tables provide the durable, hygienic, and non-porous surface needed for food safety and quick wipedowns. The quality of these tables really matters. Heavy-duty tables are built to take a beating from daily commercial use, and their smooth surfaces stop bacteria from building up. Getting this prep stage right is what allows you to maintain the consistency that high-volume baking demands.

The Power of Specialized Prep Tables

While a basic flat-top table is a must-have, specialized prep tables can seriously boost your speed and efficiency. These units combine your workspace with features like refrigerated storage, putting everything an operator needs right at their fingertips. This simple change is a game-changer for reducing wasted movement, slashing prep time, and keeping ingredients safely chilled.

By bringing refrigerated storage right into the prep zone, specialized tables can slash assembly time by over 30% in busy kitchens. This creates a smooth, unbroken line from prep to bake, which is a huge deal for your bottom line.

There are many types of stainless steel prep tables, from simple workbenches to complex, feature-rich stations. For bakeries, a few key types stand out:

- Work Tables with Undershelves/Cabinets: These are the foundational pieces. A simple flat top provides the core workspace, while an open undershelf offers easily accessible storage for bulk ingredients or small equipment. Enclosed cabinets provide more protected, organized storage for tools and supplies.

- Sandwich Prep Tables: Following a logic perfect for delis and bakeries, these tables are set up for lightning-fast assembly. They usually have a cutting board running the length of the unit, sitting directly in front of refrigerated wells for sliced meats, cheeses, and vegetables. With refrigerated storage below, they are the perfect partner for the rapid-cook or convection ovens used to toast sandwiches.

- Pizza Prep Tables: Built specifically for pizzerias and bakeries making flatbreads, these tables are a masterclass in efficient design. They feature a wide, refrigerated rail along the back that holds pans of toppings like cheese, sauce, and veggies, keeping everything perfectly chilled but instantly accessible. The large work surface in front is ideal for stretching dough, and the refrigerated cabinets below hold backups. This entire setup is built to feed a high-temperature deck oven or a continuous conveyor pizza oven.

Choosing the right combination of prep tables ensures your team can keep pace with your industrial baking oven, creating a smooth, unbroken line from prep to bake.

Understanding Modern Oven Features and Technology

Today's industrial ovens have come a long way. They're no longer just simple hot boxes with a temperature dial. Modern ovens are intelligent, high-performance machines packed with features that give you incredible control over your bake.

Today's industrial ovens have come a long way. They're no longer just simple hot boxes with a temperature dial. Modern ovens are intelligent, high-performance machines packed with features that give you incredible control over your bake.

This technology essentially decodes the science behind a perfect product, making it something you can repeat, batch after batch. Getting a handle on these features is the first step to unlocking new levels of quality, consistency, and efficiency in your bakery. Think of these advancements as powerful tools in your baking arsenal—each one designed to solve a specific challenge, from nailing the perfect crust to ensuring every cookie in a massive batch is identical.

Core Features for Baking Perfection

At the heart of any great oven are the features that control heat and humidity with pinpoint accuracy. These are the fundamentals that directly shape the final look, taste, and texture of your baked goods. Master them, and you can elevate your baking from an art to a science.

Two of the most impactful features are steam injection and advanced airflow control.

-

Steam Injection: This is the secret weapon for a phenomenal crust. By shooting a controlled burst of steam into the oven at the start of the bake, it keeps the dough's surface moist. This allows for maximum "oven spring"—that rapid initial rise—which creates a light, airy inside and that signature crisp, golden-brown crust. It's an absolute must for artisanal breads like baguettes and sourdough.

-

Advanced Airflow Control: This is all about getting a perfectly even bake, every single time. Basic convection just moves air around, but advanced systems use variable-speed fans and cleverly designed baffles to eliminate hot spots. This means the temperature is uniform everywhere, so cookies on the bottom tray bake at the same rate as the ones on top. Consistency is king.

The Rise of Smart Ovens and IoT

The biggest shift we're seeing in baking technology is the jump to smart controls and the Internet of Things (IoT). Ovens aren't isolated pieces of equipment anymore; they're connected, data-driven assets that give you a deep look into your operation. This is completely changing how bakeries manage production, maintenance, and costs.

This trend is part of a bigger movement. The entire industrial ovens market, which includes baking models, was valued at USD 8.2 billion in 2024 and is expected to hit around USD 10.4 billion by 2030. A huge driver of this growth is technology like IoT and AI, which helps optimize energy and slash downtime.

A smart industrial baking oven isn't just about convenience; it's about control. By leveraging real-time data, bakeries can proactively manage their operations, catch issues before they cause downtime, and fine-tune their processes for maximum profitability.

Of course, a smart, efficient oven needs an equally efficient prep area to support it. As ovens get smarter, so does the surrounding equipment. The right stainless steel tables and stations are the foundation of any productive kitchen.

Key Benefits of Smart Technology

Putting smart features in your industrial oven offers more than just fancy controls. It delivers real-world advantages that can give your bakery a serious competitive edge.

Here’s how this tech makes a real difference:

-

Predictive Maintenance Alerts: Instead of finding out a part has failed when production grinds to a halt, IoT sensors monitor the oven's health constantly. The system can flag potential issues—like a motor running hot or a heating element wearing out—so you can schedule maintenance before it becomes a costly emergency.

-

Real-Time Energy Monitoring: Smart ovens track every bit of energy they use. This data helps you pinpoint peak usage, calculate the energy cost per batch, and make smart decisions to lower your utility bills without compromising on quality.

-

Automated Quality Control: The most advanced systems use AI-powered cameras and sensors to watch products as they bake. They can automatically tweak the temperature or humidity to correct any issues, ensuring every item meets your exact standards. This dramatically cuts down on waste from rejected batches.

How to Select the Right Industrial Baking Oven

Choosing a new industrial baking oven is a massive decision, one that will define your bakery's output and potential for years to come. Think of this as your practical buyer's guide—a walkthrough to help you land on a choice you can be confident in. The right oven isn't just about what you bake today; it’s about empowering your ambitions for tomorrow.

Getting this right starts with answering a few critical questions upfront. This process goes way beyond the price tag. You need to picture how this piece of equipment will fit into your daily grind, from production numbers and product types to its physical footprint and long-term running costs.

Calculating Your Production Capacity

First things first: you have to nail down your production capacity needs. Don't just think about your busiest day last year. Where do you want your business to be in three, or even five, years? Start by putting that goal into real numbers, like "loaves per hour" or "cookies per shift."

Once you have that target, you can work backward. How many racks or pans does that translate to? This single calculation will instantly help you decide between smaller batch ovens, like deck or convection models, and the serious high-volume power of a tunnel oven. If you aim too low, you'll choke your own growth. Aim too high, and you're just burning cash on unused capacity and energy.

Nailing the capacity question is the cornerstone of a smart purchase. It ensures the industrial baking oven you choose becomes a powerful engine for growth, not a bottleneck holding you back.

Matching the Oven to Your Products

Next up, you have to match the oven's technology to what you actually bake. As we've already seen, different ovens have their own unique talents. If your reputation is built on artisanal bread with that perfect, crackly crust, the intense radiant heat of a deck oven is your only real choice. But if you’re churning out thousands of identical cookies, the consistent airflow from a convection or tunnel oven is what you need for uniformity.

Ask yourself these questions:

- Do my products need steam? For many breads, steam is absolutely essential for developing a great crust.

- How precise do temperatures need to be? Delicate pastries and cakes can't handle temperature swings. They need an oven that holds its heat steady.

- Do I bake a wide variety of items? If your menu is constantly changing, a flexible rack oven might serve you better than a highly specialized tunnel oven built for one thing.

Assessing Space and Energy Sources

Let's be realistic: an industrial oven is a beast. Before you get your heart set on a particular model, pull out the tape measure. You need to account for the oven itself, plus clearance for ventilation, maintenance access, and the flow of people and products around it. How will your team load and unload it? Where will the cooling racks go? A poorly placed oven can cause logistical nightmares.

You also have to think about your energy source. Gas and electric ovens both have their pros and cons.

- Gas Ovens generally have lower utility costs and heat up faster. But, you'll need proper gas lines and a serious ventilation system.

- Electric Ovens tend to offer more precise temperature control and a more even bake, though they can be more expensive to run depending on your local electricity rates.

Look beyond the initial price and calculate the total cost of ownership, factoring in installation, energy bills, and maintenance over the oven's entire life.

Future-Proofing Your Purchase

Finally, look down the road. The global market for industrial ovens, including baking models, is set to grow significantly, projected to hit USD 18.7 billion by 2034. This growth is all about the endless push for better productivity and smarter tech. You can dig deeper into these trends by reading about the industrial oven market's future outlook.

When you're making your choice, think about features that will let you adapt. Does the oven have programmable controls that make it easy to add new recipes? Could you add smart features like remote monitoring later on? Spending a little more now on a flexible, capable oven could save you from having to make another huge investment in just a few years when your business grows.

Installation Care and Safety Essentials

An industrial oven is a serious investment, and like any high-value asset, protecting it is vital for your bakery’s success. Great care starts the moment it arrives at your door and extends through every single bake, ensuring your equipment lasts and your team stays safe. It all comes down to careful installation, routine upkeep, and solid training.

An industrial oven is a serious investment, and like any high-value asset, protecting it is vital for your bakery’s success. Great care starts the moment it arrives at your door and extends through every single bake, ensuring your equipment lasts and your team stays safe. It all comes down to careful installation, routine upkeep, and solid training.

The first step is a professional installation that meets all your local building and safety codes. Let's be clear: this is not a DIY project. It requires meticulous planning for utility connections—gas or electric—and making sure your power supply can actually handle the load. Just as important is the ventilation system, which needs to be robust enough to manage the heat and emissions from your specific industrial baking oven.

Maximizing Lifespan with Routine Maintenance

Once your oven is installed and running, a consistent maintenance schedule is your best defense against costly downtime and repairs. The secret is to turn upkeep into a manageable habit, not an overwhelming chore. A simple checklist with daily, weekly, and monthly tasks helps you catch small issues before they snowball into major failures.

Here’s a practical maintenance guide you can start using today:

-

Daily Tasks: At the end of every shift, give the oven's interior and exterior a thorough cleaning. Get rid of any food debris, grease, or carbon buildup. A clean oven works better, but more importantly, it's essential for food safety and preventing fire hazards.

-

Weekly Checks: Take a close look at the door seals and gaskets for any wear, cracks, or gaps. A bad seal lets heat escape, forcing the oven to work overtime, which wastes energy and leads to inconsistent bakes. Now is also a good time to check and clean any filters to keep air flowing properly.

-

Monthly Inspections: Perform a deeper dive into the mechanical and electrical components. Make sure all moving parts, like rack rotation systems or conveyor belts, are operating smoothly. Listen for any strange noises—they’re often the first sign of a problem brewing.

Operator Training and Safety Protocols

Even the best-maintained oven can be a hazard if your operators aren't properly trained. Comprehensive training isn’t just about showing someone the on/off switch; it’s about creating a true culture of safety. Every single person who interacts with that oven needs to understand its unique operating procedures and safety features inside and out.

Establishing clear, written safety protocols is non-negotiable. This should cover everything from the right way to load and unload to avoid burns, to an emergency shutdown plan that everyone on the floor can execute in a split second.

Proper training must include:

- Correct Loading Procedures: Knowing the oven’s capacity and how to load racks or pans to guarantee even airflow and prevent anything from tipping over.

- Personal Protective Equipment (PPE): Making sure everyone wears heat-resistant gloves and other required safety gear without exception.

- Emergency Shutdown Plan: Ensuring every operator knows exactly where the emergency stop button is and what to do in case of a fire or malfunction.

By combining a professional installation with diligent maintenance and thorough training, you're doing more than just protecting a machine. You're safeguarding your team and your investment, ensuring your industrial oven remains the productive heart of your bakery for years to come.

Frequently Asked Questions About Industrial Ovens

When you're dealing with high-capacity ovens, a lot of practical questions pop up. It doesn't matter if you're thinking about buying one or you've just become a new owner—getting clear, simple answers is key to feeling confident in your decisions. We've gathered some of the most common questions we hear about industrial baking ovens right here.

What Is the Difference Between a Commercial and an Industrial Oven?

While you might hear people use these terms interchangeably, the real difference comes down to scale and what you're using it for. Think of a commercial oven as the workhorse in a restaurant, local cafe, or a small retail bakery. It’s built to be used all day, but for smaller, individual batches.

An industrial oven, however, is in a completely different league. It's built for massive operations—think manufacturing plants and large-scale food production. These machines are designed for continuous, high-volume baking and are often just one piece of a larger automated production line. The main things that set them apart are their huge production capacity, level of automation, and sheer physical size.

How Do I Calculate an Oven's Energy Consumption?

Figuring out an oven's energy use is crucial for understanding its true cost over time. The math involves its power rating—measured in kilowatts (kW) for electric models or BTUs for gas—how well it's insulated, and, of course, how you use it day-to-day.

For a quick ballpark estimate, you can use this simple formula:

Oven's Power Rating (kW or BTU) x Operational Hours x Local Energy Rate = Estimated Cost

But remember, this is just a starting point. Modern ovens with top-notch insulation, smart controls, and energy-saving designs can drastically cut your consumption, which adds up to some serious long-term savings.

Can I Bake Different Products in the Same Industrial Oven?

This really depends on the kind of industrial baking oven you have. Some are designed to be incredibly versatile, while others are specialists, built to do one thing perfectly.

- Flexible Ovens: Rack ovens and deck ovens are fantastic for baking a wide variety of products. You can easily tweak the temperature, time, and steam for every new batch, making them perfect for bakeries that have a diverse and changing menu.

- Specialized Ovens: On the flip side, a continuous tunnel oven is designed to produce one specific item at a perfectly consistent speed and temperature. It’s a master of high-volume, uniform production but doesn't offer the flexibility needed for a varied product lineup.

For a kitchen that runs on efficiency, the right equipment is everything. At PrepTables.com, we provide the durable stainless steel work tables, specialized prep stations, and commercial equipment that form the backbone of any successful food operation. Find the perfect foundation for your workflow at https://preptables.com.