Choosing Your 44 Inch Pizza Prep Table

Share

Picture the scene: it’s your kitchen’s busiest hour, the ticket machine is humming, and hungry customers are waiting. In this controlled chaos, a 44-inch pizza prep table isn't just a piece of equipment; it's the command center that keeps the entire operation flowing smoothly. This size is a real sweet spot for countless pizzerias, striking the perfect balance between a generous workspace and smart, compact refrigerated storage.

Why a 44 Inch Pizza Prep Table Is Your Kitchen's MVP

Think of this table as your master chef's personal station, where every single thing they need is right at their fingertips. It’s what transforms pizza making from a frantic scramble into a streamlined, almost artistic, process. A well-chosen unit genuinely elevates your kitchen's entire operational rhythm.

This isn't just about having a place to roll out dough. It's an investment in pure efficiency. The right table cuts down on wasted steps, keeps your staff from running back and forth, and holds every critical ingredient perfectly chilled and ready to go.

The Heartbeat of Pizzeria Operations

For most small to medium-sized kitchens, a 44-inch prep table has the ideal footprint. It’s big enough to let your crew handle multiple large pizza doughs without bumping elbows, but it's still compact enough to slot into tighter kitchen layouts. The whole setup—from the refrigerated base to the raised pan rail—is built from the ground up for making pizza.

The real magic of a dedicated pizza prep table is how it enforces consistency. When every topping is in the same spot, every single time, and the dough is always at the perfect temperature, your order accuracy and speed will skyrocket.

This focus on specialized gear isn't just a niche trend; it's a direct response to a massive industry. The market for pizza prep tables was pegged at around USD 1.75 billion in 2024 and is expected to hit USD 4.92 billion by 2033. What's driving that? The simple fact that over 93% of Americans eat pizza at least once a month, creating a huge demand for kitchens that can keep up. You can dig into more data on the pizza prep table market to see just how fast it's growing.

Balancing Space and Functionality

So, why is the 44-inch size so popular? It all comes down to a perfect compromise. You get a deep cutting board—typically 16 to 19 inches—which gives you far more room to stretch and top dough than a standard sandwich prep table ever could.

At the same time, the refrigerated pan rail holds all your topping pans, letting you offer a diverse menu without worrying about cross-contamination. This single piece of equipment ensures that from the moment you grab the dough to the second it slides into the oven, every step is optimized. It’s a true cornerstone of operational excellence for any serious pizzeria.

What Kind of Prep Table Do I Actually Need?

When you hear "prep table," you might just picture a basic stainless steel countertop. But in the real world of a busy kitchen, these units are highly specialized pieces of equipment, each built for a specific job. Picking the wrong one is like trying to dice an onion with a butter knife—you might get it done eventually, but it's going to be slow, messy, and frustrating. Getting a handle on the different types of stainless steel prep tables available is the first step to making a smart buy.

The most basic option is the standard stainless steel work table. It's the kitchen's jack-of-all-trades, a sturdy, hygienic surface for everything from weighing ingredients to plating finished dishes. They're strong and easy to clean, but they don't have the built-in refrigeration you need for a fast-paced assembly line.

Once you step into refrigerated units, you're looking at two main contenders: sandwich/salad prep tables and their bigger, tougher cousins, the pizza prep tables. They might look similar at first glance, but their designs are worlds apart.

To make this easier, let's break down the key differences between the two most common refrigerated prep tables.

Pizza Prep Table vs Sandwich Prep Table At a Glance

| Feature | Pizza Prep Table | Sandwich/Salad Prep Table |

|---|---|---|

| Primary Use | Assembling pizzas with heavy dough and bulky toppings | Building sandwiches, subs, and tossing salads |

| Cutting Board Depth | Extra-deep (16-19 inches or more) | Standard depth (8-12 inches) |

| Pan Rail Design | Raised and set back from the board | Flush with or slightly below the work surface |

| Ingredient Focus | Large quantities of cheese, sauce, and varied toppings | Sliced meats, cheeses, and fresh vegetables |

| Best For | Pizzerias, high-volume Italian restaurants | Delis, cafes, sandwich shops, salad bars |

As you can see, the choice isn't just about size—it's about designing a workflow that matches your menu.

The Specialist: Sandwich and Salad Prep Tables

A sandwich or salad prep table is all about speed and efficiency for smaller, lighter ingredients. Their cutting boards are typically on the shallower side, usually 8 to 12 inches deep. This is more than enough room for lining up bread, layering on cold cuts, or mixing a salad without having a massive, unused workspace.

The refrigerated pan rail is also built differently. Here, the pans sit either flush with or just below the countertop. This is a deliberate design choice. It keeps things like deli meat, sliced tomatoes, and cheese perfectly chilled but right at your fingertips for quick assembly. They are the undisputed champions for delis, cafes, and any spot focused on great sandwiches, subs, or fresh salads.

The Powerhouse: Pizza Prep Tables

This brings us to the star of the show: the 44-inch pizza prep table. A pizza station isn't just a bigger sandwich table; it's engineered from the ground up to handle large, heavy dough and a mountain of toppings. Its most important feature is that extra-deep cutting board, which often measures 16 to 19 inches deep—sometimes even more. This generous real estate is absolutely critical for stretching out a pizza base without running out of room.

Another major difference is the raised pan rail. On a pizza table, the ingredient pans are elevated and set back from the cutting board. This creates a clever barrier that stops loose toppings—like shredded mozzarella or diced peppers—from accidentally falling onto your dough. This raised design is also crucial for keeping cold air circulating effectively around the pans, a must-have for food safety when you're going through toppings at a rapid pace.

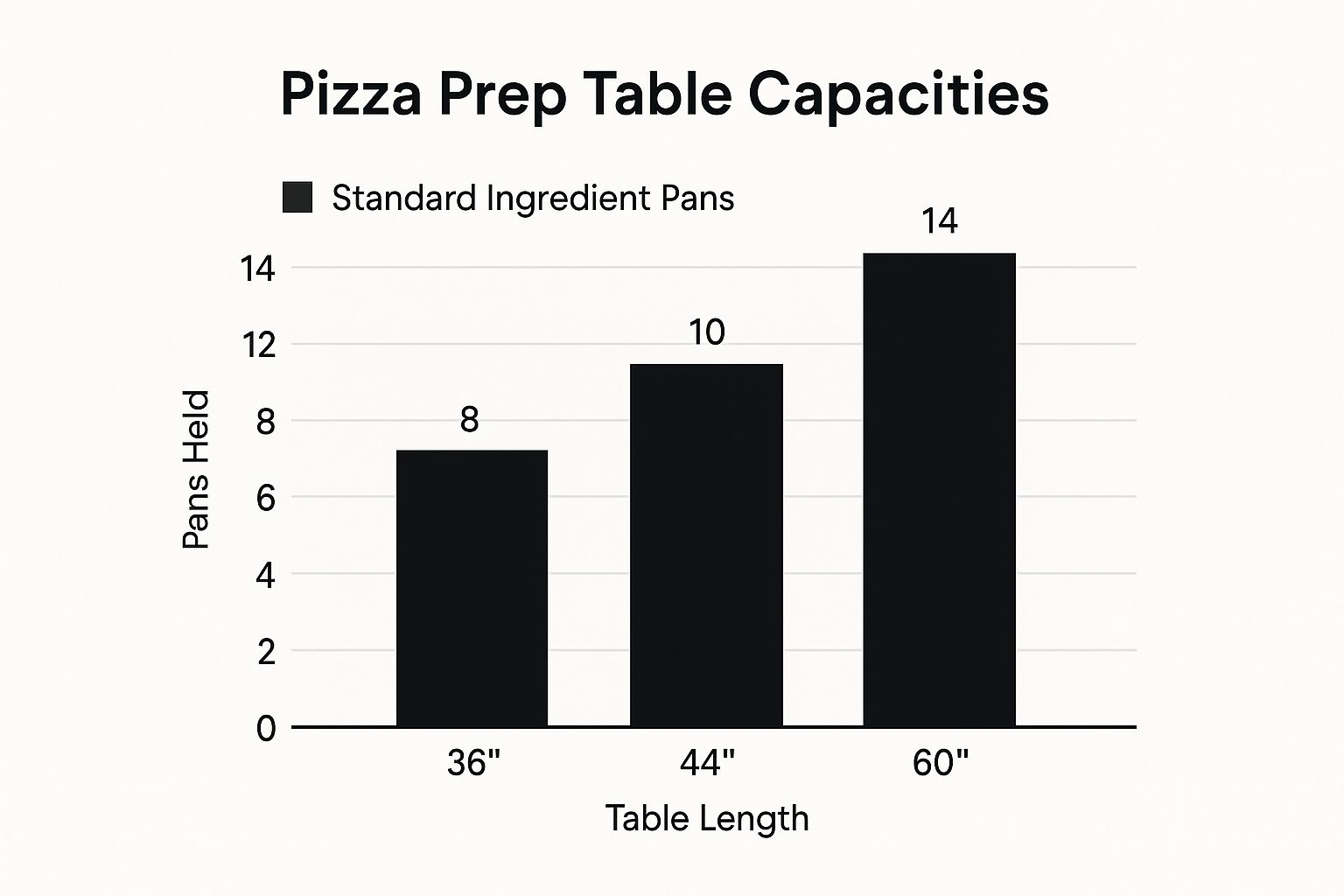

A 44-inch pizza prep table, as shown in the chart, hits a sweet spot. It gives you a huge boost in topping capacity over smaller models but doesn't take up the massive footprint of a 60-inch or 90-inch unit, making it a perfect fit for many pizzerias.

If you want to dig even deeper, be sure to check out our comprehensive buying guide on prep tables. It breaks down even more details to help you feel confident in your decision.

Ultimately, it all boils down to your menu. If you're building a business on crafting incredible pizzas, investing in a purpose-built pizza prep table isn't just a nice-to-have. It’s a foundational piece of equipment for a smooth, productive, and profitable kitchen.

What Really Matters in a High-Performance Prep Table

Once you move past the basic choice between a pizza or sandwich table, the real value emerges from the nitty-gritty details. A spec sheet can look like a foreign language, but learning to read it is what separates a decent purchase from a truly great one. These features have a direct, daily impact on your table's lifespan, performance, and ease of use.

Think of it like buying a car. Two sedans might look almost identical, but the one with the better engine, suspension, and safety features will deliver a far superior driving experience. The exact same principle applies to your 44-inch pizza prep table. What's going on under the hood makes all the difference.

The Bedrock of Durability: Stainless Steel Grades

Let's get one thing straight: not all stainless steel is the same. The grade of steel is probably the single most important factor for your table's long-term survival in a busy kitchen. You'll generally run into two main types:

- 430 Grade Stainless Steel: This is the more budget-friendly choice, often used for the exterior sides and back of a prep table. It’s magnetic and has decent corrosion resistance, making it perfectly fine for areas that aren't constantly exposed to moisture or acidic foods.

- 304 Grade Stainless Steel: This is the undisputed champ for food contact surfaces. Often called "food-grade," it has more nickel and chromium, making it way more resistant to rust from things like tomato sauce, brined olives, and harsh cleaning chemicals. For the tabletop and interior, 304 grade is the only way to go.

Smart manufacturers use a mix-and-match approach, putting the tough 304 grade where it counts and the more affordable 430 grade elsewhere. When you see a higher price tag, you're often paying for that superior steel—an investment that pays for itself in longevity.

Keeping Cool: How Your Refrigeration System Breathes

The refrigeration system is the heart of your prep table, and understanding how it "breathes" is critical. Your compressor needs to pull in cool air and push out hot air to do its job. There are two ways it can do this:

- Rear-Breathing: These units have their vents on the back. While they tend to be quieter and more energy-efficient, they need a few inches of space between the unit and the wall to breathe. If you shove it flush against the wall, you'll choke the compressor, leading to overheating and a quick burnout.

- Front-Breathing: These systems vent from the front, usually through a grille. This is a lifesaver in tight kitchens because you can install the unit right up against a wall or even build it into a counter. The trade-off? They can be a bit louder and you'll need to clean that front vent regularly to keep dust out.

Knowing this difference before you buy can save you a massive installation headache. A 44-inch pizza prep table with a front-breathing design gives you incredible placement flexibility, which is a huge advantage in a crowded kitchen.

Built for the Rush: Cutting Board and Lid Design

A table’s real-world performance comes down to ergonomics—those little design choices that make your life easier during a chaotic service. The cutting board is a perfect example. An extra-deep board, typically around 19.5 inches, gives your crew plenty of space to assemble pizzas without sending toppings flying everywhere.

The insulated lid is another game-changer. A solid, heavy-duty lid that creates a tight seal over the pan rail is non-negotiable. It locks in the cold, keeping ingredients fresher for much longer, and eases the load on your compressor, which saves you energy and money.

These kinds of efficiency-boosting features are why the commercial pizza prep table market is booming. Valued at roughly USD 1.5 billion in 2023, it's projected to climb to USD 2.3 billion by 2032. Kitchens are actively seeking out this perfect blend of workspace and refrigeration. A 44-inch pizza prep table, often offering 12 to 24 cubic feet of storage, hits that sweet spot modern restaurants need to keep up.

Finally, don't forget about digital temperature controls. They give you precise command over your cold storage, ensuring you’re always holding ingredients at food-safe temperatures. It’s a huge upgrade from old-school analog dials and provides both peace of mind and better quality control. To learn more, check out our guide on the different types of stainless prep tables available.

Placing Your Prep Table for Maximum Kitchen Flow

A top-notch prep table is a fantastic start, but its real magic happens when it's placed in a smartly designed kitchen. Think of your new 44-inch pizza prep table as the heart of your operation. When you build the kitchen's workflow around it, you're not just buying equipment; you're creating a system that cranks out more pizzas, keeps your staff happy, and makes your entire kitchen smarter.

It’s not enough to just find an empty wall and shove the table there. You have to think about movement—the dance of your kitchen staff during a hectic dinner rush. Strategic placement creates a clear, logical path for every pizza, cutting out wasted steps and letting your team build pies without tripping over each other.

The Pizzeria Work Triangle, Reimagined

You’ve probably heard about the "kitchen work triangle" for homes, which links the fridge, stove, and sink. In a busy pizzeria, we have our own version, and your 44-inch pizza prep table is right in the middle of it all. It connects three key zones:

- Cold Storage: This is your walk-in cooler or reach-in fridge—home base for dough, cheese, and tubs of sauce. It needs to be just a few steps away from the prep table so your crew can restock on the fly without a cross-kitchen expedition.

- The Prep Station: This is your shiny new 44-inch prep table. It's the command center where all the magic happens, turning cold ingredients into pizzas ready for the fire.

- The Cooking Station: This is your oven. The journey from the prep table to the oven needs to be short, direct, and completely clear. No obstacles. This ensures every pizza goes from assembly to baking in seconds.

This setup creates a natural, circular rhythm. A cook grabs dough from the cooler, pivots to the prep table to top it, then takes a couple of steps to slide it into the hot oven. It's an efficient loop that reduces physical effort and prevents the kitchen from descending into chaos.

Setting Up the Station for Speed

Once the table is in the perfect spot, it's time to organize it for sheer speed. A messy station is a bottleneck waiting to happen, grinding your whole line to a halt. Your pan rail and refrigerated base are more than just storage; they’re a toolkit built for lightning-fast pizza assembly.

A well-organized prep station is the secret to consistency. When every single topping is in the exact same spot, every single shift, your crew can build pizzas on pure muscle memory. That's how you boost speed and get orders right every time.

First, lay out your pan rail by popularity. Your superstars—mozzarella and pepperoni—should be front and center in the easiest-to-reach pans. Toppings that get less action can live on the ends.

Try grouping ingredients for specific menu items. If you have a "Veggie Deluxe," put the onions, peppers, mushrooms, and olives right next to each other. This turns a multi-step process into one smooth, sweeping motion.

Finally, make smart use of that refrigerated base. Keep backup pans of your most popular toppings on the top shelf for quick swaps when you're slammed. The bottom shelves are the perfect spot for extra dough trays, blocks of cheese, or anything else you need close by but not in the way. This kind of thoughtful organization transforms your 44-inch pizza prep table from a piece of steel into the high-performance engine of your pizzeria.

Maintenance That Protects Your Investment

Your 44-inch pizza prep table is one of the true workhorses in your kitchen. It's on duty from the moment prep starts until the very last order goes out. Looking after this crucial piece of gear isn't just about wiping it down; it's about making sure it stays reliable, safe, and efficient for the long haul.

Think of a simple, consistent maintenance routine as the best insurance policy you can have against a surprise breakdown during a chaotic dinner rush. By breaking down the essential tasks into daily, weekly, and monthly checklists, you can stay ahead of problems without feeling overwhelmed. It’s a proactive habit that will save you a fortune in emergency repair bills and add years to your table's life.

Your Daily Maintenance Playbook

These are the absolute non-negotiables. The tasks that need to happen every single day, no excuses. They form the bedrock of a safe, clean, and high-performing pizza station.

- Wipe Down All Surfaces: At the end of each shift, give all the stainless steel surfaces—inside and out—a thorough cleaning with a soft cloth and a mild, food-safe detergent. Pro tip: always wipe in the direction of the steel's grain to avoid tiny scratches and streaks. This simple action is your first line of defense against corrosive food acids and grime.

- Clean and Sanitize the Cutting Board: Your cutting board sees more action than anything else. Pull it out, scrub it down with hot, soapy water, and then sanitize it based on your local health code. This is non-negotiable for preventing cross-contamination.

- Empty and Clean Ingredient Pans: Never, ever leave toppings sitting in the pan rail overnight. Pull every pan, move leftovers into proper airtight containers for storage, and then wash and sanitize the pans. They’ll be fresh and ready for the next day.

These daily habits are less about big repairs and more about upholding a professional standard of hygiene that keeps your customers safe and your equipment in top shape.

Weekly Upkeep for Long-Term Health

Once a week, you need to dig a little deeper. These tasks hit the spots that don't need daily love but are vital for the table's mechanical and structural integrity.

A perfect example is checking and cleaning the door gaskets. Those rubber seals are the only thing keeping the cold air inside the refrigerated base. Wipe them down with a damp cloth and feel for any cracks, tears, or spots that have gone hard and brittle.

A leaky door gasket can force your refrigeration unit to work 20-30% harder just to hold its temperature. That means higher energy bills and a compressor that's racing toward an early grave. It's a tiny part with a massive impact on your bottom line.

Your weekly checklist should also include pulling out the shelves from inside the refrigerated cabinet and giving them a good scrub. This gets rid of any sticky spills or hidden crumbs, promoting much better airflow and overall hygiene inside the unit.

Monthly Checks to Prevent Breakdowns

Your monthly tasks are all about the core mechanical systems of your 44-inch pizza prep table. It's easy to put these jobs off, but they are the most critical for preventing a complete system failure. The number one task here is cleaning the condenser coils.

Over time, these coils get caked with a nasty mix of dust, grease, and flour. That buildup acts like a blanket, forcing the compressor to work overtime to get rid of heat. This is, without a doubt, the leading cause of refrigeration failure.

Monthly Maintenance Deep Dive:

- Disconnect Power: Safety first, always. Unplug the unit from the wall before you touch any mechanical parts.

- Locate and Clean Condenser Coils: Find the coils, which are usually behind a grille on the front or back. Grab a stiff-bristled brush and a vacuum to gently clear away all the gunk.

- Inspect and Clear Drain Lines: Take a look at the condensation drain line to make sure it’s not clogged. A blockage can cause water to back up and pool inside your unit, creating a real mess.

- Check Temperature Calibration: Use a separate, reliable thermometer to double-check that your unit's digital display is telling the truth. This confirms you're holding food at consistently safe temperatures.

Following this simple playbook turns maintenance from a chore into a strategic advantage. It ensures your 44-inch pizza prep table remains the reliable, productive heart of your kitchen for years to come.

How the Right Prep Table Drives Pizzeria Success

A great prep table isn't just another line item on your equipment list—it’s the beating heart of your kitchen. It’s the single piece of gear that ties your whole operation together, turning the potential chaos of a dinner rush into a smooth, profitable machine that keeps people lining up for your pizza.

Think of your 44-inch pizza prep table as the command center for speed, accuracy, and ingredient quality. When your crew can build pizzas without fumbling for ingredients, ticket times shrink and more orders fly out the door. That kind of flow is what separates the pros from the amateurs in a crowded market.

The Foundation of Speed and Quality

A well-organized prep station is the secret weapon for handling a crazy Friday night without letting quality slip. With every topping perfectly chilled and right at your fingertips, your team can assemble pizzas with lightning speed and precision. The result? Customers get their food faster, and it’s made exactly how they ordered it.

This isn’t just about getting one pizza out the door. It's about building a rock-solid reputation for excellence, one perfect pie at a time. Consistency is what creates loyal customers, and that's the real foundation of any successful restaurant. The right prep table is what makes that consistency happen when the pressure is on. You can see how specific models are designed for this kind of high-stakes environment in our review of the Atosa pizza prep table.

A Critical Tool in a Booming Industry

You don't have to take my word for it—the numbers speak for themselves. The U.S. pizza industry is projected to rake in $50.1 billion in 2024 across more than 74,000 pizzerias. In a market that big, you need every advantage you can get.

The 2025 Pizza Industry Trends Report drove this point home, revealing that 36.8% of pizzeria owners called their prep tables critical to daily operations. This data isn't just a statistic; it's a testament to how vital a reliable station is for thriving in this business. You can dive deeper into these insights in the full pizza industry trends report.

Investing in a high-performance prep table isn't an expense; it's a strategic move that directly supports your pizzeria's ability to grow. It’s the physical backbone of your goals for quality, speed, and profitability.

At the end of the day, your 44-inch pizza prep table does so much more than just hold toppings. It empowers your staff, protects your brand's reputation, and gives you the firepower to handle more business. In a competitive world, that’s not a luxury—it's a must-have for long-term success.

A Few Common Questions About Pizza Prep Tables

When you're equipping a commercial kitchen, a few questions always pop up. It's totally normal. Let's walk through some of the most common things people ask about prep tables so you can feel confident you're getting the right gear for your kitchen.

What's the Real Difference Between a Prep Table and a Work Table?

It's a fair question, especially since people sometimes use the terms interchangeably. But in the kitchen, the difference is huge.

Think of a work table as a simple, flat-topped stainless steel surface. It’s your basic canvas for all-purpose tasks like weighing out flour or plating up a finished dish. It's a static surface.

A prep table, on the other hand, is an active station. A refrigerated model like a 44-inch pizza prep table is a purpose-built machine. It combines a refrigerated base, a dedicated work surface, and a pan rail into one seamless unit. It's designed from the ground up to support an assembly line workflow, whether you're building pizzas, sandwiches, or salads.

Can I Actually Use a Pizza Prep Table for Sandwiches or Salads?

You absolutely can, but there's a small catch. A pizza prep table is designed with an extra-deep cutting board to handle large pizza skins, which might feel a bit oversized when you're just working with slices of bread.

The biggest thing to think about is the raised pan rail. It's a fantastic feature for keeping shredded cheese and pepperoni from flying everywhere. For sandwiches, though, that raised lip can make reaching for ingredients a little less natural than the flush-rail design on a dedicated sandwich prep table. If you only make a few sandwiches, it’s no big deal. But for a high-volume sandwich spot, you’ll be much happier with a dedicated unit.

How Much Energy Will a 44-Inch Pizza Prep Table Use?

This one depends on a few things: the specific model, how efficient its compressor is, and frankly, how often you're opening the doors. Modern, energy-conscious units are built to keep electricity costs in check, typically using between 5 to 9 kWh per day.

To keep that energy use on the lower end, look for a few key features:

- High-quality insulated lids that create a tight seal.

- Efficient compressors and modern, eco-friendly refrigerants.

- Well-maintained door gaskets to stop cold air from leaking out.

Honestly, the best thing you can do to keep your energy bills low is simple, routine maintenance. Keeping those condenser coils clean makes a world of difference.

What Do I Need to Know About Installation?

Getting your new table set up is usually pretty straightforward, but you absolutely need to check two things before it arrives.

First, your electrical setup. Most units just plug into a standard outlet, but don't assume. Always, always check the spec sheet for the required voltage and amperage. You need to be sure your kitchen's circuits can handle the load without tripping a breaker.

Second, and this is a big one, is ventilation. A rear-breathing unit needs a few inches of space between it and the wall to let air circulate properly. A front-breathing model, however, can be pushed right up against the wall. Getting this wrong is one of the quickest ways to burn out a compressor.

Ready to build a smarter, more efficient kitchen? Take a look at our complete collection of commercial-grade prep tables over at PrepTables.com. Find the perfect 44 inch pizza prep table that will sharpen your workflow and help you build better pizzas, day in and day out. Visit https://preptables.com to find your perfect fit.