Top Commercial Kitchen Storage Solutions for Efficiency

Share

Picture a kitchen humming with quiet efficiency, where every pan, utensil, and ingredient is exactly where it needs to be, right when the chef reaches for it. Now, imagine the flip side: a frantic, cluttered space where every ticket sends the team scrambling. That chaos isn't just stressful—it costs you time and money.

The difference between these two scenes isn't luck. It's smart, strategic storage.

Building a Kitchen That Works for You

This guide is about more than just finding a place to put things. We're going to break down how the right commercial kitchen storage solutions become the literal backbone of your operation. Good storage directly impacts your speed, your team's safety, and, ultimately, your bottom line. Think of this as your roadmap, covering everything from picking the right materials to designing a layout that creates a smooth, logical flow for your entire culinary team.

A truly great kitchen isn't just a collection of equipment; it's a carefully choreographed dance. Every element has its place and purpose. The real goal is to cut out wasted steps, reduce the physical strain on your staff, and build a space where speed and creativity can thrive together, even during the craziest dinner rush.

Setting the Stage for Success

Before you start picking out shelves and racks, you need to think about the foundation. For instance, a well-lit kitchen is a safe kitchen. When you're planning your space, don't forget the importance of selecting proper commercial lighting fixtures. If your chefs can't see what they're doing clearly, the risk of accidents goes way up. Good lighting and smart storage go hand-in-hand to create a workspace that's both safe and efficient.

With that foundation in place, you can start mapping out the kitchen's flow. Ask yourself these key questions as you develop your storage plan:

- Workflow Logic: How does an ingredient get from the delivery truck to the walk-in, over to a prep station, and then onto the line? Your storage should follow that path, not fight against it.

- Space Optimization: Every single square foot in your kitchen is prime real estate. Smart storage makes the most of your vertical space, getting clutter off your valuable work surfaces.

- Accessibility and Ergonomics: Are your most-used items within easy reach? Forcing your staff to constantly bend, stretch, or walk across the kitchen for basic tools is a recipe for fatigue and burnout.

A well-designed kitchen with strategic storage isn't an expense; it's an investment in the long-term health of your business. It helps you cut down on food waste by making stock rotation easier and eliminates the small daily frustrations that lead to big mistakes and staff turnover.

Why Material Choice Is Your First Big Decision

Before you even start sketching out a layout or browsing equipment, the first real choice you have to make for any commercial kitchen storage solution is the material. It’s like picking the right foundation for a house; everything else depends on it. In the high-stakes, fast-moving world of a professional kitchen, this isn't about what looks good—it’s about what performs and what lasts.

In this arena, stainless steel is the undisputed king. Its surface is non-porous, making it a fortress against bacteria, moisture, and the harsh reality of cleaning chemicals and acidic foods. Unlike wood, which can soak up germs, or some plastics that can hold onto odors, stainless steel gives you a clean slate every time. It’s the gold standard for a reason.

This industry-wide obsession with sanitary, tough materials is no surprise. The global market for food storage containers alone is expected to swell to around USD 265.3 billion by 2035. That massive number tells a story about the demand for hygienic, stackable, and solid solutions that meet food safety rules and cut down on spoilage. As Future Market Insights explains, it all starts with the surfaces our food touches.

Decoding Stainless Steel Grades

Now, not all stainless steel is the same. The "grade" tells you what it’s made of and, more importantly, how it’s going to hold up. Getting familiar with the two most common grades will help you invest your money wisely.

-

304 Stainless Steel: This is your top-tier workhorse. It’s packed with more chromium and nickel, which gives it incredible resistance to rust and corrosion. If a surface is going to have direct contact with food or get hit with a lot of moisture—think prep tables, sinks, or the shelving in your walk-in—this is the grade you want.

-

430 Stainless Steel: This is the more budget-conscious pick. It’s still strong, but with less nickel, it's a bit more vulnerable to corrosion over time, especially when dealing with salt or certain acids. It’s a perfectly good choice for equipment legs, undershelves, or storage in dry areas where it won't be touching food directly.

So, what's the right call? It’s a classic trade-off. The 304 steel costs more upfront, but its durability means it will likely outlast the cheaper alternative, saving you on replacement costs down the road. For most high-traffic kitchens, it’s the smarter long-term value.

A Look at Other Essential Materials

While stainless steel gets most of the glory, it doesn’t work alone. A truly functional kitchen uses a smart mix of materials, each picked for a specific job.

Specialized Plastics

High-density plastics like polyethylene and polycarbonate are the unsung heroes of the kitchen. They’re lightweight, tough as nails, and often come color-coded to make your food safety system foolproof (red for raw meat, green for veggies, you know the drill).

Think of those rolling ingredient bins, the cutting boards that take a beating every day, or the clear containers that let you see exactly what you have. These plastic tools offer a level of visibility and easy movement that stainless steel just can't, making them critical for keeping ingredients organized and preventing cross-contamination.

Wood in Modern Kitchens

Wood’s role in today's commercial kitchen is much more specific. Sure, a classic butcher block looks great and is gentler on your knives, but its porous nature makes it a real headache for sanitation. Because of that, you’ll usually only see wood used for specific tasks, like a baker's table for working dough, or as a design choice in front-of-house areas. If you do use it, it needs to be perfectly sealed and obsessively maintained to keep the health inspector happy.

Ultimately, putting together a great storage system is like building a team. You need stainless steel as your strong, reliable anchor, with specialized plastics providing the nimble, targeted support. When you understand what each material does best, you can build a kitchen that’s not just efficient, but fundamentally safe.

Your Guide to Essential Storage Equipment

Once you've nailed down the right materials, it's time to build out your kitchen's storage arsenal, piece by piece. Think of this as your essential checklist for the commercial kitchen storage solutions that really form the backbone of any professional culinary space. Each piece has a specific job, and when they all work together, they create an operation that just flows.

Getting this system right is more important than ever. The global market for kitchen storage and organization is expected to hit about USD 18.56 billion by 2033. This surge shows just how much kitchens of all sizes are focusing on smarter space management to boost their efficiency. You can dive deeper into these kitchen storage market insights from Verified Market Reports.

Foundational Shelving Systems

Shelving is the most basic storage you'll buy, acting as the skeleton for your kitchen's entire organizational setup. But not all shelves are the same; the right type is all about where it’s going and what it’s holding.

- Wire Shelving: This is your go-to for walk-in coolers and freezers. The open-wire construction allows air to circulate freely, which is absolutely vital for keeping temperatures even and food fresh. It also helps prevent moisture from pooling and makes spotting spills a breeze.

- Solid Shelving: Better suited for dry storage areas, solid shelves are perfect for protecting sensitive goods from dust and any potential drips from above. They’re the ideal choice for storing big bags of flour or sugar, keeping them secure and safe from contamination.

Choosing the right kind of shelving is the first real step in building an organized kitchen. For a much more detailed breakdown, take a look at our guide on selecting the best commercial kitchen shelves for your unique setup.

Dunnage Racks: The Unsung Heroes

Next up are dunnage racks. These are basically low-to-the-ground, heavy-duty platforms. Their job is simple but critical: keep your bulk inventory safely off the floor. This isn't just about being tidy; it's a strict health code rule you can't afford to ignore.

Dunnage racks are your first line of defense against pests, moisture damage, and contamination. Placing heavy bags of rice, boxes of produce, or large containers directly on the floor is a major health violation and puts your inventory at risk.

These racks are built tough, designed to handle immense weight. That makes them perfect for your heaviest and bulkiest items, ensuring even your biggest deliveries are stored in a way that’s safe, compliant, and easy to get to.

Specialized and Mobile Solutions

Beyond the basics, you'll find specialized storage units that can reclaim otherwise wasted space and make a huge difference in your kitchen's workflow. These pieces are designed to solve very specific organizational headaches that pop up in almost every commercial kitchen.

Wall-Mounted Shelves

When you’re out of floor space, look up. Wall-mounted shelves are fantastic for turning empty walls into valuable real estate. They’re perfect for keeping frequently used spices, small appliances, or clean dishes right where you need them, saving precious time and cutting down on prep station clutter.

Mobile Ingredient Bins

If your kitchen plows through large amounts of bulk ingredients like flour, sugar, or grains, mobile ingredient bins are a game-changer. These rolling containers let your team move heavy ingredients from dry storage to the prep or baking station without any back-breaking lifting. Most have clear lids, too, so you can see what's inside and check inventory with just a glance.

By cleverly combining these essential pieces—sturdy shelving, tough dunnage racks, and smart specialized units—you create a cohesive system. This integrated approach is what keeps your kitchen organized, compliant, and ready to handle the pressure of any service.

Finding the Perfect Stainless Steel Prep Table

The prep table is the undisputed command center of your kitchen—it's the stage where every dish begins. Since it's the heart of your workflow, picking the right one is one of the most impactful choices you'll make for your daily operations. A versatile stainless steel work table can be a simple work surface or a complex, refrigerated station designed for a specific task. Understanding the different types available is key.

At its core, a standard stainless steel prep table is a durable work surface. But the design of its base and features can dramatically change its function within your commercial kitchen storage solutions.

- Open Base Tables: These tables feature an undershelf, keeping essential tools, containers, and small appliances visible and instantly accessible. They create an open, airy feel and make it easy to grab what you need without fussing with a door.

- Enclosed Base Cabinets: Offering a sleeker, more contained look, tables with enclosed cabinets hide the clutter behind stainless steel doors. This design is perfect for storing items you want to protect from dust or splashes, creating a more organized, clean appearance.

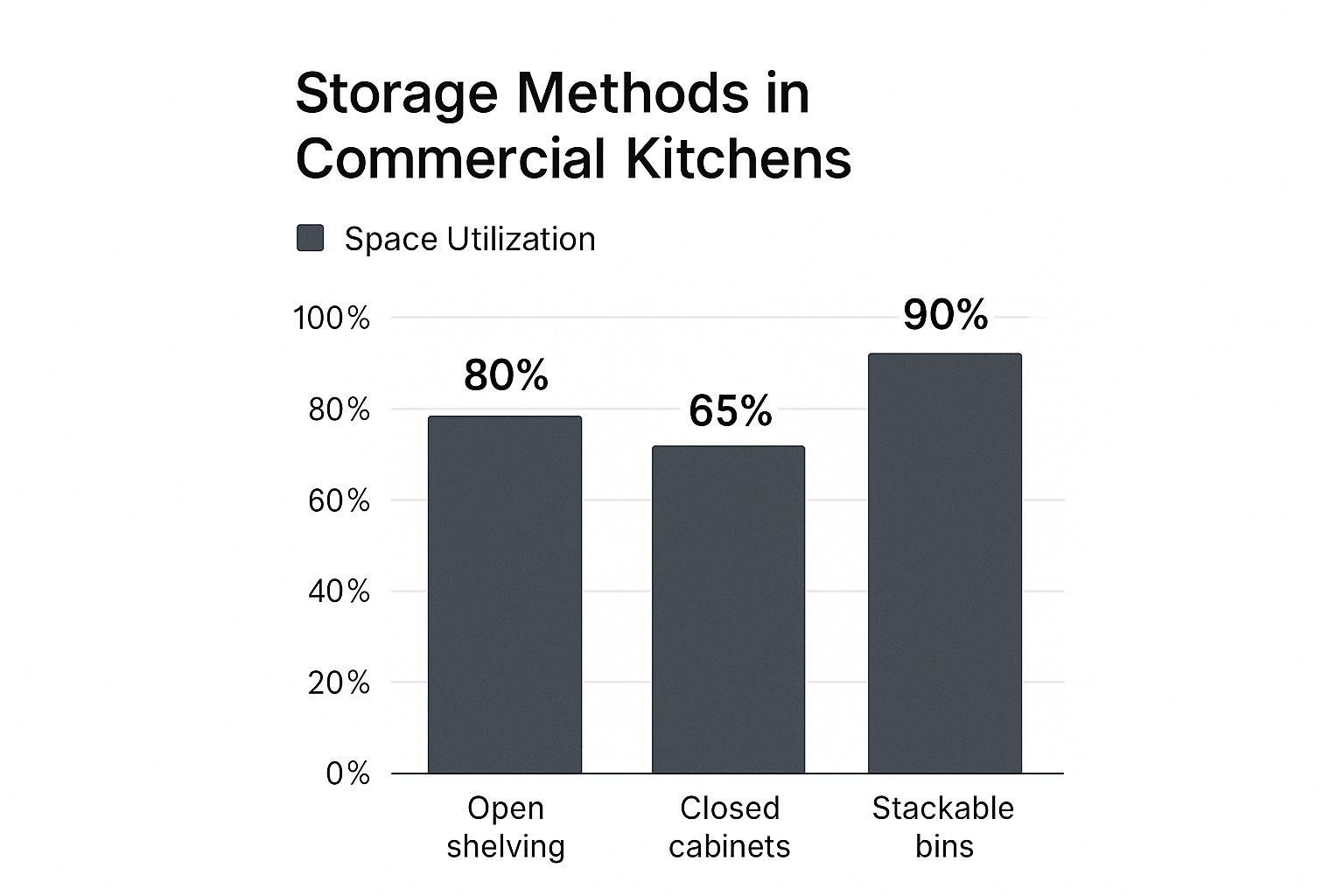

The chart below shows how different storage styles, like open shelving versus closed cabinets, can impact how well you use your kitchen space.

This highlights how stackable systems can max out your density, while open shelving offers a great balance of accessibility and capacity. The choice usually comes down to whether you need immediate access or prefer long-term organization. For a deeper dive, our complete guide on selecting a stainless steel work table has all the details.

Standard Prep Tables: The Versatile Foundation

Think of the standard stainless steel work table as a blank canvas. It's the most adaptable piece of equipment you can buy, ready to serve as a chopping station, a plating area, or a stand for heavy equipment like mixers and slicers. Its versatility is its greatest strength.

These tables are all about simplicity and raw durability. The key is to match the table's construction—especially the gauge of the steel and its load capacity—to the jobs you have in mind. A table used for light assembly doesn't need the same muscle as one holding a 100-pound dough mixer.

The most effective kitchens assign a clear purpose to each prep table. One might be dedicated solely to raw protein preparation to avoid cross-contamination, while another is designated for pastry work. This "zoning" strategy, built around your tables, is fundamental to a safe and efficient kitchen layout.

By setting up these dedicated workstations, you create a logical flow that cuts down on wasted steps and keeps your team moving smoothly, even during the most hectic service.

Specialized Prep Tables: Built for Purpose

While standard tables offer flexibility, some kitchens need equipment designed for specific, high-volume tasks. That’s where specialized prep tables come in. These units merge workspace with cold storage, creating an all-in-one station that dramatically boosts efficiency. Let's look at two popular types.

Sandwich Prep Tables: Engineered for Speed

Designed to streamline the making of salads, sandwiches, and wraps, these tables are a must for delis and cafes. They feature a refrigerated base for storing bulk ingredients, while the top is fitted with chilled wells for holding food pans full of toppings. This integrated design keeps every necessary ingredient—from sliced meats and cheeses to fresh veggies—perfectly chilled and within arm's reach. A built-in cutting board runs along the front, creating a dedicated assembly line that drastically cuts down on ticket times during a busy lunch rush.

Pizza Prep Tables: The Ultimate Assembly Line

Much like their sandwich-focused cousins, pizza prep tables are designed for one thing: making pizza assembly as fast and seamless as possible. They adapt the concept of integrated cold storage for the specific needs of a pizzeria. A key feature is the raised, refrigerated rail that holds food pans at a slight angle, making it easy to access sauces, cheeses, and toppings. The main work surface is usually deeper to provide plenty of room for stretching dough. For any high-volume pizzeria, this specialized table isn't a luxury; it's an essential tool for keeping up speed and consistency.

Designing a Smarter Kitchen Layout

Having the right equipment is only half the battle. How you place everything is what really dictates your kitchen's rhythm and flow. Let's get into the practical design principles that create a safer, more efficient space for your team.

Think of a well-designed layout for your commercial kitchen storage solutions like a perfectly written recipe—every step is logical, purposeful, and leads to a successful outcome. The first step is to stop seeing your kitchen as one big room and start thinking of it as a series of connected zones.

This push toward highly organized, space-efficient kitchens isn't just a trend; it's a massive industry shift. The worldwide kitchen storage organization market is projected to hit as high as USD 45 billion by 2033.

This growth is being fueled by a real need for smarter, space-saving systems that work well without sacrificing style, especially as kitchens get smaller. You can dig into the specifics of these market dynamics from Strategic Revenue Insights.

The Five Essential Kitchen Zones

A smart layout guides your staff and ingredients along a logical path, from raw materials to a finished dish. This simple idea drastically cuts down on wasted steps and, maybe more importantly, slashes the risk of cross-contamination.

Let’s break down the five core zones every kitchen needs.

-

Receiving Zone: This is your kitchen's front door for all deliveries. It needs to be near an entrance and should have scales and a solid table for checking incoming goods.

-

Storage Zone: Right next to receiving, this area houses your dry storage, walk-in coolers, and freezers. The whole point is to get deliveries put away quickly and efficiently.

-

Prep Zone: This is where raw ingredients get washed, chopped, and portioned out. It absolutely needs to be close to your storage zones to keep your prep cooks from running laps all day.

-

Cooking Zone: The hot line. This is the heart of the action, home to your ranges, fryers, and grills. It should be positioned centrally for a smooth hand-off to servers.

-

Sanitation Zone: This area holds your dishwashing station and trash bins. You’ll want to keep it separate from the prep and cooking zones to prevent dirty dishes from getting anywhere near fresh food.

When you arrange your storage and workstations to support this flow, you create a kitchen that moves like a well-oiled machine.

Ergonomics and the FIFO System

Beyond the big-picture layout, the small details of how you organize within each zone can make a huge difference to your team’s well-being and your bottom line. This is where ergonomics and smart inventory management really shine.

An ergonomic layout is a safer layout. When staff members aren't constantly bending, reaching, or straining to get what they need, they experience less fatigue and are far less likely to suffer injuries. This simple consideration boosts morale and reduces costly workers' compensation claims.

It's a simple fix: place your most frequently used items at waist height, somewhere between the shoulder and knee, to minimize physical strain. Always store heavy or bulky items on lower shelves, never overhead.

Implementing a First-In, First-Out (FIFO) system is just as crucial for food safety and cutting down on waste. This basic principle ensures that older stock gets used before new stock arrives, which is key to minimizing spoilage.

- Label Everything Clearly: All incoming products should get marked with the delivery date and a "use-by" date. No exceptions.

- Organize Shelves Logically: Place new items at the back of the shelf, pushing older items forward. This makes it almost automatic for staff to grab the right product.

- Regular Audits: Do a quick check of your inventory on a regular basis to make sure the FIFO system is being followed and to pull any expired products.

These strategies—from zoning and ergonomics to FIFO—do more than just tidy up your space. They fundamentally transform your kitchen into a high-performance environment where safety and efficiency are baked right into the workflow.

Maintaining Your Equipment for Longevity

Dropping a big chunk of change on high-quality commercial kitchen storage solutions is a great start, but it's only half the battle. If you want that investment to actually last, you have to commit to taking care of it. Proper, consistent maintenance isn't just about extending the life of your gear; it's absolutely critical for food safety and acing those health inspections.

A simple, disciplined approach to cleaning and organization is your best friend here. It pays off in spades, both in equipment longevity and in keeping the health inspector happy.

The bedrock of good equipment care is a non-negotiable daily cleaning schedule. For all those stainless steel surfaces, that means daily wipe-downs to stop grime and food gunk from setting up shop. Most of the time, a little mild soap and warm water with a soft cloth is all you need for the day-to-day stuff.

After washing, always—and I mean always—rinse the surfaces with clean water and dry them completely. This tiny step is what prevents those annoying water spots and can even head off corrosion down the line. It's the secret to keeping your stainless steel looking brand new.

A Simple Guide to Stainless Steel Care

Even if you're on top of daily cleaning, stainless steel can sometimes get tough stains or just start to look a little dull. Using the right technique will bring it back to life and make sure it stays a hygienic surface for all your prep work.

- Clean with the Grain: Look closely at your stainless steel and you'll see faint lines. Always wipe and scrub in the same direction as these grain lines. This helps lift dirt out more effectively and, crucially, prevents scratching.

- Use Non-Abrasive Tools: Step away from the steel wool and harsh scrubbers. They'll do more harm than good. Stick to soft cloths, sponges, or maybe a nylon scrubbing pad for tougher spots.

- Tackle Tough Stains: Got a stubborn spot that won't budge? A simple paste made from baking soda and water, applied gently, often does the trick. For the really persistent stuff, a specialized stainless steel cleaner is your best bet.

Beyond just scrubbing, think about the water you're using. Hard water can be a silent killer for kitchen equipment. Investing in high-quality industrial and commercial water softeners can be a game-changer, preventing that chalky mineral buildup that causes scaling and damages your gear over the long haul.

Organizing Walk-In Coolers and Freezers

Getting your cold storage organized isn't just about being tidy—it's a non-negotiable for preventing cross-contamination and slashing food waste. This is where the First-In, First-Out (FIFO) method becomes your mantra.

A disorganized walk-in is more than just inefficient—it's a direct threat to food safety. Implementing a clear storage hierarchy ensures that ready-to-eat foods are never stored below raw meats, preventing dangerous drips and contamination.

Follow this top-to-bottom storage order religiously:

- Top Shelves: Ready-to-eat foods (like prepared salads, dressings, and cooked dishes).

- Middle Shelves: Seafood, whole cuts of beef, and pork.

- Bottom Shelves: Ground meats and raw poultry.

This simple, structured approach, combined with clear date labels on everything, brings it all together. Smartly investing in quality storage and then diligently taking care of it isn't just an expense—it's a direct investment in your kitchen's efficiency, your business's reputation, and your overall success. For a deeper dive, check out our complete guide to commercial kitchen equipment maintenance.

Frequently Asked Questions

When outfitting a commercial kitchen, storage is one of those things that seems simple until you start digging in. Questions pop up fast. What material is best? What do the health codes say? Getting these details right from the start is the key to a smooth, efficient, and compliant operation. Let’s tackle some of the most common questions we hear.

Getting your storage strategy locked in early prevents costly headaches and keeps your kitchen humming from day one.

What Is the Best Material for Kitchen Shelving?

For most jobs in a professional kitchen, stainless steel is the undisputed champion. Its surface is non-porous, which means it won't harbor bacteria, and it stands up to rust and corrosion. This makes it a no-brainer for walk-in coolers and any prep area with high moisture. It's truly the industry standard for a reason.

If you're setting up a dry storage area, you can look at chrome-plated or epoxy-coated wire shelving. They're strong, cost-effective, and provide great air circulation, but they just don't have the same resistance to moisture as stainless steel.

How High Off the Floor Should Storage Be?

This one is non-negotiable: all food and equipment must be stored at least six inches off the floor. This is one of the very first things a health inspector will look for, and it's a critical food safety rule.

The best way to stay compliant is by using dunnage racks for your heavy, bulky items like flour bags or cases of cans. For standard shelving, make sure the units have adjustable legs that you can set to the proper height. This simple step keeps everything safe from pests, dirt, and stray mop water.

What Is the FIFO Method and Why Is It Important?

FIFO is an acronym that stands for "First-In, First-Out." It's a simple but powerful system for managing your inventory. The idea is to organize your stock so the older products get used before the newer ones. You do this by moving older items to the front of the shelf and stocking new deliveries behind them.

A strict FIFO system is the single most effective tool you have to cut down on food spoilage and waste. It guarantees you're using ingredients when they're at their best, which protects both your bottom line and your customers' experience.

How Do I Prevent Cross-Contamination in My Walk-In?

Smart organization is your best line of defense here. The golden rule is to always store food in a specific top-to-bottom order. This prevents juices from raw meats from dripping down onto foods that are ready to eat.

Here’s the breakdown:

- Top Shelf: Ready-to-eat and cooked foods.

- Middle Shelves: Seafood and whole cuts of meat (like steak or roasts).

- Bottom Shelf: Ground meat and raw poultry (chicken, turkey).

This storage hierarchy is a cornerstone of food safety. It creates a clear separation between different types of food, drastically reducing the risk of foodborne illness. Pair this method with clear date labels and a consistent cleaning schedule, and you'll have a safe, organized walk-in.

Ready to build a kitchen that combines durability with unmatched efficiency? At PrepTables.com, we offer a wide range of NSF-certified stainless steel tables, shelving, and specialized equipment designed for the demands of a professional kitchen. Explore our collection and find the perfect solutions to organize your space for success at https://preptables.com.