A Practical Guide to 27 Inch Sandwich Prep Tables

Share

Think of a 27-inch sandwich prep table as the ultimate compact, all-in-one workstation for a busy commercial kitchen. It’s smartly designed to bring together a refrigerated base for your ingredients, a prep area right on top, and a cutting board, making the whole process of building sandwiches and salads incredibly smooth.

Why a 27 Inch Prep Table Is Your Kitchen's Secret Weapon

Picture the lunch rush chaos. Tickets are flying, and your crew is darting back and forth between a packed prep counter and a refrigerator across the kitchen. This is exactly the moment a 27-inch sandwich prep table steps in and turns that frantic scramble into a streamlined, efficient flow. It’s not just a chunk of stainless steel; it's a command center.

For any business where space is at a premium—think cozy cafes, bustling delis, or food trucks—this single piece of equipment is a total game-changer. Its all-in-one design gives you refrigerated storage down below and an organized prep station up top, complete with chilled pans for toppings and a built-in cutting board. Suddenly, everything your staff needs is right there, which slashes wasted movement and gets orders out the door faster.

To give you a quick snapshot, here’s a look at the core advantages this compact unit brings to the table.

Key Benefits of a 27 Inch Prep Table at a Glance

| Benefit | Impact on Kitchen Operations |

|---|---|

| Space Efficiency | Combines refrigeration and prep space, freeing up valuable floor area. |

| Increased Speed | Keeps all ingredients within arm's reach, accelerating order assembly. |

| Improved Workflow | Creates a logical, assembly-line-style process for sandwiches and salads. |

| Enhanced Food Safety | Maintains ingredients at safe temperatures right up to the moment of use. |

| Reduced Labor Costs | A more efficient process means staff can accomplish more in less time. |

Essentially, for restaurant owners, cafe managers, and food truck operators, this compact table is the key to unlocking a more organized and productive kitchen.

Understanding the Different Types of Prep Tables

While the 27-inch sandwich prep table is a superstar for salads and sandwiches, it’s just one member of a larger family of stainless steel workstations. Each type is built for a specific job, and knowing the difference is crucial to making sure you invest in the right tool for your menu and workflow.

-

Sandwich and Salad Prep Tables: These are the most popular models. You'll recognize them by the refrigerated rail on top that holds multiple food pans (usually 1/6 size pans). They always feature a cutting board running the full length of the unit, creating that perfect assembly line for sandwiches, wraps, and salads. The cabinet below stores all your backup ingredients.

-

Pizza Prep Tables: They look similar to sandwich tables at first, but the details matter. Pizza prep tables are designed with a much deeper cutting board to handle large pizza doughs. Their refrigerated rail is also raised, creating a more ergonomic angle for slinging toppings onto pies before they hit the oven.

-

Refrigerated Worktop Tables: These are the simplest of the bunch. They offer a flat, uninterrupted stainless steel work surface right over a refrigerated base. With no top-mounted pan rail, they’re perfect for general prep that needs a chilled surface, like portioning dough or plating cold appetizers.

The demand for this kind of specialized gear is on the rise. The global market for food prep tables was valued at a whopping $1.18 billion in 2023 and is expected to climb to $1.62 billion by 2029. This trend really shows how the industry is moving toward equipment that maximizes efficiency and meets tough food safety rules. You can dive deeper into the market trends driving this growth in a detailed report from Arizton.

Anatomy of a High-Performance Prep Table

What’s the real difference between a dependable, high-performance prep table and one that becomes a constant kitchen headache? The secret lies in its core components. When you're choosing a 27-inch sandwich prep table, you're not just picking a size; you're investing in a well-engineered machine built to support your workflow, protect your ingredients, and survive the daily grind.

Think of the refrigeration system as the heart of the unit. The compressor's power and the cooling mechanism’s design are what keep your ingredients crisp and fresh instead of wilting under pressure. A weak system is a recipe for disaster, leading straight to food safety risks and expensive spoilage.

The Foundation of Durability and Hygiene

The material your prep table is made from is its first line of defense in a demanding commercial kitchen. High-quality stainless steel is the undisputed champion here, and for good reason. It’s non-porous, fights off corrosion, and is incredibly easy to clean and sanitize—all critical for passing health inspections.

When you’re looking at a unit, check for durable stainless steel on both the inside and out. This ensures the table can handle everything from accidental dings to acidic food spills without breaking down. Cheaper materials might seem like a good deal at first, but they often lead to rust, dents, and hygiene nightmares down the road. To get a better handle on the options, you can explore the different types of stainless steel prep tables and see what makes sense for your kitchen.

The Heartbeat of the Machine: The Refrigeration System

A prep table’s most important job is holding food at safe temperatures, period. A high-performance compressor is the engine that drives this process, pumping out consistent cold air even when the kitchen gets fiery during a busy service. When paired with a smart fan cooling mechanism, it guarantees air circulates evenly through the cabinet and, crucially, around the ingredient pans up top.

A superior cooling system ensures that all ingredients, especially those in the top-most pans exposed to ambient air, are held at a consistent and safe temperature, typically between 33°F and 41°F. This is a non-negotiable feature for preventing bacterial growth and upholding food safety.

This focus on cooling technology is what separates the best models from the rest. Take the ICECASA 27-inch model, for example. It uses a high-performance compressor and fan cooling to keep ingredients perfectly chilled, while its automatic defrost system stops frost buildup, keeping the unit running efficiently. Features like an LCD digital display give staff precise temperature control, and a solid warranty on parts and the compressor shows the manufacturer stands behind its durability. You can see more specs on how modern prep tables are evolving on the ICECASA product page.

The Workspace: The Cutting Board

The cutting board is where all the action is. Its design is a huge factor in your kitchen’s efficiency. It’s not just a surface; it's your primary assembly line.

- Depth Matters: A deeper cutting board—at least 10 inches—gives you enough room to build sandwiches and prep ingredients without feeling boxed in or spilling food on the floor.

- Material and Maintenance: Look for a board made from a tough, food-safe material. A removable board is a game-changer, making cleanup and sanitation way easier at the end of a long shift.

Ultimately, a high-performance prep table is a sum of its parts. By taking a close look at the stainless steel quality, the power of the refrigeration system, and the smart design of the cutting board, you can confidently pick a 27-inch sandwich prep table that will be a reliable workhorse for years to come.

Comparing Sandwich, Pizza, and Worktop Prep Tables

It's a common mistake to think all stainless steel prep tables are more or less the same. But choosing the right one is like picking the perfect tool for a specific job. A 27-inch sandwich prep table is an absolute master of efficiency for delis and cafes, but understanding how it stacks up against its cousins—the pizza prep table and the worktop table—is the key to making sure your investment actually helps your kitchen’s flow.

Think of these tables as specialists. Each one is built from the ground up with a specific menu and process in mind. If you get it wrong, you’re looking at frustrating bottlenecks during a busy lunch rush. But when you get it right? Your whole operation just runs smoother.

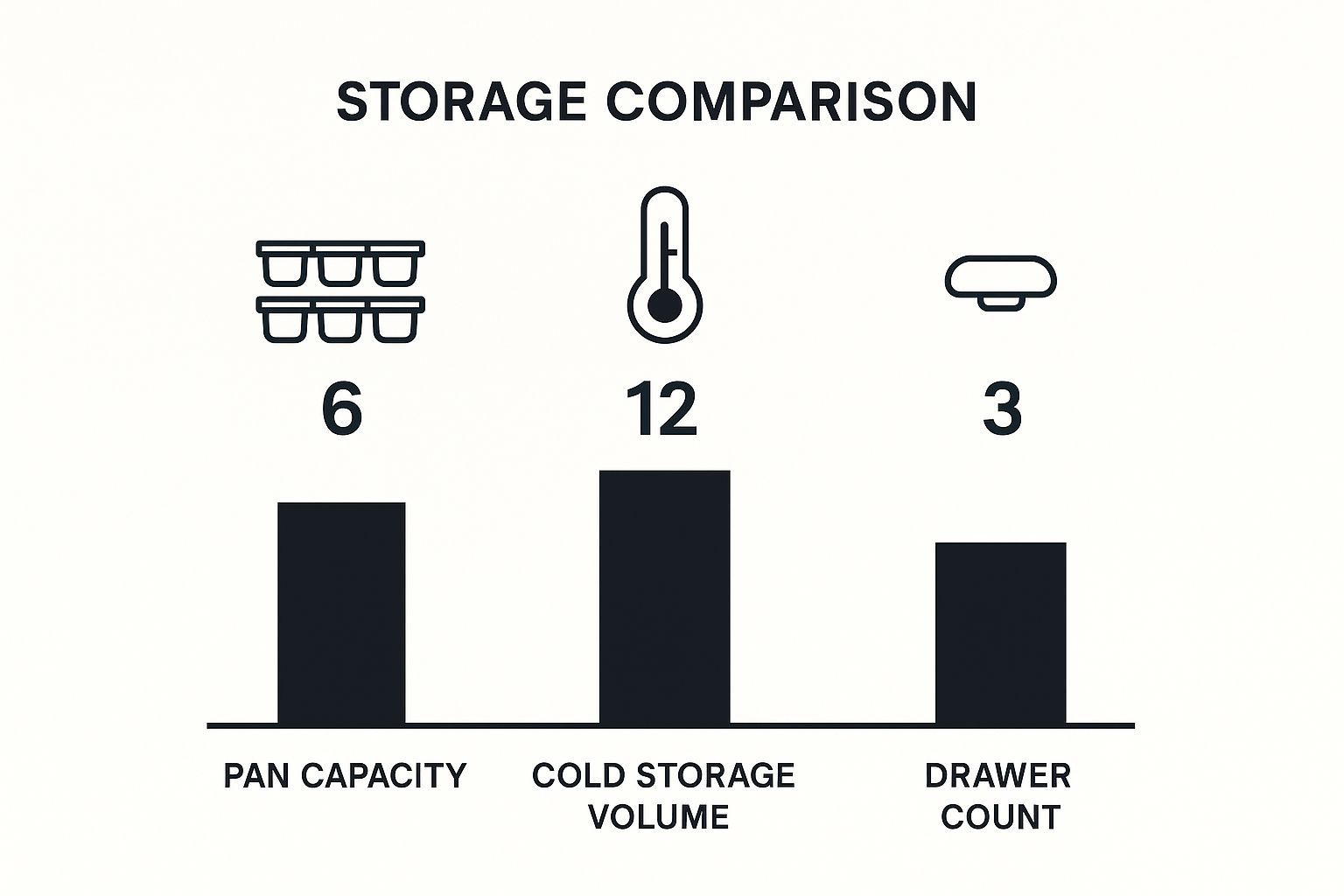

This visual breaks down the typical specs for a compact prep table, showing how features like pan capacity, storage volume, and drawer options all come together in one unit.

As you can see, these tables are true multitaskers, blending easy-to-reach ingredient storage with a surprising amount of refrigerated cabinet space and even customizable drawers to keep a fast-paced kitchen humming.

The Sandwich and Salad Specialist

Your classic 27-inch sandwich prep table is laser-focused on one mission: building fresh, made-to-order items as fast as humanly possible. Its most important feature is the refrigerated rail holding multiple food pans—usually 1/6 size pans—right at work level. This keeps a huge variety of toppings and ingredients perfectly chilled and just inches away.

The cutting board is the other half of the magic. It typically runs the full length of the unit and is about 10 inches deep, creating a perfect, straight-line assembly station. An employee can build a sandwich from left to right without ever taking a step, which slashes prep time and wasted motion. This design is the secret weapon of any high-volume sandwich shop or salad bar.

The Pizza Prep Powerhouse

At a quick glance, a pizza prep table might look like its sandwich-making sibling. Look closer, though, and you'll spot a few critical design tweaks that make it perfect for slinging pies. The most obvious difference is the cutting board. Pizza prep tables have a much deeper board, often 15 to 18 inches deep, to give you plenty of room to work with large pizza doughs.

You'll also notice the refrigerated rail on a pizza table is usually raised and angled toward the chef. This is all about ergonomics. It allows someone to easily grab and scatter toppings across a wide pizza base without having to awkwardly reach over the dough. The rail is also designed to hold bigger, round ingredient bins right alongside standard pans, which is exactly what a pizzeria needs. Trying to run a high-volume pizza line on a standard sandwich table would get real cramped, real fast.

The main takeaway here is that the "best" table is the one that eliminates friction from your primary workflow. For sandwiches, that means having tons of small-pan ingredients at your fingertips. For pizza, it's all about having the space to handle big doughs.

The Generalist Worktop Table

Finally, let's talk about the refrigerated worktop table. It's the simplest of the three, but its incredible versatility makes it a must-have in many kitchens. A worktop table is exactly what it sounds like: a completely flat, uninterrupted stainless steel work surface sitting on top of a refrigerated base.

There's no pan rail on top. This makes it perfect for all sorts of general prep tasks where you need a chilled surface but don't need immediate access to a dozen different toppings. Kitchens use these all the time for things like:

- Portioning out dough or pastries

- Plating cold appetizers and desserts

- General ingredient prep that needs to stay cool

Sure, you could technically make a sandwich on a worktop table, but you'd lose all the incredible efficiency of having your ingredients organized and chilled just inches from your hands. Each table has its place, and matching your choice to your menu is the first real step toward a more organized and productive kitchen.

How To Select The Perfect 27-Inch Sandwich Prep Table

Ready to make an investment? Choosing the right 27-inch sandwich prep table is so much more than a simple purchase. It’s a strategic decision that will directly impact your kitchen’s daily rhythm and output.

Think of it like getting a custom-tailored suit. You wouldn’t just grab one off the rack without checking the fit. In the same way, your prep table has to be perfectly suited to your space, your menu, and your workflow to give you the most bang for your buck. Let's break down exactly what to look for.

Measure Twice, Buy Once

Before you even start looking at different models, grab your tape measure. Seriously. The very first step is to confirm the actual, physical space you have to work with. A 27-inch sandwich prep table is designed to be compact, but it still needs a little breathing room to work right.

You have to account for clearance on the sides and, most importantly, the back. The refrigeration system's compressor creates heat, and it needs proper ventilation to get rid of it. Without good airflow, the compressor will be forced to work overtime, leading to higher energy bills and a much shorter life for your equipment. Plan for at least a few inches of clear space all around the unit.

Match Pan Capacity To Your Menu

Next up, take a hard look at your menu and your daily prep routine. The number and size of ingredient pans your table can hold directly affects how efficient your team can be. How many fresh toppings, sauces, and proteins do you really need to have on hand at all times?

- Standard Menu: If you're running a classic deli with a focused menu, a standard top that holds eight 1/6-size pans might be just right. This setup keeps the essentials within easy reach without being overkill.

- Complex Menu: On the other hand, if you offer elaborate "build-your-own" sandwiches or salads with tons of toppings, you might need a "Mega Top" model. These units give you an entire extra row for pans, significantly boosting your ingredient capacity.

Figuring out your pan capacity needs upfront will save you from the nightmare of running out of space during a chaotic lunch rush. This one detail can literally make or break the speed of your prep line.

A well-chosen prep table should feel like an extension of your chef's hands—everything needed is right there, chilled and ready. Mismatching the pan capacity to your menu creates a constant bottleneck, forcing staff to run back and forth to the main refrigerator.

Don't Forget The Pizza Prep Table

Sometimes, what looks like a sandwich prep table might actually be its close cousin: the pizza prep table. While they seem similar, they are built for very different workflows. Knowing the difference is key to avoiding a costly mistake.

A sandwich prep table usually has a shallower cutting board (around 10 inches) because you're working with smaller items like bread slices. A pizza prep table, however, needs a much deeper cutting board (often 19 inches or more) to accommodate large pizza doughs. The rail on a pizza prep table is also raised to keep ingredients extra cold for longer periods.

Here’s a quick comparison to help you spot the differences:

Pizza Prep Table vs. Sandwich Prep Table Comparison

| Feature | Sandwich Prep Table | Pizza Prep Table |

|---|---|---|

| Cutting Board Depth | Typically 10 inches deep | Much deeper, often 19+ inches deep |

| Ingredient Rail | Flush or slightly recessed | Raised to maintain colder temperatures |

| Primary Use | Ideal for sandwiches, salads, burritos | Designed specifically for assembling pizzas |

| Pan Configuration | Holds various pan sizes for toppings | Often configured for specific pizza ingredient pans |

Choosing the wrong one can seriously disrupt your kitchen's flow. Make sure you're buying the tool that's actually designed for the job you need it to do.

Prioritize Energy Efficiency

A prep table runs 24/7, making it a constant line item on your electricity bill. An ENERGY STAR certified model might cost a bit more upfront, but it can save you hundreds of dollars in utility costs over its lifetime. These units are simply built better, with superior insulation, more efficient compressors, and eco-friendly refrigerants.

Think of it as an investment that pays you back every single month on your energy bill. The long-term savings often blow past the initial price difference, making it a no-brainer for any smart business owner.

Understand The Warranty And Service

Finally, never, ever overlook the warranty. A solid warranty is a manufacturer's way of saying they stand behind their product. Look for separate, multi-year warranties that cover the compressor—that's the most expensive part to replace—and other components.

A comprehensive service agreement can be just as important. Knowing you have access to reliable support and labor coverage gives you peace of mind and protects you from the sting of expensive emergency repairs. For an even deeper dive into making the right choice, check out our complete prep tables buying guide. By following this checklist, you’ll choose a 27-inch sandwich prep table that will be a reliable and profitable workhorse in your kitchen for years to come.

Getting Started: Installation and Upkeep

Think of your new 27-inch sandwich prep table as a long-term partner in your kitchen's success. It’s an investment, and like any good investment, its value and performance depend on how you look after it right from the start. Correct installation and consistent maintenance are the two things that will keep it running smoothly for years, saving you from the headache of surprise breakdowns.

It’s just like owning a car—you wouldn’t dream of buying one and then just skipping all the oil changes. The same idea applies here. A little regular care goes a very long way, turning your prep table from a potential problem into a reliable workhorse that pulls its weight during your busiest hours. Let's walk through the simple habits that will protect your unit and keep those emergency repair bills at bay.

Setting Up for Success: The Right Installation

Getting your table set up correctly is about more than just finding an outlet and plugging it in. Doing it right from day one is your best defense against a whole range of future issues, especially with the refrigeration system. The single most important step is leaving enough room for proper ventilation. Your table's compressor creates heat while it runs, and it needs open space to breathe and get rid of that heat.

If there isn't enough airflow, the compressor can overheat. This forces it to work much harder and suck up more electricity, which shortens its life and inflates your utility costs. A good rule of thumb is to leave at least a few inches of clear space around the back and sides of the unit.

Leveling the unit is another step you can't afford to skip. An off-balance table can lead to a domino effect of problems:

- Bad Door Seals: If the frame is tilted, the doors won't shut tightly. This lets cold air leak out and warm air seep in, forcing the compressor into overdrive to keep things cool.

- Drainage Issues: Most prep tables have a built-in drain for condensation. If the unit is leaning, water can't flow out properly, which can cause clogs, puddles, and some serious hygiene headaches.

- Uneven Wear and Tear: An unbalanced unit puts extra stress on the frame and its parts, causing them to wear out faster than they should.

Taking those few extra minutes to get the installation perfect gives your 27-inch sandwich prep table the solid start it deserves.

Building a Proactive Maintenance Routine

Once your table is in place and running, the real secret to its longevity is being proactive, not reactive, with maintenance. Waiting for something to break is always a more expensive and stressful game than preventing the issue from happening in the first place. All it takes is a simple, consistent schedule to keep your equipment in prime condition and stay on the right side of health codes.

The most important maintenance task you can do is clean the condenser coils. Experts agree this should be done about every 30 days. When dust and grease build up on the coils, they act like a thick blanket, trapping heat and making it impossible for the unit to cool efficiently. This often leads to compressor failure—a very expensive repair that most warranties won't cover.

Just this one habit can save you from one of the most frequent and costly equipment meltdowns in a commercial kitchen.

Here’s a simple maintenance schedule you can start using right away:

Daily Habits

- Wipe Down Everything: Clean all stainless steel surfaces, the cutting board, and the food pans. Use a mild soap and a food-safe sanitizer.

- Clean the Door Gaskets: Wipe down the rubber door seals to get rid of any crumbs or spills. This keeps the seal tight and stops mold from growing.

Weekly Checks

- Inspect Gaskets: Give the door gaskets a quick look-over for any rips or tears. A damaged gasket means you're losing cold air and need to replace it.

- Check the Temperature: Use a separate, reliable thermometer to make sure the unit's display is accurate. The internal temperature should hold steady between 33°F and 41°F.

Monthly Inspections

- Clean Condenser Coils: As we covered, this is non-negotiable. Use a stiff brush or a vacuum to clear away all the built-up dust and grease from the coils.

- Check the Drainage System: Make sure the drain lines are clear and free of any clogs to stop water from backing up.

By making these simple installation and maintenance steps part of your kitchen's DNA, you’re actively protecting your investment. This forward-thinking approach ensures your 27-inch sandwich prep table remains a productive part of your team, upholds food safety, and helps you sidestep the stress and cost of unexpected failures for years to come.

Frequently Asked Questions About 27 Inch Prep Tables

Stepping into the world of commercial kitchen equipment always brings up a few questions. When you’re zeroing in on a 27-inch sandwich prep table, you want to be absolutely sure you're making a smart investment that will pull its weight in efficiency and reliability. We’ve gathered the most common questions we hear to give you clear, no-nonsense answers.

What Is The Most Important Feature To Look For?

While there are lots of bells and whistles, the single most critical feature is the refrigeration system. Its entire job is to keep your ingredients locked in at a consistently safe temperature, which for most foods means below 41°F.

A top-notch cooling system is non-negotiable, especially one with smart airflow that pushes cold air over the top pans. Think of this as the foundation of food safety in your kitchen—it's the one area where you never want to cut corners.

How Do I Know If a 27 Inch Prep Table Is The Right Size?

A 27-inch model is a real hero in kitchens where space is a premium. It's a perfect fit for a bustling café, a compact food truck, or a small deli where every inch counts. It also shines as a dedicated secondary station in a larger kitchen, maybe for handling just salads or desserts.

If you're cranking out sandwiches for a massive lunch rush or your menu is packed with a huge variety of fresh ingredients, you might find a larger 48-inch or 60-inch unit serves you better. For most focused menus, though, the compact power of a 27-inch model is the sweet spot.

What Is The Difference Between a Sandwich Prep Table and a Pizza Prep Table?

This is a classic question, and getting it right is crucial for your kitchen's flow. While they both fall under the umbrella of stainless steel prep tables, they are built for entirely different jobs.

- Sandwich Prep Tables: These units have a shallower cutting board, usually around 10 inches deep. The refrigerated rail is designed to hold an array of smaller ingredient pans, making it perfect for the fast, assembly-line process of building sandwiches, salads, and wraps.

- Pizza Prep Tables: These tables sport a much deeper cutting board, often 19 inches or more, to give you plenty of room to work with large pizza doughs. The ingredient rail is also typically raised to keep toppings extra cold and make them easy to sprinkle over a wide pizza crust.

Picking the right tool for the job is everything. Trying to run a high-volume pizza operation from a sandwich table would create a major bottleneck in no time.

The main idea is to match the equipment to what you're serving. A 27-inch sandwich prep table is a specialist, built for speed and organization in a deli or café setting. For a full picture of all the gear you might need, our guide on the essential sandwich shop equipment list is a fantastic place to start.

What Is The Most Common Maintenance Mistake To Avoid?

The one thing people forget most often is also the most critical: cleaning the condenser coils. Over time, these coils get coated in dust, grease, and kitchen grime. This gunk acts like a blanket, trapping heat and forcing the compressor to work way harder than it should. This leads to bigger energy bills and, sooner or later, a fried compressor that's expensive to replace.

Make it a habit for you or your staff to clean the condenser coils about every 30 days. It’s a simple task that isn't covered by most warranties, but it's the single best thing you can do to protect your investment for the long haul.

Why Do Prices for Prep Tables Vary So Much?

That big gap in pricing you see from one model to the next comes down to brand reputation, the quality of the materials, and the tech inside. A pricier unit might be made from a heavier gauge of stainless steel or feature a more advanced, energy-efficient cooling system that saves you money on your utility bills over its lifetime.

On the other hand, a budget-friendly model will still get the job done and can be a great starting point for a new business. The trick is to find that perfect balance of features, durability, and price that fits your kitchen's real-world needs and your financial plan.

Ready to find the perfect prep table that combines efficiency, durability, and value? Explore the professional-grade selection at PrepTables.com and discover the ideal solution to streamline your kitchen's workflow. Find your fit today at https://preptables.com.